Mark Crawford, Contributing Writer11.26.18

Even though additive manufacturing and 3D printing (AM/3DP) are still in the early adoption phase by most medical device manufacturers (MDMs), these technologies continue to evolve at a rapid pace. Today, most AM/3DP applications in the medical industry are for prototype development, anatomical models, and “one-off” custom components. 3D-printed surgical instrumentation and cutting guides for procedures such as knee, spinal, and dental implants are on the rise. On the manufacturing side, AM/3DP is used to make components for prototype mold tools, conformal cooling inserts for production tools, and jigs and fixtures for making or inspecting production parts.

Although AM/3DP has made great strides in equipment hardware and material science, it is still several years from being accepted as a viable process for scaled, precision, cost-effective manufacturing. That said, AM/3DP continues to drive innovation through advances in mass customization, low cost in low volumes, design flexibility and freedom, and transforming the supply chain with on-demand manufacturing.

“As disruptive technology, AM/3DP best positions itself not as a technology to displace existing, well-established, cost-effective manufacturing processes, but instead as a technology that allows innovation and customization of products, especially for patients,” stated Anthony Sanzari, vice president of the surgical products division for Weiss-Aug Group, an East Hanover, N.J.-based provider of precision metal stamping, complex insert molding, and custom assembly services. “The AM/3DP manufacturing platform is also a means for utilizing new materials, such as biomaterials, that do not have established methods for fabrication.”

A key driver in the rapid advance of AM/3DP is the diverse array of materials that is now available for these technologies. Many new materials are metals or metal alloys that can be 3D-printed with enhanced features, making them well-suited for implants—for example, lattice structures or roughened surfaces in titanium that optimize biocompatibility and bone growth. “Capabilities such as these are revolutionizing the orthopedic medical device industry,” said Martin Petrak, CEO of Precision ADM, a Winnipeg, Canada-based provider of global engineering and manufacturing solutions, including additive manufacturing.

Because of these advantages, metal AM is being used more for serial production of standard-sized devices in a cost-effective manner, or for patient-specific implants developed from X-ray or CT scans to create a CAD model of the implant that fits the patient perfectly. Although this is a more expensive approach for creating “one-off” implants rather than standard sizes, “the AM possibilities continue to intrigue the medical community,” added Trevor Penner, a mechanical engineer with Precision ADM.

What OEMs Want

Of course, OEMs are always focused on quality, speed, and cost. They are eager for faster times to market via improved prototyping and testing. Some OEMs seek production-quality parts from AM/3DP. However, AM/3DP must be cost competitive with proven, traditional manufacturing methods before it can be considered a viable option. Not only do AM/3DP service providers compete against each other, they must also compete with traditional manufacturing methods that OEMs have relied upon and trusted for many years.

“For an OEM to even consider AM/3DP, the technology must be able to produce the OEM part at the necessary volumes and at a cost competitive with alternative options such as computer numerical control [CNC] machining, investment casting, and metal injection molding,” said Matt Sand, president of 3DEO, a Gardena, Calif.-based provider of metal 3D printing technologies and services.

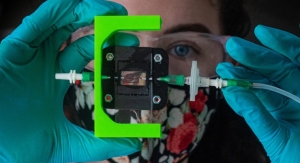

OEMs often approach their manufacturing partners for advice regarding product design and its manufacturability via AM/3DP. “OEMs often inquire about more diversity in materials, including biocompatible materials,” said Sam Onukuri, head and senior fellow for Johnson & Johnson’s 3D Printing Center of Excellence, a Miami, Fla.-based research hub that creates and delivers 3D printing solutions. “They are also interested in micro-printing, where we make the small, high-precision features that are often found in minimally invasive devices.”

As much as OEMs want their contract manufacturers (CMs) to make their devices with AM/3DP, it is not always a good match. Key factors to consider include material selection, component strength, dimensional accuracy, and run volume. In most cases, AM/3DP is best for prototyping, rather than production-quality parts or products.

“We utilize AM/3DP technology when appropriate to accelerate ideation and reduce time to market for our customers,” said Sanzari. “Typically, OEMs do not mandate the use of a specific technology, but our internal teams review the application, timeline, and target budget, and propose a ‘best-fit’ turn-key solution that utilizes our core competencies, including AM/3DP.”

“Every device OEM is different,” said Penner. “Some already have experience in designing for additive manufacturing, while others need advice on how to optimize their design to improve manufacturability. At some level, all companies are exploring the wide range of new design opportunities that AM provides.”

OEMs also count on their CMs for expertise regarding compliance and quality—two key factors that impact design for manufacturability and that need to be considered up front in the design process. OEMs expect expert guidance from their AM vendors to be certain their additive processes and printed parts are fully validated and compliant. Since the final version of the FDA’s AM technical guidance was released in December 2017, an increasing number of MDMs are asking their vendors for support with quality control and quality systems for AM in production, as well as in-house work. “Nearly all our customers who use AM for production have opted for help implementing AM into their existing quality systems,” said Laura Gilmour, global medical business development manager for EOS, a Germany-based provider of additive-manufacturing solutions.

Latest AM/3DP Trends

For decades, AM/3DP was viewed largely as a prototyping technology because of the slow production process, lack of high precision, and limited repeatability. “In recent years, however, some AM/3DP companies, such as 3DEO and 3D Metals, have come out with new technologies that can be used for mass production of parts,” said Sand.

These advances are catching the attention of forward-thinking companies that want to overcome their concerns about AM/3DP and use it to not only make better products, but also to seize a market advantage over their competitors. The FDA has already approved more than 100 additive-manufactured medical devices—proof that AM/3DP can be used successfully to make production-ready parts and products.

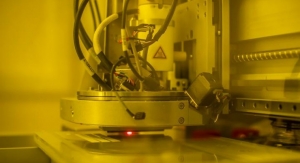

One of the fastest-growing fields is all-metal AM technologies, which continue to evolve with improved precision and higher throughputs. Different metal AM technologies provide MDMs with several manufacturing options, depending on project parameters (for example, laser sintering is becoming the preferred method for making larger parts). The best metal choice can vary greatly, depending on the metal AM processes being used. “Companies looking to get into metal AM need to explore all options in the context of their specific applications,” said Sand. “It makes a big difference to research metal AM with a specific application in mind.”

Carbon, a Redwood, Calif.-based provider of innovative AM/3DP processes, has developed a process that fuses light and oxygen to rapidly produce products from a pool of resin. Called Digital Light Synthesis technology, it utilizes a two-step process that converts a liquid to a solid. In the first step, ultraviolet light sets the shape of an object from Carbon’s programmable liquid resins. The second step applies heat to the newly produced part to cure the properties of the material and stitch together the latent chemical functions of the polymer. “This dual-cure process is critical for creating biocompatible, high-temperature resins, polyurethanes that range in properties from nylons to thermoplastic urethanes, and elastomers based on silicones—essentially new sets of polymers,” said Steven Pollack, senior staff research scientist for Carbon. “These also meet ISO 10993 biocompatibility standards, making them suitable for use in skin and mucosal contact.”

Carbon’s process also provides part traceability and serialization using next-generation software design tools. Each part is digitally traceable, with a unique ID that can be engraved or embossed on any part. The ID identifies the digital historical record of the part, including the specific printer, resin, and even post-processing protocols that were involved in making that part. “This is especially valuable within highly regulated industries like medical, where the FDA will likely increasingly require part-specific data to ensure product performance and patient safety,” Pollack added.

Within the medical industry, AM/3DP has spawned a new trend called point-of-care manufacturing. Many large hospitals and medical centers are implementing additive manufacturing labs that can create a variety of products in house, such as surgical tools, cutting guides, and planning models. Researchers within the lab, for example, use AM/3DP to produce experimental heart valves and bone implants for use in future clinical studies.

In most cases, the default settings for an AM machine and a specific material as defined by the manufacturer are sufficient to make many types of parts; however, these settings might require some adjustment to produce highly complex and integral geometries. Although this can usually be done without changing the geometry that is being printed, sometimes both machine settings and geometry modifications are needed. Any changed settings must, however, be validated to ensure the process is still within the material’s requirements.

“If an AM service provider modifies the standard manufacturer-defined AM machine settings, it opens the door to unknown metallurgical behaviors,” said Dale Kellington, general manager for Precision ADM. “Redefining this behavior essentially redefines the material, so from a quality perspective, this new material must be validated.”

With a validated process, the AM service provider can be confident that modified settings will produce specimens as consistently as with standard settings, via comparison to established control limits. Without this extensive upfront qualification, the process of reliably producing a complex part will be either very expensive or inadequate, with no guarantee the parts have acceptable properties. Validating setting edits is time-consuming, however. “First the equipment validation on standard settings is completed,” said Kellington. “Then we compare the settings edit validation data to our established dataset and pick out the discrepancies that are outlying and not expected. Our in-house laboratory and testing equipment can tell us if a certain setting is unacceptable, ruling out certain options earlier in the validation process when exploring new options.”

The ability of an AM system to employ multiple lasers with full field overlap has interesting applications for MDMs, especially when the lasers can be of different spot sizes or beam focuses. “We utilize laser field overlap in the EOS M 300-4 machine,” said Gilmour. “The idea is to keep the fine features, but also create the bulk ‘substrate’ in a more productive manner. Imagine how productivity might increase when you can implement one higher-power, larger-spot-size laser to create the bulk structure, and another lower-power, smaller-spot-size laser to create the fine features, such as porous structures, at the same time.”

Hybrid Technologies

A step toward embracing the full capabilities of AM/3DP is building “hybrid” systems, where AM/3DP is combined with multiple traditional machining technologies to speed up prototype tooling or produce complex finished parts that meet product specifications. Integrating AM/3DP with high-precision subtractive technologies speeds up the iterative nature of making a medical device, shortening the time to market. AM can complement technologies such as hard milling, electrical discharge machining (EDM), and grinding to produce parts. “This can be for a prototype tool, or the needed part itself,” said Armand Pagano, mold design manager/CNC lead for Weiss-Aug Group. “We can tie all processes together via the high-precision work holding we use and go back and forth between the needed equipment until we achieve what is needed. This is often faster and more efficient, with tighter tolerances, than AM can achieve on its own.”

Weiss-Aug Group has also developed an integrated design methodology that allows for the use of AM/3DP for progressive stamping tooling components (punch/die), and for conformal cooling in injection mold tooling, which cannot be fabricated through traditional means. In addition, the company also develops AM/3DP components using state-of-the-art laser technology. Weiss-Aug’s Laser Lab Technology Center utilizes both metal- and plastic-based AM/3DP components and bonds them together through use of specialized laser technologies. “This allows us to fabricate insert molding ‘production quality’ prototypes significantly faster and in a cost-effective manner for our OEM customers,” said Sanzari.

3DEO has developed a proprietary technology called Intelligent Layering, which uses CNC machining on a layer-by-layer basis to create parts. The four-step process consists of 1) laying down a very thin layer (100 microns) of metal powder, 2) binding the entire layer with a proprietary spray system, 3) cutting the layer with CNC micro end mills, and 4) repeating the process by adding new layers until the entire part is built.

“CNC is the most precise technology in the world, and this enables repeatability and precision in our process,” said Sand. “Since we build parts on a layer-by-layer basis, we also get the advantages of additive manufacturing. Most importantly, this translates into ultimate design freedom. New geometries are possible with AM, and designs can be changed daily with very little incremental cost.”

AM/3DP Material Science

Materials science is a research area in which the physical limits of materials are constantly being pushed—driving much of the innovation seen in AM/3DP today. Engineered materials expand the spectrum of physical properties available to designers, creating new possibilities for custom medical devices, tools, and implants. Advanced materials include polymers, metals, ceramics, and organic materials that can be used for bioprinting—the 3D printing of living biological tissues that can help the body repair itself.

“3D printing allows us to work with unique materials—for example, plant- and animal-based materials that are organically derived—to create design features and capabilities that were never possible with traditional manufacturing,” said Onukuri.

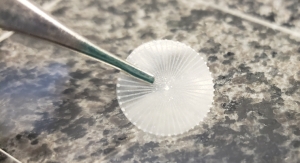

For example, researchers at Newcastle University in Tyne, England, recently mixed stem cells from a healthy cornea with alginate and collagen to create a bio-ink solution that they 3D-printed in concentric circles, layer by layer, to create the shape of a human cornea. The researchers also showed that, by scanning a patient’s eye, they could rapidly build a 3D-printed cornea to match a patient’s unique specifications.

The latest advances in materials for AM/3DP include amorphous alloys, binder-jetting metals, and specialized media for glass/ceramic applications. For metal AM technologies, “as more processes are offered, more materials are developed,” said Sand, including aluminum, steel, brass, copper, bronze, sterling silver, gold, platinum, and titanium.

Also in the metal realm, EOS is developing a version of titanium alloy with higher fatigue properties than traditional AM titanium alloy, without the need for hot isostatic pressing (HIP). Preliminary testing by EOS indicates this new alloy produces fatigue properties similar to the properties required for hip stems (one of the highest requirements for medical devices in titanium to date), without the added cost of HIP. “We are also working with Elementum 3D on tantalum and commercially pure titanium materials that could be implantable, with the right biocompatibility testing,” said Gilmour.

Moving Forward

The FDA’s December 2017 technical guidance document for additive manufacturing has given MDMs a little more confidence about moving forward with AM, knowing the regulatory pathway is better defined. The document provides helpful specifications on materials, design and manufacturing, and device testing. With the FDA providing more insights into its compliance expectations, MDMs can feel better about taking larger steps with AM/3DP, especially in product design. Significant potential markets for AM/3DP include patient-matched devices and highly customized low-volume devices for specific variants of surgical procedures. These applications create significant challenges for manufacturers, and a paradigm shift in validation practices. “For example, tighter process controls including design models, patient data, workflow, and material quality will need to evolve from current practices, as statistical capabilities models do not apply well to a total run size of one,” said Sanzari.

Material offerings, more repeatable systems, and higher throughputs will likely be the biggest advances in AM/3DP over the next few years. Continued improvements in hardware and materials science will result in smaller, higher-precision fabrication capabilities with increased speed and efficiency. Long-term adoption of AM/3DP technologies by industries will also bring down the cost of equipment and materials, making them more competitive with traditional manufacturing methods. Metal AM is expected to become the go-to technology for customized hip implants and knee replacements. The printing of biomaterials offers incredible potential for printing replacement organs, blood vessels, and other anatomical parts, or printing sensors directly on the skin.

AM/3DP provides exhilarating opportunities for transforming medical device design and manufacturing and improving patient outcomes. In contrast, though, “MDMs are typically very conservative about the methods and materials they use because the devices need to be cleared through numerous federal regulators,” said Pollack. “However, due to the need for customized medical parts and tools, the industry must embrace the innovative and rapidly evolving technologies that comprise AM/3DP.”

Because AM/3DP is evolving so rapidly, OEMs struggle with the same challenges their CMs do—keeping up with the speed of advancement. Typically, by the time a limitation to a technology has been defined, and a strategy is developed to mitigate that concern, an AM vendor will then announce a new “tweak” to the equipment, software, process, material, or some other variable that moves beyond that limitation, starting the process over again. Such rapid progress makes it difficult to establish engineering standards and integrate AM/3DP into a production manufacturing environment.

“Capital investment is challenging, as the equipment is sometimes outdated by the time a purchase order is placed,” said Sanzari. “Significant investment in full-time R&D teams and equipment is required to keep current and at the forefront of the developments in the AM/3DP industry—which is what our customers expect.”

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.

Although AM/3DP has made great strides in equipment hardware and material science, it is still several years from being accepted as a viable process for scaled, precision, cost-effective manufacturing. That said, AM/3DP continues to drive innovation through advances in mass customization, low cost in low volumes, design flexibility and freedom, and transforming the supply chain with on-demand manufacturing.

“As disruptive technology, AM/3DP best positions itself not as a technology to displace existing, well-established, cost-effective manufacturing processes, but instead as a technology that allows innovation and customization of products, especially for patients,” stated Anthony Sanzari, vice president of the surgical products division for Weiss-Aug Group, an East Hanover, N.J.-based provider of precision metal stamping, complex insert molding, and custom assembly services. “The AM/3DP manufacturing platform is also a means for utilizing new materials, such as biomaterials, that do not have established methods for fabrication.”

A key driver in the rapid advance of AM/3DP is the diverse array of materials that is now available for these technologies. Many new materials are metals or metal alloys that can be 3D-printed with enhanced features, making them well-suited for implants—for example, lattice structures or roughened surfaces in titanium that optimize biocompatibility and bone growth. “Capabilities such as these are revolutionizing the orthopedic medical device industry,” said Martin Petrak, CEO of Precision ADM, a Winnipeg, Canada-based provider of global engineering and manufacturing solutions, including additive manufacturing.

Because of these advantages, metal AM is being used more for serial production of standard-sized devices in a cost-effective manner, or for patient-specific implants developed from X-ray or CT scans to create a CAD model of the implant that fits the patient perfectly. Although this is a more expensive approach for creating “one-off” implants rather than standard sizes, “the AM possibilities continue to intrigue the medical community,” added Trevor Penner, a mechanical engineer with Precision ADM.

What OEMs Want

Of course, OEMs are always focused on quality, speed, and cost. They are eager for faster times to market via improved prototyping and testing. Some OEMs seek production-quality parts from AM/3DP. However, AM/3DP must be cost competitive with proven, traditional manufacturing methods before it can be considered a viable option. Not only do AM/3DP service providers compete against each other, they must also compete with traditional manufacturing methods that OEMs have relied upon and trusted for many years.

“For an OEM to even consider AM/3DP, the technology must be able to produce the OEM part at the necessary volumes and at a cost competitive with alternative options such as computer numerical control [CNC] machining, investment casting, and metal injection molding,” said Matt Sand, president of 3DEO, a Gardena, Calif.-based provider of metal 3D printing technologies and services.

OEMs often approach their manufacturing partners for advice regarding product design and its manufacturability via AM/3DP. “OEMs often inquire about more diversity in materials, including biocompatible materials,” said Sam Onukuri, head and senior fellow for Johnson & Johnson’s 3D Printing Center of Excellence, a Miami, Fla.-based research hub that creates and delivers 3D printing solutions. “They are also interested in micro-printing, where we make the small, high-precision features that are often found in minimally invasive devices.”

As much as OEMs want their contract manufacturers (CMs) to make their devices with AM/3DP, it is not always a good match. Key factors to consider include material selection, component strength, dimensional accuracy, and run volume. In most cases, AM/3DP is best for prototyping, rather than production-quality parts or products.

“We utilize AM/3DP technology when appropriate to accelerate ideation and reduce time to market for our customers,” said Sanzari. “Typically, OEMs do not mandate the use of a specific technology, but our internal teams review the application, timeline, and target budget, and propose a ‘best-fit’ turn-key solution that utilizes our core competencies, including AM/3DP.”

“Every device OEM is different,” said Penner. “Some already have experience in designing for additive manufacturing, while others need advice on how to optimize their design to improve manufacturability. At some level, all companies are exploring the wide range of new design opportunities that AM provides.”

OEMs also count on their CMs for expertise regarding compliance and quality—two key factors that impact design for manufacturability and that need to be considered up front in the design process. OEMs expect expert guidance from their AM vendors to be certain their additive processes and printed parts are fully validated and compliant. Since the final version of the FDA’s AM technical guidance was released in December 2017, an increasing number of MDMs are asking their vendors for support with quality control and quality systems for AM in production, as well as in-house work. “Nearly all our customers who use AM for production have opted for help implementing AM into their existing quality systems,” said Laura Gilmour, global medical business development manager for EOS, a Germany-based provider of additive-manufacturing solutions.

Latest AM/3DP Trends

For decades, AM/3DP was viewed largely as a prototyping technology because of the slow production process, lack of high precision, and limited repeatability. “In recent years, however, some AM/3DP companies, such as 3DEO and 3D Metals, have come out with new technologies that can be used for mass production of parts,” said Sand.

These advances are catching the attention of forward-thinking companies that want to overcome their concerns about AM/3DP and use it to not only make better products, but also to seize a market advantage over their competitors. The FDA has already approved more than 100 additive-manufactured medical devices—proof that AM/3DP can be used successfully to make production-ready parts and products.

One of the fastest-growing fields is all-metal AM technologies, which continue to evolve with improved precision and higher throughputs. Different metal AM technologies provide MDMs with several manufacturing options, depending on project parameters (for example, laser sintering is becoming the preferred method for making larger parts). The best metal choice can vary greatly, depending on the metal AM processes being used. “Companies looking to get into metal AM need to explore all options in the context of their specific applications,” said Sand. “It makes a big difference to research metal AM with a specific application in mind.”

Carbon, a Redwood, Calif.-based provider of innovative AM/3DP processes, has developed a process that fuses light and oxygen to rapidly produce products from a pool of resin. Called Digital Light Synthesis technology, it utilizes a two-step process that converts a liquid to a solid. In the first step, ultraviolet light sets the shape of an object from Carbon’s programmable liquid resins. The second step applies heat to the newly produced part to cure the properties of the material and stitch together the latent chemical functions of the polymer. “This dual-cure process is critical for creating biocompatible, high-temperature resins, polyurethanes that range in properties from nylons to thermoplastic urethanes, and elastomers based on silicones—essentially new sets of polymers,” said Steven Pollack, senior staff research scientist for Carbon. “These also meet ISO 10993 biocompatibility standards, making them suitable for use in skin and mucosal contact.”

Carbon’s process also provides part traceability and serialization using next-generation software design tools. Each part is digitally traceable, with a unique ID that can be engraved or embossed on any part. The ID identifies the digital historical record of the part, including the specific printer, resin, and even post-processing protocols that were involved in making that part. “This is especially valuable within highly regulated industries like medical, where the FDA will likely increasingly require part-specific data to ensure product performance and patient safety,” Pollack added.

Within the medical industry, AM/3DP has spawned a new trend called point-of-care manufacturing. Many large hospitals and medical centers are implementing additive manufacturing labs that can create a variety of products in house, such as surgical tools, cutting guides, and planning models. Researchers within the lab, for example, use AM/3DP to produce experimental heart valves and bone implants for use in future clinical studies.

In most cases, the default settings for an AM machine and a specific material as defined by the manufacturer are sufficient to make many types of parts; however, these settings might require some adjustment to produce highly complex and integral geometries. Although this can usually be done without changing the geometry that is being printed, sometimes both machine settings and geometry modifications are needed. Any changed settings must, however, be validated to ensure the process is still within the material’s requirements.

“If an AM service provider modifies the standard manufacturer-defined AM machine settings, it opens the door to unknown metallurgical behaviors,” said Dale Kellington, general manager for Precision ADM. “Redefining this behavior essentially redefines the material, so from a quality perspective, this new material must be validated.”

With a validated process, the AM service provider can be confident that modified settings will produce specimens as consistently as with standard settings, via comparison to established control limits. Without this extensive upfront qualification, the process of reliably producing a complex part will be either very expensive or inadequate, with no guarantee the parts have acceptable properties. Validating setting edits is time-consuming, however. “First the equipment validation on standard settings is completed,” said Kellington. “Then we compare the settings edit validation data to our established dataset and pick out the discrepancies that are outlying and not expected. Our in-house laboratory and testing equipment can tell us if a certain setting is unacceptable, ruling out certain options earlier in the validation process when exploring new options.”

The ability of an AM system to employ multiple lasers with full field overlap has interesting applications for MDMs, especially when the lasers can be of different spot sizes or beam focuses. “We utilize laser field overlap in the EOS M 300-4 machine,” said Gilmour. “The idea is to keep the fine features, but also create the bulk ‘substrate’ in a more productive manner. Imagine how productivity might increase when you can implement one higher-power, larger-spot-size laser to create the bulk structure, and another lower-power, smaller-spot-size laser to create the fine features, such as porous structures, at the same time.”

Hybrid Technologies

A step toward embracing the full capabilities of AM/3DP is building “hybrid” systems, where AM/3DP is combined with multiple traditional machining technologies to speed up prototype tooling or produce complex finished parts that meet product specifications. Integrating AM/3DP with high-precision subtractive technologies speeds up the iterative nature of making a medical device, shortening the time to market. AM can complement technologies such as hard milling, electrical discharge machining (EDM), and grinding to produce parts. “This can be for a prototype tool, or the needed part itself,” said Armand Pagano, mold design manager/CNC lead for Weiss-Aug Group. “We can tie all processes together via the high-precision work holding we use and go back and forth between the needed equipment until we achieve what is needed. This is often faster and more efficient, with tighter tolerances, than AM can achieve on its own.”

Weiss-Aug Group has also developed an integrated design methodology that allows for the use of AM/3DP for progressive stamping tooling components (punch/die), and for conformal cooling in injection mold tooling, which cannot be fabricated through traditional means. In addition, the company also develops AM/3DP components using state-of-the-art laser technology. Weiss-Aug’s Laser Lab Technology Center utilizes both metal- and plastic-based AM/3DP components and bonds them together through use of specialized laser technologies. “This allows us to fabricate insert molding ‘production quality’ prototypes significantly faster and in a cost-effective manner for our OEM customers,” said Sanzari.

3DEO has developed a proprietary technology called Intelligent Layering, which uses CNC machining on a layer-by-layer basis to create parts. The four-step process consists of 1) laying down a very thin layer (100 microns) of metal powder, 2) binding the entire layer with a proprietary spray system, 3) cutting the layer with CNC micro end mills, and 4) repeating the process by adding new layers until the entire part is built.

“CNC is the most precise technology in the world, and this enables repeatability and precision in our process,” said Sand. “Since we build parts on a layer-by-layer basis, we also get the advantages of additive manufacturing. Most importantly, this translates into ultimate design freedom. New geometries are possible with AM, and designs can be changed daily with very little incremental cost.”

AM/3DP Material Science

Materials science is a research area in which the physical limits of materials are constantly being pushed—driving much of the innovation seen in AM/3DP today. Engineered materials expand the spectrum of physical properties available to designers, creating new possibilities for custom medical devices, tools, and implants. Advanced materials include polymers, metals, ceramics, and organic materials that can be used for bioprinting—the 3D printing of living biological tissues that can help the body repair itself.

“3D printing allows us to work with unique materials—for example, plant- and animal-based materials that are organically derived—to create design features and capabilities that were never possible with traditional manufacturing,” said Onukuri.

For example, researchers at Newcastle University in Tyne, England, recently mixed stem cells from a healthy cornea with alginate and collagen to create a bio-ink solution that they 3D-printed in concentric circles, layer by layer, to create the shape of a human cornea. The researchers also showed that, by scanning a patient’s eye, they could rapidly build a 3D-printed cornea to match a patient’s unique specifications.

The latest advances in materials for AM/3DP include amorphous alloys, binder-jetting metals, and specialized media for glass/ceramic applications. For metal AM technologies, “as more processes are offered, more materials are developed,” said Sand, including aluminum, steel, brass, copper, bronze, sterling silver, gold, platinum, and titanium.

Also in the metal realm, EOS is developing a version of titanium alloy with higher fatigue properties than traditional AM titanium alloy, without the need for hot isostatic pressing (HIP). Preliminary testing by EOS indicates this new alloy produces fatigue properties similar to the properties required for hip stems (one of the highest requirements for medical devices in titanium to date), without the added cost of HIP. “We are also working with Elementum 3D on tantalum and commercially pure titanium materials that could be implantable, with the right biocompatibility testing,” said Gilmour.

Moving Forward

The FDA’s December 2017 technical guidance document for additive manufacturing has given MDMs a little more confidence about moving forward with AM, knowing the regulatory pathway is better defined. The document provides helpful specifications on materials, design and manufacturing, and device testing. With the FDA providing more insights into its compliance expectations, MDMs can feel better about taking larger steps with AM/3DP, especially in product design. Significant potential markets for AM/3DP include patient-matched devices and highly customized low-volume devices for specific variants of surgical procedures. These applications create significant challenges for manufacturers, and a paradigm shift in validation practices. “For example, tighter process controls including design models, patient data, workflow, and material quality will need to evolve from current practices, as statistical capabilities models do not apply well to a total run size of one,” said Sanzari.

Material offerings, more repeatable systems, and higher throughputs will likely be the biggest advances in AM/3DP over the next few years. Continued improvements in hardware and materials science will result in smaller, higher-precision fabrication capabilities with increased speed and efficiency. Long-term adoption of AM/3DP technologies by industries will also bring down the cost of equipment and materials, making them more competitive with traditional manufacturing methods. Metal AM is expected to become the go-to technology for customized hip implants and knee replacements. The printing of biomaterials offers incredible potential for printing replacement organs, blood vessels, and other anatomical parts, or printing sensors directly on the skin.

AM/3DP provides exhilarating opportunities for transforming medical device design and manufacturing and improving patient outcomes. In contrast, though, “MDMs are typically very conservative about the methods and materials they use because the devices need to be cleared through numerous federal regulators,” said Pollack. “However, due to the need for customized medical parts and tools, the industry must embrace the innovative and rapidly evolving technologies that comprise AM/3DP.”

Because AM/3DP is evolving so rapidly, OEMs struggle with the same challenges their CMs do—keeping up with the speed of advancement. Typically, by the time a limitation to a technology has been defined, and a strategy is developed to mitigate that concern, an AM vendor will then announce a new “tweak” to the equipment, software, process, material, or some other variable that moves beyond that limitation, starting the process over again. Such rapid progress makes it difficult to establish engineering standards and integrate AM/3DP into a production manufacturing environment.

“Capital investment is challenging, as the equipment is sometimes outdated by the time a purchase order is placed,” said Sanzari. “Significant investment in full-time R&D teams and equipment is required to keep current and at the forefront of the developments in the AM/3DP industry—which is what our customers expect.”

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.