Sam Brusco, Associate Editor03.04.21

The SARS-CoV-2 pandemic’s extreme disruption was by no means limited to the medical device industry; virtually every industry floundered as they struggled to cope with travel restrictions, social distancing guidelines, skeleton crews of employees on site, and anxiety about how long the pandemic would rage on.

The medical device industry, however, was uniquely impacted for a number of reasons. Procedures considered elective were cancelled or postponed to free up critical hospital beds. Medtech makers who provided technologies used in elective procedures—orthopedic manufacturers, for example—watched their revenue plummet as hospitals purchased far less of their products.

“As the spring and summer played out we saw a sharp drop off in cardiovascular and orthopedic customers due to elective surgeries being shelved,” said Patrick Pickerell, president of Peridot Corp., a Pleasanton, Calif.-based precision manufacturing firm specializing in medical components, miniature and micro-miniature components, and general product prototypes and fabrications. “Who would have thought that cardiovascular would be considered elective?”

Though some sectors were handcuffed, the pandemic has also spurred the mission-critical diagnostics industry into action. A race promptly began to develop novel and rapid diagnostics kits to detect coronavirus. During health crises, the U.S. Food and Drug Administration (FDA) often approves integral pharmaceuticals, medtech, and diagnostic tests under its far less stringent emergency use authorization (EUA). According to Grand View Research, the infectious disease segment dominated the in-vitro diagnostics (IVD) market and accounted for the lion’s share of revenue—41.8 percent—in 2020. This was attributable to increasing COVID-19, HIV, AIDS, tuberculosis, and pneumonia incidence.

The staggering demand for COVID-19 diagnostic tests sent shockwaves through the IVD industry. Once a test has been developed and evaluated, even prior to EUA, test makers had to immediately ramp up production to astronomical levels. As a result, they likely leaned heavily on their manufacturing partners. Manufacturers of RT-PCR tests, antigen tests, next-generation sequencing (NGS) tests, and antibody tests felt the squeeze as demand ballooned.

A polymerase chain reaction (PCR) test detects a specific organism’s genetic material—for example, a virus. The test is used to functionally analyze genes, diagnose and monitor hereditary diseases, clone/sequence DNA, and amplify ancient DNA. RT-PCR (reverse transcription PCR), the most recent iteration of PCR testing, detects gene expression. RT-PCR testing is hailed as the most sensitive technique available to detect and quantitate mRNA. As such, the RT-PCR test has become a valuable tool to diagnose infection within days. As the most accurate and reliable test available, RT-PCR is the “gold standard” test for diagnosing COVID-19.

A cadre of diagnostic test manufacturers—LabCorp, Quest, Thermo Fisher, Roche, Abbott Laboratories, Becton Dickinson, and a slew of others—have secured FDA EUA for their own COVID-19 PCR tests. As a result, IVD component manufacturers serving this sector have witnessed projects surge to assist their diagnostic test manufacturing partners.

“While more people have been exposed to oncotype DX testing, COVID-19 has magnified the importance of PCR testing and why it is essential to have accurate, rapid results,” said Krista Ewing, Ph.D., strategic marketing manager—diagnostics, at Porex, a Fairburn, Ga.-based developer of custom-engineered porous polymer solutions. “Prior to the pandemic, PCR testing wasn’t regularly discussed in the news. But as it stands, PCR testing is the preferred technique to identify when individuals have contracted COVID-19. As a result, we have faced increased demand for IVD components. To meet this need, we ramped up production of our most-demanded products. All eight of our manufacturing sites remain fully operational with full raw material supply from our vendors.”

Antigen tests are commonly used to diagnose respiratory pathogens like flu and respiratory syntactical virus—and more recently, COVID-19. They detect the presence of a viral antigen in a sample, implying current viral infection. Administered via nasopharyngeal or nasal swab, specimens can be placed directly into the assay’s extraction buffer or reagent. They are relatively inexpensive, and most can be used at the point of care.

Most currently authorized antigen tests return results in about 15 minutes. They’re generally less sensitive than RT-PCR tests, and proper test result interpretation and confirmatory testing, when indicated, are best practices. Antigen tests are useful tools to screen testing in high-risk congregate settings, where repeat testing could quickly identify SARS-CoV-2 infections to inform prevention and control measures, stifling transmission. Authorized for home specimen collection in late December, Abbott Laboratories’ BinaxNOW COVID-19 Ag Card identifies COVID-19 infection in 15 minutes and costs $25.

IVD manufacturing partners are also providing needed assistance to keep up with antigen test demand.

“This past year, we partnered with Maxim Biomedical to begin production of SARS-CoV-2 rapid antigen point-of-care tests to assist organizations seeking the benefits of rapid testing,” said Steve Lents, chief revenue officer at TEAM Technologies, a Morristown, Tenn.-based end-to-end manufacturing solutions provider for medical and dental products. “The test kits are lateral flow assays (LFAs) that offer a streamlined workflow and a closed-tube format that eliminates the need for expensive equipment or a reader to perform. This initiative will produce much-needed testing solutions for a variety of markets and industries.”

The co-developed assay combines the specimen swab, reagents, and test strip in a compact, self-contained environment. This allows incubation, reading, and disposal in one tube. The sample swab’s handle can be broken off to leave it in the tube for the whole process, minimizing contamination risk. The test’s interpretation is simple—two lines will appear within 15 minutes if the test is positive. No complex test readers or other expensive equipment is needed, and results remain stable for over two hours.

The co-developed test arose from the NIH’s Rapid Acceleration of Diagnostics (RADx) initiative, launched last April to supercharge innovation COVID-19 testing technology development, commercialization, and implementation. TEAM Technologies provided product development, supply line expertise, and packaging and kitting of the diagnostic tests. TEAM and Maxim aimed to produce 3 million tests by early 2021. According to a late November press release, Maxim Biomedical expects to scale up to 15 million tests per month by Q2 of this year. Though the test hasn’t yet been authorized, they stand waiting in reserve to assist the effort.

Next-generation sequencing (NGS) technology sequences DNA or RNA to study genetic variation associated with diseases or other biological phenomena. It enables examination of hundreds of thousands of genes at a time in multiple samples. NGS can also discover and analyze different types of genomic sequencing in one sequencing run. Its speed, accuracy, and throughput has enabled new applications in genomic and clinical research, reproductive health, and environmental, agricultural, and forensic science.

NGS is an effective, unbiased way to spot new coronavirus strains (and other pathogens) without prior knowledge of organisms.1 Growing worry about the spread of novel SARS-CoV-2 variants—like the B.1.1.7 strain (UK) and B1.351 strain (South Africa)—highlighted the need for more sequencing to speedily detect mutations and prevent spread of novel strains. Sequencing was used to identify the novel coronavirus causing COVID-19 early in the outbreak, and NGS continues to provide valuable and critical evidence for public health officials, vaccine and drug developers, and researchers.

“We are heavily vested in the molecular diagnostics space, so significant demand was driven by next-generation sequencing (NGS) companies’ responses to the pandemic,” commented Jeff Kelly, vice president of corporate development at LaunchWorks, a Beverly, Mass.-based contract design, development, and manufacturing organization for the life sciences industry. “We scaled to this demand via people, a larger footprint, and automation while putting in strict controls to keep the team safe. In the meantime, to do our part in supporting shortages driven by the pandemic, we added the capability to produce our own transport media for sample collection to help COVID-19 diagnostic testing capacity.”

Keeping the Supply Chain Intact

Medical manufacturing challenges in China at the outbreak’s beginning were among the first signs forecasting the disruption to come. Further turmoil in Asia predicted much wider supply chain challenges. Supercharging manufacturing amid a global competition for resources and moving product as travel was shut down and air freight transport became harder to secure became nightmarish.

Supply chains for diagnostic tests and ancillary materials were (and still are) in the spotlight. For typical medtech product lines, this meant forecasting demand in a business landscape that is changing daily. Visibility into healthcare customers’ needs in real time can be difficult. Some of the disruptions have begun to rectify, but diagnostic tests will remain in high demand for at least the next few months.

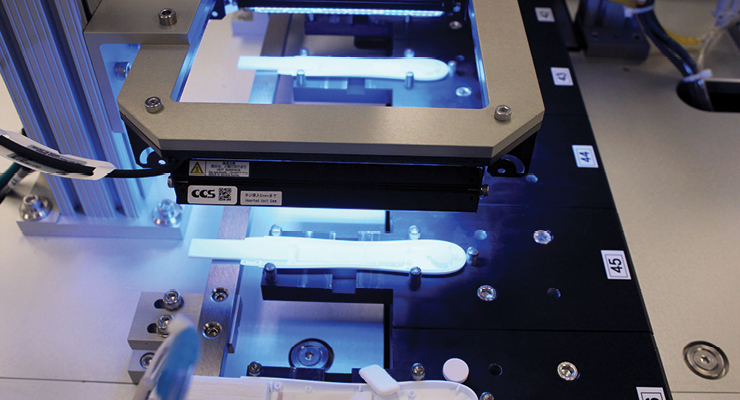

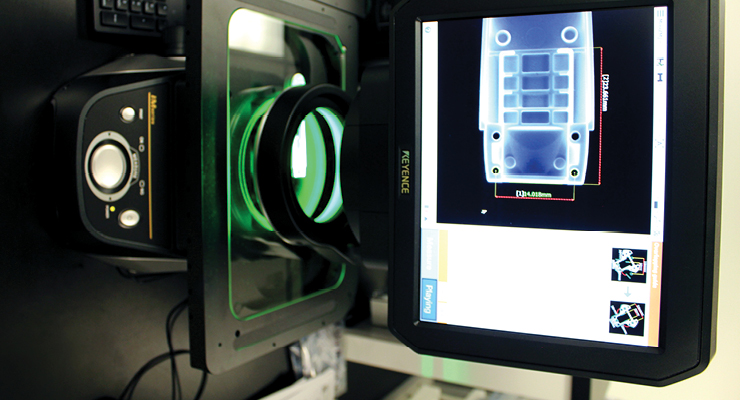

“We are molding components, subassemblies, and full test cartridges for multiple diagnostic OEMs, who are providing COVID-19 testing platforms for our nation,” said John Woodhouse, director of sales and marketing at Medbio, a Grand Rapids, Mich.-based contract manufacturer specializing in clean room injection molding of plastic components for the medical and biotechnology industries. “There has been a large spike in demand for testing and we’ve been able to quickly ramp production to meet that demand. In 2020, we expanded our molding footprint by adding six new molding machines while fully utilizing existing excess capacities, which has provided our diagnostic OEMs increased manufacturing bandwidth. This increase in diagnostic manufacturing has helped to offset the slowdown experienced in our elective procedure applications.”

An intense environment can also be the breeding ground for novel ideas.

“For our pre-pandemic customers, working relationships and communication had to strengthen due to all the demand changes in existing markets,” said Kelly. “The environment also provided opportunities for new projects as these companies developed ideas and products to support COVID-19 diagnostic testing. In parallel, due to our longtime experience in the molecular diagnostic space, we gained new customers to support PCR and ELISA kit manufacturing for COVID-19 testing.”

That suppliers to critical diagnostic technologies were able to remain in operation and, in some cases, ramp up production of critical components had a cascading effect on novel technologies developed during the pandemic. For example, the massive efforts to understand COVID-19 and the innovative technologies to analyze it could have been a major factor in such speedy development of a vaccine.

“The amazing fact that several >90 percent effective SARS-CoV-2 vaccines were developed in record time is due to the efforts of top scientific professionals employing today’s advanced molecular diagnostics systems,” said Pickerell. “These machines were already becoming ubiquitous in the fight against cancer, long before COVID. The mechanical components in these devices must be machined and molded from metals and plastics in an ISO-13485 medical grade facility. Using CNC Swiss Lathes, Laser tube cutters/welders/engravers, Wire EDMs, and multi-axis CNC mills, our professional craftspeople and engineers make miniature needles, machined manifolds, bushings, brackets, nozzles, clips, springs, etc. for the immunoassay systems.”

During times of economic disruption, it’s important to engage in business continuity planning to provide the resources and framework needed to mitigate the negative impact of disruptions while continuing to fulfill key objectives. Business continuity planning involves building resilient streams of revenue and operations. It’s an integral part of contingency planning and is an ongoing process of analysis, understanding the threats that could negatively impact operations, identifying solutions, and discovering more opportunities to be resilient.

Given the far-reaching impacts of the pandemic, effective continuity planning and risk mitigation efforts are especially important. Regardless of size or scope, all organizations should have a business continuity plan that focuses on understanding core business processes and functions, identifying dependencies that support them, and strategies to help fight negative impacts resulting from an emergency.

Qosina, supplier of OEM medical device components to the medical and pharmaceutical industries, had a Business Continuity Management System (BCMS) in place to immediately assess the crisis and begin to enact the actions needed to keep its staff safe and keep business operations running as close to normal as possible. Scott Herskovitz, the firm’s CEO, said the firm couldn’t fathom what it would have been able to accomplish amid the pandemic without a system and manual that provided the framework for action. The company spent no time figuring out who would deal with the crisis or how it would be dealt with. Once the plan was activated, the team was already established and their clearly defined roles allowed for the work to immediately begin.

“Quite frankly, our ability to act quickly, follow our plan and begin implementing solutions from day one allowed our customers—many of whom are essential healthcare companies—to rest assured the part of their supply chain dependent on us would be there so they could concentrate their efforts on other issues arising from the pandemic,” commented Herskovitz. “Our BCMS provided our customers with exactly what the plan is named for: business continuity, which we were able to deliver in the face of a global health crisis.”

Maintaining operations in order to supply critical IVD components also meant keeping employees safe from infection. This meant immediately enacting safety measures such as proper social distancing, a healthy supply of personal protective equipment, and stringent hygiene measures to limit the spread of infection.

“As a manufacturer of SARS-CoV-2 diagnostic instruments in near-patient/point-of-care settings for well-known diagnostic companies, we face two main challenges: Employee health protection/safety, and satisfying customers' high demand for instruments,” said Juergen Neumann, president of LRE Medical, a Nördlingen, Germany-based fully integrated one-stop-shop provider of high-quality engineering solutions for IVD, life science and medtech diagnostic equipment. “Safety of our employees is a top priority, and reducing the risk of infection in the workplace is a key challenge.”

“Through early proactive measures at the beginning of 2020, including regular and strict adjustment of the measures to the COVID-19 situation, we’ve managed to protect employees from infection or the spread of the virus by limiting physical interaction in the workplace, introducing enhanced hygiene measures, and promotion of working remotely,” continued Neumann. “This particularly applies to operation production planning and managing the supply chain for increased volumes. The commitment of our employees to strictly comply with our COVID-19 mandates has enabled smooth operation.”

More recent efforts to prevent the spread of COVID-19 took these procedures even further for some firms.

“Recent implementations have included daily contract trace forms, automated temperature and questionnaire screening upon entering any facility, and more permanent physical barriers if social distancing isn’t practical,” said Woodhouse. “All of these precautions have added challenges and cost, but we’ve been effectively preventing large outbreaks in the work environment, allowing us to increase production to meet the demand of our diagnostics customers.”

After the Pandemic Subsides

Diagnostic tests for COVID-19 will likely capture significant share of the IVD market for months to come. But the pandemic will eventually subside—soon, everyone hopes—and other applications will take center stage again. Development of automated IVD systems for labs and hospitals to provide efficient, accurate, and error-free diagnosis is expected to fuel market growth, according to Grand View Research. The prevalence of diseases like cancer, autoimmune diseases, and inflammatory conditions is also increasing worldwide and expected to drive the demand for IVD testing.

“Even after we get COVID under control, the IVD market will grow exponentially in the fields of genetics, disease treatment, and detection. This is Moore’s Law on steroids with new mNRA technology leapfrogging itself in speed seemingly monthly,” said Pickerell. “The stalwarts of the business (Bio-Rad, Thermo-Fisher, Becton Dickinson, and the like) will certainly prosper, but there are some upstarts that will have the old guard looking over their shoulders. The consumables aspects of these devices will be a massive market for injection molders and assemblers.”

“To better prepare for unprecedented infectious diseases, public, private and global government entities are anticipated to increase funding for improved patient care,” said Ewing. “This will likely encourage development of new disease test platforms, discrete and multiplexed. Investments of this nature may also accelerate development of new diagnostic technologies such as NGS and CRISPR.”

NGS methods—combined with increasing adoption in clinical diagnosis, genomic research, and personalized treatment of a number of diseases—are fueling demand for precise and rapid sequencing interpretation tools and algorithms to expedite data analysis. High genetic data output and a concurrent drop in sequencing prices expect to augment the scope of sequencing projects. The NGS market size is forecasted to reach about $6.9 billion in 2023, according to life sciences strategy consulting firm DeciBio. SARS-CoV-2 NGS testing will represent a small fraction of the industry—about $500 million this year—and taper off in the coming years. But other applications for NGS will likely increase as the technology becomes more widely adopted.

CRISPR is a technology used to edit genes. Its essence is simple: It’s a way to find a specific bit of DNA inside of a cell. After that, the next step in CRISPR gene editing usually alters that piece of DNA.

CRISPR has been adapted for numerous applications. Last February, Cepheid and Sherlock Biosciences began a research collaboration to develop cutting-edge molecular diagnostics tests leveraging SHERLOCK, a CRISPR-based technology that can purportedly identify virtually any target. The new tests will run on Cepheid’s GeneXpert systems. At the time of announcement, the collaboration intended to focus on molecular diagnostic tests for infectious diseases and oncology, beginning with a proof-of-concept project focused on coronavirus detection.

“Moreover, expedited market introduction and the ability to accommodate faster and higher testing volumes will continue, if not increase,” said Ewing. “Lastly, point-of-care testing has become more popular amid the pandemic. Continued growth is expected for this method, along with patient self-testing formats that use minimally invasive sampling methods and affordable consumables.”

Rising demand for point-of-care IVD devices has been a major driver for growth. Recently launched point-of-care IVD instruments and devices are convenient to use and efficient, increasing adoption. The trend of self-monitoring conditions in a proactive healthcare approach is also on the rise, necessitating smaller, more functional, and user-friendly platforms.

“The IVD space is moving more into miniaturized implantable devices—CGM sensors, bio-integrated sensors, and microelectromechanical systems (MEMS) that enable sophisticated diagnostic techniques as well as monitoring and managing glucose levels,” said Jeff Sauter, director of business development at Steri-Tek, a Fremont, Calif.-based provider of high-volume, e-beam/X-ray contract sterilization. “Terminal sterilization of these devices is a vital step in manufacturing to ensure patient safety. It’s imperative to determine optimal sterilization modality early in product development. E-beam has emerged as the preferred terminal sterilization method for these devices because it offers flexibility to optimize post-sterilized performance functionality and performance with continuous temperature control, split dose processing, and intelligent shielding.”

Reference

Full interviews with each industry expert can be viewed here:

The medical device industry, however, was uniquely impacted for a number of reasons. Procedures considered elective were cancelled or postponed to free up critical hospital beds. Medtech makers who provided technologies used in elective procedures—orthopedic manufacturers, for example—watched their revenue plummet as hospitals purchased far less of their products.

“As the spring and summer played out we saw a sharp drop off in cardiovascular and orthopedic customers due to elective surgeries being shelved,” said Patrick Pickerell, president of Peridot Corp., a Pleasanton, Calif.-based precision manufacturing firm specializing in medical components, miniature and micro-miniature components, and general product prototypes and fabrications. “Who would have thought that cardiovascular would be considered elective?”

Though some sectors were handcuffed, the pandemic has also spurred the mission-critical diagnostics industry into action. A race promptly began to develop novel and rapid diagnostics kits to detect coronavirus. During health crises, the U.S. Food and Drug Administration (FDA) often approves integral pharmaceuticals, medtech, and diagnostic tests under its far less stringent emergency use authorization (EUA). According to Grand View Research, the infectious disease segment dominated the in-vitro diagnostics (IVD) market and accounted for the lion’s share of revenue—41.8 percent—in 2020. This was attributable to increasing COVID-19, HIV, AIDS, tuberculosis, and pneumonia incidence.

The staggering demand for COVID-19 diagnostic tests sent shockwaves through the IVD industry. Once a test has been developed and evaluated, even prior to EUA, test makers had to immediately ramp up production to astronomical levels. As a result, they likely leaned heavily on their manufacturing partners. Manufacturers of RT-PCR tests, antigen tests, next-generation sequencing (NGS) tests, and antibody tests felt the squeeze as demand ballooned.

A polymerase chain reaction (PCR) test detects a specific organism’s genetic material—for example, a virus. The test is used to functionally analyze genes, diagnose and monitor hereditary diseases, clone/sequence DNA, and amplify ancient DNA. RT-PCR (reverse transcription PCR), the most recent iteration of PCR testing, detects gene expression. RT-PCR testing is hailed as the most sensitive technique available to detect and quantitate mRNA. As such, the RT-PCR test has become a valuable tool to diagnose infection within days. As the most accurate and reliable test available, RT-PCR is the “gold standard” test for diagnosing COVID-19.

A cadre of diagnostic test manufacturers—LabCorp, Quest, Thermo Fisher, Roche, Abbott Laboratories, Becton Dickinson, and a slew of others—have secured FDA EUA for their own COVID-19 PCR tests. As a result, IVD component manufacturers serving this sector have witnessed projects surge to assist their diagnostic test manufacturing partners.

“While more people have been exposed to oncotype DX testing, COVID-19 has magnified the importance of PCR testing and why it is essential to have accurate, rapid results,” said Krista Ewing, Ph.D., strategic marketing manager—diagnostics, at Porex, a Fairburn, Ga.-based developer of custom-engineered porous polymer solutions. “Prior to the pandemic, PCR testing wasn’t regularly discussed in the news. But as it stands, PCR testing is the preferred technique to identify when individuals have contracted COVID-19. As a result, we have faced increased demand for IVD components. To meet this need, we ramped up production of our most-demanded products. All eight of our manufacturing sites remain fully operational with full raw material supply from our vendors.”

Antigen tests are commonly used to diagnose respiratory pathogens like flu and respiratory syntactical virus—and more recently, COVID-19. They detect the presence of a viral antigen in a sample, implying current viral infection. Administered via nasopharyngeal or nasal swab, specimens can be placed directly into the assay’s extraction buffer or reagent. They are relatively inexpensive, and most can be used at the point of care.

Most currently authorized antigen tests return results in about 15 minutes. They’re generally less sensitive than RT-PCR tests, and proper test result interpretation and confirmatory testing, when indicated, are best practices. Antigen tests are useful tools to screen testing in high-risk congregate settings, where repeat testing could quickly identify SARS-CoV-2 infections to inform prevention and control measures, stifling transmission. Authorized for home specimen collection in late December, Abbott Laboratories’ BinaxNOW COVID-19 Ag Card identifies COVID-19 infection in 15 minutes and costs $25.

IVD manufacturing partners are also providing needed assistance to keep up with antigen test demand.

“This past year, we partnered with Maxim Biomedical to begin production of SARS-CoV-2 rapid antigen point-of-care tests to assist organizations seeking the benefits of rapid testing,” said Steve Lents, chief revenue officer at TEAM Technologies, a Morristown, Tenn.-based end-to-end manufacturing solutions provider for medical and dental products. “The test kits are lateral flow assays (LFAs) that offer a streamlined workflow and a closed-tube format that eliminates the need for expensive equipment or a reader to perform. This initiative will produce much-needed testing solutions for a variety of markets and industries.”

The co-developed assay combines the specimen swab, reagents, and test strip in a compact, self-contained environment. This allows incubation, reading, and disposal in one tube. The sample swab’s handle can be broken off to leave it in the tube for the whole process, minimizing contamination risk. The test’s interpretation is simple—two lines will appear within 15 minutes if the test is positive. No complex test readers or other expensive equipment is needed, and results remain stable for over two hours.

The co-developed test arose from the NIH’s Rapid Acceleration of Diagnostics (RADx) initiative, launched last April to supercharge innovation COVID-19 testing technology development, commercialization, and implementation. TEAM Technologies provided product development, supply line expertise, and packaging and kitting of the diagnostic tests. TEAM and Maxim aimed to produce 3 million tests by early 2021. According to a late November press release, Maxim Biomedical expects to scale up to 15 million tests per month by Q2 of this year. Though the test hasn’t yet been authorized, they stand waiting in reserve to assist the effort.

Next-generation sequencing (NGS) technology sequences DNA or RNA to study genetic variation associated with diseases or other biological phenomena. It enables examination of hundreds of thousands of genes at a time in multiple samples. NGS can also discover and analyze different types of genomic sequencing in one sequencing run. Its speed, accuracy, and throughput has enabled new applications in genomic and clinical research, reproductive health, and environmental, agricultural, and forensic science.

NGS is an effective, unbiased way to spot new coronavirus strains (and other pathogens) without prior knowledge of organisms.1 Growing worry about the spread of novel SARS-CoV-2 variants—like the B.1.1.7 strain (UK) and B1.351 strain (South Africa)—highlighted the need for more sequencing to speedily detect mutations and prevent spread of novel strains. Sequencing was used to identify the novel coronavirus causing COVID-19 early in the outbreak, and NGS continues to provide valuable and critical evidence for public health officials, vaccine and drug developers, and researchers.

“We are heavily vested in the molecular diagnostics space, so significant demand was driven by next-generation sequencing (NGS) companies’ responses to the pandemic,” commented Jeff Kelly, vice president of corporate development at LaunchWorks, a Beverly, Mass.-based contract design, development, and manufacturing organization for the life sciences industry. “We scaled to this demand via people, a larger footprint, and automation while putting in strict controls to keep the team safe. In the meantime, to do our part in supporting shortages driven by the pandemic, we added the capability to produce our own transport media for sample collection to help COVID-19 diagnostic testing capacity.”

Keeping the Supply Chain Intact

Medical manufacturing challenges in China at the outbreak’s beginning were among the first signs forecasting the disruption to come. Further turmoil in Asia predicted much wider supply chain challenges. Supercharging manufacturing amid a global competition for resources and moving product as travel was shut down and air freight transport became harder to secure became nightmarish.

Supply chains for diagnostic tests and ancillary materials were (and still are) in the spotlight. For typical medtech product lines, this meant forecasting demand in a business landscape that is changing daily. Visibility into healthcare customers’ needs in real time can be difficult. Some of the disruptions have begun to rectify, but diagnostic tests will remain in high demand for at least the next few months.

“We are molding components, subassemblies, and full test cartridges for multiple diagnostic OEMs, who are providing COVID-19 testing platforms for our nation,” said John Woodhouse, director of sales and marketing at Medbio, a Grand Rapids, Mich.-based contract manufacturer specializing in clean room injection molding of plastic components for the medical and biotechnology industries. “There has been a large spike in demand for testing and we’ve been able to quickly ramp production to meet that demand. In 2020, we expanded our molding footprint by adding six new molding machines while fully utilizing existing excess capacities, which has provided our diagnostic OEMs increased manufacturing bandwidth. This increase in diagnostic manufacturing has helped to offset the slowdown experienced in our elective procedure applications.”

An intense environment can also be the breeding ground for novel ideas.

“For our pre-pandemic customers, working relationships and communication had to strengthen due to all the demand changes in existing markets,” said Kelly. “The environment also provided opportunities for new projects as these companies developed ideas and products to support COVID-19 diagnostic testing. In parallel, due to our longtime experience in the molecular diagnostic space, we gained new customers to support PCR and ELISA kit manufacturing for COVID-19 testing.”

That suppliers to critical diagnostic technologies were able to remain in operation and, in some cases, ramp up production of critical components had a cascading effect on novel technologies developed during the pandemic. For example, the massive efforts to understand COVID-19 and the innovative technologies to analyze it could have been a major factor in such speedy development of a vaccine.

“The amazing fact that several >90 percent effective SARS-CoV-2 vaccines were developed in record time is due to the efforts of top scientific professionals employing today’s advanced molecular diagnostics systems,” said Pickerell. “These machines were already becoming ubiquitous in the fight against cancer, long before COVID. The mechanical components in these devices must be machined and molded from metals and plastics in an ISO-13485 medical grade facility. Using CNC Swiss Lathes, Laser tube cutters/welders/engravers, Wire EDMs, and multi-axis CNC mills, our professional craftspeople and engineers make miniature needles, machined manifolds, bushings, brackets, nozzles, clips, springs, etc. for the immunoassay systems.”

During times of economic disruption, it’s important to engage in business continuity planning to provide the resources and framework needed to mitigate the negative impact of disruptions while continuing to fulfill key objectives. Business continuity planning involves building resilient streams of revenue and operations. It’s an integral part of contingency planning and is an ongoing process of analysis, understanding the threats that could negatively impact operations, identifying solutions, and discovering more opportunities to be resilient.

Given the far-reaching impacts of the pandemic, effective continuity planning and risk mitigation efforts are especially important. Regardless of size or scope, all organizations should have a business continuity plan that focuses on understanding core business processes and functions, identifying dependencies that support them, and strategies to help fight negative impacts resulting from an emergency.

Qosina, supplier of OEM medical device components to the medical and pharmaceutical industries, had a Business Continuity Management System (BCMS) in place to immediately assess the crisis and begin to enact the actions needed to keep its staff safe and keep business operations running as close to normal as possible. Scott Herskovitz, the firm’s CEO, said the firm couldn’t fathom what it would have been able to accomplish amid the pandemic without a system and manual that provided the framework for action. The company spent no time figuring out who would deal with the crisis or how it would be dealt with. Once the plan was activated, the team was already established and their clearly defined roles allowed for the work to immediately begin.

“Quite frankly, our ability to act quickly, follow our plan and begin implementing solutions from day one allowed our customers—many of whom are essential healthcare companies—to rest assured the part of their supply chain dependent on us would be there so they could concentrate their efforts on other issues arising from the pandemic,” commented Herskovitz. “Our BCMS provided our customers with exactly what the plan is named for: business continuity, which we were able to deliver in the face of a global health crisis.”

Maintaining operations in order to supply critical IVD components also meant keeping employees safe from infection. This meant immediately enacting safety measures such as proper social distancing, a healthy supply of personal protective equipment, and stringent hygiene measures to limit the spread of infection.

“As a manufacturer of SARS-CoV-2 diagnostic instruments in near-patient/point-of-care settings for well-known diagnostic companies, we face two main challenges: Employee health protection/safety, and satisfying customers' high demand for instruments,” said Juergen Neumann, president of LRE Medical, a Nördlingen, Germany-based fully integrated one-stop-shop provider of high-quality engineering solutions for IVD, life science and medtech diagnostic equipment. “Safety of our employees is a top priority, and reducing the risk of infection in the workplace is a key challenge.”

“Through early proactive measures at the beginning of 2020, including regular and strict adjustment of the measures to the COVID-19 situation, we’ve managed to protect employees from infection or the spread of the virus by limiting physical interaction in the workplace, introducing enhanced hygiene measures, and promotion of working remotely,” continued Neumann. “This particularly applies to operation production planning and managing the supply chain for increased volumes. The commitment of our employees to strictly comply with our COVID-19 mandates has enabled smooth operation.”

More recent efforts to prevent the spread of COVID-19 took these procedures even further for some firms.

“Recent implementations have included daily contract trace forms, automated temperature and questionnaire screening upon entering any facility, and more permanent physical barriers if social distancing isn’t practical,” said Woodhouse. “All of these precautions have added challenges and cost, but we’ve been effectively preventing large outbreaks in the work environment, allowing us to increase production to meet the demand of our diagnostics customers.”

After the Pandemic Subsides

Diagnostic tests for COVID-19 will likely capture significant share of the IVD market for months to come. But the pandemic will eventually subside—soon, everyone hopes—and other applications will take center stage again. Development of automated IVD systems for labs and hospitals to provide efficient, accurate, and error-free diagnosis is expected to fuel market growth, according to Grand View Research. The prevalence of diseases like cancer, autoimmune diseases, and inflammatory conditions is also increasing worldwide and expected to drive the demand for IVD testing.

“Even after we get COVID under control, the IVD market will grow exponentially in the fields of genetics, disease treatment, and detection. This is Moore’s Law on steroids with new mNRA technology leapfrogging itself in speed seemingly monthly,” said Pickerell. “The stalwarts of the business (Bio-Rad, Thermo-Fisher, Becton Dickinson, and the like) will certainly prosper, but there are some upstarts that will have the old guard looking over their shoulders. The consumables aspects of these devices will be a massive market for injection molders and assemblers.”

“To better prepare for unprecedented infectious diseases, public, private and global government entities are anticipated to increase funding for improved patient care,” said Ewing. “This will likely encourage development of new disease test platforms, discrete and multiplexed. Investments of this nature may also accelerate development of new diagnostic technologies such as NGS and CRISPR.”

NGS methods—combined with increasing adoption in clinical diagnosis, genomic research, and personalized treatment of a number of diseases—are fueling demand for precise and rapid sequencing interpretation tools and algorithms to expedite data analysis. High genetic data output and a concurrent drop in sequencing prices expect to augment the scope of sequencing projects. The NGS market size is forecasted to reach about $6.9 billion in 2023, according to life sciences strategy consulting firm DeciBio. SARS-CoV-2 NGS testing will represent a small fraction of the industry—about $500 million this year—and taper off in the coming years. But other applications for NGS will likely increase as the technology becomes more widely adopted.

CRISPR is a technology used to edit genes. Its essence is simple: It’s a way to find a specific bit of DNA inside of a cell. After that, the next step in CRISPR gene editing usually alters that piece of DNA.

CRISPR has been adapted for numerous applications. Last February, Cepheid and Sherlock Biosciences began a research collaboration to develop cutting-edge molecular diagnostics tests leveraging SHERLOCK, a CRISPR-based technology that can purportedly identify virtually any target. The new tests will run on Cepheid’s GeneXpert systems. At the time of announcement, the collaboration intended to focus on molecular diagnostic tests for infectious diseases and oncology, beginning with a proof-of-concept project focused on coronavirus detection.

“Moreover, expedited market introduction and the ability to accommodate faster and higher testing volumes will continue, if not increase,” said Ewing. “Lastly, point-of-care testing has become more popular amid the pandemic. Continued growth is expected for this method, along with patient self-testing formats that use minimally invasive sampling methods and affordable consumables.”

Rising demand for point-of-care IVD devices has been a major driver for growth. Recently launched point-of-care IVD instruments and devices are convenient to use and efficient, increasing adoption. The trend of self-monitoring conditions in a proactive healthcare approach is also on the rise, necessitating smaller, more functional, and user-friendly platforms.

“The IVD space is moving more into miniaturized implantable devices—CGM sensors, bio-integrated sensors, and microelectromechanical systems (MEMS) that enable sophisticated diagnostic techniques as well as monitoring and managing glucose levels,” said Jeff Sauter, director of business development at Steri-Tek, a Fremont, Calif.-based provider of high-volume, e-beam/X-ray contract sterilization. “Terminal sterilization of these devices is a vital step in manufacturing to ensure patient safety. It’s imperative to determine optimal sterilization modality early in product development. E-beam has emerged as the preferred terminal sterilization method for these devices because it offers flexibility to optimize post-sterilized performance functionality and performance with continuous temperature control, split dose processing, and intelligent shielding.”

Reference

- Bulcha B. Review on viral metagenomics and its future perspective in zoonotic and arboviral disease surveillance. J Biol Agr Healthc. 2017; 7(21): 35–41.

Full interviews with each industry expert can be viewed here: