Sam Brusco, Associate Editor02.11.19

To most, the idea of working in a factory crafting components seems unattractive. Working in a “machine shop” can call to mind images of working in a dark factory all day, manufacturing part after part in a monotonous haze.

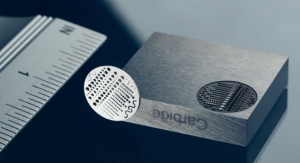

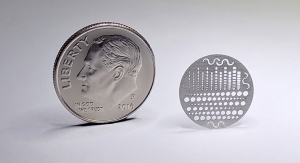

However, this couldn’t be farther from the truth when it comes to machining parts for the medical device industry. High-precision machining has significantly evolved from the lathes and mills of years past. Modern Swiss machines reach as high as 13-axis to make parts with complex geometries and can be programmed for optimal speeds and feeds. Hybrid manufacturing techniques are merging CNC machining with the additive laser sintering process. Multiple spindle machining is able to complete parts in a single setup, and some machines include capabilities like turning with live tooling and wire EDM. Laser machining continues to expand as well. Device manufacturers and their contract manufacturers rely on laser systems to make precise components with high levels of speed and accuracy, often at extremely low tolerances.

To gain more insight into the medical device machining industry, I spoke with Dan Easley, COO, and Matt Nipper, senior engineering manager, of Laser Light Technologies, a Hermann, Mo.-based service provider of laser micromachining. The breadth of their input was not included in the recent feature article entitled “Smooth Operator: Addressing Machining’s Talent Gap” (which can be read here), so their answers are included in the Q&A below.

Sam Brusco: Which services do you offer for medical device customers beyond machining? Why is it important to offer these services?

Dan Easley: We’re a trusted resource for life sciences and medical device companies because we offer services beyond machining to customers. Some additional services we offer include cleanroom processing and packaging, inventory management, assembly of components, and automated solutions. We offer climate-controlled, ISO Class 5 cleanrooms and a proprietary process developed for the most sensitive manufactured parts. We have several clients that currently take advantage of reduced delivery lead times and part storage with our flexible, intelligent in-house inventory management system.

Brusco: Which advances in laser processing technology have been most beneficial for manufacturing medical device parts, and why?

Matt Nipper: Laser sources are becoming more accessible from both economical and technical standpoints which allow us to remain competitive with competing manufacturing technologies. In our industry, throughput and reducing cycle times are driving the economics of manufacturing. To stay ahead of the curve, we have taken advantage of the many advances in motion control and material handling technologies to produce the most cost-effective products for our partners.

Brusco: Which types of medical device part manufacturing projects does your company find to be most challenging, and why?

Nipper: When manufacturing medical devices, the most difficult engineering challenge is to design a process that meets both the throughput and quality requirements for the customer. In particular, we especially enjoy designing high-throughput manufacturing processes for polymer coating removal on medical catheters. We’re constantly pushing the envelope to rapidly manufacture products with high quality.

Brusco: It has been said that the machining trade is struggling to attract new talented craftsmen. Have you found this to be true for your company? If so, why do you believe it is occurring and what steps does your company take to attract talent? If not, how have you been successful in attracting new talent?

Easley: We attract new talent through cooperative education programs (co-ops) and internships. Using proactive recruiting, we typically find talent in their younger career stages looking for their next phase. Since we are a specialized business that requires additional skills, we also provide on-the-job training. We have world-class engineers and staff with focused expertise in research and development, processes, quality, mechanical, and software. The key to attracting new talent is to be proactive.

Brusco: What will be expected of machinists in the coming years to ensure robust medical device part production?

Nipper: Our niche is laser micromachining, so in comparison to traditional machining we face both similar and dissimilar challenges. One common challenge for all U.S. manufacturing is to maintain cost-competitive offerings compared to international providers with access to lower labor costs. In our market, we have to be competent in many different areas and keep abreast of developments in both automation and machine efficiency. The combination of these different technologies drive the solutions for our customers.

Brusco: Is there anything else you’d like to say regarding machining for medical device manufacturing, or are there any particularly important topics within the machining/laser processing sector that I have not asked about that you feel MPO readers should know?

Easley: We’re finding that companies looking for contract manufacturing also want additional solutions. Today it’s not all about machining, but the additional solutions that we can provide.

However, this couldn’t be farther from the truth when it comes to machining parts for the medical device industry. High-precision machining has significantly evolved from the lathes and mills of years past. Modern Swiss machines reach as high as 13-axis to make parts with complex geometries and can be programmed for optimal speeds and feeds. Hybrid manufacturing techniques are merging CNC machining with the additive laser sintering process. Multiple spindle machining is able to complete parts in a single setup, and some machines include capabilities like turning with live tooling and wire EDM. Laser machining continues to expand as well. Device manufacturers and their contract manufacturers rely on laser systems to make precise components with high levels of speed and accuracy, often at extremely low tolerances.

To gain more insight into the medical device machining industry, I spoke with Dan Easley, COO, and Matt Nipper, senior engineering manager, of Laser Light Technologies, a Hermann, Mo.-based service provider of laser micromachining. The breadth of their input was not included in the recent feature article entitled “Smooth Operator: Addressing Machining’s Talent Gap” (which can be read here), so their answers are included in the Q&A below.

Sam Brusco: Which services do you offer for medical device customers beyond machining? Why is it important to offer these services?

Dan Easley: We’re a trusted resource for life sciences and medical device companies because we offer services beyond machining to customers. Some additional services we offer include cleanroom processing and packaging, inventory management, assembly of components, and automated solutions. We offer climate-controlled, ISO Class 5 cleanrooms and a proprietary process developed for the most sensitive manufactured parts. We have several clients that currently take advantage of reduced delivery lead times and part storage with our flexible, intelligent in-house inventory management system.

Brusco: Which advances in laser processing technology have been most beneficial for manufacturing medical device parts, and why?

Matt Nipper: Laser sources are becoming more accessible from both economical and technical standpoints which allow us to remain competitive with competing manufacturing technologies. In our industry, throughput and reducing cycle times are driving the economics of manufacturing. To stay ahead of the curve, we have taken advantage of the many advances in motion control and material handling technologies to produce the most cost-effective products for our partners.

Brusco: Which types of medical device part manufacturing projects does your company find to be most challenging, and why?

Nipper: When manufacturing medical devices, the most difficult engineering challenge is to design a process that meets both the throughput and quality requirements for the customer. In particular, we especially enjoy designing high-throughput manufacturing processes for polymer coating removal on medical catheters. We’re constantly pushing the envelope to rapidly manufacture products with high quality.

Brusco: It has been said that the machining trade is struggling to attract new talented craftsmen. Have you found this to be true for your company? If so, why do you believe it is occurring and what steps does your company take to attract talent? If not, how have you been successful in attracting new talent?

Easley: We attract new talent through cooperative education programs (co-ops) and internships. Using proactive recruiting, we typically find talent in their younger career stages looking for their next phase. Since we are a specialized business that requires additional skills, we also provide on-the-job training. We have world-class engineers and staff with focused expertise in research and development, processes, quality, mechanical, and software. The key to attracting new talent is to be proactive.

Brusco: What will be expected of machinists in the coming years to ensure robust medical device part production?

Nipper: Our niche is laser micromachining, so in comparison to traditional machining we face both similar and dissimilar challenges. One common challenge for all U.S. manufacturing is to maintain cost-competitive offerings compared to international providers with access to lower labor costs. In our market, we have to be competent in many different areas and keep abreast of developments in both automation and machine efficiency. The combination of these different technologies drive the solutions for our customers.

Brusco: Is there anything else you’d like to say regarding machining for medical device manufacturing, or are there any particularly important topics within the machining/laser processing sector that I have not asked about that you feel MPO readers should know?

Easley: We’re finding that companies looking for contract manufacturing also want additional solutions. Today it’s not all about machining, but the additional solutions that we can provide.