YOU SEARCHED BY...

SEARCH BY...

Outsourcing Directory

Country

- Canada(2)

- China(2)

- Costa Rica(1)

- France(2)

- Germany(2)

- India(3)

- Italia (2)

- Japan(1)

- Lithuania(1)

- Mexico(1)

- New Zealand(1)

- Singapore(3)

- Switzerland(3)

- Taiwan(4)

- The Dominican Republic(1)

- United Kingdom(3)

- United States(342)

Outsourcing Directory

Pulse Systems

Company Headquarters

4090 Nelson Avenue

Concord, CA 94520

United States

Outsourcing Directory

In-Vitro Diagnostic Categories

Related Content

-

Software & IT

Survey Identifies Challenges to Improving Product Development Processes

81% of medical device companies are not using tools designed for the medical device industry in their quality management processes.PRWeb 11.26.19

-

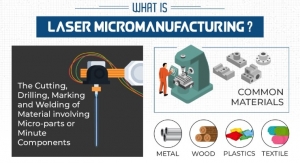

3D/Additive Manufacturing | Machining & Laser Processing | Molding

Laser Micromanufacturing 101—Everything You Need to Know

Laser micromanufacturing is used for a variety of purposes including additive manufacturing, CNC machining, and injection molding.Laser Light Technologies

-

Endonovo Therapeutics Appoints Strategic Advisor to its CEO

Angiogenesis Foundation CEO will work with company's chief executive on growth strategies.Globe Newswire 11.08.19

-

Packaging & Sterilization

Alternative Sterilization Technology for Medical Device Companies

Addressing the medical device sterilization crisis.Gustavo Varca, Manager of New Applications Development, E-BEAM SERVICES, Inc. 09.11.19

-

Update on Integrated Delivery Networks and Physician Employment

The top five IDNs employ 135,913 MDs and DOs in the U.S., approximately 15 percent of all active physicians in the country.Maria Shepherd, President and Founder, Medi-Vantage 09.06.19

-

Investment Banker Appointed to BioSig Board of Directors

Newest member brings to BioSig over 30 years of experience in investment banking and medical technology.BioSig Technologies Inc. 08.12.19

-

Contract Manufacturing | Machining & Laser Processing

Biomerics Merges with Northeast Laser & Electropolish

NLE provides contract manufacturing, laser processing, machining, and metal finishing services to a wide range of medical device manufacturers.PR Newswire 08.02.19

-

Funding Tips to Help Medtech Startups Cross the ‘Valley of Death’

...David J. Dykeman, Co-chair, Global Life Sciences & Medical Technology Group, Greenberg Traurig LLP 07.30.19

-

Software & IT

Not All Medical Device QMS Solutions Are Created Equal

How to choose a QMS that will set your emerging company up for future success.Evan Luxon, Co-Founder and CEO of Centese 06.24.19