Mary Beth Gallagher, Department of Mechanical Engineering, Massachusetts Institute of Technology03.27.20

As the number of hospitalizations due to Covid-19 continues to rise across the U.S., addressing the shortage of personal protective equipment (PPE) for health care workers has become increasingly urgent. Institutions and organizations across the country—including MIT—have been scrambling to collect and send unused face masks to local hospitals.

In the race to help protect doctors, nurses, and patients, some have suggested that technologies like 3D printing be used to quickly manufacture masks. In a recent memo, MIT faculty members Martin Culpepper, Peter Fisher, and Elazer Edelman, with input from Neil Gershenfeld and A. John Hart, detail the risks associated with using 3D printing to build PPE and Covid-19-related medical devices.

Martin Culpepper is a professor of mechanical engineering, director of Project Manus, and a member of MIT’s governance team on manufacturing opportunities for Covid-19. Here, he discusses the risks associated with using 3D printing for PPE and what designers, researchers, and engineers can do to address the PPE shortage.

Q: What are the risks associated with using 3D printing to make PPE for medical professionals?

A: One of the biggest risks with 3D printing for Covid-19 situations is the false sense of hope that we can quickly print PPE to address needs. Well-intentioned people want to help and think 3D printing can address the current demand for medical devices and PPE in hospitals. However, the production of PPE, for example masks, is much more complicated than people might appreciate and 3D printed masks may do more harm than good.

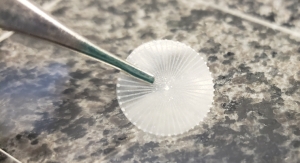

There are a lot of issues with certain types of 3D printed parts with respect to their use in a clinical setting. One example involves sterilization—material compatibility with the sterilization techniques hospitals currently use and the use of certain materials in a setting where it is uncertain how they interact with other chemicals, devices, and contact with patients and care providers. The thing is though, right now the problem isn’t masks, it’s the filter media. In particular, the use of filter media in masks is essential to their efficacy.

The filter media is really an amazing thing; it just looks like a simple piece of cloth, but it’s made through a very specific process to achieve a very specific end state. This end state is specially engineered to catch small particles. Some materials are electrostatically charged so that small particles become stuck to the fibers as they try to go through. This material works great for clinical use and is urgently needed right now. People are focusing on the masks themselves, and not addressing the real problem—filter media for the masks. Masks without the filter media don’t make much of a difference in protecting people from the spread of viruses like Covid-19.

Professor Martin Culpepper co-authored a memo on the use of 3D printing for Covid-19 response at MIT. Image courtesy of Len Rubenstein.

Q: How should designers and engineers utilize 3D printing to develop Covid-19-related medical devices and PPE?

A: At MIT, we have some of the best 3D printing capabilities you can find on the planet. The reality here is that we aren’t large volume manufacturers: Our 3D printing technologies are set up to build proof-of-concept designs, not to manufacture medical products at scale. The best use of our 3D printing technologies right now is to use them to rapidly demonstrate the feasibility needed to pave the way to high-rate manufacturing processes. Then we can work with manufacturers who can quickly spin the products up and produce these items at the rate that is needed.

The sheer volume of the need is another reason we are discouraging the use of 3D printing to produce PPE on MIT’s campus. Some hospitals need thousands of pieces of PPE each day, 3D printing just cannot keep up with that demand. However, if you can come up with a great idea for PPE that can be fabricated in a high-rate way that meets demand, then we encourage people to use 3D printing as a means to prototype. Once you have that 3D printed proof of concept prototype, MIT can look to have it rapidly vetted for use in a clinical setting and find manufacturers and medical device companies who are equipped to build and distribute products at scale.

Q: Where should researchers and engineers be focusing their efforts to help solve the PPE shortage?

A: The fastest and safest way to make an impact is to donate unopened PPE that is marketed with regulatory approval. For members of the MIT community, use the MIT program. For people elsewhere, don’t take it to a local hospital—instead find an official that is coordinating a local effort and contact them. The second most important thing is fostering collaborations and connections with others.

At MIT, we are working on a few realistic PPE designs that are suitable for rapid deployment to high-rate manufacturing processes. These prototypes are being vetted for deployment. There are many in the community that are supporting each other by offering design advice, sourcing advice, clinical feedback through MIT’s connections, and helping find places where they can connect with manufacturers if appropriate.

MIT has always been a place where great ideas can make a big difference in the world. If we are going to make a big difference in this crisis, now is the time for great ideas. One of our strengths at MIT is that we focus on “mind, hand, and heart.” This is a time when we need to use all three of those things. People across the world are worried and uncertain. Too many people are “throwing spaghetti at the wall” to see what sticks and not thinking things through. We can only solve these problems in the fastest, smartest way if we continue to apply the motto of “mind, hand, heart” to our efforts.

In the race to help protect doctors, nurses, and patients, some have suggested that technologies like 3D printing be used to quickly manufacture masks. In a recent memo, MIT faculty members Martin Culpepper, Peter Fisher, and Elazer Edelman, with input from Neil Gershenfeld and A. John Hart, detail the risks associated with using 3D printing to build PPE and Covid-19-related medical devices.

Martin Culpepper is a professor of mechanical engineering, director of Project Manus, and a member of MIT’s governance team on manufacturing opportunities for Covid-19. Here, he discusses the risks associated with using 3D printing for PPE and what designers, researchers, and engineers can do to address the PPE shortage.

Q: What are the risks associated with using 3D printing to make PPE for medical professionals?

A: One of the biggest risks with 3D printing for Covid-19 situations is the false sense of hope that we can quickly print PPE to address needs. Well-intentioned people want to help and think 3D printing can address the current demand for medical devices and PPE in hospitals. However, the production of PPE, for example masks, is much more complicated than people might appreciate and 3D printed masks may do more harm than good.

There are a lot of issues with certain types of 3D printed parts with respect to their use in a clinical setting. One example involves sterilization—material compatibility with the sterilization techniques hospitals currently use and the use of certain materials in a setting where it is uncertain how they interact with other chemicals, devices, and contact with patients and care providers. The thing is though, right now the problem isn’t masks, it’s the filter media. In particular, the use of filter media in masks is essential to their efficacy.

The filter media is really an amazing thing; it just looks like a simple piece of cloth, but it’s made through a very specific process to achieve a very specific end state. This end state is specially engineered to catch small particles. Some materials are electrostatically charged so that small particles become stuck to the fibers as they try to go through. This material works great for clinical use and is urgently needed right now. People are focusing on the masks themselves, and not addressing the real problem—filter media for the masks. Masks without the filter media don’t make much of a difference in protecting people from the spread of viruses like Covid-19.

Professor Martin Culpepper co-authored a memo on the use of 3D printing for Covid-19 response at MIT. Image courtesy of Len Rubenstein.

Q: How should designers and engineers utilize 3D printing to develop Covid-19-related medical devices and PPE?

A: At MIT, we have some of the best 3D printing capabilities you can find on the planet. The reality here is that we aren’t large volume manufacturers: Our 3D printing technologies are set up to build proof-of-concept designs, not to manufacture medical products at scale. The best use of our 3D printing technologies right now is to use them to rapidly demonstrate the feasibility needed to pave the way to high-rate manufacturing processes. Then we can work with manufacturers who can quickly spin the products up and produce these items at the rate that is needed.

The sheer volume of the need is another reason we are discouraging the use of 3D printing to produce PPE on MIT’s campus. Some hospitals need thousands of pieces of PPE each day, 3D printing just cannot keep up with that demand. However, if you can come up with a great idea for PPE that can be fabricated in a high-rate way that meets demand, then we encourage people to use 3D printing as a means to prototype. Once you have that 3D printed proof of concept prototype, MIT can look to have it rapidly vetted for use in a clinical setting and find manufacturers and medical device companies who are equipped to build and distribute products at scale.

Q: Where should researchers and engineers be focusing their efforts to help solve the PPE shortage?

A: The fastest and safest way to make an impact is to donate unopened PPE that is marketed with regulatory approval. For members of the MIT community, use the MIT program. For people elsewhere, don’t take it to a local hospital—instead find an official that is coordinating a local effort and contact them. The second most important thing is fostering collaborations and connections with others.

At MIT, we are working on a few realistic PPE designs that are suitable for rapid deployment to high-rate manufacturing processes. These prototypes are being vetted for deployment. There are many in the community that are supporting each other by offering design advice, sourcing advice, clinical feedback through MIT’s connections, and helping find places where they can connect with manufacturers if appropriate.

MIT has always been a place where great ideas can make a big difference in the world. If we are going to make a big difference in this crisis, now is the time for great ideas. One of our strengths at MIT is that we focus on “mind, hand, and heart.” This is a time when we need to use all three of those things. People across the world are worried and uncertain. Too many people are “throwing spaghetti at the wall” to see what sticks and not thinking things through. We can only solve these problems in the fastest, smartest way if we continue to apply the motto of “mind, hand, heart” to our efforts.