Steve Santoro, Executive Vice President, MICRO04.01.21

Minimally invasive laparoscopic surgical instruments today perform a wide array of essential functions in the operating room—cutting, sealing, stitching, stapling, and insufflating.

Laparoscopic instruments are much more complex than they were decades ago, allowing surgeons to perform operations faster than in the past. Procedures such as prostatectomies and hysterectomies can now be performed using minimally invasive surgery, which helps reduce complications and improve recovery time and outcomes for patients.

Medical device manufacturers can use a number of processes for producing parts and instruments for use in surgical applications like laparoscopic minimally invasive surgery. The key is to select the best process for the component being produced. A full-service contract manufacturing organization (CMO) with a range of metal fabricating operations needed for surgical instruments, including critical cleaning operations, should consider several factors, including cost, materials, and volume needed before deciding which process would best meet the customer’s objectives for each project.

Factors for Consideration

Cost is usually the biggest factor when deciding on process and technology, and cost of raw materials, process steps, and volumes all need to be factored in. For minimally invasive surgical instruments, metal components often represent a large portion of the costs. Adding process steps will also cause costs to increase, and it’s important to carefully select the optimal process. An experienced CMO will have detailed knowledge of costs and processing, and be able to recommend the best method for each project.

We conduct extensive cost models along with process capability data before beginning a project so we can recommend and align with our customers. We can typically model a number of scenarios to find the best combination. In general, the more you can simplify, the less costs you will incur.

Along with cost modeling, we also assess risk prior to each project, which is assessed by looking at factors related to commercial, technical, and compliance factors. Commercial risk is cost-driven and considers a number of factors, including:

Reducing technical risk involves an assessment of:

Compliance risk considers use of known materials and processes that have undergone testing previously, including:

An experienced CMO with prior knowledge can usually assess risk reduction to every unique project, as no two projects are completely the same.

Metal Injection Molding

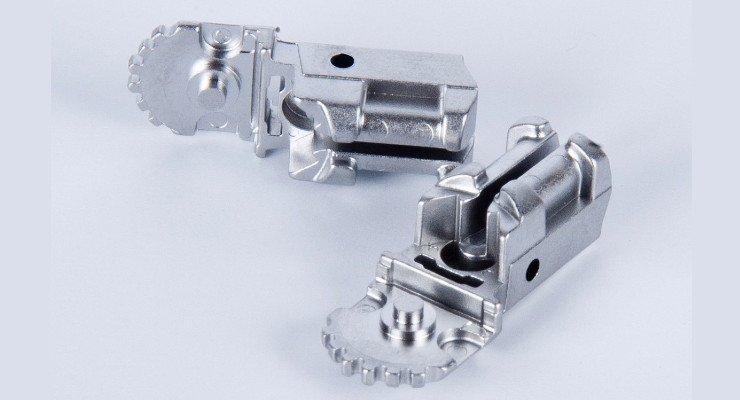

Metal injection molding (MIM) is a good choice for producing medium- to high-volume parts for medical devices for laparoscopic surgery and other high-volume applications. We’ve used MIM successfully for over 20 years to manufacture millions of parts annually for single-use surgical instruments including powered device drive chains, end effectors, connectors, and other applications. MIM is used extensively across industries and markets—it’s a good chance your cell phone has many MIM-produced parts. MIM is a versatile, proven, low-risk manufacturing technology.

Compared to plastic components, metal as a raw material is very cost-effective to manufacture and there are many more processes available for fabricating metal components. The least expensive component is usually the raw materials. When additional steps are added, costs rise. The key is to pick the best process for each component. Having detailed knowledge of the costs and processing of as many of these technologies as possible makes the job easier.

MIM integrates injection molding capability with diverse metal selection, and it can replace costly machined components. The process lends itself to automation where high volumes and consistent quality are needed. The process allows for greater design freedom in short development cycles and turnaround time. MIM is ideal for small, complex geometries and intricately-shaped parts. Post MIM, CNC machining can be used to achieve tight tolerances.

MIM parts have excellent strength, ductility, magnetic response, and can be bent, welded, hardened, and heat treated like any other wrought material. A wide variety of metals can be used for medical device manufacturing using a MIM process, including stainless steel, low alloy steels, carbon steels, Fe-Ni alloys, cobalt alloys, tool steel, and Tungsten alloys. Ceramics can be used for injection molding as well, particularly when furnace furniture is required, though most of our projects typically employ metals.

A majority of single-use disposable instruments produced through a MIM process use 17-4 grade stainless steel, which can be tempered to various hardness and close to 300-series stainless steel in corrosion resistance. In addition, 316- and 400-series stainless steel can be used in specialty applications, and 316 stainless steel is the gold standard for corrosion resistance when using injection molding. A 440-grade stainless steel can be hardened beyond what is capable with 17-4 grade, however, corrosion resistance is better with 17-4 grade and 440-grade requires tighter control of heat treating and a more robust post-cleaning process.

Some stainless-steel grades aren’t able to achieve the same degree of strength as other grades, so it’s important to consider what mechanical properties will be needed when choosing materials. Generally speaking, materials that are readily available and widely used will help reduce costs and process time.

A distinct advantage of an injection molding process is its shorter timelines. For standard components, we can produce 30 to 40 molds a month. Prototype tools will typically require two to three weeks and samples can be produced in one to two weeks. Production tools will take anywhere from four to six weeks. Time frames can be compressed by using reliable vendors to build the molds. Many projects require multiple tools, and bottlenecks can occur at the beginning when deciding on a mold and reviewing designs to ensure functionality will not be compromised. Inefficiencies also may occur at the end of the process if a touchup is needed on a mold or if extensive testing in the metallurgy lab is involved. Be aware of these potential risks and factor them into timelines.

Batch and continuous processes, both widely available, can be used for medical device manufacturing. We utilize a proprietary feedstock formulation with high quality alloy powders needed for surgical instruments. The green strength of our medical parts is quite high, and the advent of higher quality feedstocks have virtually eliminated failures due to molding and handling defects, including green and brown state cracks.

A continuous process is especially conducive for high-volume applications and uses raw materials that are readily available. However, all feedstocks and processes are not equivalent. The key to the process is achieving consistent shrinkage and diffusion of organics out of the metal matrix. Furnace furniture is another consideration that can be overlooked. The part datum structures must be married to the furnace furniture to get the most consistent results, especially if secondary machining is used.

Consistent diffusion of organic binders and surfactants is critical to achieving optimal mechanical properties. High residual carbon content is a disadvantage for components that will be subsequently welded. In addition, poor diffusion increases the voids in the metal matrix by trapping gas and the lower density will dramatically reduce strength. Coring is a common strategy used to help equalize diffusion distances, or material can be removed completely.

In terms of tolerance, a larger feature will require a larger tolerance, since parts shrink 15-18 percent during sintering. Keep in mind that more shrinkage will occur in a vertical direction due to gravity and less shrinkage will occur in a lengthwise direction due to drag on the furnace furniture.

Larger, longer parts will require tighter tolerances and machining may be necessary depending on the application. Thickness must withstand the weight of the part in the furnace and complex parts like jaws with cantilevered design features will require custom furnace furniture.

Design for Manufacturability

Design and commercial considerations are important factors for medical device manufacturing. A Design for Manufacturability (DFM) approach allows design and development cycles to be shortened so products can be manufactured at a lower cost. Using DFM, an experienced CMO can identify raw materials and methods that will optimize the manufacturing process by reducing steps and ensuring standardization in parts quality. An even thickness, stable base while sintering, and good feedstock flow can all be achieved with good design considerations.

Conclusion

CMOs should consult with OEM customers early on in the process to review and align on design and commercial needs of each project. Doing so will ensure that risks are reduced, and products achieve target functionality at cost. Using modern manufacturing techniques, including MIM, combined with engineering expertise and innovation, CMOs can deliver high-quality parts and products for their customers efficiently, cost-effectively, and on time.

Steve Santoro, executive vice president at MICRO, delivered a keynote address during MIM2021: International Conference on Injection Molding of Metals, Ceramics and Carbides, held virtually Feb. 22-25.

Laparoscopic instruments are much more complex than they were decades ago, allowing surgeons to perform operations faster than in the past. Procedures such as prostatectomies and hysterectomies can now be performed using minimally invasive surgery, which helps reduce complications and improve recovery time and outcomes for patients.

Medical device manufacturers can use a number of processes for producing parts and instruments for use in surgical applications like laparoscopic minimally invasive surgery. The key is to select the best process for the component being produced. A full-service contract manufacturing organization (CMO) with a range of metal fabricating operations needed for surgical instruments, including critical cleaning operations, should consider several factors, including cost, materials, and volume needed before deciding which process would best meet the customer’s objectives for each project.

Factors for Consideration

Cost is usually the biggest factor when deciding on process and technology, and cost of raw materials, process steps, and volumes all need to be factored in. For minimally invasive surgical instruments, metal components often represent a large portion of the costs. Adding process steps will also cause costs to increase, and it’s important to carefully select the optimal process. An experienced CMO will have detailed knowledge of costs and processing, and be able to recommend the best method for each project.

We conduct extensive cost models along with process capability data before beginning a project so we can recommend and align with our customers. We can typically model a number of scenarios to find the best combination. In general, the more you can simplify, the less costs you will incur.

Along with cost modeling, we also assess risk prior to each project, which is assessed by looking at factors related to commercial, technical, and compliance factors. Commercial risk is cost-driven and considers a number of factors, including:

- Over design adds costs

- Under design not functional/failures

- Scrap

- Cycle times

- Equipment cost

- Automation

- Secondary operations

Reducing technical risk involves an assessment of:

- Feasibility

- Timeline

- Process development

- Project and tooling cost

- Process stability

Compliance risk considers use of known materials and processes that have undergone testing previously, including:

- Materials of construction

- Biocompatibility

- Homogenous

- Additive manufacturing

An experienced CMO with prior knowledge can usually assess risk reduction to every unique project, as no two projects are completely the same.

Metal Injection Molding

Metal injection molding (MIM) is a good choice for producing medium- to high-volume parts for medical devices for laparoscopic surgery and other high-volume applications. We’ve used MIM successfully for over 20 years to manufacture millions of parts annually for single-use surgical instruments including powered device drive chains, end effectors, connectors, and other applications. MIM is used extensively across industries and markets—it’s a good chance your cell phone has many MIM-produced parts. MIM is a versatile, proven, low-risk manufacturing technology.

Compared to plastic components, metal as a raw material is very cost-effective to manufacture and there are many more processes available for fabricating metal components. The least expensive component is usually the raw materials. When additional steps are added, costs rise. The key is to pick the best process for each component. Having detailed knowledge of the costs and processing of as many of these technologies as possible makes the job easier.

MIM integrates injection molding capability with diverse metal selection, and it can replace costly machined components. The process lends itself to automation where high volumes and consistent quality are needed. The process allows for greater design freedom in short development cycles and turnaround time. MIM is ideal for small, complex geometries and intricately-shaped parts. Post MIM, CNC machining can be used to achieve tight tolerances.

MIM parts have excellent strength, ductility, magnetic response, and can be bent, welded, hardened, and heat treated like any other wrought material. A wide variety of metals can be used for medical device manufacturing using a MIM process, including stainless steel, low alloy steels, carbon steels, Fe-Ni alloys, cobalt alloys, tool steel, and Tungsten alloys. Ceramics can be used for injection molding as well, particularly when furnace furniture is required, though most of our projects typically employ metals.

A majority of single-use disposable instruments produced through a MIM process use 17-4 grade stainless steel, which can be tempered to various hardness and close to 300-series stainless steel in corrosion resistance. In addition, 316- and 400-series stainless steel can be used in specialty applications, and 316 stainless steel is the gold standard for corrosion resistance when using injection molding. A 440-grade stainless steel can be hardened beyond what is capable with 17-4 grade, however, corrosion resistance is better with 17-4 grade and 440-grade requires tighter control of heat treating and a more robust post-cleaning process.

Some stainless-steel grades aren’t able to achieve the same degree of strength as other grades, so it’s important to consider what mechanical properties will be needed when choosing materials. Generally speaking, materials that are readily available and widely used will help reduce costs and process time.

A distinct advantage of an injection molding process is its shorter timelines. For standard components, we can produce 30 to 40 molds a month. Prototype tools will typically require two to three weeks and samples can be produced in one to two weeks. Production tools will take anywhere from four to six weeks. Time frames can be compressed by using reliable vendors to build the molds. Many projects require multiple tools, and bottlenecks can occur at the beginning when deciding on a mold and reviewing designs to ensure functionality will not be compromised. Inefficiencies also may occur at the end of the process if a touchup is needed on a mold or if extensive testing in the metallurgy lab is involved. Be aware of these potential risks and factor them into timelines.

Batch and continuous processes, both widely available, can be used for medical device manufacturing. We utilize a proprietary feedstock formulation with high quality alloy powders needed for surgical instruments. The green strength of our medical parts is quite high, and the advent of higher quality feedstocks have virtually eliminated failures due to molding and handling defects, including green and brown state cracks.

A continuous process is especially conducive for high-volume applications and uses raw materials that are readily available. However, all feedstocks and processes are not equivalent. The key to the process is achieving consistent shrinkage and diffusion of organics out of the metal matrix. Furnace furniture is another consideration that can be overlooked. The part datum structures must be married to the furnace furniture to get the most consistent results, especially if secondary machining is used.

Consistent diffusion of organic binders and surfactants is critical to achieving optimal mechanical properties. High residual carbon content is a disadvantage for components that will be subsequently welded. In addition, poor diffusion increases the voids in the metal matrix by trapping gas and the lower density will dramatically reduce strength. Coring is a common strategy used to help equalize diffusion distances, or material can be removed completely.

In terms of tolerance, a larger feature will require a larger tolerance, since parts shrink 15-18 percent during sintering. Keep in mind that more shrinkage will occur in a vertical direction due to gravity and less shrinkage will occur in a lengthwise direction due to drag on the furnace furniture.

Larger, longer parts will require tighter tolerances and machining may be necessary depending on the application. Thickness must withstand the weight of the part in the furnace and complex parts like jaws with cantilevered design features will require custom furnace furniture.

Design for Manufacturability

Design and commercial considerations are important factors for medical device manufacturing. A Design for Manufacturability (DFM) approach allows design and development cycles to be shortened so products can be manufactured at a lower cost. Using DFM, an experienced CMO can identify raw materials and methods that will optimize the manufacturing process by reducing steps and ensuring standardization in parts quality. An even thickness, stable base while sintering, and good feedstock flow can all be achieved with good design considerations.

Conclusion

CMOs should consult with OEM customers early on in the process to review and align on design and commercial needs of each project. Doing so will ensure that risks are reduced, and products achieve target functionality at cost. Using modern manufacturing techniques, including MIM, combined with engineering expertise and innovation, CMOs can deliver high-quality parts and products for their customers efficiently, cost-effectively, and on time.

Steve Santoro, executive vice president at MICRO, delivered a keynote address during MIM2021: International Conference on Injection Molding of Metals, Ceramics and Carbides, held virtually Feb. 22-25.