Sam Brusco, Associate Editor05.29.19

The skilled labor shortage, which according to a Deloitte and Manufacturing Institute study threatens to render two million American manufacturing jobs vacant by 2025, has begun to affect the medical device industry.

Despite medtech’s potential for a rewarding career in an industry whose purpose is to save lives, there is still a stereotype associated with employment in the skilled trades. The perception that a factory job requires little skill or thinking and offers no advancement opportunities unfortunately still prevails, and popular culture doesn’t help—trade workers are still depicted as bumbling, poor, uneducated, lazy, and rude.

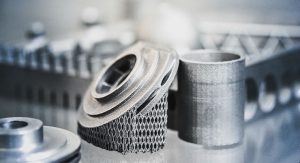

This is simply not true, especially in medical device manufacturing. Today, skilled tradespeople working to build medical devices and components need strong technical know-how and experience to operate complex part fabrication machinery. To work in medical manufacturing, prospective employees must often complete work-based learning programs, undergo an apprenticeship program, or obtain an associate’s degree.

But changing the attitude toward the skilled trades is only the first step to build a competent and, more importantly, passionate medical manufacturing workforce. Medical manufacturing companies must also do their part to recruit and retain employees. It can cost significant time and effort to implement workforce development programs, but without them the skilled labor shortage will continue to decline.

To gain more insight into how medtech manufacturers are attracting and developing a passionate workforce, I spoke with Scott Covert, training coordinator at Penn United Technologies, a Cabot, Pa.-based provider of manufacturing solutions for customers needing precision components or precision-assembled products.. The breadth of his/her/their input was not included in the recent feature article entitled “The Human Factor: How Medtech Firms Are Battling the Labor Shortage” (which can be read here), so the entirety of our discussion is included in the Q&A below.

Sam Brusco: What efforts, if any, does your company make to reach out to schools to generate interest in the industry? (Colleges, trade schools, high schools, even middle or grade schools?)

Scott Covert: We work closely with all of the Vo-Tech and CTC schools in the area by offering plant tours and co-op experiences. We also do job/career fairs, school assemblies, and STEM classroom activities. We also have pre-apprentice program partnerships with our local school districts and community colleges to help expose the students to what a career in manufacturing may look like.

Members of Penn United's adult/veterans pre-apprenticeship program.

Brusco: Is there a way industry can get involved in the classrooms for a STEM program?

Covert: We have created and offer manufacturing-related STEM activities that we bring into classrooms. We also hold teacher trainings to show educators how we use the math and science they are teaching in their classrooms.

Brusco: Does your company offer internships or apprenticeships as a means to attract and train employees? If so, what benefits have you found in using these programs? How can interns and/or apprentices be effectively used?

Covert: We offer internships, co-ops, and pre-apprentice programs to area high school students and apprenticeships to those we hire after graduation. This has been a great way to teach students job-related skills and give them a tremendous head start as full-time employees after graduation. We also get an "extended interview" with all of these students, meaning we can see what type of work habits they have and how quickly they pick up new skills before offering them full-time employment. These programs attract new employees and help to retain them.

Brusco: What education and training do you offer to enhance the expertise of your workforce? Is there a minimum “term of service” with your company once a training/educational program has been completed?

Covert: In addition to one-, two-, three-, and four-year apprenticeships, we offer continuing education in the form of tuition reimbursement. We also have a duel articulation agreement with our local community college that gives our apprentices college credit for completing their apprenticeship. Any employee needing additional training will receive it, either internally at our in-house learning center or externally.

Participants in Penn United's high school pre-apprentice program.

Brusco: What strategies do you employ regarding employee compensation and recognition to help retain your workforce?

Covert: Using the apprentice training module has long been an effective way of training and retaining employees. We also offer a total compensation package that is one of the best in the area. Being an employee-owned company has let us offer our employees more than most companies can.

Brusco: How do you instill a sense of purpose (which is VERY important to the millennial workforce) in your employees to help ensure pride in their work and their retention?

Covert: As an employee owned company, everything an employee does directly effects his or her salary and bonuses. This helps instill a sense of purpose when you can see the direct results of your efforts in each paycheck and monthly bonus. Cross-training is very important to us as a company, and is effective in keeping employees engaged and interested. We also promote from within as much as possible, giving each employee a chance to express interest in new opportunities that become available.

Brusco: What future new efforts, if any, will you make to attract, educate/train, and/or retain your workforce?

Covert: We are constantly looking to expand current relationships and forge new community partnerships that will help train and retain employees. We are not afraid to act outside the box to make this happen.

Brusco: Is there anything else you’d like to say regarding medical device industry workforce development?

Covert: Attracting new talent is becoming very competitive. Companies must be willing to look beyond past best practices and learn to be creative and innovative to compete in the new employee marketplace.

Despite medtech’s potential for a rewarding career in an industry whose purpose is to save lives, there is still a stereotype associated with employment in the skilled trades. The perception that a factory job requires little skill or thinking and offers no advancement opportunities unfortunately still prevails, and popular culture doesn’t help—trade workers are still depicted as bumbling, poor, uneducated, lazy, and rude.

This is simply not true, especially in medical device manufacturing. Today, skilled tradespeople working to build medical devices and components need strong technical know-how and experience to operate complex part fabrication machinery. To work in medical manufacturing, prospective employees must often complete work-based learning programs, undergo an apprenticeship program, or obtain an associate’s degree.

But changing the attitude toward the skilled trades is only the first step to build a competent and, more importantly, passionate medical manufacturing workforce. Medical manufacturing companies must also do their part to recruit and retain employees. It can cost significant time and effort to implement workforce development programs, but without them the skilled labor shortage will continue to decline.

To gain more insight into how medtech manufacturers are attracting and developing a passionate workforce, I spoke with Scott Covert, training coordinator at Penn United Technologies, a Cabot, Pa.-based provider of manufacturing solutions for customers needing precision components or precision-assembled products.. The breadth of his/her/their input was not included in the recent feature article entitled “The Human Factor: How Medtech Firms Are Battling the Labor Shortage” (which can be read here), so the entirety of our discussion is included in the Q&A below.

Sam Brusco: What efforts, if any, does your company make to reach out to schools to generate interest in the industry? (Colleges, trade schools, high schools, even middle or grade schools?)

Scott Covert: We work closely with all of the Vo-Tech and CTC schools in the area by offering plant tours and co-op experiences. We also do job/career fairs, school assemblies, and STEM classroom activities. We also have pre-apprentice program partnerships with our local school districts and community colleges to help expose the students to what a career in manufacturing may look like.

Members of Penn United's adult/veterans pre-apprenticeship program.

Brusco: Is there a way industry can get involved in the classrooms for a STEM program?

Covert: We have created and offer manufacturing-related STEM activities that we bring into classrooms. We also hold teacher trainings to show educators how we use the math and science they are teaching in their classrooms.

Brusco: Does your company offer internships or apprenticeships as a means to attract and train employees? If so, what benefits have you found in using these programs? How can interns and/or apprentices be effectively used?

Covert: We offer internships, co-ops, and pre-apprentice programs to area high school students and apprenticeships to those we hire after graduation. This has been a great way to teach students job-related skills and give them a tremendous head start as full-time employees after graduation. We also get an "extended interview" with all of these students, meaning we can see what type of work habits they have and how quickly they pick up new skills before offering them full-time employment. These programs attract new employees and help to retain them.

Brusco: What education and training do you offer to enhance the expertise of your workforce? Is there a minimum “term of service” with your company once a training/educational program has been completed?

Covert: In addition to one-, two-, three-, and four-year apprenticeships, we offer continuing education in the form of tuition reimbursement. We also have a duel articulation agreement with our local community college that gives our apprentices college credit for completing their apprenticeship. Any employee needing additional training will receive it, either internally at our in-house learning center or externally.

Participants in Penn United's high school pre-apprentice program.

Brusco: What strategies do you employ regarding employee compensation and recognition to help retain your workforce?

Covert: Using the apprentice training module has long been an effective way of training and retaining employees. We also offer a total compensation package that is one of the best in the area. Being an employee-owned company has let us offer our employees more than most companies can.

Brusco: How do you instill a sense of purpose (which is VERY important to the millennial workforce) in your employees to help ensure pride in their work and their retention?

Covert: As an employee owned company, everything an employee does directly effects his or her salary and bonuses. This helps instill a sense of purpose when you can see the direct results of your efforts in each paycheck and monthly bonus. Cross-training is very important to us as a company, and is effective in keeping employees engaged and interested. We also promote from within as much as possible, giving each employee a chance to express interest in new opportunities that become available.

Brusco: What future new efforts, if any, will you make to attract, educate/train, and/or retain your workforce?

Covert: We are constantly looking to expand current relationships and forge new community partnerships that will help train and retain employees. We are not afraid to act outside the box to make this happen.

Brusco: Is there anything else you’d like to say regarding medical device industry workforce development?

Covert: Attracting new talent is becoming very competitive. Companies must be willing to look beyond past best practices and learn to be creative and innovative to compete in the new employee marketplace.