Sam Brusco, Associate Editor05.29.19

The skilled labor shortage, which according to a Deloitte and Manufacturing Institute study threatens to render two million American manufacturing jobs vacant by 2025, has begun to affect the medical device industry.

Despite medtech’s potential for a rewarding career in an industry whose purpose is to save lives, there is still a stereotype associated with employment in the skilled trades. The perception that a factory job requires little skill or thinking and offers no advancement opportunities unfortunately still prevails, and popular culture doesn’t help—trade workers are still depicted as bumbling, poor, uneducated, lazy, and rude.

This is simply not true, especially in medical device manufacturing. Today, skilled tradespeople working to build medical devices and components need strong technical know-how and experience to operate complex part fabrication machinery. To work in medical manufacturing, prospective employees must often complete work-based learning programs, undergo an apprenticeship program, or obtain an associate’s degree.

But changing the attitude toward the skilled trades is only the first step to build a competent and, more importantly, passionate medical manufacturing workforce. Medical manufacturing companies must also do their part to recruit and retain employees. It can cost significant time and effort to implement workforce development programs, but without them the skilled labor shortage will continue to decline.

To gain more insight into how medtech manufacturers are attracting and developing a passionate workforce, I spoke with Cathy Tempesta, VP of human resources at GW Plastics, a Bethel, Vt.-based provider of complex injection-molded thermoplastic and silicone solutions to the healthcare, automotive, and consumer/industrial industries. The breadth of her input was not included in the recent feature article entitled “The Human Factor: How Medtech Firms Are Battling the Labor Shortage” (which can be read here), so the entirety of our discussion is included in the Q&A below.

Sam Brusco: What efforts, if any, does your company make to reach out to schools to generate interest in the industry? (Colleges, trade schools, high schools, even middle or grade schools?)

Cathy Tempesta: In 2015, we launched a holistic workforce development program that starts at the high school level with our GW Plastics School of Tech. We have partnered with several local schools for students to enroll in a semester-long, for-credit class at our state-of-the-art facilities to learn all about advanced manufacturing. Students are bussed to GW twice a week and taught by our tooling, automation, and molding professionals. The class begins with basic business and manufacturing exposure and progresses through the entire manufacturing process, including material selection, pricing, mold design, mold-making, injection molding, and quality. We have graduated over 50 students from our School of Tech.

Apprenticeship programs help a firm’s workforce keep pace with advancing technologies and innovations in training and human resource development.

For students pursuing further education, we offer a scholarship-internship package in conjunction with Vermont Technical College (VTC) to encourage earning a degree and beginning a career in the advanced manufacturing industry. Between the scholarship and paid internship, we cover the cost of their college tuition. We have further partnered with VTC to launch the GW Plastics Advanced Manufacturing Lab, the first on-campus plastics technology facility, to further expose students to careers in manufacturing and help develop their skills before entering the workforce.

For those looking to grow their technical skills without higher education, we also offer a formal apprenticeship program for both current employees and new team members. These apprenticeships last for 12-24 months and include customized placements in our tooling, molding, and automation departments.

In addition to these formal programs, we are active in the local educational community and are regularly invited to participate in informational sessions about careers in advanced manufacturing for the area high schools and technical centers. Employees are key members of community groups to offer guidance in technical programs offered to the local students.

We also host an annual National Manufacturing Day event, where we welcome all types of students, teachers, families, government representatives, media, and community members to our facilities to expose the general public to the world of advanced manufacturing.

Brusco: Is there a way the industry can get involved in the classrooms for a STEM program?

Tempesta: The plastics healthcare industry requires such specialized skills that it is nearly impossible for someone to learn everything in a standard classroom. There is always room for an industry leader to get more involved in students’ exposure, whether from a design and technological perspective or a more hands-on approach. We noticed in our region the largest opportunity was in overall plastics processing education, which is why we partnered with VTC to launch the Advanced Manufacturing Lab.

Brusco: Does your company offer internships or apprenticeships as a means to attract and train employees? If so, what benefits have you found in using these programs? How can interns and/or apprentices be effectively used?

Tempesta: We offer a formal internship program, apprenticeship program, and co-op partnerships with universities for those who are college-bound or looking for further technical training.

We recognize the importance of creating highly-skilled engineers both for the future of our industry and the careers of local students. Because of this, our internship program was built to provide students with an outlet to obtain real, employable skills in a beneficial area of our business. Every intern is assigned a project they develop throughout the program under the guidance of a GW manager, culminating in a final presentation to our senior management group. Our partnership with Vermont Technical College makes our internship program truly unique beyond the formal project. For select students, we offer a generous scholarship package to VTC in addition to the paid summer internship, and successful interns are offered a full-time position with us upon graduation. Between the scholarship and paid internship, we cover the cost of our interns’ tuition.

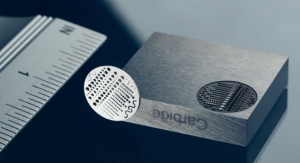

Junior engineers master innovative technology such as steel 3D printing under the guidance of senior engineers, ensuring the next generation of technical development.

We recognize a traditional route of high school, college, then employment does not apply to everyone, and following a different path should not limit success. To address our national skilled labor shortage and support those pursuing an alternate career path, we are proud to offer 12-24-month technical training apprenticeships in mold-making, molding, and automation. Our program is an open door to cutting-edge technology and hands-on career development, and it is our way of building the talent of tomorrow today, with training and expertise handed down one-on-one from experienced professionals. Our apprenticeship program is open to both existing employees and new team members, and employees interested in developing their skills in a more technical capacity and outside applicants with the same desire are encouraged to apply each year. Upon graduation, apprentices are hired as a Process Technician or other relevant role.

What education and training do you offer to enhance the expertise of your workforce? Is there a minimum “term of service” with your company once a training/educational program has been completed?

Tempesta: We offer a plethora of options for enhancing our team members’ expertise. We now employ several RJG-certified technical trainers, who lead internal workshops, classes, and formal certification courses to boost our technical team’s skills in the areas of precision mold-making, scientific injection molding, and automation. We have successfully completed our goal of employing at least one RJG-certified MasterMolder at every GW Plastics facility around the world to ensure process and product quality, with the majority of our technical workforce having also completed the RJG systematic molding and decoupled molding courses.

Scientific Injection Molding courses and advanced certifications are available to GW Plastics associates and customers in their state-of-the-art training facilities.

For the next stage of technical development, we offer our Manufacturing Technology Leadership Program to train our future generation of technical leaders. While working full-time with us, participants enroll in two classes per year for four full years at Vermont Technical College focused on a manufacturing technology and engineering course curriculum, culminating in a final project during their last semester. The projects are selected based on improvements needed in their areas of responsibility at GW, and are mentored by a GW manager. Graduates of the Manufacturing Technology Leadership Program earn college credits that can be applied toward an Associate’s Degree in Applied Science in Engineering Technology at VTC. In addition to receiving college credits funded by GW, every graduate is awarded a bonus after each class and a 10 percent increase in their compensation upon graduation to recognize their commitment to improving their skills.

We also offer tuition reimbursement as part of our benefits package available to all associates. We always support our team members’ dedication to obtaining an education and furthering their careers, and our tuition reimbursement program has helped many take that next step who otherwise could not.

Brusco: What strategies do you employ regarding employee compensation and recognition to help retain your workforce?

Tempesta: We offer competitive compensation and benefits packages to all employees, including a fixed 401(k) match and excellent healthcare coverage. With some of the highest retention rates in the industry, we mean it seriously when we say that we have “the experience to deliver” for our customers. The success of our business depends on the dedication and experience of our team, and we prioritize recognizing our associates’ service from five years up to fifty years with company awards, luncheons, and announcements. Every year, we award at least one 45-year service award, with many years reaching 50.

Brusco: How do you instill a sense of purpose (which is VERY important to the millennial workforce) in your employees to help ensure pride in their work and their retention?

Tempesta: We focus on manufacturing lifesaving devices for both patients and passengers. As a company who dedicates ourselves to improving patient lives, it is easy for our team to take pride in our work. The products we manufacture affect us and our loved ones every day, and we take every opportunity to reflect on what that responsibility means. We recently launched an internal “Quality Begins with Me” campaign to highlight this mentality and stress the importance of high-quality production in all of our facilities regardless of position.

Brothers and senior engineers Joe and Garrett Sargent graduating from GW Plastics’ first Manufacturing Technology Leadership Program, which ensures a pipeline of technical talent.

Brusco: What future new efforts, if any, will you make to attract, educate/train, and/or retain your workforce?

We have long recognized the value of internal training and development, in partnership with the educational institutions in the local community. We plan on continuing to develop these educational opportunities to students in order to offer challenging, well paid careers.

Despite medtech’s potential for a rewarding career in an industry whose purpose is to save lives, there is still a stereotype associated with employment in the skilled trades. The perception that a factory job requires little skill or thinking and offers no advancement opportunities unfortunately still prevails, and popular culture doesn’t help—trade workers are still depicted as bumbling, poor, uneducated, lazy, and rude.

This is simply not true, especially in medical device manufacturing. Today, skilled tradespeople working to build medical devices and components need strong technical know-how and experience to operate complex part fabrication machinery. To work in medical manufacturing, prospective employees must often complete work-based learning programs, undergo an apprenticeship program, or obtain an associate’s degree.

But changing the attitude toward the skilled trades is only the first step to build a competent and, more importantly, passionate medical manufacturing workforce. Medical manufacturing companies must also do their part to recruit and retain employees. It can cost significant time and effort to implement workforce development programs, but without them the skilled labor shortage will continue to decline.

To gain more insight into how medtech manufacturers are attracting and developing a passionate workforce, I spoke with Cathy Tempesta, VP of human resources at GW Plastics, a Bethel, Vt.-based provider of complex injection-molded thermoplastic and silicone solutions to the healthcare, automotive, and consumer/industrial industries. The breadth of her input was not included in the recent feature article entitled “The Human Factor: How Medtech Firms Are Battling the Labor Shortage” (which can be read here), so the entirety of our discussion is included in the Q&A below.

Sam Brusco: What efforts, if any, does your company make to reach out to schools to generate interest in the industry? (Colleges, trade schools, high schools, even middle or grade schools?)

Cathy Tempesta: In 2015, we launched a holistic workforce development program that starts at the high school level with our GW Plastics School of Tech. We have partnered with several local schools for students to enroll in a semester-long, for-credit class at our state-of-the-art facilities to learn all about advanced manufacturing. Students are bussed to GW twice a week and taught by our tooling, automation, and molding professionals. The class begins with basic business and manufacturing exposure and progresses through the entire manufacturing process, including material selection, pricing, mold design, mold-making, injection molding, and quality. We have graduated over 50 students from our School of Tech.

Apprenticeship programs help a firm’s workforce keep pace with advancing technologies and innovations in training and human resource development.

For students pursuing further education, we offer a scholarship-internship package in conjunction with Vermont Technical College (VTC) to encourage earning a degree and beginning a career in the advanced manufacturing industry. Between the scholarship and paid internship, we cover the cost of their college tuition. We have further partnered with VTC to launch the GW Plastics Advanced Manufacturing Lab, the first on-campus plastics technology facility, to further expose students to careers in manufacturing and help develop their skills before entering the workforce.

For those looking to grow their technical skills without higher education, we also offer a formal apprenticeship program for both current employees and new team members. These apprenticeships last for 12-24 months and include customized placements in our tooling, molding, and automation departments.

In addition to these formal programs, we are active in the local educational community and are regularly invited to participate in informational sessions about careers in advanced manufacturing for the area high schools and technical centers. Employees are key members of community groups to offer guidance in technical programs offered to the local students.

We also host an annual National Manufacturing Day event, where we welcome all types of students, teachers, families, government representatives, media, and community members to our facilities to expose the general public to the world of advanced manufacturing.

Brusco: Is there a way the industry can get involved in the classrooms for a STEM program?

Tempesta: The plastics healthcare industry requires such specialized skills that it is nearly impossible for someone to learn everything in a standard classroom. There is always room for an industry leader to get more involved in students’ exposure, whether from a design and technological perspective or a more hands-on approach. We noticed in our region the largest opportunity was in overall plastics processing education, which is why we partnered with VTC to launch the Advanced Manufacturing Lab.

Brusco: Does your company offer internships or apprenticeships as a means to attract and train employees? If so, what benefits have you found in using these programs? How can interns and/or apprentices be effectively used?

Tempesta: We offer a formal internship program, apprenticeship program, and co-op partnerships with universities for those who are college-bound or looking for further technical training.

We recognize the importance of creating highly-skilled engineers both for the future of our industry and the careers of local students. Because of this, our internship program was built to provide students with an outlet to obtain real, employable skills in a beneficial area of our business. Every intern is assigned a project they develop throughout the program under the guidance of a GW manager, culminating in a final presentation to our senior management group. Our partnership with Vermont Technical College makes our internship program truly unique beyond the formal project. For select students, we offer a generous scholarship package to VTC in addition to the paid summer internship, and successful interns are offered a full-time position with us upon graduation. Between the scholarship and paid internship, we cover the cost of our interns’ tuition.

Junior engineers master innovative technology such as steel 3D printing under the guidance of senior engineers, ensuring the next generation of technical development.

We recognize a traditional route of high school, college, then employment does not apply to everyone, and following a different path should not limit success. To address our national skilled labor shortage and support those pursuing an alternate career path, we are proud to offer 12-24-month technical training apprenticeships in mold-making, molding, and automation. Our program is an open door to cutting-edge technology and hands-on career development, and it is our way of building the talent of tomorrow today, with training and expertise handed down one-on-one from experienced professionals. Our apprenticeship program is open to both existing employees and new team members, and employees interested in developing their skills in a more technical capacity and outside applicants with the same desire are encouraged to apply each year. Upon graduation, apprentices are hired as a Process Technician or other relevant role.

What education and training do you offer to enhance the expertise of your workforce? Is there a minimum “term of service” with your company once a training/educational program has been completed?

Tempesta: We offer a plethora of options for enhancing our team members’ expertise. We now employ several RJG-certified technical trainers, who lead internal workshops, classes, and formal certification courses to boost our technical team’s skills in the areas of precision mold-making, scientific injection molding, and automation. We have successfully completed our goal of employing at least one RJG-certified MasterMolder at every GW Plastics facility around the world to ensure process and product quality, with the majority of our technical workforce having also completed the RJG systematic molding and decoupled molding courses.

Scientific Injection Molding courses and advanced certifications are available to GW Plastics associates and customers in their state-of-the-art training facilities.

For the next stage of technical development, we offer our Manufacturing Technology Leadership Program to train our future generation of technical leaders. While working full-time with us, participants enroll in two classes per year for four full years at Vermont Technical College focused on a manufacturing technology and engineering course curriculum, culminating in a final project during their last semester. The projects are selected based on improvements needed in their areas of responsibility at GW, and are mentored by a GW manager. Graduates of the Manufacturing Technology Leadership Program earn college credits that can be applied toward an Associate’s Degree in Applied Science in Engineering Technology at VTC. In addition to receiving college credits funded by GW, every graduate is awarded a bonus after each class and a 10 percent increase in their compensation upon graduation to recognize their commitment to improving their skills.

We also offer tuition reimbursement as part of our benefits package available to all associates. We always support our team members’ dedication to obtaining an education and furthering their careers, and our tuition reimbursement program has helped many take that next step who otherwise could not.

Brusco: What strategies do you employ regarding employee compensation and recognition to help retain your workforce?

Tempesta: We offer competitive compensation and benefits packages to all employees, including a fixed 401(k) match and excellent healthcare coverage. With some of the highest retention rates in the industry, we mean it seriously when we say that we have “the experience to deliver” for our customers. The success of our business depends on the dedication and experience of our team, and we prioritize recognizing our associates’ service from five years up to fifty years with company awards, luncheons, and announcements. Every year, we award at least one 45-year service award, with many years reaching 50.

Brusco: How do you instill a sense of purpose (which is VERY important to the millennial workforce) in your employees to help ensure pride in their work and their retention?

Tempesta: We focus on manufacturing lifesaving devices for both patients and passengers. As a company who dedicates ourselves to improving patient lives, it is easy for our team to take pride in our work. The products we manufacture affect us and our loved ones every day, and we take every opportunity to reflect on what that responsibility means. We recently launched an internal “Quality Begins with Me” campaign to highlight this mentality and stress the importance of high-quality production in all of our facilities regardless of position.

Brothers and senior engineers Joe and Garrett Sargent graduating from GW Plastics’ first Manufacturing Technology Leadership Program, which ensures a pipeline of technical talent.

Brusco: What future new efforts, if any, will you make to attract, educate/train, and/or retain your workforce?

We have long recognized the value of internal training and development, in partnership with the educational institutions in the local community. We plan on continuing to develop these educational opportunities to students in order to offer challenging, well paid careers.