Sam Brusco, Associate Editor02.11.19

To most, the idea of working in a factory crafting components seems unattractive. Working in a “machine shop” can call to mind images of working in a dark factory all day, manufacturing part after part in a monotonous haze.

However, this couldn’t be farther from the truth when it comes to machining parts for the medical device industry. High-precision machining has significantly evolved from the lathes and mills of years past. Modern Swiss machines reach as high as 13-axis to make parts with complex geometries and can be programmed for optimal speeds and feeds. Hybrid manufacturing techniques are merging CNC machining with the additive laser sintering process. Multiple spindle machining is able to complete parts in a single setup, and some machines include capabilities like turning with live tooling and wire EDM. Laser machining continues to expand as well. Device manufacturers and their contract manufacturers rely on laser systems to make precise components with high levels of speed and accuracy, often at extremely low tolerances.

To gain more insight into the medical device machining industry, I spoke with Anthony Sanzari, VP Surgical Products of Weiss-Aug. The Surgical Products Division of The Weiss-Aug Group is focused on the development and manufacture of device components and assemblies used in surgical instrumentation. The breadth of his input was not included in the recent feature article entitled “Smooth Operator: Addressing Machining’s Talent Gap” (which can be read here), so the entirety of our discussion is included in the Q&A below.

Brusco: What are the most exciting recent advances in machining technology?

Sanzari: Integration of advanced processing options, software improvements, and the creation of hybrid systems are some of the most exciting advances in machining technology. Further integration of 4th and 5th axis capabilities to standard equipment platforms, integration of metrology including optics, lasers, and touch-probes to further accuracy/repeatability of these systems, and higher fidelity software including simulation steps to optimize the fabrication process are all major recent advances. Hybrid systems combining additive manufacturing with traditional CNC machining and/or laser system integration is allowing us to deliver miniature, high-precision components to medical device OEMs in record time. These were previously multi-step operations that required fixturing and moving of parts between work centers, which now can be finished in a single setup.

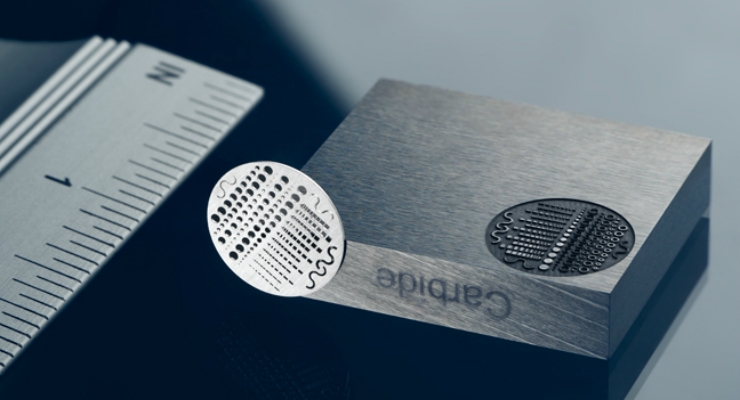

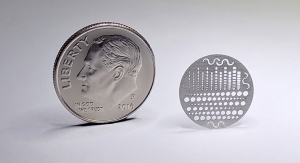

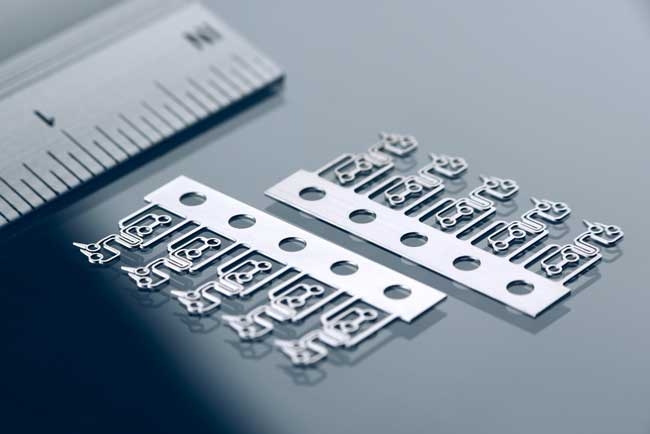

High tolerance stainless steel laser cut assembly rings.

Brusco: How is the technology evolving to meet the needs of medical device manufacturers?

Sanzari: Medical device OEMs are looking for methods to improve their time to market (TTM), and for cost-effective prototype and manufacturing methods to support low- to mid-volume products. With a greater focus on more intelligent/complex devices customized to specific procedures, while still maintaining a minimally invasive envelope, advanced machining technologies are key to this evolution. We have collected feedback from medical device customers and have included those latest technologies in our portfolio, which will allow us to deliver on those market requirements. An example of this is the creation of our Laser Application Lab, within our Surgical Products Division, and the creation of an R&D group focused exclusively on finding new equipment, software, advanced materials, and technologies that will drive innovation through all areas of our organization.

Brusco: Which services do you offer for medical device customers beyond machining?

Sanzari: The Weiss-Aug Group offers a large portfolio of engineering, design, and manufacturing services through our multiple divisions. Through our different teams, we offer product design support, tooling, program management, advanced metrology, prototyping, injection and insert molding, precision metal stamping, and component assembly, including automated, semi-automated, and manual, low-cost options through our facility in Mexico. In addition, we have advanced application labs in precision-CNC, materials, and Laser Applications to support development needs. Why is it important to offer these services? It is critical to offer a full solution, or “one-stop shop,” as it is imperative to be involved in all aspects of product design from early concept through mature manufacture. This involvement is critical to ensure a strong knowledge base is formed which can optimize products for TTM, cost, quality, and overall manufacturability. We view ourself not only as a CM but a true partner in the process, with our team taking on a high level of ownership and accountability. Without having the portfolio of technologies and expertise in house, we could not deliver on the level of service our medical device OEMs have come to expect.

Brusco: Which advances in laser processing technology have been most beneficial for manufacturing medical device parts, and why?

Sanzari: We have created a Laser Applications Lab that specializes in supporting the requirements of medical device OEMs. Our capabilities and technologies are focused on delivery of high quality, high precision components and sub-assemblies. Significant advances have been made in the types of materials we are able to process in the lab (adding plastics, ceramics, and glasses to our existing portfolio of metals). Our newest laser equipment has hardware and optics improvements that further the accuracy of the laser systems (tolerances as tight as +/- 0.0005”). Integration of metrology capabilities into the laser systems has improved part-to-part and feature-to-feature repeatability. Scanning head technology has vastly improved our layered engraving and etching capabilities—that has improved to a level of refinement that can now rival conventional EDM or chemical etching, without the need of additional tooling, from a quality perspective. Our lab has expertise in a broad range of laser systems and laser applications including cutting, joining (welding), marking, and precision depth etching.

Brusco: Which types of medical device part manufacturing projects does your company find to be most challenging, and why?

Sanzari: Medical device OEMs that work with us typically bring their challenging parts, as we take on those difficult designs. Product miniaturization has posed a significant challenge, as processing materials less than or equal to .001” requires a non-standard means of fabrication. Materials are pushed to their physical limits for the required customer geometries, and at times the energy required to process the material makes it nearly impossible to handle in fixturing or manufacturing processes. Our team is continuously working on advanced means for handling these miniature, highly specialized applications.

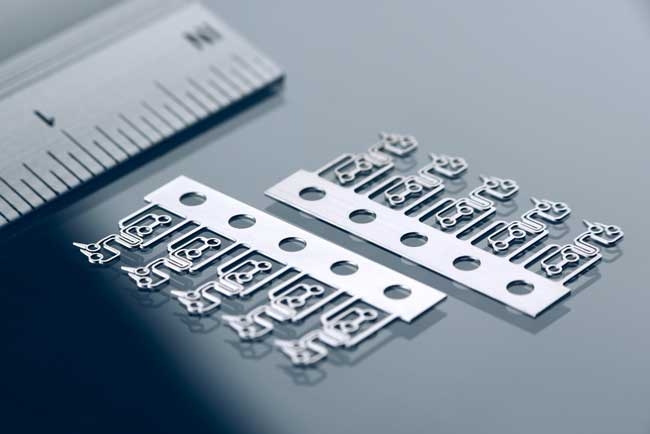

Laser cut stainless steel part for secondary operations, with sharp tips and close proximity beams.

Sam Brusco: It has been said that the machining trade is struggling to attract new talented craftsmen. Have you found this to be true for your company? If so, why do you believe it is occurring and what steps does your company take to attract talent? If not, how have you been successful in attracting new talent?

Anthony Sanzari: We have been growing at an unprecedented rate. In general, finding strong, talented individuals with technical and engineering backgrounds is a challenge. Fortunately, our organization has a strong, well-established base that is leading the industry both in learning the latest advances in machining and laser technologies and in the development of more junior talent in these key areas. We invest in apprenticeship and mentorship programs, whereby our apprentices gain experience in all aspects of product manufacture, including our design, tooling, precision-CNC, EDM, and Laser Technology Programs. Additionally, through heavy capital investment and continued training, we have created a culture of innovation that attracts and retains talent. We offer these team members state-of-the-art equipment, software, and a “technology-based” infrastructure that rivals larger medical device OEMs. This strategy ensures we have proper resources to sustain our growth and meet our customer requirements, both for today and the future.

Brusco: What will be expected of machinists in the coming years to ensure robust medical device part production?

Sanzari: Machinists will need to continue to train on the latest technologies (both hardware and software) to remain current as additive manufacturing and laser technologies continue to improve and replace more traditional methods. Working in solids, in multi-axis spatial geometry, and being versed in multiple technologies will be key to long-term success.

Brusco: Is there anything else you’d like to say regarding machining for medical device manufacturing, or are there any particularly important topics within the machining/laser processing sector that I have not asked about that you feel MPO readers should know?

Sanzari: In many cases, machining and laser technologies offer an advantage for new products and programs, specifically in the areas of prototyping and low-volume production. The investment of capital for traditional methods of product manufacture (dedicated tooling) is significantly higher than the one-time capital investment for machining technologies that can produce a multitude of parts. This is one of the many variables that must be considered when determining the right solution for a particular product and medical device OEM’s requirements. We have expertise in many disciplines, and our teams are able to help customers make the right selection for technologies to ensure success in their programs.

However, this couldn’t be farther from the truth when it comes to machining parts for the medical device industry. High-precision machining has significantly evolved from the lathes and mills of years past. Modern Swiss machines reach as high as 13-axis to make parts with complex geometries and can be programmed for optimal speeds and feeds. Hybrid manufacturing techniques are merging CNC machining with the additive laser sintering process. Multiple spindle machining is able to complete parts in a single setup, and some machines include capabilities like turning with live tooling and wire EDM. Laser machining continues to expand as well. Device manufacturers and their contract manufacturers rely on laser systems to make precise components with high levels of speed and accuracy, often at extremely low tolerances.

To gain more insight into the medical device machining industry, I spoke with Anthony Sanzari, VP Surgical Products of Weiss-Aug. The Surgical Products Division of The Weiss-Aug Group is focused on the development and manufacture of device components and assemblies used in surgical instrumentation. The breadth of his input was not included in the recent feature article entitled “Smooth Operator: Addressing Machining’s Talent Gap” (which can be read here), so the entirety of our discussion is included in the Q&A below.

Brusco: What are the most exciting recent advances in machining technology?

Sanzari: Integration of advanced processing options, software improvements, and the creation of hybrid systems are some of the most exciting advances in machining technology. Further integration of 4th and 5th axis capabilities to standard equipment platforms, integration of metrology including optics, lasers, and touch-probes to further accuracy/repeatability of these systems, and higher fidelity software including simulation steps to optimize the fabrication process are all major recent advances. Hybrid systems combining additive manufacturing with traditional CNC machining and/or laser system integration is allowing us to deliver miniature, high-precision components to medical device OEMs in record time. These were previously multi-step operations that required fixturing and moving of parts between work centers, which now can be finished in a single setup.

High tolerance stainless steel laser cut assembly rings.

Brusco: How is the technology evolving to meet the needs of medical device manufacturers?

Sanzari: Medical device OEMs are looking for methods to improve their time to market (TTM), and for cost-effective prototype and manufacturing methods to support low- to mid-volume products. With a greater focus on more intelligent/complex devices customized to specific procedures, while still maintaining a minimally invasive envelope, advanced machining technologies are key to this evolution. We have collected feedback from medical device customers and have included those latest technologies in our portfolio, which will allow us to deliver on those market requirements. An example of this is the creation of our Laser Application Lab, within our Surgical Products Division, and the creation of an R&D group focused exclusively on finding new equipment, software, advanced materials, and technologies that will drive innovation through all areas of our organization.

Brusco: Which services do you offer for medical device customers beyond machining?

Sanzari: The Weiss-Aug Group offers a large portfolio of engineering, design, and manufacturing services through our multiple divisions. Through our different teams, we offer product design support, tooling, program management, advanced metrology, prototyping, injection and insert molding, precision metal stamping, and component assembly, including automated, semi-automated, and manual, low-cost options through our facility in Mexico. In addition, we have advanced application labs in precision-CNC, materials, and Laser Applications to support development needs. Why is it important to offer these services? It is critical to offer a full solution, or “one-stop shop,” as it is imperative to be involved in all aspects of product design from early concept through mature manufacture. This involvement is critical to ensure a strong knowledge base is formed which can optimize products for TTM, cost, quality, and overall manufacturability. We view ourself not only as a CM but a true partner in the process, with our team taking on a high level of ownership and accountability. Without having the portfolio of technologies and expertise in house, we could not deliver on the level of service our medical device OEMs have come to expect.

Brusco: Which advances in laser processing technology have been most beneficial for manufacturing medical device parts, and why?

Sanzari: We have created a Laser Applications Lab that specializes in supporting the requirements of medical device OEMs. Our capabilities and technologies are focused on delivery of high quality, high precision components and sub-assemblies. Significant advances have been made in the types of materials we are able to process in the lab (adding plastics, ceramics, and glasses to our existing portfolio of metals). Our newest laser equipment has hardware and optics improvements that further the accuracy of the laser systems (tolerances as tight as +/- 0.0005”). Integration of metrology capabilities into the laser systems has improved part-to-part and feature-to-feature repeatability. Scanning head technology has vastly improved our layered engraving and etching capabilities—that has improved to a level of refinement that can now rival conventional EDM or chemical etching, without the need of additional tooling, from a quality perspective. Our lab has expertise in a broad range of laser systems and laser applications including cutting, joining (welding), marking, and precision depth etching.

Brusco: Which types of medical device part manufacturing projects does your company find to be most challenging, and why?

Sanzari: Medical device OEMs that work with us typically bring their challenging parts, as we take on those difficult designs. Product miniaturization has posed a significant challenge, as processing materials less than or equal to .001” requires a non-standard means of fabrication. Materials are pushed to their physical limits for the required customer geometries, and at times the energy required to process the material makes it nearly impossible to handle in fixturing or manufacturing processes. Our team is continuously working on advanced means for handling these miniature, highly specialized applications.

Laser cut stainless steel part for secondary operations, with sharp tips and close proximity beams.

Sam Brusco: It has been said that the machining trade is struggling to attract new talented craftsmen. Have you found this to be true for your company? If so, why do you believe it is occurring and what steps does your company take to attract talent? If not, how have you been successful in attracting new talent?

Anthony Sanzari: We have been growing at an unprecedented rate. In general, finding strong, talented individuals with technical and engineering backgrounds is a challenge. Fortunately, our organization has a strong, well-established base that is leading the industry both in learning the latest advances in machining and laser technologies and in the development of more junior talent in these key areas. We invest in apprenticeship and mentorship programs, whereby our apprentices gain experience in all aspects of product manufacture, including our design, tooling, precision-CNC, EDM, and Laser Technology Programs. Additionally, through heavy capital investment and continued training, we have created a culture of innovation that attracts and retains talent. We offer these team members state-of-the-art equipment, software, and a “technology-based” infrastructure that rivals larger medical device OEMs. This strategy ensures we have proper resources to sustain our growth and meet our customer requirements, both for today and the future.

Brusco: What will be expected of machinists in the coming years to ensure robust medical device part production?

Sanzari: Machinists will need to continue to train on the latest technologies (both hardware and software) to remain current as additive manufacturing and laser technologies continue to improve and replace more traditional methods. Working in solids, in multi-axis spatial geometry, and being versed in multiple technologies will be key to long-term success.

Brusco: Is there anything else you’d like to say regarding machining for medical device manufacturing, or are there any particularly important topics within the machining/laser processing sector that I have not asked about that you feel MPO readers should know?

Sanzari: In many cases, machining and laser technologies offer an advantage for new products and programs, specifically in the areas of prototyping and low-volume production. The investment of capital for traditional methods of product manufacture (dedicated tooling) is significantly higher than the one-time capital investment for machining technologies that can produce a multitude of parts. This is one of the many variables that must be considered when determining the right solution for a particular product and medical device OEM’s requirements. We have expertise in many disciplines, and our teams are able to help customers make the right selection for technologies to ensure success in their programs.