Bruce Sargeant, Dr. Andreas Faulstich and Brian Jarvis05.17.10

Development time for a large-scale diagnostic system generally is measured in years. Consequently, reducing that time period by half (or more) is a significant achievement. Reducing the costs associated with that time-savings can be even more impressive. Since speed to market and competitive cost structures are primary drivers when it comes to outsourcing the development of a diagnostic instrument or other medical devices, more in-vitro diagnostic (IVD) OEMs are considering platform technology. By exploiting the fact that many instruments share the basic building blocks with regard to both hardware and software, a manufacturer can repurpose a foundation that is proven and validated and spend development dollars on the functionality or feature that makes the instrument unique. With the availability of a virtual library of basic, certified components that are scalable and updateable, platform technology has changed the way many IVD OEMs do business.

While this article concentrates primarily on IVD clinical instrumentation, it is important to note that platform technology solutions are developed to fit not only specific in-vitro diagnostics applications (the "vertical" approach), but also to fulfill the completely different requirements of other medical market segments, as well as other industries (the "horizontal" approach).All systems are designed and developed on the lowest level possible to allow for the highest vertical and horizontal integration.For example, a platform solution can provide the fundamental design of a ventilation system for pharma research or even service tools, as well as a high-end, clinical-chemistry diagnostic system or molecular or immunology instrumentation. In addition to improved time to completion and cost, the OEMs (in all industries) receive the same benefits of an easy customization path for new instrumentation/system designs and a higher economy of scale due to the multiple reuse of standard components.

Today, more medical professionals around the world turn to large-scale diagnostic systems as well as small-scale, point-of-care (POC) diagnostic platforms and compact medical devices (CMDs) to provide reliable answers to common laboratory tests so that patients can receive appropriate treatment quickly. Large-scale diagnostic systems are used extensively in hospitals, blood banks, forensic science, research, or in centralized laboratories, which may process thousands of samples per day. Modern medicine and scientific research rely heavily on assay diagnostics for detection of disease. A broad range of diagnostic assays are available, ranging from mass tests analyzing glucose, hemoglobin and coagulation, to other more customized panels that are designed to detect infectious diseases or identify very specific DNA-based conditions. Increasing economic pressures drive the need for affordable, highly reliable, high-throughput, automated IVD analyzers that represent the most cost-efficient processes for less time-critical laboratory tests.

In many medical situations, however, time is not always an affordable luxury. The critical demand for immediacy is a primary driver for the development of the POC/CMD platform-a small-scale (often portable )diagnostic platform that offers high sensitivity, accuracy, rapid turnaround and ease of use. Another driver of the popularity of POC devices is the cost efficiency of the small-scale device with regard to specialized tests. Rather than sending a sample out to a centralized lab using a high-volume, mass-sample-test device, the medical professional uses a low-throughput device that provides more rapid results at a lower cost. Not unexpectedly, POC devices are in high demand within doctors' offices located far from city labs.In addition to the convenience factor, there are many tests-such as blood gas-where samples simply cannot be sent away for testing due to their rapid deterioration. Finally, the miniaturization of certain specialized instruments enables many common tests to be performed by the patient, often with a pocket-sized instrument.

Whether it is used by a patient at home to maintain proper blood sugar levels or in a doctor's office in a remote village to diagnose a potentially serious disease, POC systems are becoming increasingly crucial to patient care. These systems are capable of determining a multitude of variables (such as blood glucose, hemoglobin, DNA, blood gases or coagulation factors) from blood, urine, saliva and/or other bodily fluids.

Development and manufacture of an IVD system requires much specialized knowledge, a qualified, experienced interdisciplinary team sporting a variety of scientific and technical disciplines, a fully equipped laboratory/development facility, and, in the best case scenario, an integrated manufacturing arm.

Due to the highly complex nature of IVD instrumentation, OEMs frequently team up with specialized IVD Instrumentation companies to design and develop the next generation of diagnostic systems. Both parties bring their previous application/technical knowledge into the partnership in order to develop tailor-made solutions. At the beginning of a cooperative relationship, the overall scope of the project, its intended use and hardware/software requirements are discussed. System requirements specifications are defined and turnkey requirements surrounding medical automation and instrumentation are clarified. Specific services expected from the IVD development company often include:

System and software design, prototyping, testing and system validation comprise the development stage. Also included in this phase is the manufacturing aspect of the prototype. Production materials, tooling, cost estimates of the bill of materials, build timing and work procedures all are documented. The IVD developers must have rigorous experience with the implementation of the recommended design controls from the U.S. Food and Drug Administration (FDA), ISO-compliant processes and FDA registration and certification of the company is advised. It is important to note that regulations often vary depending on where in the world the system or device will be marketed.

Following system development comes design transfer, pre-production and production phases. During this time, pilot builds, process validation, regulatory submissions, documentation, manufacturing scale-up and, finally, production unit manufacturing occur.

For a small instrument with a singular purpose, the development through manufacture process may be completed in one or two years. A larger, complex system often takes more than three years.

With regard to results, the OEM routinely requires superior operation, the ultimate in accuracy, unfailing dependability and stylish design. When it comes to the process, the objectives are simple: short time to market and competitive development and manufacturing costs. How is this possible?

With the development process time measured in years, and the average cost in the millions of dollars, OEMs are eager to "fast-forward" their projects by repurposing fundamental, proven technology in the shape of existing, validated platform modules. Platform modules are previously designed, developed components that have been tested, proven, certified and used in other IVD systems over time. They are composed of selections from a portfolio of existing hardware, electronics and software systems that can be scaled upward or downward to suit the purpose. All of the components comprising the platform module were specifically designed for operation within a complex medical diagnostic instrument and all systems were developed on the lowest level possible to allow for the highest vertical and horizontal integration.

Obviously, some modules are common and often used either in different types of analyzers (such as rotor drives, robotic units, temperature controls, etc.) or within one type of analyzer (such as detection units or user software modules). Thus, a set of platform modules providing standard and off-the-shelf solutions is preferable. However, there are different requirements even within one type of analyzer. For example, rotor sizes vary due to different assay packaging dimensions (different bottles, reagent packs) or variable throughput or "walk away time" requirements.Therefore, just employing a single module for different customer projects may not always be an option. Typically, a high level of modularization usually leads to some over-engineering, with features being included (to maintain modularity) that are not always required. In such cases, it is possible for unnecessary cost to be incurred.

To overcome this challenge and keep the cost to a minimum, the developing party needs to be able to take "one step back," developing autonomous sub-modules (ASMs) that are independent of such varying requirements. Examples of ASMs are:

Taking advantage of ASMs could save the OEM up to 25 percent in both time and development costs. More importantly, there is an immeasurable savings during the lifetime of the product due to the fact that the basic foundation of the system is validated and proven robust.

An important part of the ASM is the electronics hidden within. In addition to having a major impact on speed to market and development cost, embedded software often is the source of the highest risk for a new instrument development effort. In addition, when the support effort over the lifetime of the product is factored in, poorly developed code can have a major impact.

According to the FDA's "General Principles of Software Validation Final Guidance for Industry & FDA Staff," the agency's analysis of 3,140 medical device recalls conducted between 1992 and 1998 revealed that 242 of them (7.7 percent) were attributable to software failures. Of the software-related recalls, 192(79 percent) were caused by software defects that were introduced when changes were made to the software after its initial production and distribution.

Software development techniques can be used to improve software code quality and reduce the risk of delays. One highly successful design process revolves around a "platform configuration" approach in which independent modules are developed for reuse in multiple devices. Such modules essentially are micro-processors running on a common bus structure and used for various functions for which new instrument software easily can be reconfigured. The software that makes this possible is based on reusable code components, written in object-oriented C++, and designed to integrate into an optimized real time operating system. Each separate module can be tested fully and independently from the complete system, running scripts from a PC application. The pre-tested and validated modules contain the various software drivers and controls required to support the module's function. The reusable software easily can be extended as the technology or the instrument's requirements change.

A point-of-care instrument is typically a smaller, less-automated device and, therefore, has fewer identifiable modules per se. Internal sub-systems , however, such as a graphical liquid-crystal display (LCD)/microcontroller or a photo-counter module, as well as all of the drivers and operating system of a device, would be examples of specific functions controlled by these modules.

Common functions include serial communication, displays, memory access, non-volatile storage, universal serial bus (also known as USB) control and smaller device drivers such as analog-to-digital converters, pulse-width modulators, etc. Unique functions might include image analysis, data analysis, complex graphical display screens, main loop program flow and data storage structures. An IVD automated instrument might have eight internal modules (platter drives, pumps, wash station, display heating, cooling, optics). A small POC device might appear to be one integrated design.

Designers adopt user interface software to improve or enhance an instrument's graphical style and/or ease of use. Not unlike an iPhone, the software behind the magic is virtually invisible.

Each project gets the advantage of using a given, validated codebase, leaving only the project-specific software for new development.The codebase allows the device drivers, common services, central processing unit-specific code and operating system to be pre-qualified, reducing the project development time while increasing the code quality.

The shared, object-oriented C++ codebase supplies the software for the following capabilities and features:

In terms of time and cost saved in the development process, 25 percent for each is a safe estimate. The real savings comes over time. Poorly developed code can be "buggy," hard to support and easily broken, which vastly increases cost of the device over time. Additionally, the risk of a latent design flaw going undetected into production is higher, thus becoming the biggest cause for recalled products. Subsequent software verification and validation will be more costly.

Certainly, every developer wants to have a set of reusable functions with the idea of reducing the effort "next time."However, in reality, often after spending the time that it takes to develop it, technology has lunged forward and what was accomplished is no longer relevant-unless the developer planned for change upfront. If the IVD company has the advantage of leveraging a number of instrument projects over multiple years, it is able to construct this platform idea across various levels, from the module approach for the IVD instrument to common circuit blocks and software at the detail level.

At a high level, platform modules can be designed to be flexible and divisible, i.e. the technology can be used in several ways. In terms of IVD instruments, for example, a rotor module is composed of a mechanical system (supports, bearings, sensors, rotor platform, etc.) and a control module (electronics and software). The communications between modules is well defined (such as controller area network, or CAN-bus) so one easily could replace a module with a newer design without redesigning the system, if for example, one wanted to use a newer generation microprocessor. Mechanics could be modified or changed and the control electronics easily could be configured to handle it. If the IVD developers have control of all of the design data, they can readily spin off special versions or modifications for new instruments. The reusable code base is one tool that helps to achieve this ability.

Regarding a POC instrument, none of the modules developed for the IVD instrument would be used directly; however, the underlying technology is common and can be carried down to the POC design. Again, the common code makes this possible by reusing the low-level drivers. This becomes an integration effort to add the necessary technology support to a single control board.

As the global medical diagnostics market continues to expand, the need for reliable instruments-both large-scale and POC-is increasing steadily. According to BIT's marketing trend analysis, industry growth rates over the next few years will vary by segment; for example, growth rate estimates for clinical chemistry will be about 2.5 percent, immunology about 4.5 percent, hematology about 4 percent and molecular up to 17 percent.At the same time, economic pressures are driving instrument manufacturers to engineer new ways of lowering development costs without sacrificing quality and dependability or slowing turnaround time, and smaller, lower-cost analyzers are becoming increasingly important for developing countries.

Platform technology addresses all of these concerns. The repurposing of hardware and software saves time and money up front and over time. Autonomous sub-modules strip platform technology down to its basic underpinnings, allowing dissimilar analyzers to share common building blocks and for engineering innovation to begin at the halfway point of the system. It stands to reason that a company with a large library of these autonomous sub-modules has a distinct advantage over competitors with less experience and fewer electronic components from which to draw. OEMs choosing this approach also will have the advantage of cost efficiency and speed to market.

Bruce Sargeant serves as president and chief technology officer of Source Scientific, LLC, a BITGroup Company located inIrvine, Calif. He can be reached at bruce@sourcescientific.com.

|

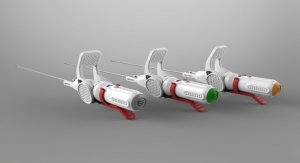

Point-of-care BITSMARTSOLUTIONS diagnostic instruments use platform technology components that are scalable. Photo courtesy of BIT Analytical Instruments. |

The Horizontal & Vertical Platform Approach

While this article concentrates primarily on IVD clinical instrumentation, it is important to note that platform technology solutions are developed to fit not only specific in-vitro diagnostics applications (the "vertical" approach), but also to fulfill the completely different requirements of other medical market segments, as well as other industries (the "horizontal" approach).All systems are designed and developed on the lowest level possible to allow for the highest vertical and horizontal integration.For example, a platform solution can provide the fundamental design of a ventilation system for pharma research or even service tools, as well as a high-end, clinical-chemistry diagnostic system or molecular or immunology instrumentation. In addition to improved time to completion and cost, the OEMs (in all industries) receive the same benefits of an easy customization path for new instrumentation/system designs and a higher economy of scale due to the multiple reuse of standard components.

|

Robotic systems are one type of platform technology component used within BITSMARTSOLUTIONS instrumentation. Photo courtesy of BIT Analytical Instruments. |

The IVD Marketplace

Today, more medical professionals around the world turn to large-scale diagnostic systems as well as small-scale, point-of-care (POC) diagnostic platforms and compact medical devices (CMDs) to provide reliable answers to common laboratory tests so that patients can receive appropriate treatment quickly. Large-scale diagnostic systems are used extensively in hospitals, blood banks, forensic science, research, or in centralized laboratories, which may process thousands of samples per day. Modern medicine and scientific research rely heavily on assay diagnostics for detection of disease. A broad range of diagnostic assays are available, ranging from mass tests analyzing glucose, hemoglobin and coagulation, to other more customized panels that are designed to detect infectious diseases or identify very specific DNA-based conditions. Increasing economic pressures drive the need for affordable, highly reliable, high-throughput, automated IVD analyzers that represent the most cost-efficient processes for less time-critical laboratory tests.

In many medical situations, however, time is not always an affordable luxury. The critical demand for immediacy is a primary driver for the development of the POC/CMD platform-a small-scale (often portable )diagnostic platform that offers high sensitivity, accuracy, rapid turnaround and ease of use. Another driver of the popularity of POC devices is the cost efficiency of the small-scale device with regard to specialized tests. Rather than sending a sample out to a centralized lab using a high-volume, mass-sample-test device, the medical professional uses a low-throughput device that provides more rapid results at a lower cost. Not unexpectedly, POC devices are in high demand within doctors' offices located far from city labs.In addition to the convenience factor, there are many tests-such as blood gas-where samples simply cannot be sent away for testing due to their rapid deterioration. Finally, the miniaturization of certain specialized instruments enables many common tests to be performed by the patient, often with a pocket-sized instrument.

Whether it is used by a patient at home to maintain proper blood sugar levels or in a doctor's office in a remote village to diagnose a potentially serious disease, POC systems are becoming increasingly crucial to patient care. These systems are capable of determining a multitude of variables (such as blood glucose, hemoglobin, DNA, blood gases or coagulation factors) from blood, urine, saliva and/or other bodily fluids.

Developing an IVD Analyzer

Development and manufacture of an IVD system requires much specialized knowledge, a qualified, experienced interdisciplinary team sporting a variety of scientific and technical disciplines, a fully equipped laboratory/development facility, and, in the best case scenario, an integrated manufacturing arm.

Due to the highly complex nature of IVD instrumentation, OEMs frequently team up with specialized IVD Instrumentation companies to design and develop the next generation of diagnostic systems. Both parties bring their previous application/technical knowledge into the partnership in order to develop tailor-made solutions. At the beginning of a cooperative relationship, the overall scope of the project, its intended use and hardware/software requirements are discussed. System requirements specifications are defined and turnkey requirements surrounding medical automation and instrumentation are clarified. Specific services expected from the IVD development company often include:

- Feasibility studies;

- Comprehensive turnkey instrument or module development;

- Provision of prototype batches for system evaluation or field trials;

- Transfer of developments into manufacturing;

- System integration of instrument, software, reagents and

- disposables;

- Shipping and logistics services; and

- After-sale services.

System and software design, prototyping, testing and system validation comprise the development stage. Also included in this phase is the manufacturing aspect of the prototype. Production materials, tooling, cost estimates of the bill of materials, build timing and work procedures all are documented. The IVD developers must have rigorous experience with the implementation of the recommended design controls from the U.S. Food and Drug Administration (FDA), ISO-compliant processes and FDA registration and certification of the company is advised. It is important to note that regulations often vary depending on where in the world the system or device will be marketed.

Following system development comes design transfer, pre-production and production phases. During this time, pilot builds, process validation, regulatory submissions, documentation, manufacturing scale-up and, finally, production unit manufacturing occur.

For a small instrument with a singular purpose, the development through manufacture process may be completed in one or two years. A larger, complex system often takes more than three years.

Platform Modules

With regard to results, the OEM routinely requires superior operation, the ultimate in accuracy, unfailing dependability and stylish design. When it comes to the process, the objectives are simple: short time to market and competitive development and manufacturing costs. How is this possible?

With the development process time measured in years, and the average cost in the millions of dollars, OEMs are eager to "fast-forward" their projects by repurposing fundamental, proven technology in the shape of existing, validated platform modules. Platform modules are previously designed, developed components that have been tested, proven, certified and used in other IVD systems over time. They are composed of selections from a portfolio of existing hardware, electronics and software systems that can be scaled upward or downward to suit the purpose. All of the components comprising the platform module were specifically designed for operation within a complex medical diagnostic instrument and all systems were developed on the lowest level possible to allow for the highest vertical and horizontal integration.

Challenges and Solutions

Obviously, some modules are common and often used either in different types of analyzers (such as rotor drives, robotic units, temperature controls, etc.) or within one type of analyzer (such as detection units or user software modules). Thus, a set of platform modules providing standard and off-the-shelf solutions is preferable. However, there are different requirements even within one type of analyzer. For example, rotor sizes vary due to different assay packaging dimensions (different bottles, reagent packs) or variable throughput or "walk away time" requirements.Therefore, just employing a single module for different customer projects may not always be an option. Typically, a high level of modularization usually leads to some over-engineering, with features being included (to maintain modularity) that are not always required. In such cases, it is possible for unnecessary cost to be incurred.

To overcome this challenge and keep the cost to a minimum, the developing party needs to be able to take "one step back," developing autonomous sub-modules (ASMs) that are independent of such varying requirements. Examples of ASMs are:

- Linear drives;

- Multiple axis drives;

- Rotor drives;

- Dilutors;

- Needle plus liquid level detection;

- Mix and wash stations;

- Agitation units;

- Photometer module; and

- Microcomputer basic control shell.

Taking advantage of ASMs could save the OEM up to 25 percent in both time and development costs. More importantly, there is an immeasurable savings during the lifetime of the product due to the fact that the basic foundation of the system is validated and proven robust.

Reusable Software for Clinical Instruments

An important part of the ASM is the electronics hidden within. In addition to having a major impact on speed to market and development cost, embedded software often is the source of the highest risk for a new instrument development effort. In addition, when the support effort over the lifetime of the product is factored in, poorly developed code can have a major impact.

According to the FDA's "General Principles of Software Validation Final Guidance for Industry & FDA Staff," the agency's analysis of 3,140 medical device recalls conducted between 1992 and 1998 revealed that 242 of them (7.7 percent) were attributable to software failures. Of the software-related recalls, 192(79 percent) were caused by software defects that were introduced when changes were made to the software after its initial production and distribution.

Software development techniques can be used to improve software code quality and reduce the risk of delays. One highly successful design process revolves around a "platform configuration" approach in which independent modules are developed for reuse in multiple devices. Such modules essentially are micro-processors running on a common bus structure and used for various functions for which new instrument software easily can be reconfigured. The software that makes this possible is based on reusable code components, written in object-oriented C++, and designed to integrate into an optimized real time operating system. Each separate module can be tested fully and independently from the complete system, running scripts from a PC application. The pre-tested and validated modules contain the various software drivers and controls required to support the module's function. The reusable software easily can be extended as the technology or the instrument's requirements change.

A point-of-care instrument is typically a smaller, less-automated device and, therefore, has fewer identifiable modules per se. Internal sub-systems , however, such as a graphical liquid-crystal display (LCD)/microcontroller or a photo-counter module, as well as all of the drivers and operating system of a device, would be examples of specific functions controlled by these modules.

Common functions include serial communication, displays, memory access, non-volatile storage, universal serial bus (also known as USB) control and smaller device drivers such as analog-to-digital converters, pulse-width modulators, etc. Unique functions might include image analysis, data analysis, complex graphical display screens, main loop program flow and data storage structures. An IVD automated instrument might have eight internal modules (platter drives, pumps, wash station, display heating, cooling, optics). A small POC device might appear to be one integrated design.

Designers adopt user interface software to improve or enhance an instrument's graphical style and/or ease of use. Not unlike an iPhone, the software behind the magic is virtually invisible.

|

Main/module computer boards as well as reusable software are platform technology components utilized to operate other platform technology components. Photo courtesy of BIT Analytical Instruments. |

Shared Codebase

Each project gets the advantage of using a given, validated codebase, leaving only the project-specific software for new development.The codebase allows the device drivers, common services, central processing unit-specific code and operating system to be pre-qualified, reducing the project development time while increasing the code quality.

Features Supported

The shared, object-oriented C++ codebase supplies the software for the following capabilities and features:

- Full user-interface library, supporting LCDs, touch screens and buttons support;

- Easy replacement of hardware components: Polymorphic access to devices provides for easy replacement of hardware components, without impact to other parts of the codebase other than the device driver;

- Non-volatile storage management: Supporting rotating data logs, cyclic-redundancy-checked block memory, and non-volatile random access memory, all with protection against data loss or corruption from inopportune power loss (as with during a write cycle); and

- Task management, communication stacks, state machine support, software version reporting, device drivers, etc.

In terms of time and cost saved in the development process, 25 percent for each is a safe estimate. The real savings comes over time. Poorly developed code can be "buggy," hard to support and easily broken, which vastly increases cost of the device over time. Additionally, the risk of a latent design flaw going undetected into production is higher, thus becoming the biggest cause for recalled products. Subsequent software verification and validation will be more costly.

Certainly, every developer wants to have a set of reusable functions with the idea of reducing the effort "next time."However, in reality, often after spending the time that it takes to develop it, technology has lunged forward and what was accomplished is no longer relevant-unless the developer planned for change upfront. If the IVD company has the advantage of leveraging a number of instrument projects over multiple years, it is able to construct this platform idea across various levels, from the module approach for the IVD instrument to common circuit blocks and software at the detail level.

At a high level, platform modules can be designed to be flexible and divisible, i.e. the technology can be used in several ways. In terms of IVD instruments, for example, a rotor module is composed of a mechanical system (supports, bearings, sensors, rotor platform, etc.) and a control module (electronics and software). The communications between modules is well defined (such as controller area network, or CAN-bus) so one easily could replace a module with a newer design without redesigning the system, if for example, one wanted to use a newer generation microprocessor. Mechanics could be modified or changed and the control electronics easily could be configured to handle it. If the IVD developers have control of all of the design data, they can readily spin off special versions or modifications for new instruments. The reusable code base is one tool that helps to achieve this ability.

Regarding a POC instrument, none of the modules developed for the IVD instrument would be used directly; however, the underlying technology is common and can be carried down to the POC design. Again, the common code makes this possible by reusing the low-level drivers. This becomes an integration effort to add the necessary technology support to a single control board.

Existing Hardware + Existing Software = Platform Technology

As the global medical diagnostics market continues to expand, the need for reliable instruments-both large-scale and POC-is increasing steadily. According to BIT's marketing trend analysis, industry growth rates over the next few years will vary by segment; for example, growth rate estimates for clinical chemistry will be about 2.5 percent, immunology about 4.5 percent, hematology about 4 percent and molecular up to 17 percent.At the same time, economic pressures are driving instrument manufacturers to engineer new ways of lowering development costs without sacrificing quality and dependability or slowing turnaround time, and smaller, lower-cost analyzers are becoming increasingly important for developing countries.

Platform technology addresses all of these concerns. The repurposing of hardware and software saves time and money up front and over time. Autonomous sub-modules strip platform technology down to its basic underpinnings, allowing dissimilar analyzers to share common building blocks and for engineering innovation to begin at the halfway point of the system. It stands to reason that a company with a large library of these autonomous sub-modules has a distinct advantage over competitors with less experience and fewer electronic components from which to draw. OEMs choosing this approach also will have the advantage of cost efficiency and speed to market.

SIDEBAR:

Platform Technology:Major Benefits for OEMs

- Better DesignControl

- Lowest Unit Cost

- Best Configuration Control

- Shortest Approval Path

- Lowest IntegrationRisk

- Low Design Costs

- Shorter Development Time