Sam Brusco, Associate Editor09.01.22

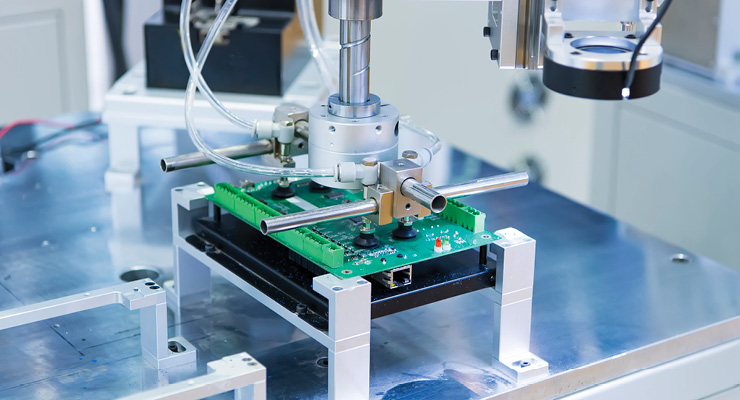

Electronics manufacturing has been quickly evolving over the last few years. For one, the electronics industry has been increasingly adopting Internet of Things (IoT) technology to interconnect different equipment networked though an internet connection. Using the technologies has impacted manufacturers by reducing cost, fostering product innovation, boosting efficiency, and improving safety.

Predictive maintenance has also been a boon to electronics makers, helping them to prevent costs associated with machine downtime as well as potentially reducing repair and maintenance costs. A lot of this work is made possible thanks to IoT tech that can track equipment health, predicting how equipment might fail, and helping businesses avoid it.

These are merely a few of the recent tools in electronics manufacturers’ belts—and in the highly regulated custom medical electronics landscape, tools to ensure quality and repeatability are paramount. Making electronics used in medical devices—many of which are highly customized orders for a single application—is also highly affected by the medtech industry’s macro trends.

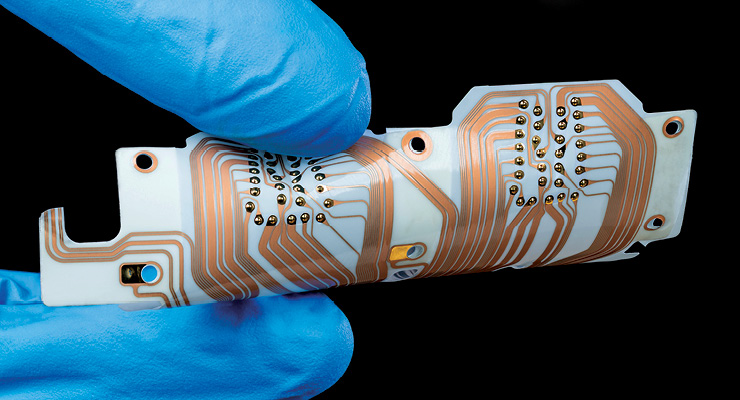

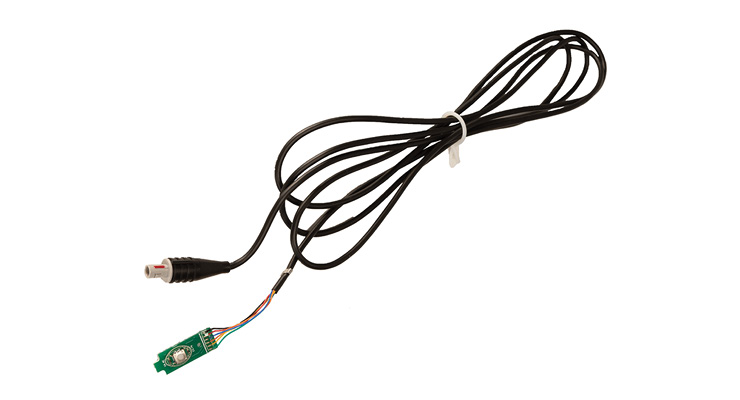

The ever-shrinking form factor of medical devices is a key challenge makers of medical electronic components must tackle. Minimally invasive procedures and patient discretion are driving smaller and smaller architectures with even tinier electrical components and manufacturing partners specialized in making these components are working to meet the demand.

To gain more insights on the various market trends and challenges affecting the custom electronics industry for medical devices, MPO spoke to the following experts over the past few weeks:

Sam Brusco: What factors must be taken into consideration when designing and/or manufacturing custom electronics for medical devices?

Brian Allen: The required clinical outcome has to be paramount in the design. A skilled partner can help develop and reduce your idea to practice but the clinical need and the parameters around that must come first. In manufacturing, there are two primary factors: the first is component selection with an eye toward understanding what, if any the supply chain challenges will be; the second is understanding the volume potential as early as possible. That will inform design for manufacturability and the associated custom manufacturing processes needed.

This article is featured in the MPO eBook "Engaging Electronics." Click here to download the eBook and finish reading this article.

Predictive maintenance has also been a boon to electronics makers, helping them to prevent costs associated with machine downtime as well as potentially reducing repair and maintenance costs. A lot of this work is made possible thanks to IoT tech that can track equipment health, predicting how equipment might fail, and helping businesses avoid it.

These are merely a few of the recent tools in electronics manufacturers’ belts—and in the highly regulated custom medical electronics landscape, tools to ensure quality and repeatability are paramount. Making electronics used in medical devices—many of which are highly customized orders for a single application—is also highly affected by the medtech industry’s macro trends.

The ever-shrinking form factor of medical devices is a key challenge makers of medical electronic components must tackle. Minimally invasive procedures and patient discretion are driving smaller and smaller architectures with even tinier electrical components and manufacturing partners specialized in making these components are working to meet the demand.

To gain more insights on the various market trends and challenges affecting the custom electronics industry for medical devices, MPO spoke to the following experts over the past few weeks:

- Brian Allen, development director at Minnetronix Medical, a St. Paul, Minn.-based design, development, and manufacturing partner to medical device companies.

- Peter van Beek, business development manager—medical and Biren Patel, business development manager mobility solutions and electronic systems, at maxon precision motors, a Taunton, Mass.-based provider of high-precision drive systems.

- Juan Contreras, senior product manager, medical interconnect at Carlisle Medical Technologies, a St. Augustine, Fla.-based designer and manufacturer of high-performance product solutions for the medical device market.

- Ben Dose, director, new product management for Nortech Systems, a Maple Grove, Minn.-based full-service electronics manufacturing services provider of complex interconnect solutions, diagnostic repair, and integration services.

- Darrell Goff, application engineer at ATL Technology, a Springville, Utah-based development and full-service manufacturing partner to medical device OEMs.

- Steven Lassen, senior customer application engineer at LEMO USA, a Rohnert Park, Calif.-based designer and manufacturer of precision custom connection and cable solutions.

- Angel Lasso, senior director of engineering services at Jabil, a St. Petersburg, Fla.-based full-service manufacturing partner to various industries.

- Joe Tam, assistant director of R&D at Providence Enterprise, a Hong Kong-based full-service global electro-mechanical contract manufacturer.

Sam Brusco: What factors must be taken into consideration when designing and/or manufacturing custom electronics for medical devices?

Brian Allen: The required clinical outcome has to be paramount in the design. A skilled partner can help develop and reduce your idea to practice but the clinical need and the parameters around that must come first. In manufacturing, there are two primary factors: the first is component selection with an eye toward understanding what, if any the supply chain challenges will be; the second is understanding the volume potential as early as possible. That will inform design for manufacturability and the associated custom manufacturing processes needed.

This article is featured in the MPO eBook "Engaging Electronics." Click here to download the eBook and finish reading this article.