Mark Crawford , Contributing Writer05.01.19

Medical device designers are pleased with the high demand for their services these days—for creating groundbreaking new products as well as redesigning legacy devices to make them more functional and user friendly.

A wide range of medical device companies, from Fortune 100 giants to high-tech startups, continue to push for innovative new medical devices—often with an emphasis on data capture, transmission, and analysis to provide user-friendly feedback on personal health.

“These companies understand that good design leads to improved usability,” said Tor Alden, a principal at HS Design, a Gladstone, N.J.-based medical design firm that provides full-service product development. “The FDA is also very focused on making sure OEMs document the use and usability of their devices, focusing on human factors. This trend has elevated both industrial design and user interface design to more strategic positions.”

Medical devices are becoming more personalized and merging with consumer products, a market with a greater emphasis on style, simplicity, and aesthetics. OEMs are therefore emphasizing ease of use when they talk with their engineers and designers. Even though the main driver for differentiation in the marketplace is more technology and higher functionality, there is also a mindset that believes in achieving the intended functionality in the easiest way by focusing on human factors and simple design—which also keeps costs down.

Justin Rowland, project manager for Kapstone Medical, a Charlotte, N.C.-based product development firm that commercializes new medical devices, has seen this trend toward simpler designs, which incorporate only the technology features and capabilities that are truly needed. “Simplicity will always be a timeless design principle, but I think medical devices and systems got more attention in the past when they were full of features and bells and whistles,” he said. “Now, with the increased popularity of health-related consumer devices, clinicians want medical devices that are simple and easy to use, with fewer steps.”

With this emphasis on personalization, it has never been more important to listen to the voice of the consumer when it comes to designing the ideal medical device solution. Customers continue to expect more from their medical products in terms of ergonomics, improved therapeutic and diagnostic outcomes, and connectivity to other devices and the cloud. Knowing exactly what their customers want gives medical device manufacturers (MDMs) a competitive edge in the marketplace—but it also requires a depth of consumer research that many have not undertaken.

“The medical device industry is struggling to incorporate consumer-type design technologies and elements in an environment with rapidly changing regulatory constraints,” said Kenneth Fine, president of Proven Process Medical Devices, a Mansfield, Mass.-based developer and manufacturer of complex and implanted electromechanical medical devices and equipment. “Design teams are being asked to address these challenges, while also reducing product development timelines as demanded by OEMs.”

Talking with the end user to determine product capabilities and features is essential for solving these challenges in a timely and cost-effective way. “We use our own internal research process to gather critical insights related to understanding current solutions and their issues, unboxing to set-up to disposal/sterilization, user interface challenges with display content and workflow, and grasping competitive product offerings,” said Yani Deros, president of ATOM Innovation + Product Development, a Scottsdale, Ariz.-based product development firm that works across a variety of markets, including medical devices and implants. “You can bet that if you aren’t talking to your customers, the competition is.”

Latest Trends

A major industry trend is the collaboration of medical, life science, and pharma companies to create innovative delivery systems for new medicines, driven in part by the push for personalized medicine and improved diagnostics instrumentation. An increasing number of point-of-care devices designed for home use to monitor and transmit valuable health information are coming into the market. Another hot sector is sensor-based flexible and wearable technologies.

The medical device industry tries to stay aligned with these rapidly evolving digital health and personalized medicine strategies. Connectivity and user-centric design are the key drivers. Technology and patient value streams are guiding product portfolio decisions. More emphasis is being placed on understanding how the data from a medical device or diagnostic instrument impacts patient treatment and reduce healthcare costs. For specific disease states, it is especially important to understand the various medical touchpoints during the patient’s journey.

“Assessing the value of the data, and how information integrates with third-party devices such as wearables is essential for success,” said Martha Najib, vice president of strategic marketing for Ximedica, a Los Gatos, Calif.-based provider of engineering services for diagnostics and medical devices. “Another factor to consider is the software in the device. From experience with clinical laboratory improvement amendments—waived products, the graphic user interface needs to be extremely intuitive. If the user gets frustrated, it’s likely the product will not be chosen.”

To personalize new products, OEMs are instructing their design partners to create meaningful user experiences, whether it is for physicians, clinicians, or patients. This requires a user interface that is simple, intuitive, and engaging to avoid misuse or errors. The medical device itself should not be intimidating or complex—instead it needs to be attractive to the eye, which may require special materials, colors, and finishes to make it stand out from the competition.

This is especially true for wearable devices, which are rapidly evolving, not only as healthcare devices, but also as fashion statements. Improved microelectromechanical system technologies create “tiny integrated electronics for wearable devices or systems,” said Deros. “These miniaturized solutions contain smaller, more powerful, and compact electronics that allow for more pliable or wearable devices that seamlessly integrate into people’s lives.”

“There is great interest in sensor technologies with wearable devices,” agreed Dan Stipe, director of industrial design for Forma Medical Device Design, a Raleigh, N.C.-based firm that specializes in medical devices and laboratory and scientific instrumentation. “Wearable devices and applications are prevalent in the fitness market, but their accuracy needs to be improved before they can be utilized for medical purposes. A number of companies are working on this.”

What OEMs Want

OEMs seek designs that yield the lowest reasonable commercial product cost with the highest degree of robustness. Forward-thinking OEMs realize that well-thought-out design can save money and increase sales in the long run, especially as devices become more complicated and more secular in nature. “Having four or five different devices working together during a surgical procedure is not uncommon,” said Alden. “Therefore, designs that are intuitive, compact, and cleanable are important.”

Designers and contract manufacturers also feel constant pressure from OEMs to reduce development times to ensure that narrow windows of opportunity are not missed. More new products are being designed to include features found in consumer products, such as intuitive graphical user interfaces, connectivity, and attractive looks. For some applications, new products must be miniaturized so they can be worn discreetly. Because OEMs are asking for a lot more from product design firms than in the past, most design firms have added additional capabilities. “For example, we now have research/human factors, user interface, industrial design, and engineering groups fully integrated into a collaborative organization,” said Alden.

OEMs want creative design features that resonate with customers, coupled with cost reduction and streamlined assembly to reduce build, testing, and servicing timeframes. Consumer opinion is also essential for designing products that reinforce the OEM’s brand and establish the company as a player in a category or market. “They understand that the product/innovation has to not only function reliably and repeatedly, but also be designed to be a differentiator in the marketplace that inspires users to purchase the device to improve the quality of their healthcare experience,” said Deros.

A top concern for OEMs is shorter development timelines to gain a competitive edge in the marketplace—which is often easier to do with products of simpler design. Shared platforms among devices can also save money and launch products faster. Many companies want quick prototype development of about two years from phase 0 to clinical trials, as well as low quantities of instruments manufactured locally to test the market, reliability, market stamina, low cost of goods sold, and regulatory ease. “For designing diagnostic instruments, it’s important to identify factors that allow your platform to be flexible and scalable in order to penetrate additional markets,” said Najib.

New Technology Trends

Machine learning and artificial intelligence technologies are making it easier to diagnose a variety of health conditions. “Augmented reality [AR] and virtual reality [VR] tools are the new game in town,” said Alden. “AR allows us to build models and capture user insights without physical prototyping. We recently developed an instrument that was so complex and large, it would have been unrealistic to make early explorative prototypes. However, integrating a low-cost frame, we worked with the client to reproduce the design in AR. By wearing a HoloLens, we could reach out and touch the design, capturing details we would never have seen in the CAD model.”

Additive Manufacturing

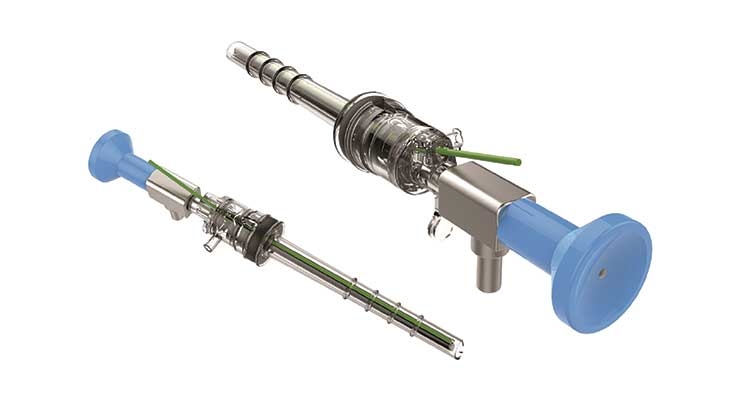

Additive manufacturing (AM) technologies continue to change the way medical devices are designed and developed, to the point where AM can be utilized in almost every stage of product development. AM speeds up rapid prototyping and, with lower-cost 3D polymer and metal printers, can reduce costs and shorten timelines. For production, AM tends to be the fastest and least-expensive way to create complex geometries at low volumes.

“AM materials and accuracy have come a long way, which further increase the attractiveness of these methods for certain applications,” said Scott Jarnagin, director of business development for Simplexity Product Development, a West-Coast-based engineering design firm specializing in hardware design for wearables, medical devices, and molecular diagnostic equipment. “For ultra-specific organic shapes that match the anatomy of a particular person—such as implantable devices—additive manufacturing is often the best option available.”

AM enables the creation of complex parts with undercuts and other complicated geometric features that cannot be manufactured using any other method. Direct metal laser sintering is a popular AM process for developing patient-specific devices and implants. The rough surface finish on sintered implant parts is ideal for facilitating osteointegration. Also, with AM or 3D printing, there is no set-up or tooling costs.

“Additive manufacturing is still a way off from replacing the high-volume speed of injection molding,” said Alden. “However, if you are running less than 500 parts, or need parts in a rapid timeframe, additive manufacturing can be attractive.”

Designing AM-manufactured products requires a development team that is highly experienced with these processes, especially regarding material behavior and variability. Because of the complex interaction of the materials during the additive manufacturing process, designers must fully understand material properties, as well as the best methods to ensure biocompatibility and sterility, if required.

“It is up to the design team to ensure that the required material properties and dimensional tolerances are compatible with the manufacturing method,” said Fine. “They must also employ inspection techniques and tools that ensure that each product manufactured meets its specified requirements. This often requires the use of novel 3D measurement and inspection tools.”

Ximedica has had success using AM for parts that were hard to make using traditional subtractive manufacturing processes—for example, small parts for surgical robotics. “However,” cautioned Najib, “unless the part can only be made with AM, subtractive manufacturing is still much faster compared to additive processes. Although subtractive requires more up-front programming time, the material removal rate is much faster than additive’s material addition rate.”

Taking this idea one step further, some companies want to have a 3D-printed device for its marketing value—even if they can make it easily with traditional methods. “I would caution that not everything needs to be additively manufactured, just because it can,” said Rowland. “Only do it if there is a true benefit, such as a manufacturing cost reduction or a geometry that can’t be fabricated any other way. Also question whether that geometry actually brings better clinical or performance results.”

Internet of Things (IoT)

IoT-connected devices are constantly evolving. Whether IoT is used for monitoring patients, inventory management, procedure logging, or other tasks, it streamlines the healthcare experience, optimizes quality, and improves patient outcomes. Designers and engineers need to monitor the marketplace to stay on top of emerging technologies, such as Bluetooth 5. For example, if wireless technology is desired, should it be Bluetooth, Wi-Fi, or some other radio protocol? Regardless, developing IoT devices requires a high level of integration among hardware, software, and database specialists.

“A huge diversity of skills is required to create an IoT product,” said Jarnagin. “From a practical standpoint, a company can only specialize in some of the skills required to design, develop, and ship a world-class IoT product. Typically, developers and engineers specialize in either the networking side or creating the hardware.”

IoT product designers require the following skills and experience:

IoT is still a rapidly developing technology. A top concern is cybersecurity and the risk of devices being hacked. Rowland indicates that it will take time for MDMs to embrace IoT and for product developers to understand and create the regulations needed to ensure safety and security.

“Kapstone Medical is currently working on a project with a wearable technology that will be continuously connected to the internet, and potentially other devices in the future, and it’s a bit uncharted territory,” said Rowland. “We are definitely pulling in partners to help think through design considerations, especially on the software side. The FDA is still working on guidelines for this topic, so I don’t think anyone has locked down best practices completely.”

IoT products require the same security requirements that other cloud-based applications do, including a comprehensive cybersecurity plan and appropriate architecture. Understanding compliance with the associated regulatory and privacy requirements is also essential, including the Health Insurance Portability and Accountability Act (HIPAA) and the General Data Protection Regulation (GDPR) in the EU.

“Connecting to the internet brings the issues of cybersecurity and HIPAA compliance front and foremost to the product design,” said Fine. “Our teams have needed to increase their capabilities regarding both hardware and software encryption techniques to ensure data security and compliance with new cybersecurity guidances.”

Designing for the Future

Medical device materials and manufacturing technologies will continue to advance, opening up new opportunities for engineers and designers. For example, biologics, hydrogels, and large-molecule therapies are becoming more prevalent—how these therapies can be delivered with minimal discomfort is a top design challenge. Although considerable research and development remains to be done, combined hydrogel/flexible electronic devices have potential as artificial muscle, cartilage, or drug delivery devices.

Designers must also keep up with technology advances in collection methods, non-invasive testing methods, wearables, advanced artificial intelligence, robotic surgery enhancements, and other applications. Smaller and more powerful sensors can detect potentially life-threatening situations and communicate essential data to physicians, enabling better diagnoses and expedited treatment options. For example, in December 2018, researchers at the Massachusetts Institute of Technology and Brigham and Women’s Hospital announced they had designed an ingestible capsule that is controlled using Bluetooth wireless technology. The capsule resides in the stomach for a month and can be customized to deliver drugs or measure and report on internal conditions—transmitting information and responding to instructions from a user’s smartphone.

Limitations on power transfer and management are continued problems in the world of electronic hardware. Technology advances continue to drive more efficient batteries and systems, and computational capability per watt of power is increasing rapidly. Major improvements have also been made in wireless power transfer, with more companies using very high frequency signals to transfer power over longer distances.

“For electronics system development, programmable system on chip technology allows for faster and less expensive design iterations,” said Fine. “Our development teams also use more computer simulation modeling and computer-controlled testing to expedite this process.”

Despite the pressure to develop and commercialize products very quickly, perhaps the most important aspect of medical device design is to slow down and take the time to fully embrace user research. Not only does this result in well-targeted, cost-effective medical innovations, it improves a company’s brand and market share.

“Many OEMs believe they need to rush to market to stay ahead of their competitors, but if they do not take user research seriously, they are also missing a grand opportunity to set a new bar for user experience, product configuration, user interface, and other critical aspects that can make or break an innovative device,” said Deros.

Forma Medical Device Design takes a similar holistic approach to design by paying attention to the entire ecosystem in which discrete products are used. Design teams can often find opportunities for clients to add value and extend their own offerings by developing products and services that are adjunct to the primary product. For example, a recent Forma client wanted to improve a device that was used in cosmetic dermatology. Through its user research, Forma discovered there were significant unmet needs in both the pre-operative phase and in the post-operative phase. “We developed a number of improvements for the device itself, but also provided the company with ways they could augment the device and increase revenue by expanding their product line,” said Stipe. “Procedural efficiency was enhanced—a big win for the provider—and recovery time was shortened, making it better for the patient.”

Huge conglomerates such as Alphabet (Google’s parent company) and Apple, which are entering the healthcare market, have the power to leverage huge amounts of data and artificial intelligence for developing medical products—something medical device firms cannot compete with. Of course, how this data is wielded, and how it might shift design trends in the future, is undetermined. There is no doubt, however, that analyzing the behavior of diseases and patient populations on a large scale will “bring us a better understanding of the means to produce products and methods that yield improved diagnostic and therapeutic outcomes,” said Fine. “It will be exciting to see how applying artificial intelligence to medical products may result in the design of adaptive devices and equipment that evolve and improve the performance of their functions over time.”

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.

A wide range of medical device companies, from Fortune 100 giants to high-tech startups, continue to push for innovative new medical devices—often with an emphasis on data capture, transmission, and analysis to provide user-friendly feedback on personal health.

“These companies understand that good design leads to improved usability,” said Tor Alden, a principal at HS Design, a Gladstone, N.J.-based medical design firm that provides full-service product development. “The FDA is also very focused on making sure OEMs document the use and usability of their devices, focusing on human factors. This trend has elevated both industrial design and user interface design to more strategic positions.”

Medical devices are becoming more personalized and merging with consumer products, a market with a greater emphasis on style, simplicity, and aesthetics. OEMs are therefore emphasizing ease of use when they talk with their engineers and designers. Even though the main driver for differentiation in the marketplace is more technology and higher functionality, there is also a mindset that believes in achieving the intended functionality in the easiest way by focusing on human factors and simple design—which also keeps costs down.

Justin Rowland, project manager for Kapstone Medical, a Charlotte, N.C.-based product development firm that commercializes new medical devices, has seen this trend toward simpler designs, which incorporate only the technology features and capabilities that are truly needed. “Simplicity will always be a timeless design principle, but I think medical devices and systems got more attention in the past when they were full of features and bells and whistles,” he said. “Now, with the increased popularity of health-related consumer devices, clinicians want medical devices that are simple and easy to use, with fewer steps.”

With this emphasis on personalization, it has never been more important to listen to the voice of the consumer when it comes to designing the ideal medical device solution. Customers continue to expect more from their medical products in terms of ergonomics, improved therapeutic and diagnostic outcomes, and connectivity to other devices and the cloud. Knowing exactly what their customers want gives medical device manufacturers (MDMs) a competitive edge in the marketplace—but it also requires a depth of consumer research that many have not undertaken.

“The medical device industry is struggling to incorporate consumer-type design technologies and elements in an environment with rapidly changing regulatory constraints,” said Kenneth Fine, president of Proven Process Medical Devices, a Mansfield, Mass.-based developer and manufacturer of complex and implanted electromechanical medical devices and equipment. “Design teams are being asked to address these challenges, while also reducing product development timelines as demanded by OEMs.”

Talking with the end user to determine product capabilities and features is essential for solving these challenges in a timely and cost-effective way. “We use our own internal research process to gather critical insights related to understanding current solutions and their issues, unboxing to set-up to disposal/sterilization, user interface challenges with display content and workflow, and grasping competitive product offerings,” said Yani Deros, president of ATOM Innovation + Product Development, a Scottsdale, Ariz.-based product development firm that works across a variety of markets, including medical devices and implants. “You can bet that if you aren’t talking to your customers, the competition is.”

Latest Trends

A major industry trend is the collaboration of medical, life science, and pharma companies to create innovative delivery systems for new medicines, driven in part by the push for personalized medicine and improved diagnostics instrumentation. An increasing number of point-of-care devices designed for home use to monitor and transmit valuable health information are coming into the market. Another hot sector is sensor-based flexible and wearable technologies.

The medical device industry tries to stay aligned with these rapidly evolving digital health and personalized medicine strategies. Connectivity and user-centric design are the key drivers. Technology and patient value streams are guiding product portfolio decisions. More emphasis is being placed on understanding how the data from a medical device or diagnostic instrument impacts patient treatment and reduce healthcare costs. For specific disease states, it is especially important to understand the various medical touchpoints during the patient’s journey.

“Assessing the value of the data, and how information integrates with third-party devices such as wearables is essential for success,” said Martha Najib, vice president of strategic marketing for Ximedica, a Los Gatos, Calif.-based provider of engineering services for diagnostics and medical devices. “Another factor to consider is the software in the device. From experience with clinical laboratory improvement amendments—waived products, the graphic user interface needs to be extremely intuitive. If the user gets frustrated, it’s likely the product will not be chosen.”

To personalize new products, OEMs are instructing their design partners to create meaningful user experiences, whether it is for physicians, clinicians, or patients. This requires a user interface that is simple, intuitive, and engaging to avoid misuse or errors. The medical device itself should not be intimidating or complex—instead it needs to be attractive to the eye, which may require special materials, colors, and finishes to make it stand out from the competition.

This is especially true for wearable devices, which are rapidly evolving, not only as healthcare devices, but also as fashion statements. Improved microelectromechanical system technologies create “tiny integrated electronics for wearable devices or systems,” said Deros. “These miniaturized solutions contain smaller, more powerful, and compact electronics that allow for more pliable or wearable devices that seamlessly integrate into people’s lives.”

“There is great interest in sensor technologies with wearable devices,” agreed Dan Stipe, director of industrial design for Forma Medical Device Design, a Raleigh, N.C.-based firm that specializes in medical devices and laboratory and scientific instrumentation. “Wearable devices and applications are prevalent in the fitness market, but their accuracy needs to be improved before they can be utilized for medical purposes. A number of companies are working on this.”

What OEMs Want

OEMs seek designs that yield the lowest reasonable commercial product cost with the highest degree of robustness. Forward-thinking OEMs realize that well-thought-out design can save money and increase sales in the long run, especially as devices become more complicated and more secular in nature. “Having four or five different devices working together during a surgical procedure is not uncommon,” said Alden. “Therefore, designs that are intuitive, compact, and cleanable are important.”

Designers and contract manufacturers also feel constant pressure from OEMs to reduce development times to ensure that narrow windows of opportunity are not missed. More new products are being designed to include features found in consumer products, such as intuitive graphical user interfaces, connectivity, and attractive looks. For some applications, new products must be miniaturized so they can be worn discreetly. Because OEMs are asking for a lot more from product design firms than in the past, most design firms have added additional capabilities. “For example, we now have research/human factors, user interface, industrial design, and engineering groups fully integrated into a collaborative organization,” said Alden.

OEMs want creative design features that resonate with customers, coupled with cost reduction and streamlined assembly to reduce build, testing, and servicing timeframes. Consumer opinion is also essential for designing products that reinforce the OEM’s brand and establish the company as a player in a category or market. “They understand that the product/innovation has to not only function reliably and repeatedly, but also be designed to be a differentiator in the marketplace that inspires users to purchase the device to improve the quality of their healthcare experience,” said Deros.

A top concern for OEMs is shorter development timelines to gain a competitive edge in the marketplace—which is often easier to do with products of simpler design. Shared platforms among devices can also save money and launch products faster. Many companies want quick prototype development of about two years from phase 0 to clinical trials, as well as low quantities of instruments manufactured locally to test the market, reliability, market stamina, low cost of goods sold, and regulatory ease. “For designing diagnostic instruments, it’s important to identify factors that allow your platform to be flexible and scalable in order to penetrate additional markets,” said Najib.

New Technology Trends

Machine learning and artificial intelligence technologies are making it easier to diagnose a variety of health conditions. “Augmented reality [AR] and virtual reality [VR] tools are the new game in town,” said Alden. “AR allows us to build models and capture user insights without physical prototyping. We recently developed an instrument that was so complex and large, it would have been unrealistic to make early explorative prototypes. However, integrating a low-cost frame, we worked with the client to reproduce the design in AR. By wearing a HoloLens, we could reach out and touch the design, capturing details we would never have seen in the CAD model.”

Additive Manufacturing

Additive manufacturing (AM) technologies continue to change the way medical devices are designed and developed, to the point where AM can be utilized in almost every stage of product development. AM speeds up rapid prototyping and, with lower-cost 3D polymer and metal printers, can reduce costs and shorten timelines. For production, AM tends to be the fastest and least-expensive way to create complex geometries at low volumes.

“AM materials and accuracy have come a long way, which further increase the attractiveness of these methods for certain applications,” said Scott Jarnagin, director of business development for Simplexity Product Development, a West-Coast-based engineering design firm specializing in hardware design for wearables, medical devices, and molecular diagnostic equipment. “For ultra-specific organic shapes that match the anatomy of a particular person—such as implantable devices—additive manufacturing is often the best option available.”

AM enables the creation of complex parts with undercuts and other complicated geometric features that cannot be manufactured using any other method. Direct metal laser sintering is a popular AM process for developing patient-specific devices and implants. The rough surface finish on sintered implant parts is ideal for facilitating osteointegration. Also, with AM or 3D printing, there is no set-up or tooling costs.

“Additive manufacturing is still a way off from replacing the high-volume speed of injection molding,” said Alden. “However, if you are running less than 500 parts, or need parts in a rapid timeframe, additive manufacturing can be attractive.”

Designing AM-manufactured products requires a development team that is highly experienced with these processes, especially regarding material behavior and variability. Because of the complex interaction of the materials during the additive manufacturing process, designers must fully understand material properties, as well as the best methods to ensure biocompatibility and sterility, if required.

“It is up to the design team to ensure that the required material properties and dimensional tolerances are compatible with the manufacturing method,” said Fine. “They must also employ inspection techniques and tools that ensure that each product manufactured meets its specified requirements. This often requires the use of novel 3D measurement and inspection tools.”

Ximedica has had success using AM for parts that were hard to make using traditional subtractive manufacturing processes—for example, small parts for surgical robotics. “However,” cautioned Najib, “unless the part can only be made with AM, subtractive manufacturing is still much faster compared to additive processes. Although subtractive requires more up-front programming time, the material removal rate is much faster than additive’s material addition rate.”

Taking this idea one step further, some companies want to have a 3D-printed device for its marketing value—even if they can make it easily with traditional methods. “I would caution that not everything needs to be additively manufactured, just because it can,” said Rowland. “Only do it if there is a true benefit, such as a manufacturing cost reduction or a geometry that can’t be fabricated any other way. Also question whether that geometry actually brings better clinical or performance results.”

Internet of Things (IoT)

IoT-connected devices are constantly evolving. Whether IoT is used for monitoring patients, inventory management, procedure logging, or other tasks, it streamlines the healthcare experience, optimizes quality, and improves patient outcomes. Designers and engineers need to monitor the marketplace to stay on top of emerging technologies, such as Bluetooth 5. For example, if wireless technology is desired, should it be Bluetooth, Wi-Fi, or some other radio protocol? Regardless, developing IoT devices requires a high level of integration among hardware, software, and database specialists.

“A huge diversity of skills is required to create an IoT product,” said Jarnagin. “From a practical standpoint, a company can only specialize in some of the skills required to design, develop, and ship a world-class IoT product. Typically, developers and engineers specialize in either the networking side or creating the hardware.”

IoT product designers require the following skills and experience:

- Sensors, sensor data fusion, and data processing algorithms

- Various wireless protocols and interfaces with remote apps

- Data encryption and security requirements

- Low-power, miniaturized electronics

- Hardware design for low-cost, high-volume processes

- Ruggedized, environmental mechanical design

IoT is still a rapidly developing technology. A top concern is cybersecurity and the risk of devices being hacked. Rowland indicates that it will take time for MDMs to embrace IoT and for product developers to understand and create the regulations needed to ensure safety and security.

“Kapstone Medical is currently working on a project with a wearable technology that will be continuously connected to the internet, and potentially other devices in the future, and it’s a bit uncharted territory,” said Rowland. “We are definitely pulling in partners to help think through design considerations, especially on the software side. The FDA is still working on guidelines for this topic, so I don’t think anyone has locked down best practices completely.”

IoT products require the same security requirements that other cloud-based applications do, including a comprehensive cybersecurity plan and appropriate architecture. Understanding compliance with the associated regulatory and privacy requirements is also essential, including the Health Insurance Portability and Accountability Act (HIPAA) and the General Data Protection Regulation (GDPR) in the EU.

“Connecting to the internet brings the issues of cybersecurity and HIPAA compliance front and foremost to the product design,” said Fine. “Our teams have needed to increase their capabilities regarding both hardware and software encryption techniques to ensure data security and compliance with new cybersecurity guidances.”

Designing for the Future

Medical device materials and manufacturing technologies will continue to advance, opening up new opportunities for engineers and designers. For example, biologics, hydrogels, and large-molecule therapies are becoming more prevalent—how these therapies can be delivered with minimal discomfort is a top design challenge. Although considerable research and development remains to be done, combined hydrogel/flexible electronic devices have potential as artificial muscle, cartilage, or drug delivery devices.

Designers must also keep up with technology advances in collection methods, non-invasive testing methods, wearables, advanced artificial intelligence, robotic surgery enhancements, and other applications. Smaller and more powerful sensors can detect potentially life-threatening situations and communicate essential data to physicians, enabling better diagnoses and expedited treatment options. For example, in December 2018, researchers at the Massachusetts Institute of Technology and Brigham and Women’s Hospital announced they had designed an ingestible capsule that is controlled using Bluetooth wireless technology. The capsule resides in the stomach for a month and can be customized to deliver drugs or measure and report on internal conditions—transmitting information and responding to instructions from a user’s smartphone.

Limitations on power transfer and management are continued problems in the world of electronic hardware. Technology advances continue to drive more efficient batteries and systems, and computational capability per watt of power is increasing rapidly. Major improvements have also been made in wireless power transfer, with more companies using very high frequency signals to transfer power over longer distances.

“For electronics system development, programmable system on chip technology allows for faster and less expensive design iterations,” said Fine. “Our development teams also use more computer simulation modeling and computer-controlled testing to expedite this process.”

Despite the pressure to develop and commercialize products very quickly, perhaps the most important aspect of medical device design is to slow down and take the time to fully embrace user research. Not only does this result in well-targeted, cost-effective medical innovations, it improves a company’s brand and market share.

“Many OEMs believe they need to rush to market to stay ahead of their competitors, but if they do not take user research seriously, they are also missing a grand opportunity to set a new bar for user experience, product configuration, user interface, and other critical aspects that can make or break an innovative device,” said Deros.

Forma Medical Device Design takes a similar holistic approach to design by paying attention to the entire ecosystem in which discrete products are used. Design teams can often find opportunities for clients to add value and extend their own offerings by developing products and services that are adjunct to the primary product. For example, a recent Forma client wanted to improve a device that was used in cosmetic dermatology. Through its user research, Forma discovered there were significant unmet needs in both the pre-operative phase and in the post-operative phase. “We developed a number of improvements for the device itself, but also provided the company with ways they could augment the device and increase revenue by expanding their product line,” said Stipe. “Procedural efficiency was enhanced—a big win for the provider—and recovery time was shortened, making it better for the patient.”

Huge conglomerates such as Alphabet (Google’s parent company) and Apple, which are entering the healthcare market, have the power to leverage huge amounts of data and artificial intelligence for developing medical products—something medical device firms cannot compete with. Of course, how this data is wielded, and how it might shift design trends in the future, is undetermined. There is no doubt, however, that analyzing the behavior of diseases and patient populations on a large scale will “bring us a better understanding of the means to produce products and methods that yield improved diagnostic and therapeutic outcomes,” said Fine. “It will be exciting to see how applying artificial intelligence to medical products may result in the design of adaptive devices and equipment that evolve and improve the performance of their functions over time.”

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.