Sam Brusco, Associate Editor06.13.19

Injection molding and toolmaking remain as strong as ever in the medical device industry, both for development of new products as well as for legacy products. Manufacturers of molding equipment continue to enhance control systems, allowing tighter tolerances and improved surface finishes. Molders are becoming more adept at fabricating complex part geometry like thin walls, undercuts, and overhangs, and a wider variety of advanced materials are becoming available for molding.

Medical device designs continue to evolve, and more new molded products and components are entering the market than ever before. Some examples include laser-based surgical tools, micro-implants, and bioabsorbable technologies. Creating smaller and more complex medical devices necessitates more experience and precision from molders. Molders must also have comprehensive knowledge of materials behavior, particularly for advanced materials. Because of these requirements, medical device makers frequently want to work with molders who are dedicated to manufacturing medical products or else have a large portion of their business dedicated to medical manufacturing.

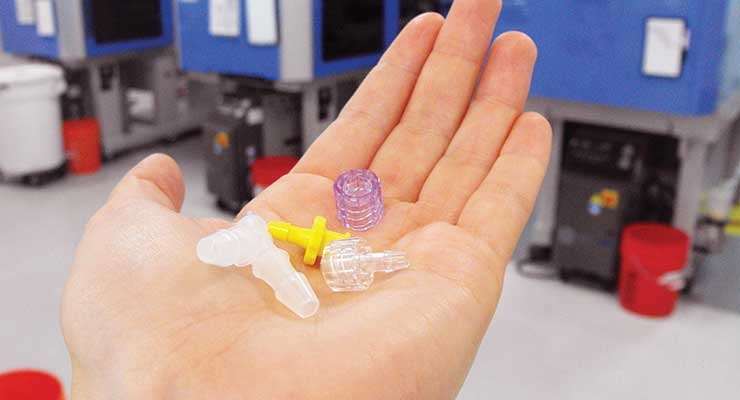

What’s more, instead of focusing on one or two aspects of the molding process, a significant number of medical molders work in partnership with their medical device customers. They may provide all manner of needed services: design, prototype development, guidance on design for manufacturing (DFM), material selection, and full production. Further, it has become practice for molders to have the ability to successfully manage all elements involved in the molding process from design to regulatory support. This can be difficult for medical device OEMs to accomplish cost-effectively, especially when working with multiple sources. Parts are also becoming so small that in some cases a full production run can be held in one hand. Many small parts require a molder that is strong in 2-shot, multi-component, or electronically integrated parts. Medical device manufacturers are constantly designing more products that need processes like overmolding or insert molding to combine materials—for example, plastic, metal, rubber, or thin, flexible surface electrodes—to make unique physical properties or specific surfaces or textures.

To gain more insight on molding for medical manufacturing, MPO spoke with the following molders serving the medical device industry:

Donna Bibber, VP of business development at Isometric Micro Molding, a New Richmond, Wis.-based micromolding company that provides medical and drug delivery OEMs with micromolded and automated assemblies.

Frank Dilly, managing director at SIMTEC Silicone Parts, a Miramar, Fla.-based manufacturer of custom, high-quality liquid silicone rubber (LSR) and LSR 2-shot (LSR/thermoplastics) parts.

Michael Eck, mold engineering manager at The Weiss-Aug Group, an East Hanover, N.J.-based firm that provides precision metal stamping, complex insert molding, custom assembly, progressive die tooling, and precision medium gauge complex stampings and assemblies.

Clay Hommel, an engineer at Injectech LLC, a Fort Collins, Colo.-based supplier of fluid-control components to medical device OEMs, biomedical/pharmaceutical manufacturers, veterinary suppliers, and industrial businesses.

This article is featured in the MPO eBook "Molding Modern Medtech." Click here to download the eBook and finish reading this article.

Medical device designs continue to evolve, and more new molded products and components are entering the market than ever before. Some examples include laser-based surgical tools, micro-implants, and bioabsorbable technologies. Creating smaller and more complex medical devices necessitates more experience and precision from molders. Molders must also have comprehensive knowledge of materials behavior, particularly for advanced materials. Because of these requirements, medical device makers frequently want to work with molders who are dedicated to manufacturing medical products or else have a large portion of their business dedicated to medical manufacturing.

What’s more, instead of focusing on one or two aspects of the molding process, a significant number of medical molders work in partnership with their medical device customers. They may provide all manner of needed services: design, prototype development, guidance on design for manufacturing (DFM), material selection, and full production. Further, it has become practice for molders to have the ability to successfully manage all elements involved in the molding process from design to regulatory support. This can be difficult for medical device OEMs to accomplish cost-effectively, especially when working with multiple sources. Parts are also becoming so small that in some cases a full production run can be held in one hand. Many small parts require a molder that is strong in 2-shot, multi-component, or electronically integrated parts. Medical device manufacturers are constantly designing more products that need processes like overmolding or insert molding to combine materials—for example, plastic, metal, rubber, or thin, flexible surface electrodes—to make unique physical properties or specific surfaces or textures.

To gain more insight on molding for medical manufacturing, MPO spoke with the following molders serving the medical device industry:

Donna Bibber, VP of business development at Isometric Micro Molding, a New Richmond, Wis.-based micromolding company that provides medical and drug delivery OEMs with micromolded and automated assemblies.

Frank Dilly, managing director at SIMTEC Silicone Parts, a Miramar, Fla.-based manufacturer of custom, high-quality liquid silicone rubber (LSR) and LSR 2-shot (LSR/thermoplastics) parts.

Michael Eck, mold engineering manager at The Weiss-Aug Group, an East Hanover, N.J.-based firm that provides precision metal stamping, complex insert molding, custom assembly, progressive die tooling, and precision medium gauge complex stampings and assemblies.

Clay Hommel, an engineer at Injectech LLC, a Fort Collins, Colo.-based supplier of fluid-control components to medical device OEMs, biomedical/pharmaceutical manufacturers, veterinary suppliers, and industrial businesses.

This article is featured in the MPO eBook "Molding Modern Medtech." Click here to download the eBook and finish reading this article.