Sam Brusco, Associate Editor05.29.19

The skilled labor shortage, which according to a Deloitte and Manufacturing Institute study threatens to render two million American manufacturing jobs vacant by 2025, has begun to affect the medical device industry.

Despite medtech’s potential for a rewarding career in an industry whose purpose is to save lives, there is still a stereotype associated with employment in the skilled trades. The perception that a factory job requires little skill or thinking and offers no advancement opportunities unfortunately still prevails, and popular culture doesn’t help—trade workers are still depicted as bumbling, poor, uneducated, lazy, and rude.

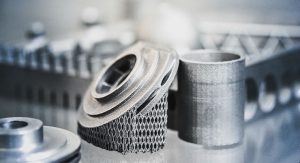

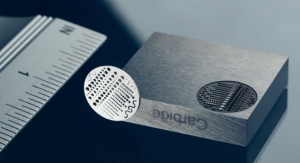

This is simply not true, especially in medical device manufacturing. Today, skilled tradespeople working to build medical devices and components need strong technical know-how and experience to operate complex part fabrication machinery. To work in medical manufacturing, prospective employees must often complete work-based learning programs, undergo an apprenticeship program, or obtain an associate’s degree.

But changing the attitude toward the skilled trades is only the first step to build a competent and, more importantly, passionate medical manufacturing workforce. Medical manufacturing companies must also do their part to recruit and retain employees. It can cost significant time and effort to implement workforce development programs, but without them the skilled labor shortage will continue to decline.

To gain more insight into how medtech manufacturers are attracting and developing a passionate workforce, I spoke with four employees from Cadence Inc., a provider of complex high-precision components and finished devices for advanced surgical and specialty industrial applications, which is headquartered in Staunton, Va.:

The breadth of their input was not included in the recent feature article entitled “The Human Factor: How Medtech Firms Are Battling the Labor Shortage” (which can be read here), so the entirety of our discussion is included in the Q&A below.

Sam Brusco: What efforts, if any, does your company make to reach out to schools to generate interest in the industry? (Colleges, trade schools, high schools, even middle or grade schools?)

Beth Alltop: We often invite local high school students (those enrolled in a STEM or technical program—all students are welcome, but we specifically target those students) into all of our facilities for tours on a regular basis so that students can see, first-hand, what we make and how we make it. It gives students a chance to speak to our employees and is always very engaging for everyone involved. We also actively attend local career fairs at community colleges and trade schools.

Our Virginia facility partners with Blue Ridge Community College to recruit new hires once students have completed their certification or degree. Mechatronics students come to the facility for tours and we also attend career fairs at the school. We also have a strong relationship with Valley Career and Technical Center, which provides technical education for high school juniors and seniors. They come here each semester for plant tours followed by a Q&A session with members from our manufacturing, engineering, and human resources teams.

Blue Ridge Community College mechatronics students troubleshoot testing equipment during class.

Lorie Frea: Our Wisconsin facility participates in a local annual event called “Manufacturing Days,” which targets sophomore students from all county high schools. The students tour our facility to gain knowledge of our precision metal stamping and plastic injection molding capabilities. Our goal is to educate them about what modern day manufacturing can offer in terms of career opportunities, as well as show them what a great work environment and culture we have.

Brusco: Is there a way industry can get involved in the classrooms for a STEM program?

Alltop: Absolutely! We embrace helping the next generation of manufacturing. There are always many ways to help STEM programs—anything from volunteering to monetary donations. Several of our engineers volunteer their time at local high schools, trade schools, and community colleges. We’ve also provided endowments in the past and other funding for various technical programs at local community colleges and technical schools.

Frea: This year, our Wisconsin facility will be participating in a STEM-based activity sponsored by our local Boys and Girls Club that provides an opportunity to connect fourth through sixth grade students with our engineering staff. We’re being challenged with finding a fun way to capture these students’ attention—who may very well be our future employees—by engaging them hands-on in a technology-based problem-solving activity that will help them understand what we do here.

Brusco: Does your company offer internships or apprenticeships as a means to attract and train employees? If so, what benefits have you found in using these programs? How can interns and/or apprentices be effectively used?

Alltop: We offer engineering internships at all of our locations, as well as apprenticeships for tool and die making at our Wisconsin facility. These programs are intended to help educate future engineers and tool and die makers about the manufacturing industry. We also love hiring these students if we have open positions upon the student’s graduation or completion of his/her apprenticeship program.

Dan Briggs: Our Rhode Island location is actively working with multiple colleges and trade schools—Quinebaug Valley Community College in CT works with us to place students into full-time CNC Machinist positions upon completion of their Advanced Manufacturing Certificate Program. Community College of Rhode Island currently has five students participating in a job shadow program and students will have the opportunity to apply for open positions in manufacturing upon completion of the Fast Track to CNC Machining Certificate Program. Providence College has the Student Athletic Experiential Program placing Engineering, Accounting, and Computer Science students into Cadence on a fully funded internship. Diman Regional Vocational Technical High School places students at Cadence as interns on our CNC Machining team, with hopes to gain full-time employment upon graduation. Additionally, we host three engineering interns from various colleges on a regular basis with a steady pool of candidates from Northeastern College and Worchester Polytechnic Institute.

Frea: Our Wisconsin location experienced a great deal of success in their first engineering internship experience. They employed an industrial engineering student attending University of Wisconsin-Platteville during the summers of 2017 and 2018. He did an outstanding job for them and was a great cultural fit. With that student now graduating, an employment offer was made and accepted, making this previous intern a full-time Tooling Engineer working in our Wisconsin facility as of June.

Brusco: What education and training do you offer to enhance the expertise of your workforce? Is there a minimum “term of service” with your company once a training/educational program has been completed?

Alltop: At our Virginia facility, we partner with Blue Ridge Community College and bring their Workforce and Continuing Education (WCE) instructors on-site to provide all of our employees with quarterly training. We also provide all our employees tuition reimbursement for any schooling (classes, certifications, or degrees) pertaining to their career with the company.

Keri Rankin: Cadence’s “term of service” for employees is 12 months.

Brusco: What strategies do you employ regarding employee compensation and recognition to help retain your workforce?

Rankin: We provide performance-based pay and also have a company-wide incentive plan. Our internal job posting policies support employee growth, as well as the use of career ladders that recognize development/growth of skill and experience in roles over time.

Brusco: How do you instill a sense of purpose (which is VERY important to the millennial workforce) in your employees to help ensure pride in their work and their retention?

Rankin: We have strong core values that reflect our “Do the Right Thing” culture. We also provide product spotlights at our employee meetings that describe how the products we manufacture are used and we also bring awareness that the devices we manufacture may one day save our life or the life of someone we love.

We have an “Ideas are Free” program that gives employees a voice and mechanism for contributing to organizational improvements.

Brusco: What future new efforts, if any, will you make to attract, educate/train, and/or retain your workforce?

Alltop: We plan on continuing our partnerships with local community colleges and trade schools to provide training, certification, and degrees for our employees.

Rankin: We continue to evaluate and evolve policies that support the work-life balance for our employees.

Despite medtech’s potential for a rewarding career in an industry whose purpose is to save lives, there is still a stereotype associated with employment in the skilled trades. The perception that a factory job requires little skill or thinking and offers no advancement opportunities unfortunately still prevails, and popular culture doesn’t help—trade workers are still depicted as bumbling, poor, uneducated, lazy, and rude.

This is simply not true, especially in medical device manufacturing. Today, skilled tradespeople working to build medical devices and components need strong technical know-how and experience to operate complex part fabrication machinery. To work in medical manufacturing, prospective employees must often complete work-based learning programs, undergo an apprenticeship program, or obtain an associate’s degree.

But changing the attitude toward the skilled trades is only the first step to build a competent and, more importantly, passionate medical manufacturing workforce. Medical manufacturing companies must also do their part to recruit and retain employees. It can cost significant time and effort to implement workforce development programs, but without them the skilled labor shortage will continue to decline.

To gain more insight into how medtech manufacturers are attracting and developing a passionate workforce, I spoke with four employees from Cadence Inc., a provider of complex high-precision components and finished devices for advanced surgical and specialty industrial applications, which is headquartered in Staunton, Va.:

- Beth Alltop, marketing and communications specialist

- Dan Briggs, HR manager at Cadence's R.I. facility

- Lorie Frea, HR representative at Cadence's Wis. facility

- Keri Rankin, VP of human resources

The breadth of their input was not included in the recent feature article entitled “The Human Factor: How Medtech Firms Are Battling the Labor Shortage” (which can be read here), so the entirety of our discussion is included in the Q&A below.

Sam Brusco: What efforts, if any, does your company make to reach out to schools to generate interest in the industry? (Colleges, trade schools, high schools, even middle or grade schools?)

Beth Alltop: We often invite local high school students (those enrolled in a STEM or technical program—all students are welcome, but we specifically target those students) into all of our facilities for tours on a regular basis so that students can see, first-hand, what we make and how we make it. It gives students a chance to speak to our employees and is always very engaging for everyone involved. We also actively attend local career fairs at community colleges and trade schools.

Our Virginia facility partners with Blue Ridge Community College to recruit new hires once students have completed their certification or degree. Mechatronics students come to the facility for tours and we also attend career fairs at the school. We also have a strong relationship with Valley Career and Technical Center, which provides technical education for high school juniors and seniors. They come here each semester for plant tours followed by a Q&A session with members from our manufacturing, engineering, and human resources teams.

Blue Ridge Community College mechatronics students troubleshoot testing equipment during class.

Lorie Frea: Our Wisconsin facility participates in a local annual event called “Manufacturing Days,” which targets sophomore students from all county high schools. The students tour our facility to gain knowledge of our precision metal stamping and plastic injection molding capabilities. Our goal is to educate them about what modern day manufacturing can offer in terms of career opportunities, as well as show them what a great work environment and culture we have.

Brusco: Is there a way industry can get involved in the classrooms for a STEM program?

Alltop: Absolutely! We embrace helping the next generation of manufacturing. There are always many ways to help STEM programs—anything from volunteering to monetary donations. Several of our engineers volunteer their time at local high schools, trade schools, and community colleges. We’ve also provided endowments in the past and other funding for various technical programs at local community colleges and technical schools.

Frea: This year, our Wisconsin facility will be participating in a STEM-based activity sponsored by our local Boys and Girls Club that provides an opportunity to connect fourth through sixth grade students with our engineering staff. We’re being challenged with finding a fun way to capture these students’ attention—who may very well be our future employees—by engaging them hands-on in a technology-based problem-solving activity that will help them understand what we do here.

Brusco: Does your company offer internships or apprenticeships as a means to attract and train employees? If so, what benefits have you found in using these programs? How can interns and/or apprentices be effectively used?

Alltop: We offer engineering internships at all of our locations, as well as apprenticeships for tool and die making at our Wisconsin facility. These programs are intended to help educate future engineers and tool and die makers about the manufacturing industry. We also love hiring these students if we have open positions upon the student’s graduation or completion of his/her apprenticeship program.

Dan Briggs: Our Rhode Island location is actively working with multiple colleges and trade schools—Quinebaug Valley Community College in CT works with us to place students into full-time CNC Machinist positions upon completion of their Advanced Manufacturing Certificate Program. Community College of Rhode Island currently has five students participating in a job shadow program and students will have the opportunity to apply for open positions in manufacturing upon completion of the Fast Track to CNC Machining Certificate Program. Providence College has the Student Athletic Experiential Program placing Engineering, Accounting, and Computer Science students into Cadence on a fully funded internship. Diman Regional Vocational Technical High School places students at Cadence as interns on our CNC Machining team, with hopes to gain full-time employment upon graduation. Additionally, we host three engineering interns from various colleges on a regular basis with a steady pool of candidates from Northeastern College and Worchester Polytechnic Institute.

Frea: Our Wisconsin location experienced a great deal of success in their first engineering internship experience. They employed an industrial engineering student attending University of Wisconsin-Platteville during the summers of 2017 and 2018. He did an outstanding job for them and was a great cultural fit. With that student now graduating, an employment offer was made and accepted, making this previous intern a full-time Tooling Engineer working in our Wisconsin facility as of June.

Brusco: What education and training do you offer to enhance the expertise of your workforce? Is there a minimum “term of service” with your company once a training/educational program has been completed?

Alltop: At our Virginia facility, we partner with Blue Ridge Community College and bring their Workforce and Continuing Education (WCE) instructors on-site to provide all of our employees with quarterly training. We also provide all our employees tuition reimbursement for any schooling (classes, certifications, or degrees) pertaining to their career with the company.

Keri Rankin: Cadence’s “term of service” for employees is 12 months.

Brusco: What strategies do you employ regarding employee compensation and recognition to help retain your workforce?

Rankin: We provide performance-based pay and also have a company-wide incentive plan. Our internal job posting policies support employee growth, as well as the use of career ladders that recognize development/growth of skill and experience in roles over time.

Brusco: How do you instill a sense of purpose (which is VERY important to the millennial workforce) in your employees to help ensure pride in their work and their retention?

Rankin: We have strong core values that reflect our “Do the Right Thing” culture. We also provide product spotlights at our employee meetings that describe how the products we manufacture are used and we also bring awareness that the devices we manufacture may one day save our life or the life of someone we love.

We have an “Ideas are Free” program that gives employees a voice and mechanism for contributing to organizational improvements.

Brusco: What future new efforts, if any, will you make to attract, educate/train, and/or retain your workforce?

Alltop: We plan on continuing our partnerships with local community colleges and trade schools to provide training, certification, and degrees for our employees.

Rankin: We continue to evaluate and evolve policies that support the work-life balance for our employees.