Megan Ray Nichols, Science Writer; Editor, Schooled By Science08.07.19

According to the Environmental Protection Agency, the average person spends 90 percent of their time indoors, so indoor air quality should be a priority for all business owners. In medical manufacturing, many of the standard activities from injection molding to welding and cutting can all reduce the facility’s air quality. What can managers and supervisors do to improve indoor air quality (IAQ) and protect their employees without sacrificing productivity and efficiency?

Medical Manufacturing and IAQ

What aspects of medical device manufacturing negatively impact the interior air quality in these facilities?

Facilities that use thermoplastic injection molding are at risk due to the fumes the plastic emits when heated. PVC plastic emits hydrogen chloride, and acetal plastics have been shown to emit formaldehyde. Pure PVC can even break down into hydrogen chloride gas. All of these fumes can irritate the lungs and are thought to cause cancer.

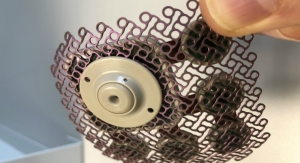

Machining, cutting, and grinding components—whether they're made from metal, glass, plastic, fiberglass, or other materials—can release small particles into the air that workers can inhale. Machining metal and glass often requires a lubricant to keep the materials from overheating. The process can produce a fine mist of lubricant that, when inhaled, can cause a variety of health problems, including everything from asthma to chronic bronchitis.

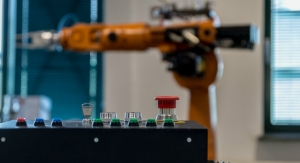

Welding, especially in an enclosed space, generates a variety of different metal fumes and smokes depending on the metal being welded and the tools utilized. Many of these emissions can be toxic if inhaled and can negatively affect a medical manufacturing facility’s internal air quality.

Signs of Poor Interior Air Quality

IAQ issues aren’t often visible if manufacturers aren’t testing for them. What are some of the invisible signs a facility's interior air quality needs some work?

First, look at productivity levels. A 2017 Harvard study found that poor indoor air quality impacts productivity, cognitive function, and even mood, making it harder to focus and difficult to be productive.

Poor air quality can also negatively impact product quality, which can be especially detrimental in the medical device industry. Products produced in these facilities are already subject to a higher degree of monitoring and scrutiny. Contamination with metal dust, machining lubricant, or other air contaminants can compromise the safety and sterility of the products. Poor IAQ in a facility that produces medical air compressors, for example, could take the entire facility offline until the problem is rectified because it will become impossible to adhere to NFPA 99 regulations.

With dust and lubricant mist, there is also the risk of combustion if the air quality is too poor. Metals like magnesium, titanium, and aluminum can combust if their dust is exposed to a spark. Many chemicals are either flammable or will reach a flashpoint when air quality is poor, resulting in a fire or explosion. When utilizing laser cutters or other similar technology, poor IAQ might result in an explosion, putting the facility and its employees at risk.

Improving IAQ In Medical Manufacturing

What can managers and plant supervisors do to improve the interior air quality in their facilities?

Start by having the facility’s air quality professionally tested. These tests will look for airborne chemicals concentrations and particulates as well as CO2 concentrations, temperature, and humidity throughout the facility. Once there’s a better idea of where to find the problems, they become easier to address.

Improving IAQ within medical manufacturing facilities should be a top priority, both to keep employees safe and to ensure the products manufactured within are safe, sterile, and meet all FDA requirements.

Take steps to improve interior ventilation, using fans, fume hoods, or other tools to ensure air keeps moving. If specific techniques or areas are causing air contamination, place fume hoods or ventilation fans directly over the area to draw toxic fumes and chemicals away from the work area.

Depending on the type of fumes, you may be able to vent them directly to the exterior of the building. For particulates or dust, you may need to filter the waste before it's released into the atmosphere.

Take a closer look at manufacturing processes and see if there is any option to switch to less toxic materials or processes. Alternative options may be found for chemicals used in daily processes, welding fillers or gasses, and even plastics used in injection molding. This may also help reduce the company's carbon footprint.

The Future of IAQ in Medical Manufacturing

Interior air quality has a dramatic impact on employee health, product quality, and productivity. If there is a distinct drop in productivity or efficiency, consider having the facility’s air quality tested. Focus on areas that use thermoplastic injection molding, welding, milling, and grinding, or anywhere that utilizes chemicals with high VOCs (volatile organic compounds). Once it is discovered what manufacturing processes are creating the most interior air pollution, the company will be better equipped to rectify the problem.

Megan Ray Nichols is a science writer and the editor of Schooled By Science. Her work regularly appears on Real Clear Science, Manufacturing.net, and Astronaut.com. Keep up with Megan by following her on Twitter.

Medical Manufacturing and IAQ

What aspects of medical device manufacturing negatively impact the interior air quality in these facilities?

Facilities that use thermoplastic injection molding are at risk due to the fumes the plastic emits when heated. PVC plastic emits hydrogen chloride, and acetal plastics have been shown to emit formaldehyde. Pure PVC can even break down into hydrogen chloride gas. All of these fumes can irritate the lungs and are thought to cause cancer.

Machining, cutting, and grinding components—whether they're made from metal, glass, plastic, fiberglass, or other materials—can release small particles into the air that workers can inhale. Machining metal and glass often requires a lubricant to keep the materials from overheating. The process can produce a fine mist of lubricant that, when inhaled, can cause a variety of health problems, including everything from asthma to chronic bronchitis.

Welding, especially in an enclosed space, generates a variety of different metal fumes and smokes depending on the metal being welded and the tools utilized. Many of these emissions can be toxic if inhaled and can negatively affect a medical manufacturing facility’s internal air quality.

Signs of Poor Interior Air Quality

IAQ issues aren’t often visible if manufacturers aren’t testing for them. What are some of the invisible signs a facility's interior air quality needs some work?

First, look at productivity levels. A 2017 Harvard study found that poor indoor air quality impacts productivity, cognitive function, and even mood, making it harder to focus and difficult to be productive.

Poor air quality can also negatively impact product quality, which can be especially detrimental in the medical device industry. Products produced in these facilities are already subject to a higher degree of monitoring and scrutiny. Contamination with metal dust, machining lubricant, or other air contaminants can compromise the safety and sterility of the products. Poor IAQ in a facility that produces medical air compressors, for example, could take the entire facility offline until the problem is rectified because it will become impossible to adhere to NFPA 99 regulations.

With dust and lubricant mist, there is also the risk of combustion if the air quality is too poor. Metals like magnesium, titanium, and aluminum can combust if their dust is exposed to a spark. Many chemicals are either flammable or will reach a flashpoint when air quality is poor, resulting in a fire or explosion. When utilizing laser cutters or other similar technology, poor IAQ might result in an explosion, putting the facility and its employees at risk.

Improving IAQ In Medical Manufacturing

What can managers and plant supervisors do to improve the interior air quality in their facilities?

Start by having the facility’s air quality professionally tested. These tests will look for airborne chemicals concentrations and particulates as well as CO2 concentrations, temperature, and humidity throughout the facility. Once there’s a better idea of where to find the problems, they become easier to address.

Improving IAQ within medical manufacturing facilities should be a top priority, both to keep employees safe and to ensure the products manufactured within are safe, sterile, and meet all FDA requirements.

Take steps to improve interior ventilation, using fans, fume hoods, or other tools to ensure air keeps moving. If specific techniques or areas are causing air contamination, place fume hoods or ventilation fans directly over the area to draw toxic fumes and chemicals away from the work area.

Depending on the type of fumes, you may be able to vent them directly to the exterior of the building. For particulates or dust, you may need to filter the waste before it's released into the atmosphere.

Take a closer look at manufacturing processes and see if there is any option to switch to less toxic materials or processes. Alternative options may be found for chemicals used in daily processes, welding fillers or gasses, and even plastics used in injection molding. This may also help reduce the company's carbon footprint.

The Future of IAQ in Medical Manufacturing

Interior air quality has a dramatic impact on employee health, product quality, and productivity. If there is a distinct drop in productivity or efficiency, consider having the facility’s air quality tested. Focus on areas that use thermoplastic injection molding, welding, milling, and grinding, or anywhere that utilizes chemicals with high VOCs (volatile organic compounds). Once it is discovered what manufacturing processes are creating the most interior air pollution, the company will be better equipped to rectify the problem.

Megan Ray Nichols is a science writer and the editor of Schooled By Science. Her work regularly appears on Real Clear Science, Manufacturing.net, and Astronaut.com. Keep up with Megan by following her on Twitter.