Gerald Law, CEO, InnovationDB03.31.17

Imagine a bio-tattoo that monitors your body and alerts medical professionals if you’re about to have a heart attack, a fitness tracker on the back of your hand, or “smart skin” instead of a smart watch. These innovations are on the brink of entering the real world. The plastic electronics sector promises a mind-blowing array of new products and applications, throwing the sector into disarray. Now is the time for healthcare innovators to adopt plastic electronics and revolutionize healthcare monitoring and diagnosis.

InnovationDB, the world’s largest IP licensable technology database, has carried out a comprehensive study of the use of plastic electronics in healthcare devices to spot the biggest trends and identify the full potential of this exciting technology to transform our lives. With investment and cutting edge research unceasing, it is a case of “when” not “if” plastic electronics will see commercial maturity

Gerald Law is the CEO of InnovationDB.

What Are Plastic Electronics

Plastic electronics, or organic electronics, uses organic semiconducting materials to create electronic devices, as opposed to the inorganic semiconducting materials found in conventional electronic devices. Plastic electronics enable circuits to be deposited or printed onto almost any surface—rigid or flexible, substrate or plastic.

Plastic electronics excel compared to conventional electronic contraptions in several respects:

Applying Plastic Electronics

Plastic electronics doesn’t have one “killer” application. The scope of plastic electronics to generate new, innovative products and improve a myriad of existing goods means this technology is in demand across many commercial and industrial sectors.

It will not replace conventional, silicon electronics, but supplement and complement existing electronic solutions to expand product functionality in areas where conventional devices have failed to secure market traction, creating new market opportunities. The following list offers a sample of application areas and products.

Organic Light-Emitting Diodes (OLEDs)

The most established sector in the plastics electronics industry, OLEDs use organic semiconductors to create a thin, light emitting panel. OLEDs generate light via electroluminescence, removing the need for a backlight, increasing energy efficiency over conventional LEDs.

Organic Thin-Film Transistors (OTFTs)

Most organic transistors are OTFTs. These devices are easier to fabricate than traditional silicon-based transistors, as OTFTs can be printed on plastic or flexible substrates at room temperature.

Body Area Networks (BAN)

This interdisciplinary field explores the possibility of inexpensive and continuous health monitoring with real-time updates of medical records through the internet. Plastic electronics could be used to monitor and treat diseases unobtrusively in the home using smart clothing or even smart furniture. Alternatively, biosensors living in the body could monitor the patient’s health status and relay this information to your family doctor or other medical professionals.

These sensors do not necessarily need to exist in the body. For example, Google-owned business Motorola Mobility lodged a patent application for a device described as a “tattoo that could be applied to the throat” in May 2012. This temporary patch would include an embedded microphone, a transceiver for enabling wireless communications, and a power supply to receive signals from your smartphone.3 The healthcare potential is compelling. For example, the tattoo could read facial movements and aid technologies to help people who cannot speak.

Overall Assessment

Investment and interest in this sector continues unabated. The market, including healthcare and all other applications, is predicted to grow from $26 billion in 2016 to $69 billion in 2026, and 3,000 organizations are now pursuing plastic electronics.4

Plastic electronics are a step change in the way we use electronics at every point of the product lifecycle, and the sector faces many economic, social, technological, legal, and environmental challenges. However, the industry’s cautious approach in changing manufacture, design, and implementation will enable the industry to survive and futureproof itself. Ultimately, plastic electronic devices have the potential to revolutionize the healthcare sector.

References

1 The Fraunhofer FEP developed an ultra-low power OLED microdisplay

2 51. “Stretchable Electronics: A Shapely Future for Circuits,” The Economist, March 10, 2011.

3 Who needs Bluetooth headsets? Motorola patents “neck tattoo” smartphone accessory

4 Printed, Organic & Flexible Electronics Forecasts, Players & Opportunities 2016-2026. IDTechEx.

InnovationDB, the world’s largest IP licensable technology database, has carried out a comprehensive study of the use of plastic electronics in healthcare devices to spot the biggest trends and identify the full potential of this exciting technology to transform our lives. With investment and cutting edge research unceasing, it is a case of “when” not “if” plastic electronics will see commercial maturity

Gerald Law is the CEO of InnovationDB.

Plastic electronics, or organic electronics, uses organic semiconducting materials to create electronic devices, as opposed to the inorganic semiconducting materials found in conventional electronic devices. Plastic electronics enable circuits to be deposited or printed onto almost any surface—rigid or flexible, substrate or plastic.

Plastic electronics excel compared to conventional electronic contraptions in several respects:

- Low cost: Manufacture does not require complex assembly lines or excessive man hours, and materials are cheaper than conventional substrate and semiconductor material.

- Low material waste: Material used in production is greatly reduced for plastic electronics as the manufacture is based on additive, as opposed to subtractive, methods.

- Low energy consumption manufacturing: Plastic electronics can be fabricated at much lower temperatures than conventional materials.

- Novel physical properties: Very thin layers (below one micron) of material are needed in plastic electronic devices, and substrates and electronic components can be created using a bendable, stretchable, or transparent material. The resulting devices are easy to handle, easy to integrate into other products, easy-to-wear, and unbreakable due to their plastic and flexible nature.

- Sustainability: Organic materials are synthesized (not mined), and energy efficient and low-temperature manufacturing techniques protect resources by minimizing waste. Also, the devices are potentially biodegradable or recyclable, reusable, and produced without harmful heavy metals.

Applying Plastic Electronics

Plastic electronics doesn’t have one “killer” application. The scope of plastic electronics to generate new, innovative products and improve a myriad of existing goods means this technology is in demand across many commercial and industrial sectors.

It will not replace conventional, silicon electronics, but supplement and complement existing electronic solutions to expand product functionality in areas where conventional devices have failed to secure market traction, creating new market opportunities. The following list offers a sample of application areas and products.

Organic Light-Emitting Diodes (OLEDs)

The most established sector in the plastics electronics industry, OLEDs use organic semiconductors to create a thin, light emitting panel. OLEDs generate light via electroluminescence, removing the need for a backlight, increasing energy efficiency over conventional LEDs.

- Smart contact lenses impregnated with OLEDS: Google, Samsung, and Sony are investing in this technology for applications including, blood glucose level monitoring, augmented reality, and vision correction or enhancement.

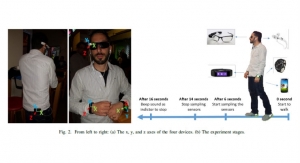

- Wearable devices: Lightweight and high definition, OLEDs are an ideal candidate for micro-displays used in virtual reality headsets. Fraunhofer FEP has integrated image sensor capabilities into micro-displays monitoring eye movements1, potentially allowing patients with degenerative diseases to use eye movements to convert pre-composed text to speech.

Organic Thin-Film Transistors (OTFTs)

Most organic transistors are OTFTs. These devices are easier to fabricate than traditional silicon-based transistors, as OTFTs can be printed on plastic or flexible substrates at room temperature.

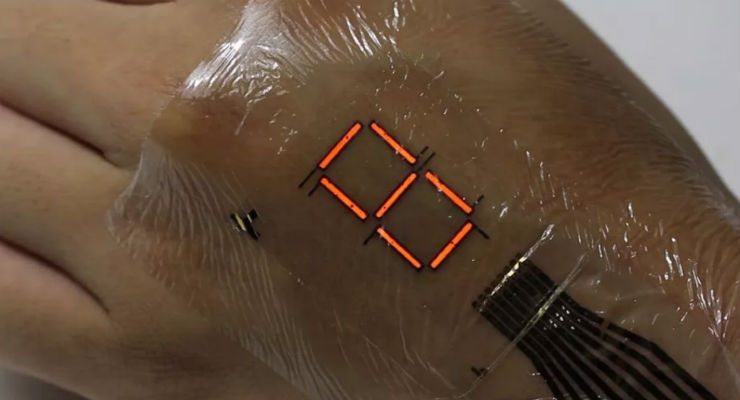

- Electronic skin: Ultra-stretchy and extremely thin material, mimicking the flexibility of human skin, and capable of self-healing under heat application. Special coating keeps out oxygen and water vapor so it can work for several days, as opposed to the hour-long lives of previous e-skin attempts.

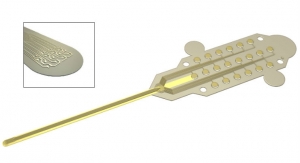

- Bio-sensors: Cheap and disposable components, with high sensitivity to biological and chemical agents, lend OTFTs to biomedical sensors. When in the patient’s body, they could predict a stroke, an asthma attack, or prompt a diabetic patient to take their insulin. Improvements in thermal stability are required to survive necessary high-heat sterilization.

- MC10 and Reebok have collaborated2 to launch a wearable device using a technology called “BioStampRC.” This stretchable, sensor-impregnated surface looks a bit like a sticking plaster, but it can be placed in a range of locations on the body to gather complex physiological data as part of medical studies.

Body Area Networks (BAN)

This interdisciplinary field explores the possibility of inexpensive and continuous health monitoring with real-time updates of medical records through the internet. Plastic electronics could be used to monitor and treat diseases unobtrusively in the home using smart clothing or even smart furniture. Alternatively, biosensors living in the body could monitor the patient’s health status and relay this information to your family doctor or other medical professionals.

These sensors do not necessarily need to exist in the body. For example, Google-owned business Motorola Mobility lodged a patent application for a device described as a “tattoo that could be applied to the throat” in May 2012. This temporary patch would include an embedded microphone, a transceiver for enabling wireless communications, and a power supply to receive signals from your smartphone.3 The healthcare potential is compelling. For example, the tattoo could read facial movements and aid technologies to help people who cannot speak.

Overall Assessment

Investment and interest in this sector continues unabated. The market, including healthcare and all other applications, is predicted to grow from $26 billion in 2016 to $69 billion in 2026, and 3,000 organizations are now pursuing plastic electronics.4

Plastic electronics are a step change in the way we use electronics at every point of the product lifecycle, and the sector faces many economic, social, technological, legal, and environmental challenges. However, the industry’s cautious approach in changing manufacture, design, and implementation will enable the industry to survive and futureproof itself. Ultimately, plastic electronic devices have the potential to revolutionize the healthcare sector.

References

1 The Fraunhofer FEP developed an ultra-low power OLED microdisplay

2 51. “Stretchable Electronics: A Shapely Future for Circuits,” The Economist, March 10, 2011.

3 Who needs Bluetooth headsets? Motorola patents “neck tattoo” smartphone accessory

4 Printed, Organic & Flexible Electronics Forecasts, Players & Opportunities 2016-2026. IDTechEx.