Michael Barbella, Managing Editor02.06.15

Babak Parviz wants to change our view of the world.

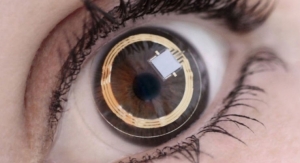

In 2009, the Google Glass founder built the first prototype for a bionic contact lens that could be embedded with cell-sized sensors. The breakthrough was so inspirational and remarkable that Parviz, a Ph.D. now with Amazon, devised an infinitely more ambitious follow-up project: Converting the contact lens into a platform of endless possibilities, capable of warning the hearing-impaired, simulcasting television shows, downloading electronic games or translating speech into captions. With basic image processing and Internet access, he surmised, a contact-lens display potentially could unlock whole new worlds of visual information, unfettered by the constraints of the physical world.

Much like the Terminator.

Parviz’s aspiration is still years away from commercialization, but the former Google[x] project leader has taken a giant step forward toward his dream vision with the development of a contact lens that can help manage diabetes. Crafted in tandem with Brian P. Otis, Ph.D., an electrical engineering faculty member at the University of Washington in Seattle, the contact lens contains a low-power microchip and a near-invisible, hair-thin electronic circuit that measures blood glucose levels directly from tear fluid on the eyeball’s surface. The system sends data to a mobile device to keep the wearer (and clinicians) informed.

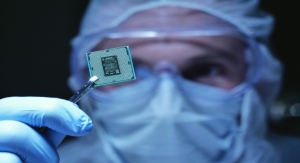

“At Google[x], we wondered if miniaturized electronics—think chips and sensors so small they look like bits of glitter, and an antenna thinner than a human hair—might be a way to crack the mystery of tear glucose and measure it with greater accuracy,” the engineers wrote in a January 2014 blog post.

Indeed, miniaturized electronics solved the mystery. Toiling diligently in the search giant’s “secret lab”—the birthing factory for those million-to-one scientific bets that require generous amounts of capital, massive leaps of faith and a willingness to break things—Parviz and Otis built smart lens prototypes from polyethylene terephthalate that generated a reading every second. The two also explored the feasibility of integrating tiny LED lights that would illuminate when blood sugar levels cross certain thresholds, essentially creating an early warning system.

Parviz and Otis’ work caught the attention of Novartis AG, which teamed up with Google last summer to hone the smart lens technology and create autofocusing contacts for the 1.7 billion people worldwide struggling with hyperopia (farsightedness). The somewhat odd pairing combines Google’s expertise in miniaturized electronics, low-power chip design and microfabrication with Novartis’ prowess (through its Alcon eyecare division) in eye physiology/visual performance, clinical development/evaluation, and commercialization of both contact and intraocular lenses.

For Google, the marriage is a clear sign of its resolve to challenge Apple Inc. and Samsung for a sizable chunk of the global digital health market, which is projected to double in the next three years and be worth more than $200 billion by 2020. Novartis is looking for its fair share as well, but the pharmaceutical giant also is banking on the smart lens technology spearheading a new product category based on biometric measurements from tears.

Comprised of water, proteins, minerals, hormones, antibodies and enzymes, tears act as a natural lubricant and protectant for the eyes. But they also are an effective physiological barometer, detecting the chemical changes often associated with disease. A protein called lacryglobin, for example, is a common biomarker for breast, colon, lung, prostate and ovarian cancers; monitoring its level could be particularly useful for cancer patients in remission.

“Now is the time to put a little computer and a lot of miniaturized technologies in the contact lens,” Franck Leveiller, vice president in charge of vision care R&D at Alcon Laboratories Inc., said shortly after the Google deal was announced.

Doing so, however, will require further advancements in miniaturized medical electronics and the manufacturing proficiency to overcome the various challenges associated with producing such miniscule systems. Devices such as neurostimulators and intraocular pressure-sensing contact lenses rely on glitter-sized solar cells or thin-film lithium batteries for power, but battery size is directly proportional to electrical output (translation: small battery, low power). Resolving the power dissipation quandry demand innovative solutions like the kind contrived by researchers from the National Institute of Standards and Technology (NIST) in Gaithersburg, Md. Scientists there have found a way to explore the inside of microscopic, multi-layered batteries and study the cells’ performance without destroying them. The discovery is being hailed as both a useful tool for analysts and a potential power source for micromachines.

NIST experts created the tiny lithium-ion batteries by taking a silicon wire a few micrometers long and covering it in successive layers of different materials, like a tree. They attached the batteries by their “roots” to silicon wafers and clustered them together by the millions into “nanoforests,” as the team dubbed them.

The layers enable the batteries to store and discharge electricity, and be recharged—attributes that could make them valuable for powering the autonomous microelectromechanical machines (MEMS) currently used in various industries, including medical. MEMS manufacturers could make use of the batteries themselves, a million of which can be fabricated on a square centimeter of a silicon wafer, or analyze products using the scientists’ home-built diagnostic tool (multimode scanning transmission electron microscopy). The NIST team’s approach might be particularly useful for additive manufacturers, who often need to analyze their creations in a non-invasive way.

With battery nanoforests on the horizon and the consumerization of medical devices driving component miniaturization, electronics manufacturing service (EMS) providers increasingly are becoming an integral part of the product development process. The medtech market is a potential gold mine for EMS companies, expected to be worth more than $34 billion by 2019, with cardiovascular, remote diagnostics and patient monitoring sectors among the fastest-growing in the industry, according to data from global consulting firm Frost & Sullivan.

“One of the ways the healthcare industry is looking to cut costs is reduce the time patients spend in hospitals, which means using technology to monitor patients in their home settings,” noted Susan Mucha, president and founder of El Paso, Texas-based Powell-Mucha Consulting Inc., a management consultancy focused on the EMS industry. “This is driving a focus on wearable or small user-friendly devices, since patients are most comfortable with products similar to the consumer electronics they already use.

Medical device manufacturers are looking for their EMS providers to be able support this trend toward miniaturization and use of microelectronics. They also expect all their contractors to be able to provide a full range of engineering and manufacturing services, regardless of whether they are a global EMS company or a much smaller regional player. And from what I’m seeing, there are a lot of small regional contractors that have risen to that challenge.”

Those contractors, though, really have no other choice. A growing number of medical device manufacturers are turning to EMS providers for help in designing, developing and marketing their products. Contract manufacturer Spectrum Assembly Inc., for example, has found success in providing scalable support to startups.

“We began doing medical product box builds in 2006. For one of our customers it started with a single cable assembly and progressed to printed circuit board assemblies,” said Alexandra Topp, sales and marketing manager at the Carlsbad, Calif.-headquartered Spectrum. “Medical startups are a large part of our [medical] business segment. We focus on startups that have funding and a clear business vision. We like to get started at the protopye phase and we’ve set up flexible service packages that make it easy for teams that are new to outsourcing to pick the best mix of services for their product requirements. I think the key to serving this segment of the market is understanding customer concerns and being flexible in terms of how those concerns are addressed.”

The winning formula is different for original equipment manufacturers (OEMs), however. Global companies like Medtronic plc, Boston Scientific Corp., Philips Healthcare and others expect EMS providers not only to design, manufacture, subassemble and assemble printed circuit boards (PCBs) but test them as well. Such lofty assumptions are prompting vendors to develop a new generation of testing products with higher frequencies, embedded passives, greater densities and finer lines. Many also are focusing on in-circuit testing, which is used to evaluate passive components of PCBs for presence, continuity, connection and faults. Others, such as Axiom Electronics, stick with old favorites: automatic optical inspection or flying probes, while some have fine-tuned their testing capabilities to accommodate increasing circuit board densities, decreasing space between holes and enhancing PCB performance in hot and humid environments.

Despite such testing diversity, business from an OEM—or any medtech firm, for that matter—is not guaranteed. Granted, many manufacturers finally are realizing the competitive advantage and cost benefits of outsourcing, but some still remain hesitant to do so due to past recalls or supplier issues. A good number also remain committed to their in-house competencies such as high-end manufacturing, design and procurement, particularly those making high-risk Class III medical devices. In addition, OEMs tend to retain all of their distribution operations in-house due to the complex and strategic nature of their relationships with hospitals—physicians are key to their success and many are hard-pressed to relinquish this functionality to an outside contractor.

“EMS providers have definitely come a long way in terms of transforming OEM mindset regarding their expertise,” Lavanya Rammohan, research analyst, electronics manufacturing equipment at Frost & Sullivan, told Design News. “Most EMS companies have better manufacturing and in-house resources and domain knowledge for low- to mid-volume and high-mix manufacturing in comparison to medical OEMs. “

The Matchmaking Process

Act II of Oscar Wilde’s 1895 classic “An Ideal Husband” begins with Sir Robert Chiltern, a member of England’s House of Commons, sharing the secret of his success with dandified bachelor Lord Goring, son of Earl Caversham. He admits building his fortune through deception, specifically by selling a British government secret to an extremely wealthy baron.

“Since then everything that I have touched has turned out a success. In all things connected with money I have had a luck so extraordinary that sometimes it has made me almost afraid,” he tells Lord Gorling. “I remember having read somewhere, in some strange book, that when the gods wish to punish us they answer our prayers.”

If so, then medtech OEMs are in for quite a bit of suffering. For years, they’ve demanded more from EMS providers, trusting them with product development, engineering, clean room manufacturing, testing and support. EMS firms, consequently, have risen to the challenge, thus expanding the field of potential OEM suitors.

Prayers answered. To the gods’ amusement, of course.

With the EMS dating pool growing, OEMs face a tougher partner selection process. Myriad factors come into play, including design expertise, manufacturing capabilities, depot repair, corporate culture and testing/support services.

Quality, though, is perhaps most important to large device firms. OEMs prefer electronics vendors that can evaluate, document, and retain data from manufacturing and product test process requirements, industry experts claim. Suppliers also can win points with the ability to reference the data whenever necessary and satisfy U.S. Food and Drug Administration (FDA) or other regulatory requirements.

“There’s a lot more discussion at the front end of design with regards to meeting FDA regulations and the increased pressure for quality systems. You have to have everthing in place, whether it be the proper registrations or certifications, or the proper controls in place to monitor your quality system,” explained Richard Bickford, U.S. sales manager for Nicolay GmbH, a Nagold, Germany-based vertically integrated manufacturer of customized medical cables, connectors and cable assemblies. “Quality is becoming more and more important. If you are a new supplier, companies tend to want documentation that will allow them to say, ‘OK, these guys are qualified, they’ve got their ducks in a row, they have a quality system in place.’ Or, there’s a new product introduction process that requires testing and certain data during the development process so they are requiring that as a supplier, you go through those processes or have those processes in place.”

Design/engineering expertise is essential to OEMs as well. Besides manufacturing data processing/evaluation abilities, EMS providers that attempt to understand device functionality and analyze its manufacturability are most likely to play in the big leagues. By performing such an analysis, OEMs gain access to in-depth knowledge about their product before the manufacturer has begun building the first part. Design for manufacturability is crucial too, as it helps companies optimize all manufacturing functions (fabrication, assembly, test, procurement, etc.), and ensure the best cost, quality, reliability, regulatory compliance, safety, time-to-market and customer satisfaction.

Many OEMs are charmed by refurbishment and depot repair capabilities, since they are unlikely to have the necessary staff to manage that work. Moreover, miniaturization wherewithal is becoming a growing priority as the line between consumer and medical devices continues to blur. And while most EMS providers are extremely adept at miniaturization, not all electronics vendors can, for instance, create chip designs with high-density interconnect to increase functionality, or meet demand for data transmission capability of up to 25 gigabits per second, which requires lower-loss tangents and signal integrity. Companies that can place and test small package components on circuit boards have the best chance of attracting OEM partners, industry observers note. Benchmark Electronics is a prime example: The Phoenix, Ariz.-based electronics contract manufacturer can place and test a 01005 case component—half the size of the 0201, previously considered to be the smallest case size in surface mount technology. Valtronic, on the other hand, can place high-density parts ranging from 01005 to 47 millimeters by 47 millimeters at speeds up to 17,100 chips per hour.

Placing and testing components are essential proficiencies for any EMS provider, but the standouts offer variability in their test offerings and encourage customers to incorporate testing early in the design phase.

“DFT (design for testing) is very important when you’re talking about testing. Let’s say a medical designer comes up with his own [circuit] board design—he lays out the schematics, the EMS company goes out and buys all the parts and they put it together,” said Bob Miller, vice president of sales at Qual-Pro Corporation, a Gardena, Calif.-based EMS provider offering turnkey manufacturing services and complete box-level assembly of mission critical electronics. “In days old they would shoot them the board and say, ‘Plug it into your system and see if it works.’ Now you’re seeing customers that don’t want the board to leave their factory unless they know it’s 100 percent good. The only way you can validate that the board is 100 percent good is by a test vehicle, whether it is an in-circut test, a flying probe test or a functional test. You plug in a board to a test set and you run it through its paces before you ship it and the customer plugs it into their device. On the EMS side of things, from Tier I to Tier III guys, there will be a push to capture more of that chain from the design to put it into a box. When you go to a customer you need to say, ‘When you design this board make sure you design it with some test points or some connectors or some vehicle so I can use a box that we built or something that can run it through its paces.’ Sometimes someone will design something where they don’t accommodate the need for testing, therefore reducing the ability to test it and giving the EMS provider and the customer less test coverage on the board, unless it’s designed in on the front end.”

Ultimately, the EMS contractors that are most appealing to OEMs are those that can tailor their solutions to customers’ needs. This strategy has worked like a charm for both Burton Industries Inc. and Valtronic.

Burton Industries, a regional EMS provider, focuses on helping its customers solve the various challenges they face, including optimizing project transfer, supporting variable demand and helping in cost reduction efforts. Recently, Burton Industries has seen the percentage of value-add assembly services increase.

“We are starting to see medical device manufacturers outsource more of the product,” Business Development Director Gary Burnett Jr. told Medical Product Outsourcing. “Previously, they tended to keep higher-level assembly inside. Over the last few years, that’s been changing. Customers are now outsourcing either more complex subassemblies or the full chassis to us. In addition to supporting a more complex production process, this also requires our team to provide a more complex testing solution.”

Versatility has contributed to Valtronic’s longevity as well. The Swiss component manufacturer for the medical, aerospace and industrial markets invested in a JUKI RS800 eco-friendly reflow oven last year at its U.S. facility to reinforce its core competency in miniaturization and enter the light-emitting-diode industry. Such a bold market entrée is not uncommon for the company: In 1999, the firm built a clean room to breach the fast-growing medical electronics sector. It turned out to be one of the smartest choices in Valtronic’s 32-year history—today, 80 percent of the company’s business is derived from healthcare applications, in areas such as active implants, diagnostic imaging, intelligent orthopedics and electro-mechanical medical devices (e.g., laser therapy, irrigation pumps for endoscopy).

Valtronic executives are hoping for similar results in the wearable technology market. Last fall, the company debuted its mhealth platform (Compendium) for tracking, storing and relaying physiological data. “...the sector in medical wearables is about to explode as we see big players like Apple and Google, and thousands of start-ups globally dabble in remote patient monitoring,” Marketing/Communications Manager Monica Gasbarre blogged when the system launched. “With the wearable device market expanding, it only made sense for Valtronic’s Compendium platform to come to realization.”

Reinvention is essential to survival in the 21st century medtech market. Valtronic’s evolving metamorphosis has enabled the company to embrace new markets and position itself both as a catalyst of the global healthcare system and a problem-solver for customers. The makeovers, however, are not the only building blocks to long-term growth.

Valtronic has invested heavily in its U.S. facility in recent years, moving to a larger headquarters in 2012 and adding a 288-square-foot BioBurden ISO Class 8 clean room to its Solon, Ohio, production base two years ago. The new clean room qualifies temperature, humidity, and contamination controls, and also enables Valtronic to package electronic and mechanical assemblies in a pouch ready for ethylene oxide (EtO) sterilization.

On the surface, the expansion seems odd, considering the global nature of modern business and the love affair most OEMs have been conducting with China and other BRICs. But Valtronic’s loyalty to the United States, and more broadly, North America, makes sense in light of recent outsourcing trends.

“North America is gaining cost competitiveness,” said Curtis Campbell, vice president of sales, West Coast Operations, at SigmaTron International , a mid-tier EMS firm with operations in the United States, Mexico, China and Vietnam. “We recently had a customer focused on building in China opt for Mexico when all costs were considered. We are also seeing good opportunities in the U.S. and have recently expanded our capabilities to support medical customers in our Illinois facility so that customers could have a Midwest as well as a West Coast manufacturing operation.”

There are a multitude of reasons for the shift, including stringent FDA regulations, intellectual property protection concerns, supplier consolidation, and, of course, cost. But the most influential factor might also be the most telling—the desire for face-to-face contact.

“Location does matter,” said Dirk Smith, vice president of Systems and Technology for Minnetronix Inc., a St. Paul, Minn.-based firm specializing in design, manufacturing and support of electronic-based medical devices and technology. “With high volume and labor-intensive products, the cost benefits of doing things remotely and in a different culture can outweigh the challenges. Minnetronix has effective remote communications tools to work with customers across the U.S., but location can be an advantage. Talking face-to-face with our customers in the Twin Cities can be a real asset to both parties. Nothing beats interpersonal communication.”

* * *

Advancements in microelectronics have revolutionized industry and manufacturing, shrinking the size of conventional components to nearly a molecular level. In healthcare, the results are extraordinary: Pacemakers the size of a vitamin, hearing aids small enough to fit inside the ear, and batteries comprised of millions of silicon nanowires. The future has definitely arrived.

EMS providers are key to the development of such technologies, as they collaborate with OEMs and other customers to design, develop, manufacture and market these miniature marvels. To survive, though, EMS vendors must be able to evolve with their partners—to truly become an extension of their customer, growing and adapting to market demands. As Mucha noted: “EMS outsourcing is driven by the way companies like to work, and different companies have different needs. Some companies like to outsource for a distance, others like to have their engineering team intimately involved with manufacturing. There’s really no one-size-fits-all model. It just evolves based on what the companies need.”

In 2009, the Google Glass founder built the first prototype for a bionic contact lens that could be embedded with cell-sized sensors. The breakthrough was so inspirational and remarkable that Parviz, a Ph.D. now with Amazon, devised an infinitely more ambitious follow-up project: Converting the contact lens into a platform of endless possibilities, capable of warning the hearing-impaired, simulcasting television shows, downloading electronic games or translating speech into captions. With basic image processing and Internet access, he surmised, a contact-lens display potentially could unlock whole new worlds of visual information, unfettered by the constraints of the physical world.

Much like the Terminator.

Parviz’s aspiration is still years away from commercialization, but the former Google[x] project leader has taken a giant step forward toward his dream vision with the development of a contact lens that can help manage diabetes. Crafted in tandem with Brian P. Otis, Ph.D., an electrical engineering faculty member at the University of Washington in Seattle, the contact lens contains a low-power microchip and a near-invisible, hair-thin electronic circuit that measures blood glucose levels directly from tear fluid on the eyeball’s surface. The system sends data to a mobile device to keep the wearer (and clinicians) informed.

“At Google[x], we wondered if miniaturized electronics—think chips and sensors so small they look like bits of glitter, and an antenna thinner than a human hair—might be a way to crack the mystery of tear glucose and measure it with greater accuracy,” the engineers wrote in a January 2014 blog post.

Indeed, miniaturized electronics solved the mystery. Toiling diligently in the search giant’s “secret lab”—the birthing factory for those million-to-one scientific bets that require generous amounts of capital, massive leaps of faith and a willingness to break things—Parviz and Otis built smart lens prototypes from polyethylene terephthalate that generated a reading every second. The two also explored the feasibility of integrating tiny LED lights that would illuminate when blood sugar levels cross certain thresholds, essentially creating an early warning system.

Parviz and Otis’ work caught the attention of Novartis AG, which teamed up with Google last summer to hone the smart lens technology and create autofocusing contacts for the 1.7 billion people worldwide struggling with hyperopia (farsightedness). The somewhat odd pairing combines Google’s expertise in miniaturized electronics, low-power chip design and microfabrication with Novartis’ prowess (through its Alcon eyecare division) in eye physiology/visual performance, clinical development/evaluation, and commercialization of both contact and intraocular lenses.

For Google, the marriage is a clear sign of its resolve to challenge Apple Inc. and Samsung for a sizable chunk of the global digital health market, which is projected to double in the next three years and be worth more than $200 billion by 2020. Novartis is looking for its fair share as well, but the pharmaceutical giant also is banking on the smart lens technology spearheading a new product category based on biometric measurements from tears.

Comprised of water, proteins, minerals, hormones, antibodies and enzymes, tears act as a natural lubricant and protectant for the eyes. But they also are an effective physiological barometer, detecting the chemical changes often associated with disease. A protein called lacryglobin, for example, is a common biomarker for breast, colon, lung, prostate and ovarian cancers; monitoring its level could be particularly useful for cancer patients in remission.

“Now is the time to put a little computer and a lot of miniaturized technologies in the contact lens,” Franck Leveiller, vice president in charge of vision care R&D at Alcon Laboratories Inc., said shortly after the Google deal was announced.

Doing so, however, will require further advancements in miniaturized medical electronics and the manufacturing proficiency to overcome the various challenges associated with producing such miniscule systems. Devices such as neurostimulators and intraocular pressure-sensing contact lenses rely on glitter-sized solar cells or thin-film lithium batteries for power, but battery size is directly proportional to electrical output (translation: small battery, low power). Resolving the power dissipation quandry demand innovative solutions like the kind contrived by researchers from the National Institute of Standards and Technology (NIST) in Gaithersburg, Md. Scientists there have found a way to explore the inside of microscopic, multi-layered batteries and study the cells’ performance without destroying them. The discovery is being hailed as both a useful tool for analysts and a potential power source for micromachines.

NIST experts created the tiny lithium-ion batteries by taking a silicon wire a few micrometers long and covering it in successive layers of different materials, like a tree. They attached the batteries by their “roots” to silicon wafers and clustered them together by the millions into “nanoforests,” as the team dubbed them.

The layers enable the batteries to store and discharge electricity, and be recharged—attributes that could make them valuable for powering the autonomous microelectromechanical machines (MEMS) currently used in various industries, including medical. MEMS manufacturers could make use of the batteries themselves, a million of which can be fabricated on a square centimeter of a silicon wafer, or analyze products using the scientists’ home-built diagnostic tool (multimode scanning transmission electron microscopy). The NIST team’s approach might be particularly useful for additive manufacturers, who often need to analyze their creations in a non-invasive way.

With battery nanoforests on the horizon and the consumerization of medical devices driving component miniaturization, electronics manufacturing service (EMS) providers increasingly are becoming an integral part of the product development process. The medtech market is a potential gold mine for EMS companies, expected to be worth more than $34 billion by 2019, with cardiovascular, remote diagnostics and patient monitoring sectors among the fastest-growing in the industry, according to data from global consulting firm Frost & Sullivan.

“One of the ways the healthcare industry is looking to cut costs is reduce the time patients spend in hospitals, which means using technology to monitor patients in their home settings,” noted Susan Mucha, president and founder of El Paso, Texas-based Powell-Mucha Consulting Inc., a management consultancy focused on the EMS industry. “This is driving a focus on wearable or small user-friendly devices, since patients are most comfortable with products similar to the consumer electronics they already use.

Medical device manufacturers are looking for their EMS providers to be able support this trend toward miniaturization and use of microelectronics. They also expect all their contractors to be able to provide a full range of engineering and manufacturing services, regardless of whether they are a global EMS company or a much smaller regional player. And from what I’m seeing, there are a lot of small regional contractors that have risen to that challenge.”

Those contractors, though, really have no other choice. A growing number of medical device manufacturers are turning to EMS providers for help in designing, developing and marketing their products. Contract manufacturer Spectrum Assembly Inc., for example, has found success in providing scalable support to startups.

“We began doing medical product box builds in 2006. For one of our customers it started with a single cable assembly and progressed to printed circuit board assemblies,” said Alexandra Topp, sales and marketing manager at the Carlsbad, Calif.-headquartered Spectrum. “Medical startups are a large part of our [medical] business segment. We focus on startups that have funding and a clear business vision. We like to get started at the protopye phase and we’ve set up flexible service packages that make it easy for teams that are new to outsourcing to pick the best mix of services for their product requirements. I think the key to serving this segment of the market is understanding customer concerns and being flexible in terms of how those concerns are addressed.”

The winning formula is different for original equipment manufacturers (OEMs), however. Global companies like Medtronic plc, Boston Scientific Corp., Philips Healthcare and others expect EMS providers not only to design, manufacture, subassemble and assemble printed circuit boards (PCBs) but test them as well. Such lofty assumptions are prompting vendors to develop a new generation of testing products with higher frequencies, embedded passives, greater densities and finer lines. Many also are focusing on in-circuit testing, which is used to evaluate passive components of PCBs for presence, continuity, connection and faults. Others, such as Axiom Electronics, stick with old favorites: automatic optical inspection or flying probes, while some have fine-tuned their testing capabilities to accommodate increasing circuit board densities, decreasing space between holes and enhancing PCB performance in hot and humid environments.

Despite such testing diversity, business from an OEM—or any medtech firm, for that matter—is not guaranteed. Granted, many manufacturers finally are realizing the competitive advantage and cost benefits of outsourcing, but some still remain hesitant to do so due to past recalls or supplier issues. A good number also remain committed to their in-house competencies such as high-end manufacturing, design and procurement, particularly those making high-risk Class III medical devices. In addition, OEMs tend to retain all of their distribution operations in-house due to the complex and strategic nature of their relationships with hospitals—physicians are key to their success and many are hard-pressed to relinquish this functionality to an outside contractor.

“EMS providers have definitely come a long way in terms of transforming OEM mindset regarding their expertise,” Lavanya Rammohan, research analyst, electronics manufacturing equipment at Frost & Sullivan, told Design News. “Most EMS companies have better manufacturing and in-house resources and domain knowledge for low- to mid-volume and high-mix manufacturing in comparison to medical OEMs. “

The Matchmaking Process

Act II of Oscar Wilde’s 1895 classic “An Ideal Husband” begins with Sir Robert Chiltern, a member of England’s House of Commons, sharing the secret of his success with dandified bachelor Lord Goring, son of Earl Caversham. He admits building his fortune through deception, specifically by selling a British government secret to an extremely wealthy baron.

“Since then everything that I have touched has turned out a success. In all things connected with money I have had a luck so extraordinary that sometimes it has made me almost afraid,” he tells Lord Gorling. “I remember having read somewhere, in some strange book, that when the gods wish to punish us they answer our prayers.”

If so, then medtech OEMs are in for quite a bit of suffering. For years, they’ve demanded more from EMS providers, trusting them with product development, engineering, clean room manufacturing, testing and support. EMS firms, consequently, have risen to the challenge, thus expanding the field of potential OEM suitors.

Prayers answered. To the gods’ amusement, of course.

With the EMS dating pool growing, OEMs face a tougher partner selection process. Myriad factors come into play, including design expertise, manufacturing capabilities, depot repair, corporate culture and testing/support services.

Quality, though, is perhaps most important to large device firms. OEMs prefer electronics vendors that can evaluate, document, and retain data from manufacturing and product test process requirements, industry experts claim. Suppliers also can win points with the ability to reference the data whenever necessary and satisfy U.S. Food and Drug Administration (FDA) or other regulatory requirements.

“There’s a lot more discussion at the front end of design with regards to meeting FDA regulations and the increased pressure for quality systems. You have to have everthing in place, whether it be the proper registrations or certifications, or the proper controls in place to monitor your quality system,” explained Richard Bickford, U.S. sales manager for Nicolay GmbH, a Nagold, Germany-based vertically integrated manufacturer of customized medical cables, connectors and cable assemblies. “Quality is becoming more and more important. If you are a new supplier, companies tend to want documentation that will allow them to say, ‘OK, these guys are qualified, they’ve got their ducks in a row, they have a quality system in place.’ Or, there’s a new product introduction process that requires testing and certain data during the development process so they are requiring that as a supplier, you go through those processes or have those processes in place.”

Design/engineering expertise is essential to OEMs as well. Besides manufacturing data processing/evaluation abilities, EMS providers that attempt to understand device functionality and analyze its manufacturability are most likely to play in the big leagues. By performing such an analysis, OEMs gain access to in-depth knowledge about their product before the manufacturer has begun building the first part. Design for manufacturability is crucial too, as it helps companies optimize all manufacturing functions (fabrication, assembly, test, procurement, etc.), and ensure the best cost, quality, reliability, regulatory compliance, safety, time-to-market and customer satisfaction.

Many OEMs are charmed by refurbishment and depot repair capabilities, since they are unlikely to have the necessary staff to manage that work. Moreover, miniaturization wherewithal is becoming a growing priority as the line between consumer and medical devices continues to blur. And while most EMS providers are extremely adept at miniaturization, not all electronics vendors can, for instance, create chip designs with high-density interconnect to increase functionality, or meet demand for data transmission capability of up to 25 gigabits per second, which requires lower-loss tangents and signal integrity. Companies that can place and test small package components on circuit boards have the best chance of attracting OEM partners, industry observers note. Benchmark Electronics is a prime example: The Phoenix, Ariz.-based electronics contract manufacturer can place and test a 01005 case component—half the size of the 0201, previously considered to be the smallest case size in surface mount technology. Valtronic, on the other hand, can place high-density parts ranging from 01005 to 47 millimeters by 47 millimeters at speeds up to 17,100 chips per hour.

Placing and testing components are essential proficiencies for any EMS provider, but the standouts offer variability in their test offerings and encourage customers to incorporate testing early in the design phase.

“DFT (design for testing) is very important when you’re talking about testing. Let’s say a medical designer comes up with his own [circuit] board design—he lays out the schematics, the EMS company goes out and buys all the parts and they put it together,” said Bob Miller, vice president of sales at Qual-Pro Corporation, a Gardena, Calif.-based EMS provider offering turnkey manufacturing services and complete box-level assembly of mission critical electronics. “In days old they would shoot them the board and say, ‘Plug it into your system and see if it works.’ Now you’re seeing customers that don’t want the board to leave their factory unless they know it’s 100 percent good. The only way you can validate that the board is 100 percent good is by a test vehicle, whether it is an in-circut test, a flying probe test or a functional test. You plug in a board to a test set and you run it through its paces before you ship it and the customer plugs it into their device. On the EMS side of things, from Tier I to Tier III guys, there will be a push to capture more of that chain from the design to put it into a box. When you go to a customer you need to say, ‘When you design this board make sure you design it with some test points or some connectors or some vehicle so I can use a box that we built or something that can run it through its paces.’ Sometimes someone will design something where they don’t accommodate the need for testing, therefore reducing the ability to test it and giving the EMS provider and the customer less test coverage on the board, unless it’s designed in on the front end.”

Ultimately, the EMS contractors that are most appealing to OEMs are those that can tailor their solutions to customers’ needs. This strategy has worked like a charm for both Burton Industries Inc. and Valtronic.

Burton Industries, a regional EMS provider, focuses on helping its customers solve the various challenges they face, including optimizing project transfer, supporting variable demand and helping in cost reduction efforts. Recently, Burton Industries has seen the percentage of value-add assembly services increase.

“We are starting to see medical device manufacturers outsource more of the product,” Business Development Director Gary Burnett Jr. told Medical Product Outsourcing. “Previously, they tended to keep higher-level assembly inside. Over the last few years, that’s been changing. Customers are now outsourcing either more complex subassemblies or the full chassis to us. In addition to supporting a more complex production process, this also requires our team to provide a more complex testing solution.”

Versatility has contributed to Valtronic’s longevity as well. The Swiss component manufacturer for the medical, aerospace and industrial markets invested in a JUKI RS800 eco-friendly reflow oven last year at its U.S. facility to reinforce its core competency in miniaturization and enter the light-emitting-diode industry. Such a bold market entrée is not uncommon for the company: In 1999, the firm built a clean room to breach the fast-growing medical electronics sector. It turned out to be one of the smartest choices in Valtronic’s 32-year history—today, 80 percent of the company’s business is derived from healthcare applications, in areas such as active implants, diagnostic imaging, intelligent orthopedics and electro-mechanical medical devices (e.g., laser therapy, irrigation pumps for endoscopy).

Valtronic executives are hoping for similar results in the wearable technology market. Last fall, the company debuted its mhealth platform (Compendium) for tracking, storing and relaying physiological data. “...the sector in medical wearables is about to explode as we see big players like Apple and Google, and thousands of start-ups globally dabble in remote patient monitoring,” Marketing/Communications Manager Monica Gasbarre blogged when the system launched. “With the wearable device market expanding, it only made sense for Valtronic’s Compendium platform to come to realization.”

Reinvention is essential to survival in the 21st century medtech market. Valtronic’s evolving metamorphosis has enabled the company to embrace new markets and position itself both as a catalyst of the global healthcare system and a problem-solver for customers. The makeovers, however, are not the only building blocks to long-term growth.

Valtronic has invested heavily in its U.S. facility in recent years, moving to a larger headquarters in 2012 and adding a 288-square-foot BioBurden ISO Class 8 clean room to its Solon, Ohio, production base two years ago. The new clean room qualifies temperature, humidity, and contamination controls, and also enables Valtronic to package electronic and mechanical assemblies in a pouch ready for ethylene oxide (EtO) sterilization.

On the surface, the expansion seems odd, considering the global nature of modern business and the love affair most OEMs have been conducting with China and other BRICs. But Valtronic’s loyalty to the United States, and more broadly, North America, makes sense in light of recent outsourcing trends.

“North America is gaining cost competitiveness,” said Curtis Campbell, vice president of sales, West Coast Operations, at SigmaTron International , a mid-tier EMS firm with operations in the United States, Mexico, China and Vietnam. “We recently had a customer focused on building in China opt for Mexico when all costs were considered. We are also seeing good opportunities in the U.S. and have recently expanded our capabilities to support medical customers in our Illinois facility so that customers could have a Midwest as well as a West Coast manufacturing operation.”

There are a multitude of reasons for the shift, including stringent FDA regulations, intellectual property protection concerns, supplier consolidation, and, of course, cost. But the most influential factor might also be the most telling—the desire for face-to-face contact.

“Location does matter,” said Dirk Smith, vice president of Systems and Technology for Minnetronix Inc., a St. Paul, Minn.-based firm specializing in design, manufacturing and support of electronic-based medical devices and technology. “With high volume and labor-intensive products, the cost benefits of doing things remotely and in a different culture can outweigh the challenges. Minnetronix has effective remote communications tools to work with customers across the U.S., but location can be an advantage. Talking face-to-face with our customers in the Twin Cities can be a real asset to both parties. Nothing beats interpersonal communication.”

* * *

Advancements in microelectronics have revolutionized industry and manufacturing, shrinking the size of conventional components to nearly a molecular level. In healthcare, the results are extraordinary: Pacemakers the size of a vitamin, hearing aids small enough to fit inside the ear, and batteries comprised of millions of silicon nanowires. The future has definitely arrived.

EMS providers are key to the development of such technologies, as they collaborate with OEMs and other customers to design, develop, manufacture and market these miniature marvels. To survive, though, EMS vendors must be able to evolve with their partners—to truly become an extension of their customer, growing and adapting to market demands. As Mucha noted: “EMS outsourcing is driven by the way companies like to work, and different companies have different needs. Some companies like to outsource for a distance, others like to have their engineering team intimately involved with manufacturing. There’s really no one-size-fits-all model. It just evolves based on what the companies need.”