Sam Brusco, Associate Editor05.01.19

Clemson University students will soon have the means and education to be fast-tracked into a career in the medical device industry.

The MKT 4950 Developing and Selling Medical Devices course is set to debut at the South Carolina-based university this fall as the first in a series of courses designed to develop the specialized skill set necessary to work in the medical device industry. The two-year pilot program arose from a partnership with global orthopedic device maker Arthrex Inc., which is scheduled to open a new $40 million facility in Sandy Springs, S.C. The program was crafted with the needs of the surgical device industry in mind and Arthrex will offer a gift of ten $7,500 scholarships to those participating in the program.

“Our collaboration with Arthrex helps us create a new type of focused course,” said Ryan Mullins, a Clemson College of Business professor who will teach the MKT 4950 course. “We will walk students through real case studies at Arthrex to understand how surgical devices get translated from marketable idea to surgeon or physician adoption. This helps us illustrate the challenges inherent to both the healthcare marketplace and marketing of new offerings, which is not taught anywhere else.”

The program will also include internships with Arthrex and additional learning opportunities for rising third-year students majoring in bioengineering, marketing, and health sciences fields. The program is a win-win for Clemson and Arthrex—students are given a chance to begin their career in a necessary and highly rewarding field, and Arthrex receives a steady stream of graduating students specially trained for its workforce.

Mutually beneficial solutions like Clemson and Arthrex’s partnership are worth their weight in gold due to the looming skilled labor shortage, which has also begun to touch the medical device industry. Manufacturing positions in particular are not being filled quickly enough. A Deloitte and Manufacturing Institute study predicts American manufacturers will need to fill 3.5 million jobs by 2025 but also predicts 2 million of those spots will remain vacant due to the lack of skilled trade workers.

Part of the problem is the stereotype associated with a career in skilled trades. There’s a perception that those pursuing skilled trades have no interest in earning a degree after high school and spend their workday becoming disgusting and dirty in a factory. Many also believe these jobs require little skill or thinking (ironic for something called a skilled trade) and offer no career advancement. Pop culture doesn’t help the cause, depicting trade workers as bumbling, poor, uneducated, lazy, and rude.

“Manufacturing needs to do a better community PR job because the public (i.e., parents) view manufacturing as dark, dirty, dangerous, and low paying,” commented William Pratt, VP of operations and director of creative design at Kinamed Inc., a Camarillo, Calif.-based developer, manufacturer, and distributor of specialty orthopedic, neurosurgical, and cardiothoracic medical devices. “The same parents are now getting stuck with kids in their late 20s still living at home with nothing to do except paying off their student loans and playing video games—college didn’t work out for them. Demystify manufacturing, and create entry points for young people to experience it.”

Those unfortunate perceptions are just not true, particularly for skilled tradespeople serving the medical device industry. Today, skilled trade occupations require a strong level of technical know-how and experience. Individuals seeking to enter the type of skilled trades needed for the medical device industry must complete work-based learning programs, and many of the careers also require a certificate of completing, apprenticeship, or an associate’s degree.

To begin shifting the perception, generating interest in a skilled trade should start at a young age. Children even as young as grade school should be encouraged to explore the trades. While it may not necessarily be their career path, children should be made aware that it is a good option. They should also be taught to appreciate the training and education that goes into learning a skill.

High school, of course, is the most crucial time to introduce the notion of a career in a skilled trade. Many high school students apply to college believing it is the only option to begin a rewarding career, when many are not interested or not suited for that sort of education. Further, the skilled trades offer financial and job security without crippling student loan debt. Attending trade school must not be viewed as a “second choice” because those students are trained in valuable career and life skills: specialized training, problem-solving, creative thinking, effective communication, and exceptional customer service skills.

The medical device industry must also do its part to garner interest among students. It should be relatively easy to generate enthusiasm for careers in medtech because everyone from the executives to the machinists on the shop floor plays an integral role in getting a lifesaving device to a patient in need. Companies that reach out to high schools and vocational schools may also find some of those students within the ranks of their employees, a win for everyone involved.

“We work closely with all of the Vo-Tech and CTC schools in the area by offering plant tours and co-op experiences,” described Scott Covert, training coordinator at Penn United Technologies, a Cabot, Pa.-based provider of manufacturing solutions for customers needing precision components or precision-assembled products. “We also do job/career fairs, school assemblies, and STEM classroom activities. We also have pre-apprentice program partnerships with our local school districts and community colleges to help expose the students to what a career in manufacturing may look like.”

Some companies have even created specific programs for students interested in advanced manufacturing. These programs immerse the students in the experience of working for a company’s skilled trade staff.

“In 2015, we launched a holistic workforce development program that starts at the high school level with our GW Plastics School of Tech,” explained Cathy Tempesta, VP of human resources at GW Plastics, a Bethel, Vt.-based provider of complex injection-molded thermoplastic and silicone solutions to the healthcare, automotive, and consumer/industrial industries. “We have partnered with several local schools for students to enroll in a semester-long, for-credit class at our state-of-the-art facilities to learn all about advanced manufacturing. Students are bussed to GW twice a week and taught by our tooling, automation, and molding professionals. The class begins with basic business and manufacturing exposure and progresses through the entire manufacturing process, including material selection, pricing, mold design, mold-making, injection molding, and quality. We have graduated over 50 students from our School of Tech.”

These sorts of tasks may seem daunting for companies interested in augmenting a workforce development program without the infrastructure already in place. But it isn’t necessary to dive in headfirst to begin a program. Simply reaching out and becoming involved with the local community can be an excellent place to start.

“There are many entry points: contact your local workforce development board and participate on manufacturing-related committees, participate on advisory committees of your local colleges, host a high school F.I.R.S.T. robotics team, contact your local school district and advise its Career Technical Education program,” suggested Pratt. “You need to learn about the institutional ecosystem of your local area and where you can plug in. Schools also need your obsolete equipment, down to buckets of dull cutters.”

Of course, not every effort to generate interest in a skilled trade and convert young, interested hopefuls into dedicated employees will be successful.

“We have had a mixed-bag response from such efforts,” said John MacDonald, president of AIP Precision Machining, a Daytona Beach, Fla.-based provider of precision machining services for the medical device industry. “We are partnered with a local advanced training center which included machining as one of their courses of study. To date, we have hired two machinists from the program with fair results. In the past, we have hired engineering students from local colleges, some of which came to us with excellent work ethic and a desire to learn the trade. However, these employees were later hired off at other companies which offered more formalized engineering programs.”

The stigma against blue-collar work is also incredibly difficult to shake off in a society that continually pushes college as an essential step toward a fulfilling career.

“At the end of the day, machining is a ‘blue-collar’ trade,” MacDonald continued. “Unfortunately, as a society we have mentally downgraded the image of blue collar workers. Inevitably this resulted in many of our children looking toward desk jobs rather than trade jobs to alleviate the misaligned stigma that a career in the trades is substandard.”

As if developing interest in a stigmatized industry wasn’t hard enough, firms must then find avenues to recruit students who have pursued the skilled trade path and graduate with the necessary certification or degree. Some possible strategies for recruitment may include a formal internship program, apprenticeship program, or co-op partnerships with universities for people who are college-bound or seeking further technical training.

“Our Virginia facility partners with Blue Ridge Community College to recruit new hires once students have completed their certification or degree,” explained Beth Alltop, marketing and communications specialist at Cadence Inc., a provider of complex high-precision components and finished devices for advanced surgical and specialty industrial applications headquartered in Staunton, Va. “Mechatronics students come to the facility for tours, and we also attend career fairs at the school. We also have a strong relationship with Valley Career and Technical Center, which provides technical education for high school juniors and seniors. They come here each semester for plant tours followed by a Q&A session with members from our manufacturing, engineering, and human resources teams.”

Building partnerships with the local colleges and trade schools is integral for firms seeking to curry millennial favor toward skilled manufacturing careers. These students have to be shown the constant gloom and doom rhetoric of disappearing jobs isn’t necessarily true, and that there are companies actively seeking new employees within the area in which they’re attending college or trade school.

“Our Rhode Island location is actively working with multiple colleges and trade schools—Quinebaug Valley Community College in Connecticut works with us to place students into full-time CNC machinist positions upon completion of their Advanced Manufacturing Certificate Program. Community College of Rhode Island currently has five students participating in a job shadow program and students will have the opportunity to apply for open positions in manufacturing upon completion of the Fast Track to CNC Machining Certificate Program,” described Dan Briggs, HR manager at Cadence’s Cranston, R.I. location. “Providence College has the Student Athletic Experiential Program placing Engineering, Accounting, and Computer Science students into Cadence on a fully funded internship. Diman Regional Vocational Technical High School places students at Cadence as interns on our CNC Machining team, with hopes to gain full-time employment upon graduation. Additionally, we host three engineering interns from various colleges on a regular basis with a steady pool of candidates from Northeastern College and Worchester Polytechnic Institute.”

Internships can also effectively strengthen a workforce, provided its aims are genuine—hiring someone to make copies and retrieve coffee won’t adequately prepare the prospective employee or help the company’s workforce in a long-term, meaningful way. It is important to create highly skilled workers for both the future of the medical device industry as well as local students’ careers. To be truly beneficial, an internship program should allow students an outlet to gain real, employable skills in their chosen sector of the industry.

To address the stereotype that manufacturing jobs offer no advancement, interns could be paired with a mentor within the company. That way, they can learn about the organization’s culture, what it takes to be recognized by management, and ultimately become more successful on the job. And in addition to gaining the requisite knowledge and skills sought in new candidates, interns who understand professional culture are often viewed as top candidates who are much easier to work with in the long run.

However, workforce training and education should by no means stop once the employee’s foot is in the door. That should be merely the beginning—it is a disservice to both the employee and the company not to offer opportunities to grow their skills within the company, or learn new skills to potentially advance to a role with more responsibility.

Apprenticeship is an excellent strategy to begin training employees. The employer-driven, “learn-while-you-earn” model combines on-the-job training and job-related instruction tied to the attainment of national standards. The model may also involve progressive skill and wage increases for the apprentice. The flexible training strategy can be customized to meet any business’ needs. Apprentices can either be new hires or current employees seeking skill upgrades.

Apprenticeship programs help a firm’s workforce keep pace with advancing technologies and innovations in training and human resource development via employers’ complete involvement in the educational process. While apprenticeship has historically been used primarily in the construction and manufacturing industries, it is also instrumental in the healthcare industry.

“In addition to one-, two-, three-, and four-year apprenticeships, we offer continuing education in the form of tuition reimbursement,” stated Covert. “We also have a duel articulation agreement with our local community college that gives our apprentices college credit for completing their apprenticeship. Any employee needing additional training will receive it, either internally at our in-house learning center or externally.”

Well-run training opportunities help businesses attract and retain talented employees. These programs can essentially pay for themselves by cultivating a knowledgeable and efficient workplace. Tuition reimbursement, onsite training courses to enhance job-related skills, and access to job-related conferences and seminars are just a few of the resources that medical device makers and contract manufacturers would do well to offer employees to increase the skill of their workforce.

“We offer a plethora of options for enhancing our team members’ expertise,” said Tempesta. “We now employ several RJG-certified technical trainers, who lead internal workshops, classes, and formal certification courses to boost our technical team’s skills in the areas of precision mold-making, scientific injection molding, and automation. We have successfully completed our goal of employing at least one RJG-certified MasterMolder at every GW Plastics facility around the world to ensure process and product quality, with the majority of our technical workforce having also completed the RJG systematic molding and decoupled molding courses.”

The RJG MasterMolder program, one example of a comprehensive training course, is designed for the process technician, engineer, or manager needing to understand and demonstrate injection molding skills at the machine. Anyone responsible for implementing a process strategy in their plant or anyone held accountable for quality issues is a prime candidate for this program. Students learn to apply methods, strategies, and techniques of injection molding from the plastic’s point of view in a real-world production floor environment. The hands-on, in-depth training endows students with solid skills that can be immediately applied in their facility.

And continuing education can follow employees up the career ladder. A leadership program can help team members further their technical and leadership skills to support career path aspirations and their firm’s technical needs.

“For the next stage of technical development, we offer our Manufacturing Technology Leadership Program to train our future generation of technical leaders,” Tempesta went on. “While working full-time with us, participants enroll in two classes per year for four full years at Vermont Technical College focused on a manufacturing technology and engineering course curriculum, culminating in a final project during their last semester. The projects are selected based on improvements needed in their areas of responsibility at GW and are mentored by a GW manager. Graduates of the Manufacturing Technology Leadership Program earn college credits that can be applied toward an Associate’s Degree in Applied Science in Engineering Technology at VTC. In addition to receiving college credits funded by GW, every graduate is awarded a bonus after each class and a 10 percent increase in their compensation upon graduation to recognize their commitment to improving their skills.”

Once employees are acquired and educated, further efforts must be taken to keep them with the company. Conventional methods to ensure workforce retention are common to most full-time jobs—competitive compensation and periodic salary increases, benefits packages, 401(k)s or other retirement packages, opportunities for advancement within the company, stock options, company-wide events and retreats, and internal awards are just a few of the practices companies can begin with to keep employees happy.

Job satisfaction, however, has long been the most effective means of keeping employees in the door. An employee without pride in their work will always be a professional uncertainty despite their compensation or incentives. This extends beyond the employee—if management isn’t passionate about the work, it will trickle down to the rest of the workforce. In many cases, job satisfaction extends beyond the workforce. Something as simple as a satisfied customer goes a long way to keeping employees excited about their work.

“Thank goodness our customers help instill a sense of purpose every day via compliments on our work,” said MacDonald. “I work very hard to keep the communication from the customer as direct to the floor as possible. This includes application details and many discussions regarding where the parts go, what it means for the end product or customer as well as feedback from the customer after receipt of our services. This is the key to the satisfied craftsman; there is, of course, the base desire to manufacture a part to specification and efficiently as possible.”

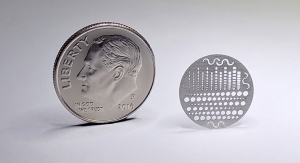

A sense of purpose and pride in the work is frequently cited as the millennial workforce’s primary career motivation. The medical device industry conveniently comes with a sense of purpose built in; every effort goes toward a patient receiving a lifesaving device. Even the beginner craftsman at the CNC machine or injection molding press plays a vital role in improving patient lives.

“Then there is the bigger picture of where the part goes and what value that craftsman’s work provided to propel the larger assembly to its proper function,” concluded MacDonald. “When we sit back and think of where some of our parts are going or have been—in human bodies, in space, flying around the world every day, and keeping our military safer and more capable than ever before—that is when you realize the bigger picture than ‘just another part.’”

The MKT 4950 Developing and Selling Medical Devices course is set to debut at the South Carolina-based university this fall as the first in a series of courses designed to develop the specialized skill set necessary to work in the medical device industry. The two-year pilot program arose from a partnership with global orthopedic device maker Arthrex Inc., which is scheduled to open a new $40 million facility in Sandy Springs, S.C. The program was crafted with the needs of the surgical device industry in mind and Arthrex will offer a gift of ten $7,500 scholarships to those participating in the program.

“Our collaboration with Arthrex helps us create a new type of focused course,” said Ryan Mullins, a Clemson College of Business professor who will teach the MKT 4950 course. “We will walk students through real case studies at Arthrex to understand how surgical devices get translated from marketable idea to surgeon or physician adoption. This helps us illustrate the challenges inherent to both the healthcare marketplace and marketing of new offerings, which is not taught anywhere else.”

The program will also include internships with Arthrex and additional learning opportunities for rising third-year students majoring in bioengineering, marketing, and health sciences fields. The program is a win-win for Clemson and Arthrex—students are given a chance to begin their career in a necessary and highly rewarding field, and Arthrex receives a steady stream of graduating students specially trained for its workforce.

Mutually beneficial solutions like Clemson and Arthrex’s partnership are worth their weight in gold due to the looming skilled labor shortage, which has also begun to touch the medical device industry. Manufacturing positions in particular are not being filled quickly enough. A Deloitte and Manufacturing Institute study predicts American manufacturers will need to fill 3.5 million jobs by 2025 but also predicts 2 million of those spots will remain vacant due to the lack of skilled trade workers.

Part of the problem is the stereotype associated with a career in skilled trades. There’s a perception that those pursuing skilled trades have no interest in earning a degree after high school and spend their workday becoming disgusting and dirty in a factory. Many also believe these jobs require little skill or thinking (ironic for something called a skilled trade) and offer no career advancement. Pop culture doesn’t help the cause, depicting trade workers as bumbling, poor, uneducated, lazy, and rude.

“Manufacturing needs to do a better community PR job because the public (i.e., parents) view manufacturing as dark, dirty, dangerous, and low paying,” commented William Pratt, VP of operations and director of creative design at Kinamed Inc., a Camarillo, Calif.-based developer, manufacturer, and distributor of specialty orthopedic, neurosurgical, and cardiothoracic medical devices. “The same parents are now getting stuck with kids in their late 20s still living at home with nothing to do except paying off their student loans and playing video games—college didn’t work out for them. Demystify manufacturing, and create entry points for young people to experience it.”

Those unfortunate perceptions are just not true, particularly for skilled tradespeople serving the medical device industry. Today, skilled trade occupations require a strong level of technical know-how and experience. Individuals seeking to enter the type of skilled trades needed for the medical device industry must complete work-based learning programs, and many of the careers also require a certificate of completing, apprenticeship, or an associate’s degree.

To begin shifting the perception, generating interest in a skilled trade should start at a young age. Children even as young as grade school should be encouraged to explore the trades. While it may not necessarily be their career path, children should be made aware that it is a good option. They should also be taught to appreciate the training and education that goes into learning a skill.

High school, of course, is the most crucial time to introduce the notion of a career in a skilled trade. Many high school students apply to college believing it is the only option to begin a rewarding career, when many are not interested or not suited for that sort of education. Further, the skilled trades offer financial and job security without crippling student loan debt. Attending trade school must not be viewed as a “second choice” because those students are trained in valuable career and life skills: specialized training, problem-solving, creative thinking, effective communication, and exceptional customer service skills.

The medical device industry must also do its part to garner interest among students. It should be relatively easy to generate enthusiasm for careers in medtech because everyone from the executives to the machinists on the shop floor plays an integral role in getting a lifesaving device to a patient in need. Companies that reach out to high schools and vocational schools may also find some of those students within the ranks of their employees, a win for everyone involved.

“We work closely with all of the Vo-Tech and CTC schools in the area by offering plant tours and co-op experiences,” described Scott Covert, training coordinator at Penn United Technologies, a Cabot, Pa.-based provider of manufacturing solutions for customers needing precision components or precision-assembled products. “We also do job/career fairs, school assemblies, and STEM classroom activities. We also have pre-apprentice program partnerships with our local school districts and community colleges to help expose the students to what a career in manufacturing may look like.”

Some companies have even created specific programs for students interested in advanced manufacturing. These programs immerse the students in the experience of working for a company’s skilled trade staff.

“In 2015, we launched a holistic workforce development program that starts at the high school level with our GW Plastics School of Tech,” explained Cathy Tempesta, VP of human resources at GW Plastics, a Bethel, Vt.-based provider of complex injection-molded thermoplastic and silicone solutions to the healthcare, automotive, and consumer/industrial industries. “We have partnered with several local schools for students to enroll in a semester-long, for-credit class at our state-of-the-art facilities to learn all about advanced manufacturing. Students are bussed to GW twice a week and taught by our tooling, automation, and molding professionals. The class begins with basic business and manufacturing exposure and progresses through the entire manufacturing process, including material selection, pricing, mold design, mold-making, injection molding, and quality. We have graduated over 50 students from our School of Tech.”

These sorts of tasks may seem daunting for companies interested in augmenting a workforce development program without the infrastructure already in place. But it isn’t necessary to dive in headfirst to begin a program. Simply reaching out and becoming involved with the local community can be an excellent place to start.

“There are many entry points: contact your local workforce development board and participate on manufacturing-related committees, participate on advisory committees of your local colleges, host a high school F.I.R.S.T. robotics team, contact your local school district and advise its Career Technical Education program,” suggested Pratt. “You need to learn about the institutional ecosystem of your local area and where you can plug in. Schools also need your obsolete equipment, down to buckets of dull cutters.”

Of course, not every effort to generate interest in a skilled trade and convert young, interested hopefuls into dedicated employees will be successful.

“We have had a mixed-bag response from such efforts,” said John MacDonald, president of AIP Precision Machining, a Daytona Beach, Fla.-based provider of precision machining services for the medical device industry. “We are partnered with a local advanced training center which included machining as one of their courses of study. To date, we have hired two machinists from the program with fair results. In the past, we have hired engineering students from local colleges, some of which came to us with excellent work ethic and a desire to learn the trade. However, these employees were later hired off at other companies which offered more formalized engineering programs.”

The stigma against blue-collar work is also incredibly difficult to shake off in a society that continually pushes college as an essential step toward a fulfilling career.

“At the end of the day, machining is a ‘blue-collar’ trade,” MacDonald continued. “Unfortunately, as a society we have mentally downgraded the image of blue collar workers. Inevitably this resulted in many of our children looking toward desk jobs rather than trade jobs to alleviate the misaligned stigma that a career in the trades is substandard.”

As if developing interest in a stigmatized industry wasn’t hard enough, firms must then find avenues to recruit students who have pursued the skilled trade path and graduate with the necessary certification or degree. Some possible strategies for recruitment may include a formal internship program, apprenticeship program, or co-op partnerships with universities for people who are college-bound or seeking further technical training.

“Our Virginia facility partners with Blue Ridge Community College to recruit new hires once students have completed their certification or degree,” explained Beth Alltop, marketing and communications specialist at Cadence Inc., a provider of complex high-precision components and finished devices for advanced surgical and specialty industrial applications headquartered in Staunton, Va. “Mechatronics students come to the facility for tours, and we also attend career fairs at the school. We also have a strong relationship with Valley Career and Technical Center, which provides technical education for high school juniors and seniors. They come here each semester for plant tours followed by a Q&A session with members from our manufacturing, engineering, and human resources teams.”

Building partnerships with the local colleges and trade schools is integral for firms seeking to curry millennial favor toward skilled manufacturing careers. These students have to be shown the constant gloom and doom rhetoric of disappearing jobs isn’t necessarily true, and that there are companies actively seeking new employees within the area in which they’re attending college or trade school.

“Our Rhode Island location is actively working with multiple colleges and trade schools—Quinebaug Valley Community College in Connecticut works with us to place students into full-time CNC machinist positions upon completion of their Advanced Manufacturing Certificate Program. Community College of Rhode Island currently has five students participating in a job shadow program and students will have the opportunity to apply for open positions in manufacturing upon completion of the Fast Track to CNC Machining Certificate Program,” described Dan Briggs, HR manager at Cadence’s Cranston, R.I. location. “Providence College has the Student Athletic Experiential Program placing Engineering, Accounting, and Computer Science students into Cadence on a fully funded internship. Diman Regional Vocational Technical High School places students at Cadence as interns on our CNC Machining team, with hopes to gain full-time employment upon graduation. Additionally, we host three engineering interns from various colleges on a regular basis with a steady pool of candidates from Northeastern College and Worchester Polytechnic Institute.”

Internships can also effectively strengthen a workforce, provided its aims are genuine—hiring someone to make copies and retrieve coffee won’t adequately prepare the prospective employee or help the company’s workforce in a long-term, meaningful way. It is important to create highly skilled workers for both the future of the medical device industry as well as local students’ careers. To be truly beneficial, an internship program should allow students an outlet to gain real, employable skills in their chosen sector of the industry.

To address the stereotype that manufacturing jobs offer no advancement, interns could be paired with a mentor within the company. That way, they can learn about the organization’s culture, what it takes to be recognized by management, and ultimately become more successful on the job. And in addition to gaining the requisite knowledge and skills sought in new candidates, interns who understand professional culture are often viewed as top candidates who are much easier to work with in the long run.

However, workforce training and education should by no means stop once the employee’s foot is in the door. That should be merely the beginning—it is a disservice to both the employee and the company not to offer opportunities to grow their skills within the company, or learn new skills to potentially advance to a role with more responsibility.

Apprenticeship is an excellent strategy to begin training employees. The employer-driven, “learn-while-you-earn” model combines on-the-job training and job-related instruction tied to the attainment of national standards. The model may also involve progressive skill and wage increases for the apprentice. The flexible training strategy can be customized to meet any business’ needs. Apprentices can either be new hires or current employees seeking skill upgrades.

Apprenticeship programs help a firm’s workforce keep pace with advancing technologies and innovations in training and human resource development via employers’ complete involvement in the educational process. While apprenticeship has historically been used primarily in the construction and manufacturing industries, it is also instrumental in the healthcare industry.

“In addition to one-, two-, three-, and four-year apprenticeships, we offer continuing education in the form of tuition reimbursement,” stated Covert. “We also have a duel articulation agreement with our local community college that gives our apprentices college credit for completing their apprenticeship. Any employee needing additional training will receive it, either internally at our in-house learning center or externally.”

Well-run training opportunities help businesses attract and retain talented employees. These programs can essentially pay for themselves by cultivating a knowledgeable and efficient workplace. Tuition reimbursement, onsite training courses to enhance job-related skills, and access to job-related conferences and seminars are just a few of the resources that medical device makers and contract manufacturers would do well to offer employees to increase the skill of their workforce.

“We offer a plethora of options for enhancing our team members’ expertise,” said Tempesta. “We now employ several RJG-certified technical trainers, who lead internal workshops, classes, and formal certification courses to boost our technical team’s skills in the areas of precision mold-making, scientific injection molding, and automation. We have successfully completed our goal of employing at least one RJG-certified MasterMolder at every GW Plastics facility around the world to ensure process and product quality, with the majority of our technical workforce having also completed the RJG systematic molding and decoupled molding courses.”

The RJG MasterMolder program, one example of a comprehensive training course, is designed for the process technician, engineer, or manager needing to understand and demonstrate injection molding skills at the machine. Anyone responsible for implementing a process strategy in their plant or anyone held accountable for quality issues is a prime candidate for this program. Students learn to apply methods, strategies, and techniques of injection molding from the plastic’s point of view in a real-world production floor environment. The hands-on, in-depth training endows students with solid skills that can be immediately applied in their facility.

And continuing education can follow employees up the career ladder. A leadership program can help team members further their technical and leadership skills to support career path aspirations and their firm’s technical needs.

“For the next stage of technical development, we offer our Manufacturing Technology Leadership Program to train our future generation of technical leaders,” Tempesta went on. “While working full-time with us, participants enroll in two classes per year for four full years at Vermont Technical College focused on a manufacturing technology and engineering course curriculum, culminating in a final project during their last semester. The projects are selected based on improvements needed in their areas of responsibility at GW and are mentored by a GW manager. Graduates of the Manufacturing Technology Leadership Program earn college credits that can be applied toward an Associate’s Degree in Applied Science in Engineering Technology at VTC. In addition to receiving college credits funded by GW, every graduate is awarded a bonus after each class and a 10 percent increase in their compensation upon graduation to recognize their commitment to improving their skills.”

Once employees are acquired and educated, further efforts must be taken to keep them with the company. Conventional methods to ensure workforce retention are common to most full-time jobs—competitive compensation and periodic salary increases, benefits packages, 401(k)s or other retirement packages, opportunities for advancement within the company, stock options, company-wide events and retreats, and internal awards are just a few of the practices companies can begin with to keep employees happy.

Job satisfaction, however, has long been the most effective means of keeping employees in the door. An employee without pride in their work will always be a professional uncertainty despite their compensation or incentives. This extends beyond the employee—if management isn’t passionate about the work, it will trickle down to the rest of the workforce. In many cases, job satisfaction extends beyond the workforce. Something as simple as a satisfied customer goes a long way to keeping employees excited about their work.

“Thank goodness our customers help instill a sense of purpose every day via compliments on our work,” said MacDonald. “I work very hard to keep the communication from the customer as direct to the floor as possible. This includes application details and many discussions regarding where the parts go, what it means for the end product or customer as well as feedback from the customer after receipt of our services. This is the key to the satisfied craftsman; there is, of course, the base desire to manufacture a part to specification and efficiently as possible.”

A sense of purpose and pride in the work is frequently cited as the millennial workforce’s primary career motivation. The medical device industry conveniently comes with a sense of purpose built in; every effort goes toward a patient receiving a lifesaving device. Even the beginner craftsman at the CNC machine or injection molding press plays a vital role in improving patient lives.

“Then there is the bigger picture of where the part goes and what value that craftsman’s work provided to propel the larger assembly to its proper function,” concluded MacDonald. “When we sit back and think of where some of our parts are going or have been—in human bodies, in space, flying around the world every day, and keeping our military safer and more capable than ever before—that is when you realize the bigger picture than ‘just another part.’”