Sam Brusco, Associate Editor09.07.18

The medical industry’s demands are continually challenging suppliers and manufacturers to stretch their technical competencies into areas where they may fear to tread. Doctors and surgeons urge instruments for less invasive procedures and quicker recovery times, devices are shrinking and becoming more complex, and designers seek out smaller, high-precision components with materials and tolerances that years ago were deemed impossible.

To further advance minimally invasive device designs and reduce part sizes, manufacturers are turning to micromolding. By definition, micromolding is an injection molding process, but the manufactured components require magnification to view details on or within the part. It can also be defined as parts with sizes or tolerances that are so small they are unable to be manufactured correctly with a high degree of precision using traditional injection molding equipment and standard thought processes. Micromolded parts usually weigh a gram or less, with a typical range from one gram to less than 0.004 grams. The required tolerances are often tighter than 0.0001 inches, or 2.54 microns.

It sounds outright impossible to ensure robustly manufactured parts with such an astronomically small scale to work with, but micromolders are constantly making it happen through specialized equipment and an enormous level of tooling precision. It is impressive to hear just how small some parts made via micromolding can be.

“The smallest part we have manufactured is 0.001 grams using silicone injection molding,” noted Peter Johnson, an applications development engineer focused on medical components at Saint-Gobain Performance Plastics’ Portage, Wis., facility. Saint-Gobain is a producer of engineered, high-performance polymer products. “There are three specific challenges for a part this size that come to mind. One is being able to come up with a reliable and reproducible measurement technique, particularly when cross-sections are required. The second is tooling design that allows for the ability to control such a small shot size with standard manufacturing equipment (micromolding equipment for silicone injection molding is relatively new and limited). The third challenge is part handling. Whether using automation or an operator, companies must learn the specialized techniques and designs to be able to manage such small parts.”

“To date, the smallest commercial part we have produced measures in at 0.00004173 grams,” said Aaron Johnson, vice president of marketing and customer strategy for Ankeny, Iowa-based Accumold, a manufacturer of precision micromolded plastic parts and components. “We also make another part at 0.00008848 grams, including an optic lens feature. There is certainly a significant undertaking when agreeing to build a tool and produce such minute parts correctly. Handling parts of this size is often even more difficult than the molding process.”

The push for part miniaturization has tested the limits of micromolders’ creativity, sometimes to the point where manufacturing solutions for the tiniest of molded parts have been invented during the development phase.

“Quite a few years ago, we molded a part that used 2.5 pounds of material to produce a million parts,” recalled Raghu Vadlamudi, chief research and technology director at Donatelle, a New Brighton, Minn.-based outsourcing services provider focused exclusively on the design, development, and manufacturing of medical devices. “That part was molded in a mold with the smallest sprue bushing, which is around 10 mm in length. Recently, we were quite successful in molding another part that weighs around a tenth of a milligram with feature sizes around 40 microns. We learned that sometimes the technology needed cannot be bought, but it can be invented while working on these projects.”

Applications for micromolded components range from ophthalmic, cardiac rhythm management, and audiologic components to short- and long-term implantable devices. The parts are also used in medical equipment necessitating extraordinarily small, precise components for external devices.

The optic lens feature Accumold’s Johnson mentioned seems to be a trend for record-breaking micromolded parts—the smallest parts most micromolders are constructing appear to be those for the ophthalmic industry. These may include—but are not limited to—intraocular lenses (IOLs) to improve vision, or drug delivery systems to treat eye disorders.

Miniaturization is vital when concerning temporary or permanent implants used in medical interventions in the eye. Drug delivery devices for use in the eye respond to the difficulties inherent in targeting drugs to the eye’s posterior segment—the blood-retina barrier limits drug diffusion from the systemic blood to the posterior segment. A solution emerged in polymeric sustained drug release systems for eye implantation.

“We fabricate a number of different micromolded components and micro extrusions in silicone for the ophthalmic industry,” explained Jeff Mohror, vice president and general manager of Freudenberg Medical, a Carpinteria, Calif.-based manufacturer of high-precision silicone and thermoplastic components and tubing as well as metal hypotubes and coating technology for the medical device and pharmaceutical industries. “Specifically, a product for dry eye therapy with an overall dimension of .050 x .030 inches and with features as small as .004 inches.”

“The smallest part we ever molded was an ophthalmic implant that weighed in around 0.00000316 grams, which equates to around one-twentieth the weight of a grain of salt,” commented Jon Clark, operations manager at MTD Micro Molding, a Charlton, Mass.-based micro-injection molder for the medical device industry.”

Manufacturing parts at that scale is as much an art as it is a science. Even with a shop full of specialized equipment, engineers at firms providing micromolding services must sometimes tinker with their machines to achieve the desired part size and geometry.

“I actually was the process engineer for the ophthalmic implant project and to even get the part to fill, I had to manually program the machine in an unconventional way,” recounted Peter Wojtas, a senior process engineer at MTD Micro Molding.

When it comes to micro manufacturing and implantable applications, the most vibrant sector for commercial applications appears to be IOLs. Typically used for cataracts or myopia treatment, they are most commonly manufactured from plastic and consist of a small plastic lens and two plastic side struts to hold the lens in place within the eye.

IOLs are implanted through incision holes sometimes as small as one millimeter. Today’s demand for increasingly minimally invasive procedures means micromolders are being tasked to manufacture products with potentially both surface structures at the nanometer level and aspheric designs with spherical and cylindrical shapes in differing axes. Micromolders are especially valuable in these cases, as OEMs seeking to commercialize ophthalmic drug delivery devices and IOLs may not have the necessary micro manufacturing equipment or expertise.

Not Simply Scaled-Down Molding

A successful micromolding project involves much more than a small injection molding press and a microscope. Specialty or custom equipment is a must to create accurate part geometries and tooling features in the micro scale. Every phase of the process must be engineered to manage the problems unique to making micro components.

“From beginning to end, it’s a different process. Unfortunately, most try to apply a simple brush stroke of ‘it’s just plastic molding,’” declared Scott Herbert, founder and president of Rapidwerks, a Pleasanton, Calif.-based plastics manufacturer specializing in precision micromolding. “However, they soon realize from tool design, to tool fabrication, to material control it is very different and specialized.”

Careful thought must be given toward many aspects—some of which are also considerations for macro-level molding projects—but some that are specific to the micro manufacturing realm. These considerations include resin selection, component design, equipment and molding processes, tooling construction, measuring equipment, component handling, and packaging. Many of these are standard practice in the injection molding industry, but micromolding necessitates specialized solutions to guarantee success and a satisfied OEM customer.

“Micromolding is defined in several ways, one of which is micro features on larger parts,” explained Donna Bibber, vice president of business development for Isometric Micro Molding, a New Richmond, Wis.-based micromolding company that provides medical and drug delivery OEMs with micromolded and automated assemblies. “In this case, both the beginning and the end of the process requires ultra-precision and micro expertise. For example, microfluidic devices can be the size of a quarter; however, they have channels and features for capillary action that need micro tooling (mold making) at the beginning of the program and micro metrology to measure the micron-sized features at the end of the program. In the middle (molding), micron isn’t truly required, however, the risk is high on both ends of the program so OEMs would select a micromolder before selecting a macro molder to mitigate these risks.”

“There are two approaches to micromolding,” said Saint-Gobain’s Johnson. “ The first is to utilize new equipment, which while fundamentally the same as traditional molding equipment, is designed to have finer resolution specifically for micromolding. The second approach is to utilize existing equipment, and novel tooling and fixturing, to create finer control over the injection molding and part handling process.”

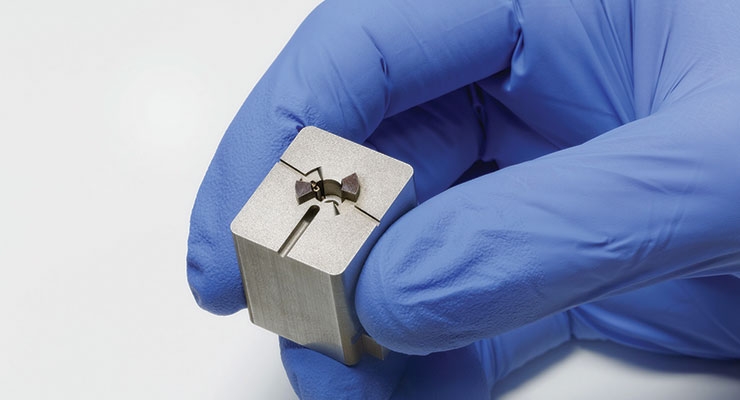

Tool construction is integral to successful micromolding. Traditional, time-tested tool construction methods can generate issues when tolerances and geometries are microscopic and critical. This may be the most crucial phase of development; it’s imperative to manufacture the tooling using processes that can fabricate fine, sharp corners, very flat surfaces, and complex geometries. These prerequisites do not come standard with molding equipment or tooling.

“When it comes to tooling, the micromolding process is as good as the mold being used,” said Vadlamudi. “The mold has to be built to exact dimensions because of small feature sizes. This necessitates using advanced micromachining techniques along with conventional micromachining techniques.”

“Tolerances that would be acceptable for standard molds cannot be applied to micromolding. This goes beyond pure manufacturing precision,” Mohror added. “Important considerations include parting line offset and alignment features as well as docking features for end of arm tools. All of this has to be considered in the tool design.”

Molding tools used in micro manufacturing generally consist of a micro-structured mold insert, as well as the tool. This separation does not exist in macroscopic molding technology, due to completely different requirements the micro structure and tool must meet.

For example, the micromolding tool has to execute the traditional tasks of encapsulating the polymer and ejecting the molded parts. It must also provide for a vacuum and undergo a variotherm process. Evacuated tools are also required in micromolding because the micro structures form pocket holes air cannot escape from when the polymer is filled in. The structure has to be empty from the beginning, and mold inserts must be heated above the glass transition temperature so the tiny amount of material processed doesn’t immediately solidify when coming in contact with the mold insert’s large mass.

“At the scale and level of complexity we work in, the tool construction needs to be broken down into building multiple inserts (like a jigsaw puzzle) so we can vent all of the thin features,” advised Clark. “The molding equipment is not off-the-shelf equipment. Extensive updates to the injection units are made in-house to achieve higher injection speeds and pressures that allow micro features to fill more effectively.”

The mold insert must also provide for the primary micro structure and is therefore manufactured with that in mind. The micro structure should exhibit smooth side walls to prevent friction during demolding, and a small inclination angle—if it can be tolerated by the application of the micro structures to be molded—is ideal.

“The management of the relationship between material, geometry, and the tool build for micromolding is critically important,” stated Accumold’s Johnson. “There is no shortcut to learn how each component works together. When dialing in a few microns or pushing the limits of size and features, the system and practices used matter. If micromolding was simply big molding made smaller, everyone would be doing it.”

Micro-Management

Once the molded component is completed, it must of course be verified to be acceptable. Micromolders must then carefully select and perhaps invest in metrology and measurement systems to provide the necessary data to be sure the part is adequate. Calipers and micrometers won’t be enough in this situation—the inspection equipment absolutely must have the ability to measure minuscule dimensions, with the tiniest tolerances, and demand Gage Repeatability & Reproducibility results better than 10 percent.

“Dedicated inspection equipment is essential when measuring micro parts with very small tolerances,” Mohror recommended. “We also have automated inspection systems integrated into the molding equipment, allowing any defects to be sorted out immediately. Automated visual control and stringent quality checks are essential to all molding operations.”

Over the past few years, metrology and measurement systems have come a long way. Laser scanners, CT scanning, and non-contact optical vision systems are readily available and offer packages that can be customized and programmed for micromolding projects. Because of the incredibly small scale and tight tolerance involved in micro manufacturing, micromolders consider on-site inspection equipment a must-have.

“One of the growing trends in our industry is to use a combination of CT or laser scanning and optical measurement systems to be able to meet the demands of the market,” declared Saint-Gobain’s Johnson. “The challenge with micromolded products is not so much their size, but the extremely tight tolerances associated with the products. Having inspection equipment with very fine resolution, and the ability to program the equipment to get repeatable and reproducible results, is the key to being a successful supplier.”

“Among various part inspection capabilities, we utilize polymer characterization equipment such as Differential Scanning Calorimetry, Gas Chromatography, and Intrinsic Viscosity (IV) Testing that offer quintessential insight for our research and development goals,” said Patrick Haney, a research and development engineer at MTD Micro Molding. “By extending our understanding of our customer’s products beyond physical inspection and mechanical properties, we are able to understand degradation, thermal, and even molecular behavior of these materials.”

IV is the measure of a polymer’s weight and reflects its melting point, crystallinity, and tensile strength. Resin with the appropriate IV should always be used during molding to ensure processability and final product specification are within the desired range. The molding process can also impact the final product’s IV, so equipment to assess it is crucial to have in the shop.

“Having real-time IV data available to our team while running a molding study is extremely helpful to verify we are maintaining the part quality through the development process,” advised Brendan Finnegan, a process development specialist at MTD. “Sending out parts for testing at a lab takes multiple days and can extend a project timeline. For the amount of IV testing we perform through a bioabsorbable validation process, having this equipment in-house is essential.”

Housing the right equipment is merely the first step to take in developing a robust and repeatable quality plan for micromolded components. A stringent quality plan is integral for medical manufacturing of any kind, but it is especially important for micro manufacturers to validate their parts effectively and efficiently.

“If a customer asked for a part 2mm in length with features of 250 microns and a +/- 3-micron tolerance, we plan to consistently prove it possible,” noted Accumold’s Johnson. “This means any project should have a set quality plan with the customer before steel is cut. If additional in-line inspection or automation is required, that will need to be known upfront as well. It would certainly be a challenge for anyone to provide quality micromolded parts without the essential inspection and vision systems to note the details of the work at hand.”

Isometric Micro Molding’s Microns Matter™ process is one such example of an end-to-end, best-practice risk assessment strategy for the development and high-volume production of critical-to-function micromolded devices. It follows a Japanese-like approach—essentially “plan, plan, plan, execute”—to accurately estimate percentage tolerance risks and mitigate them at each phase of the process. The process’s phases include ultra-precision tooling, metrology, material drying, material lot to lot variation, and the micro injection molding process.

“In this process, and the mold tolerances are built to 20 percent or less of the tolerance, leaving 80 percent for the rest of the process,” explained Bibber, who developed the Microns MatterTM process. “Keep in mind, this is 20 percent regardless of tolerance, so if the part tolerances are (±8 microns) 16 microns total, the tool must be built to 4 micron (0.00012”) tolerances to provide ‘room’ for success in the processes down the road.”

“The next factor in the process is Gage R&R,” she went on. “In micromolding, it’s common to hear ‘you can’t make it if you can’t measure it.’ Microns Matter™ takes this one step further to say ‘you can’t make it if you can’t validate it.’ Validating to micron tolerances requires an accurate and point of use feedback loop to the micromolding process variables being attempted. CT scanning provides an STL ‘view’ of every dimension in every plane and datum on the drawing within 10 minutes of molding it. This extremely accurate and measurable file allows process and project technicians to accurately dial in the micro molding process. Generally speaking, the remaining 60 percent of the tolerances is spread between the molding process, material lot-to-lot variation, hygroscopicity of the material, and just basic hysteresis of the process.”

Tiny Parts, Enormous Potential

As the demand for minimally invasive procedures and shortened recovery times continues, medical devices will continue to shrink. Patients will want wearable devices to be user-friendly and easily concealable, and device makers will continue to strive to add more features or embedded electronics into their products. This will put further strain on micromolders for smaller products, tolerance, and wall thicknesses, as well as the rising need to demonstrate process capabilities that can control the production of complex components.

“There is a general trend toward miniaturization,” observed Mohror. “We anticipate the opportunities in micromolding only to increase, particularly in the areas of the human body that require very small devices—the eyes for example.”

The “eyes” of part inspection must also progress. Successful micromolding endeavors require both robust solutions and risk mitigation strategies to evaluate micromolded parts. Bibber stressed the importance of additional tools to handle the large amounts of data generated during component validation. The ability to “dial in” processes is important for OEM customers as well as micro device contract manufacturers.

“As devices decrease in size and tolerance, the importance of singular microns becomes more critical to detect and analyze,” she noted. “Software tools for data and algorithmic design of experiments, coupled with CT scanning point cloud data during validation, will be key to both visually and quantifiably validating future micro devices.”

Whether the molding material is thermoplastic, silicone, metal powder, or some heretofore unheard of hybrid material, tooling design is critical to success. As of today, micro machining is the enabling technology to create the hair-sized core pins and micro channels and cavities.

“I expect to see big changes in tooling schemes, in addition to smaller and smaller features being created outside the wire and sinker world—more so directly to the production tool and in record times,” predicted Herbert.

In addition to the devices themselves, micromolders also hope for the miniaturization trend to extend to the injection molding equipment itself. (After all, if 3D printers can comfortably fit on a table-top, why not molding machines?) Further, nearly every industry has experienced the impact of automation. Automated tools and robotics in the injection molding industry would help boost speed, accuracy, agility, and adaptability, allowing for significant production increases. Even when working with low- to mid-volume parts, automation can improve cost and labor efficiency.

“I would like to see table-top injection molding equipment—particularly in the silicone injection molding market—as well as specialization from automation vendors in the integration and handling of micromolded products with new and existing machines,” expressed Saint-Gobain’s Johnson.

Cavity pressure control during filling, packing, and the cooling phases of plastic injection molding is imperative to maintain product quality during the injection molding process. For macro injection molded parts, cavity pressure monitoring can be employed to spot any process deviation—sometimes with real-time detection.

However, with molds used to make parts that are sized at millimeters or less, the sensor technology isn’t there yet. Sensors sized in the millimeter range do exist, but keep in mind that to be incorporated in a micromold cavity, there will likely need to be multiple sensors to accommodate a potentially complex geometry. Those sensors would presumably need to be at the micron size. It sounds like an impossibility, but then again, so did micron-sized molded components at one point.

“The more we understand cavity control within our processes, the better off the micromolding industry will become,” declared Haney. “Currently, many of the products we manufacture are too small to incorporate cavity sensors into the molds, which forces us to use alternative molding techniques to maintain cavity control. However, the development of technology small enough to accurately track mold cavity pressures (along with injection equipment precise enough to manipulate cavity conditions) would greatly benefit the micromolding industry.”

The chief sentiment among micromolders reflects their pioneering spirit: Making an “impossible” manufacturing project seem not only possible, but feasible enough to guarantee repeat business for micromolders, many of which will be novel projects.

“We do not anticipate that customers will want to stop shrinking their devices any time soon,” forecasted Accumold’s Johnson. “Often, today’s devices do not look like they can be made more efficient or compact, but one small breakthrough in technology can change the landscape entirely. In some circumstances, a new industry is born. We are dedicated to pushing the limits of micro injection molding wherever our customers ask.”

To further advance minimally invasive device designs and reduce part sizes, manufacturers are turning to micromolding. By definition, micromolding is an injection molding process, but the manufactured components require magnification to view details on or within the part. It can also be defined as parts with sizes or tolerances that are so small they are unable to be manufactured correctly with a high degree of precision using traditional injection molding equipment and standard thought processes. Micromolded parts usually weigh a gram or less, with a typical range from one gram to less than 0.004 grams. The required tolerances are often tighter than 0.0001 inches, or 2.54 microns.

It sounds outright impossible to ensure robustly manufactured parts with such an astronomically small scale to work with, but micromolders are constantly making it happen through specialized equipment and an enormous level of tooling precision. It is impressive to hear just how small some parts made via micromolding can be.

“The smallest part we have manufactured is 0.001 grams using silicone injection molding,” noted Peter Johnson, an applications development engineer focused on medical components at Saint-Gobain Performance Plastics’ Portage, Wis., facility. Saint-Gobain is a producer of engineered, high-performance polymer products. “There are three specific challenges for a part this size that come to mind. One is being able to come up with a reliable and reproducible measurement technique, particularly when cross-sections are required. The second is tooling design that allows for the ability to control such a small shot size with standard manufacturing equipment (micromolding equipment for silicone injection molding is relatively new and limited). The third challenge is part handling. Whether using automation or an operator, companies must learn the specialized techniques and designs to be able to manage such small parts.”

“To date, the smallest commercial part we have produced measures in at 0.00004173 grams,” said Aaron Johnson, vice president of marketing and customer strategy for Ankeny, Iowa-based Accumold, a manufacturer of precision micromolded plastic parts and components. “We also make another part at 0.00008848 grams, including an optic lens feature. There is certainly a significant undertaking when agreeing to build a tool and produce such minute parts correctly. Handling parts of this size is often even more difficult than the molding process.”

The push for part miniaturization has tested the limits of micromolders’ creativity, sometimes to the point where manufacturing solutions for the tiniest of molded parts have been invented during the development phase.

“Quite a few years ago, we molded a part that used 2.5 pounds of material to produce a million parts,” recalled Raghu Vadlamudi, chief research and technology director at Donatelle, a New Brighton, Minn.-based outsourcing services provider focused exclusively on the design, development, and manufacturing of medical devices. “That part was molded in a mold with the smallest sprue bushing, which is around 10 mm in length. Recently, we were quite successful in molding another part that weighs around a tenth of a milligram with feature sizes around 40 microns. We learned that sometimes the technology needed cannot be bought, but it can be invented while working on these projects.”

Applications for micromolded components range from ophthalmic, cardiac rhythm management, and audiologic components to short- and long-term implantable devices. The parts are also used in medical equipment necessitating extraordinarily small, precise components for external devices.

The optic lens feature Accumold’s Johnson mentioned seems to be a trend for record-breaking micromolded parts—the smallest parts most micromolders are constructing appear to be those for the ophthalmic industry. These may include—but are not limited to—intraocular lenses (IOLs) to improve vision, or drug delivery systems to treat eye disorders.

Miniaturization is vital when concerning temporary or permanent implants used in medical interventions in the eye. Drug delivery devices for use in the eye respond to the difficulties inherent in targeting drugs to the eye’s posterior segment—the blood-retina barrier limits drug diffusion from the systemic blood to the posterior segment. A solution emerged in polymeric sustained drug release systems for eye implantation.

“We fabricate a number of different micromolded components and micro extrusions in silicone for the ophthalmic industry,” explained Jeff Mohror, vice president and general manager of Freudenberg Medical, a Carpinteria, Calif.-based manufacturer of high-precision silicone and thermoplastic components and tubing as well as metal hypotubes and coating technology for the medical device and pharmaceutical industries. “Specifically, a product for dry eye therapy with an overall dimension of .050 x .030 inches and with features as small as .004 inches.”

“The smallest part we ever molded was an ophthalmic implant that weighed in around 0.00000316 grams, which equates to around one-twentieth the weight of a grain of salt,” commented Jon Clark, operations manager at MTD Micro Molding, a Charlton, Mass.-based micro-injection molder for the medical device industry.”

Manufacturing parts at that scale is as much an art as it is a science. Even with a shop full of specialized equipment, engineers at firms providing micromolding services must sometimes tinker with their machines to achieve the desired part size and geometry.

“I actually was the process engineer for the ophthalmic implant project and to even get the part to fill, I had to manually program the machine in an unconventional way,” recounted Peter Wojtas, a senior process engineer at MTD Micro Molding.

When it comes to micro manufacturing and implantable applications, the most vibrant sector for commercial applications appears to be IOLs. Typically used for cataracts or myopia treatment, they are most commonly manufactured from plastic and consist of a small plastic lens and two plastic side struts to hold the lens in place within the eye.

IOLs are implanted through incision holes sometimes as small as one millimeter. Today’s demand for increasingly minimally invasive procedures means micromolders are being tasked to manufacture products with potentially both surface structures at the nanometer level and aspheric designs with spherical and cylindrical shapes in differing axes. Micromolders are especially valuable in these cases, as OEMs seeking to commercialize ophthalmic drug delivery devices and IOLs may not have the necessary micro manufacturing equipment or expertise.

Not Simply Scaled-Down Molding

A successful micromolding project involves much more than a small injection molding press and a microscope. Specialty or custom equipment is a must to create accurate part geometries and tooling features in the micro scale. Every phase of the process must be engineered to manage the problems unique to making micro components.

“From beginning to end, it’s a different process. Unfortunately, most try to apply a simple brush stroke of ‘it’s just plastic molding,’” declared Scott Herbert, founder and president of Rapidwerks, a Pleasanton, Calif.-based plastics manufacturer specializing in precision micromolding. “However, they soon realize from tool design, to tool fabrication, to material control it is very different and specialized.”

Careful thought must be given toward many aspects—some of which are also considerations for macro-level molding projects—but some that are specific to the micro manufacturing realm. These considerations include resin selection, component design, equipment and molding processes, tooling construction, measuring equipment, component handling, and packaging. Many of these are standard practice in the injection molding industry, but micromolding necessitates specialized solutions to guarantee success and a satisfied OEM customer.

“Micromolding is defined in several ways, one of which is micro features on larger parts,” explained Donna Bibber, vice president of business development for Isometric Micro Molding, a New Richmond, Wis.-based micromolding company that provides medical and drug delivery OEMs with micromolded and automated assemblies. “In this case, both the beginning and the end of the process requires ultra-precision and micro expertise. For example, microfluidic devices can be the size of a quarter; however, they have channels and features for capillary action that need micro tooling (mold making) at the beginning of the program and micro metrology to measure the micron-sized features at the end of the program. In the middle (molding), micron isn’t truly required, however, the risk is high on both ends of the program so OEMs would select a micromolder before selecting a macro molder to mitigate these risks.”

“There are two approaches to micromolding,” said Saint-Gobain’s Johnson. “ The first is to utilize new equipment, which while fundamentally the same as traditional molding equipment, is designed to have finer resolution specifically for micromolding. The second approach is to utilize existing equipment, and novel tooling and fixturing, to create finer control over the injection molding and part handling process.”

Tool construction is integral to successful micromolding. Traditional, time-tested tool construction methods can generate issues when tolerances and geometries are microscopic and critical. This may be the most crucial phase of development; it’s imperative to manufacture the tooling using processes that can fabricate fine, sharp corners, very flat surfaces, and complex geometries. These prerequisites do not come standard with molding equipment or tooling.

“When it comes to tooling, the micromolding process is as good as the mold being used,” said Vadlamudi. “The mold has to be built to exact dimensions because of small feature sizes. This necessitates using advanced micromachining techniques along with conventional micromachining techniques.”

“Tolerances that would be acceptable for standard molds cannot be applied to micromolding. This goes beyond pure manufacturing precision,” Mohror added. “Important considerations include parting line offset and alignment features as well as docking features for end of arm tools. All of this has to be considered in the tool design.”

Molding tools used in micro manufacturing generally consist of a micro-structured mold insert, as well as the tool. This separation does not exist in macroscopic molding technology, due to completely different requirements the micro structure and tool must meet.

For example, the micromolding tool has to execute the traditional tasks of encapsulating the polymer and ejecting the molded parts. It must also provide for a vacuum and undergo a variotherm process. Evacuated tools are also required in micromolding because the micro structures form pocket holes air cannot escape from when the polymer is filled in. The structure has to be empty from the beginning, and mold inserts must be heated above the glass transition temperature so the tiny amount of material processed doesn’t immediately solidify when coming in contact with the mold insert’s large mass.

“At the scale and level of complexity we work in, the tool construction needs to be broken down into building multiple inserts (like a jigsaw puzzle) so we can vent all of the thin features,” advised Clark. “The molding equipment is not off-the-shelf equipment. Extensive updates to the injection units are made in-house to achieve higher injection speeds and pressures that allow micro features to fill more effectively.”

The mold insert must also provide for the primary micro structure and is therefore manufactured with that in mind. The micro structure should exhibit smooth side walls to prevent friction during demolding, and a small inclination angle—if it can be tolerated by the application of the micro structures to be molded—is ideal.

“The management of the relationship between material, geometry, and the tool build for micromolding is critically important,” stated Accumold’s Johnson. “There is no shortcut to learn how each component works together. When dialing in a few microns or pushing the limits of size and features, the system and practices used matter. If micromolding was simply big molding made smaller, everyone would be doing it.”

Micro-Management

Once the molded component is completed, it must of course be verified to be acceptable. Micromolders must then carefully select and perhaps invest in metrology and measurement systems to provide the necessary data to be sure the part is adequate. Calipers and micrometers won’t be enough in this situation—the inspection equipment absolutely must have the ability to measure minuscule dimensions, with the tiniest tolerances, and demand Gage Repeatability & Reproducibility results better than 10 percent.

“Dedicated inspection equipment is essential when measuring micro parts with very small tolerances,” Mohror recommended. “We also have automated inspection systems integrated into the molding equipment, allowing any defects to be sorted out immediately. Automated visual control and stringent quality checks are essential to all molding operations.”

Over the past few years, metrology and measurement systems have come a long way. Laser scanners, CT scanning, and non-contact optical vision systems are readily available and offer packages that can be customized and programmed for micromolding projects. Because of the incredibly small scale and tight tolerance involved in micro manufacturing, micromolders consider on-site inspection equipment a must-have.

“One of the growing trends in our industry is to use a combination of CT or laser scanning and optical measurement systems to be able to meet the demands of the market,” declared Saint-Gobain’s Johnson. “The challenge with micromolded products is not so much their size, but the extremely tight tolerances associated with the products. Having inspection equipment with very fine resolution, and the ability to program the equipment to get repeatable and reproducible results, is the key to being a successful supplier.”

“Among various part inspection capabilities, we utilize polymer characterization equipment such as Differential Scanning Calorimetry, Gas Chromatography, and Intrinsic Viscosity (IV) Testing that offer quintessential insight for our research and development goals,” said Patrick Haney, a research and development engineer at MTD Micro Molding. “By extending our understanding of our customer’s products beyond physical inspection and mechanical properties, we are able to understand degradation, thermal, and even molecular behavior of these materials.”

IV is the measure of a polymer’s weight and reflects its melting point, crystallinity, and tensile strength. Resin with the appropriate IV should always be used during molding to ensure processability and final product specification are within the desired range. The molding process can also impact the final product’s IV, so equipment to assess it is crucial to have in the shop.

“Having real-time IV data available to our team while running a molding study is extremely helpful to verify we are maintaining the part quality through the development process,” advised Brendan Finnegan, a process development specialist at MTD. “Sending out parts for testing at a lab takes multiple days and can extend a project timeline. For the amount of IV testing we perform through a bioabsorbable validation process, having this equipment in-house is essential.”

Housing the right equipment is merely the first step to take in developing a robust and repeatable quality plan for micromolded components. A stringent quality plan is integral for medical manufacturing of any kind, but it is especially important for micro manufacturers to validate their parts effectively and efficiently.

“If a customer asked for a part 2mm in length with features of 250 microns and a +/- 3-micron tolerance, we plan to consistently prove it possible,” noted Accumold’s Johnson. “This means any project should have a set quality plan with the customer before steel is cut. If additional in-line inspection or automation is required, that will need to be known upfront as well. It would certainly be a challenge for anyone to provide quality micromolded parts without the essential inspection and vision systems to note the details of the work at hand.”

Isometric Micro Molding’s Microns Matter™ process is one such example of an end-to-end, best-practice risk assessment strategy for the development and high-volume production of critical-to-function micromolded devices. It follows a Japanese-like approach—essentially “plan, plan, plan, execute”—to accurately estimate percentage tolerance risks and mitigate them at each phase of the process. The process’s phases include ultra-precision tooling, metrology, material drying, material lot to lot variation, and the micro injection molding process.

“In this process, and the mold tolerances are built to 20 percent or less of the tolerance, leaving 80 percent for the rest of the process,” explained Bibber, who developed the Microns MatterTM process. “Keep in mind, this is 20 percent regardless of tolerance, so if the part tolerances are (±8 microns) 16 microns total, the tool must be built to 4 micron (0.00012”) tolerances to provide ‘room’ for success in the processes down the road.”

“The next factor in the process is Gage R&R,” she went on. “In micromolding, it’s common to hear ‘you can’t make it if you can’t measure it.’ Microns Matter™ takes this one step further to say ‘you can’t make it if you can’t validate it.’ Validating to micron tolerances requires an accurate and point of use feedback loop to the micromolding process variables being attempted. CT scanning provides an STL ‘view’ of every dimension in every plane and datum on the drawing within 10 minutes of molding it. This extremely accurate and measurable file allows process and project technicians to accurately dial in the micro molding process. Generally speaking, the remaining 60 percent of the tolerances is spread between the molding process, material lot-to-lot variation, hygroscopicity of the material, and just basic hysteresis of the process.”

Tiny Parts, Enormous Potential

As the demand for minimally invasive procedures and shortened recovery times continues, medical devices will continue to shrink. Patients will want wearable devices to be user-friendly and easily concealable, and device makers will continue to strive to add more features or embedded electronics into their products. This will put further strain on micromolders for smaller products, tolerance, and wall thicknesses, as well as the rising need to demonstrate process capabilities that can control the production of complex components.

“There is a general trend toward miniaturization,” observed Mohror. “We anticipate the opportunities in micromolding only to increase, particularly in the areas of the human body that require very small devices—the eyes for example.”

The “eyes” of part inspection must also progress. Successful micromolding endeavors require both robust solutions and risk mitigation strategies to evaluate micromolded parts. Bibber stressed the importance of additional tools to handle the large amounts of data generated during component validation. The ability to “dial in” processes is important for OEM customers as well as micro device contract manufacturers.

“As devices decrease in size and tolerance, the importance of singular microns becomes more critical to detect and analyze,” she noted. “Software tools for data and algorithmic design of experiments, coupled with CT scanning point cloud data during validation, will be key to both visually and quantifiably validating future micro devices.”

Whether the molding material is thermoplastic, silicone, metal powder, or some heretofore unheard of hybrid material, tooling design is critical to success. As of today, micro machining is the enabling technology to create the hair-sized core pins and micro channels and cavities.

“I expect to see big changes in tooling schemes, in addition to smaller and smaller features being created outside the wire and sinker world—more so directly to the production tool and in record times,” predicted Herbert.

In addition to the devices themselves, micromolders also hope for the miniaturization trend to extend to the injection molding equipment itself. (After all, if 3D printers can comfortably fit on a table-top, why not molding machines?) Further, nearly every industry has experienced the impact of automation. Automated tools and robotics in the injection molding industry would help boost speed, accuracy, agility, and adaptability, allowing for significant production increases. Even when working with low- to mid-volume parts, automation can improve cost and labor efficiency.

“I would like to see table-top injection molding equipment—particularly in the silicone injection molding market—as well as specialization from automation vendors in the integration and handling of micromolded products with new and existing machines,” expressed Saint-Gobain’s Johnson.

Cavity pressure control during filling, packing, and the cooling phases of plastic injection molding is imperative to maintain product quality during the injection molding process. For macro injection molded parts, cavity pressure monitoring can be employed to spot any process deviation—sometimes with real-time detection.

However, with molds used to make parts that are sized at millimeters or less, the sensor technology isn’t there yet. Sensors sized in the millimeter range do exist, but keep in mind that to be incorporated in a micromold cavity, there will likely need to be multiple sensors to accommodate a potentially complex geometry. Those sensors would presumably need to be at the micron size. It sounds like an impossibility, but then again, so did micron-sized molded components at one point.

“The more we understand cavity control within our processes, the better off the micromolding industry will become,” declared Haney. “Currently, many of the products we manufacture are too small to incorporate cavity sensors into the molds, which forces us to use alternative molding techniques to maintain cavity control. However, the development of technology small enough to accurately track mold cavity pressures (along with injection equipment precise enough to manipulate cavity conditions) would greatly benefit the micromolding industry.”

The chief sentiment among micromolders reflects their pioneering spirit: Making an “impossible” manufacturing project seem not only possible, but feasible enough to guarantee repeat business for micromolders, many of which will be novel projects.

“We do not anticipate that customers will want to stop shrinking their devices any time soon,” forecasted Accumold’s Johnson. “Often, today’s devices do not look like they can be made more efficient or compact, but one small breakthrough in technology can change the landscape entirely. In some circumstances, a new industry is born. We are dedicated to pushing the limits of micro injection molding wherever our customers ask.”