Mark Crawford, Contributing Writer07.30.19

As the demand increases for complex medical devices, especially for implants and minimally invasive and robotic surgical procedures, there is also an increased demand for high-performance, biocompatible specialty coatings that meet the clinical, engineering, and operational (cost, quality, delivery) requirements for these devices.

Medical coatings range from lubrications to antimicrobials to water-repellent polymers and can be customized to the type of device or application to improve patient outcomes. They can also improve the effectiveness of these devices and extend their usable life. Antimicrobial, hydrophilic, fluoropolymer, and anodic coatings are some of the most popular. Medical device manufacturers (MDMs) are also using physical vapor deposition (PVD) to create durable, functional coatings for surgical instruments, knee replacements, dental implants, and other specialty items.

Regardless of the type of coating required, surface preparation is always required for creating a strong bond with the substrate (features can be as small as 20-50 nm). Manufacturers continue to develop more comprehensive specifications and new processes for creating consistent surfaces prior to coating.

“Surface treatment methods and techniques are constantly evolving to keep up with improvements to existing substrates, as well as newly developed substrates and polymers,” said Bruce Mahan, engineering manager for CI Medical, a Norton, Mass.-based pad printing company that serves the medical device industry.

Latest Trends

A greater selection of coating materials, with highly specific engineered properties, is being developed to meet the multifunctionality of advanced medical devices. Sometimes different coatings are even required for different surfaces on the same device. Existing substrate materials are being utilized in innovative ways, including nitinol, titanium, cast aluminum, and polyetheretherketone (PEEK). In addition, additive manufacturing (AM) creates new material structures and textures that challenge the effectiveness of traditional coating methods.

Hydrophilic coatings are in high demand, especially for lower-cost medical devices.

“In the past, a device such as an introducer would be unlikely to have a coating on it,” said Drew Summerville, vice president of marketing for Harland Medical Systems, an Eden Prairie, Minn.-based provider of medical device coatings and automated coating and testing equipment. “Now, however, because of the adoption of radial access procedures, coated introducers are quite common. This trend puts pressure on the economics of adding a hydrophilic coating.”

According to MarketWatch, cardiovascular devices accounted for the largest share of the coatings market in the U.S. in 2015—about 35 percent. This segment is expected to grow at a compound annual growth (CAGR) rate of 3.22 percent from 2016 to 2021. Orthopedics was the second-largest application market in 2015, capturing 21.84 percent volume share, growing at a slightly faster rate of 5 percent.

“Devices for structural heart, peripheral vascular, robotic surgery, and diagnostics are among the highest-growth segments,” said Bill Ellerkamp, president of Precision Coating, a Hudson, Mass.-based provider of fluoropolymer, anodic, and hydrophilic coating application services for the medical device industry. “These segments are looking for a range of functionality from specialty coatings including life cycle integrity, substrate compatibility and adhesion, conformance, and precision and accuracy of application. Biocompatibility is a must, of course. Bioeffectiveness is critical for active coatings, which promote or inhibit biodynamic activity such as drug elution, osseointegration, coagulation, and anti-bacterial/anti-microbial functionality.”

According to Nader Kalkhoran, vice president of business development and global sales for N2 Biomedical, a Bedford, Mass.-based provider of coating and surface treatment services for a wide range of medical and industrial applications, orthopedic OEMs are highly aware of patient sensitivity to metal ion release and infection rate. “Therefore coatings and surface treatment options addressing these issues are gaining more attention in the industry,” he said. “There is also increased emphasis on surface texturing of medical devices on nanoscale to enhance tissue attachment and growth, as well as inhibit bacterial colonization.”

As more catheter-based procedures are developed for brain procedures, the neuro-interventional market is also expanding. “The rapid growth of structural heart devices also makes hydrophilic coatings a necessity for these delivery systems,” said Summerville.

OEMs also want durable, long-lasting products with coatings that can withstand multiple cleaning and sterilization cycles. In addition, “we have noticed the progression of minimally invasive and robotic procedures has produced an upturn in insulative and abrasion-resistant coatings,” said James Morris, president and CEO of Surgical Coatings, a Sedalia, Colo.-based provider of surface coating services for the medical device industry.

What OEMs Want

Using safe, cost-effective coatings is a top priority for any MDM. Well-established, off-the-shelf coatings and materials are preferred because they are low risk and have an established cost. However, more expensive proprietary coating formulas, specific to a single device or application, are often required for many advanced devices. This higher degree of customization for advanced devices often presents unique coating challenges.

“Coatings may be required to cover the entire complex structure, or just part of the complex structure, and must adhere to the variety of materials used within the device,” said Khristine Carroll, executive vice president for AdvanSource Biomaterials, a Wilmington, Mass.-based material technology company specializing in material formulation and synthesis for custom coatings and coating process applications. “This requires a combination of various coating techniques to achieve the best results. With a wide range of customizable coating materials, and an expansive range of customizable coating techniques, including plasma polymerization, coatings can be optimized for complex devices.”

Other common OEM requests include low particle generation, more abrasion resistance, increased durability, infection resistance, reduced friction, and efficient curing systems. MDMs are also asking for thinner coatings that add minimal additional thickness to coated devices—for example, those that navigate small and tortuous pathways inside the body.

The bottom line, however, is that MDMs want long-lasting coatings with improved properties at the lowest possible price.

“There is no question that manufacturers want high-quality, durable, and long-lasting products,” said David Wayne, director of sales and marketing for Vapor Technologies, a Longmont, Colo.-based manufacturer of physical vapor deposition (PVD) coating equipment. “But they also want to be able to coat parts for $20 a batch instead of $20 a part.”

With cost always top of mind, OEMs are eager to find ways to reduce expenses. One way is by overhauling supply chains and reducing the number of approved vendors. Coating applicators that can handle multiple tasks—such as sourcing, procuring, and managing raw materials—are preferred. “OEMs want their coating applicators to manage more of the value stream activities associated with the parts they need coated,” said Ellerkamp. “These can include cleaning, surface preparation, marking and printing, secondary operations, packaging, and Kanban/inventory management.”

Technology Advances

New materials and substrates are constantly being developed for the demands of the medical device industry. Medical device design engineers, working collaboratively with plastics engineers, are constantly pushing the technology envelope to develop new materials that enhance the functionality of their medical device designs. For example, coatings that can self-heal after being damaged are actively being developed.

Multi-functionality—for example, designing integrated chemistry and process solutions which optimize competing design criteria (such as example abrasion resistance and lubricity in a fluoropolymer coating, or hardness and chemical resistance in an anodic coating)—is in high demand. Another example is the combination of selective conductive/non-conductive coatings and identification and traceability markers.

AdvanSource Biomaterials Corporation continues to expand upon options associated with solution use or combination solutions using its core material platforms. By targeting specific formulation adaptations to create certain solubility and associated properties, “we can offer materials with a greater range of characteristics, such as able hardening or damping, insolation or conductivity, increased visibility under multiple sources, and targeted delivery mechanisms as well as diffusion rates,” said Carroll.

For the implanted and wearable biosensor segments, there is an increasing need for precision coatings that not only improve the biocompatibility of the sensors, but also protect the enzyme sensing layer so the biosensor can function longer in the body and regulate the flux analytes in and out of the sensors. Several challenges exist for this type of coating—for example, the coating needs to be thin enough to allow the permeation of the analytes, the thickness needs to be very well controlled to ensure consistency from device to device, and the coating process must be gentle enough to preserve the functionality of the enzyme-sensing layer.

“Plasma polymerization is an excellent coating technology platform for creating highly customizable and precise ultrathin coatings for biosensors,” said Kevin Chen, chief technology officer for Medical Surface, a Natick, Mass.-based medical device coating company specializing in plasma surface treatment, plasma polymerization coating, and plasma-enhanced chemical vapor deposition. “This process allows us to create ultrathin [nanometer] coatings, while using a quartz crystal microbalance during the coating process to control the thickness accurately.”

A challenge for many of the new plastics being developed is that very little will adhere to the substrate, including medical grade inks. Such specialty plastics require pre-treatment to promote ink adhesion. CI Medical has formulated specialty gases that, by adjusting the volume of the component gases and exposure time of the components to the gases, can promote superior ink adhesion on many of these challenging surfaces. “Our proprietary coatings can be used on a variety of substrates and enable the device to be seen under fluoroscopy and x-ray,” said Mahan.

“Combining surface treatments and coatings have yielded new opportunities to coat materials that previously resisted adhesion,” agreed Carroll. “For example, plasma polymerization or alternate surface conditioning can activate surfaces that were previously very difficult to coat.”

Application Approaches

Areas that are coating-free are mission-critical in electrosurgical devices. Surgical Coatings utilizes a proprietary “virtual masking” process to ensure perfectly defined coating-free areas and eliminate poor edge quality, boosting overall surface quality. Virtual masking processes have continued to advance over the last two decades. “Using automated laser systems, we can remove the coating from substrates in very specific and tight-tolerance areas, producing a perfect quality edge surrounding coating-free areas,” said Morris. “This ensures flake-free edges and allows us to apply coatings on complex geometries. The automation behind these systems is critical to high-volume production and allows us to focus on coating applications, without wasting time on traditional masking procedures.”

Surgical Coatings has also developed a tunable corona discharge for electrostatic powder coatings. Although several powder-coating equipment manufacturers offer corona discharges to reduce back-ionization, orange peel, and other typical Faraday effects, “we found they did not perform well for the complex geometries and unique materials we often see in the medical device industry,” said Morris. “Using our tunable corona discharge, we have been able to coat difficult materials onto especially complex geometries, while maintaining coating thickness tolerances ±0.0005” in some cases.”

An increasing number of MDMs seek out durable color options for stainless steel and other non-anodizable alloys for product differentiation or aesthetics. N2 Biomedical recently developed a durable ceramic-based color-coating process called Spectrum that serves as an alternative or supplement to the color anodizing process. Spectrum coatings can be applied to any metal alloy including stainless steel, cobalt-chromium, nickel-titanium, and copper-nickel-titanium, providing many more color tones than currently available from anodized titanium.

Chemical vapor deposition and plasma-enhanced chemical vapor deposition (PECVD) have been widely used for electronic devices, such as application of water-proof coatings. In recent years there has been increased interest in coating carbon nanotube and graphene materials, which have attractive properties such as surface conductivity and transparency. “Plasma polymerization methods can be used to create surface functional groups on carbon nanotube and graphene materials, making them even more attractive in a variety of applications,” said Chen.

Manufacturers have known for decades about the benefits of in-house PVD (physical vapor deposition) coating: time savings, quality control, and customized thin film coatings that differentiate products by improving function and appearance. The process can sidestep the use of hexavalent chromium and concentrated acids common in traditional chrome plating. In the past, however, this equipment was too expensive for lower-volume operations and too difficult to integrate into existing manufacturing facilities. There was also the misconception that PVD-based techniques could only process a limited number of parts in a single batch over a relatively long processing time. Today, however, there exists both batch-based and in-line high throughput PVD systems that can process parts at high volumes as cost-effectively as non-vacuum-based coating techniques.

“PVD can deposit a durable decorative, pure chromium coating without toxic components,” said Wayne. “The addition of elements such as nitrogen can also produce even more durable chrome alternatives such as chromium nitride that greatly improve performance in high-wear applications.”

PVD systems are also now available in compact, affordable systems that are easy to install and use. “We recommend that smaller operations that send their parts out to coating services look at the in-house alternative,” continued Wayne. “If it makes financial sense, a smaller operation can get all the benefits that large-scale operations get from investing in a coating machine.”

For sandblasting surface treatments, many OEMs don’t realize how precisely micro-abrasive blasting (or precision sandblasting) can be controlled. For example, equipment made by Comco, a Burbank, Calif.-based manufacturer of micro-precision sandblasting equipment, can create consistent surface finishes that meet tightly defined surface texture parameters of Ra, Sa, and Sdr. “The AccuFlo abrasive blaster uses a patented method of mixing air and abrasive to ensure the consistent flow necessary to achieve such exacting results,” said Colin Weightman, director of technology for Comco. “For example, we can achieve an Ra [arithmetical mean height of a line] of 5-150 μin with a standard deviation of less than 5.0 μin. No masking is necessary to achieve a sharp delineation between the blasted and unblasted surface—we can achieve a transition zone of less than 0.007 inches.”

A key area of innovation and advancement in quality control is automation and inspection. Manual coating and human error have typically been the biggest source of scrap in coating applications and services. Automated coating equipment with a computer interface allows operators to design and apply customized coatings to a greater variety of complex devices, especially when the process is coupled with 3D printing.

“Significant investments in robotics enable us to achieve very thin and highly consistent process control [8 Sigma] against increasingly tight tolerances,” said Ellerkamp. “This has required significant changes in the manufacturing process as well as manufacturing support and process engineering. Advances in machine learning systems are enabling us to automate inspection of critical attributes.”

The Challenges of Additive Manufacturing

Parts constructed using additive manufacturing (AM) methods typically require coatings. Implantable devices often need a surface that isolates the materials used in the AM process from the patient. Perhaps the biggest challenge for coating AM parts is the substrate itself. For example, 3D-printed plastics have unique mesh patterns that present varying levels of surface roughness and porosity. Liquid coating a surface that presents irregular or uneven levels of porosity and surface roughness usually requires some adaptive and reactive automation techniques to achieve success. AM devices often require a thicker coating to smooth out uneven surfaces. The surface adhesion properties of 3D-printed devices may also be different from molded devices, even when the substrate material is similar. “Therefore coatings optimized for molded devices may need to be re-optimized for 3D printed devices,” said Chen.

New raw materials for AM, especially for metal additive manufacturing, typically contain binders which may inhibit certain coatings from adhering effectively and/or change the porosity of the finished substrate. This may also require the coatings and/or application process to be re-engineered.

In addition, many AM plastics cannot withstand the process or curing temperatures required by even the lowest cure temperature powder coatings, therefore limiting the available application options. “These additive substrates limit and challenge the coating selection process, especially in the medical device industry, where particular materials and ingredients are off limits for biocompatibility reasons,” said Morris. “Adapting to these new substrates will likely result in the development of new and coating materials that will specifically address these challenges.

Nonstop Innovation

Forward-thinking coating providers will stay ahead of the technology curve and integrate new technologies such as advanced laser processing, automation, and machine learning into their core processes, thereby being able to meet challenging OEM demands when others cannot. OEMs now regularly design more complex or customized devices made from new substrates that often don’t “take” to existing coating methods. Finding the right coatings for these products, which meet their highly specific performance requirements, often pushes material science to the limits to find an innovative solution.

“Some of the newer treatments utilize coatings as a carrier for drugs or biologics, permitting localized and controlled release of therapeutics to overcome problems associated with systemic administration,” said Kalkhoran. “Although this concept is not new and has been applied to several devices such as drug-eluting stents and balloons, there are few such coated products currently on the market and the breadth of research continues to expand.”

For example, researchers at Stevens Institute of Technology have developed a “self-defensive surface” for joint implants. The implants are dipped first into microgel flecks and then covered with a charged solution. The resulting coating can release micro-doses of antibiotics when bacteria approach, using antibiotics tailored to the patient’s specific risk factors. In another study, scientists at Boston University School of Medicine have studied the intrinsic structure of drug coatings from balloon catheters under a scanning electron microscope. They discovered that some of the microscopic particles in the coatings are shaped like needles and others are round, which create differences in the amount and rate of drug transfer. The researchers hope they will be able to homogenize the structure of the coating to optimize drug release, leading to better outcomes for people suffering with arterial disease.

A new antibacterial polyurethane coating for intravascular catheters has been developed at Brown University. The coating gradually releases a drug called auranofin that can kill both planktonic (free-floating) bacteria and prevent colonization of bacteria on device surfaces, a big step toward reducing catheter-related bloodstream infections. Finally, a research team from Chalmers University of Technology in Sweden has developed a novel coating whose surface is covered with vertical graphene flakes that slice up any bacteria that try to take hold, killing them.

As medical devices become smaller and more complex, and utilize advanced materials with tighter dimensional constraints, the need for specialized coatings and innovative surface treatments will grow. “This, coupled with continuing enhancements in design opportunities and material advancements, will continue to create high-growth opportunities and a pressing market need for an increasing array of coating options,” said Carroll.

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.

Medical coatings range from lubrications to antimicrobials to water-repellent polymers and can be customized to the type of device or application to improve patient outcomes. They can also improve the effectiveness of these devices and extend their usable life. Antimicrobial, hydrophilic, fluoropolymer, and anodic coatings are some of the most popular. Medical device manufacturers (MDMs) are also using physical vapor deposition (PVD) to create durable, functional coatings for surgical instruments, knee replacements, dental implants, and other specialty items.

Regardless of the type of coating required, surface preparation is always required for creating a strong bond with the substrate (features can be as small as 20-50 nm). Manufacturers continue to develop more comprehensive specifications and new processes for creating consistent surfaces prior to coating.

“Surface treatment methods and techniques are constantly evolving to keep up with improvements to existing substrates, as well as newly developed substrates and polymers,” said Bruce Mahan, engineering manager for CI Medical, a Norton, Mass.-based pad printing company that serves the medical device industry.

Latest Trends

A greater selection of coating materials, with highly specific engineered properties, is being developed to meet the multifunctionality of advanced medical devices. Sometimes different coatings are even required for different surfaces on the same device. Existing substrate materials are being utilized in innovative ways, including nitinol, titanium, cast aluminum, and polyetheretherketone (PEEK). In addition, additive manufacturing (AM) creates new material structures and textures that challenge the effectiveness of traditional coating methods.

Hydrophilic coatings are in high demand, especially for lower-cost medical devices.

“In the past, a device such as an introducer would be unlikely to have a coating on it,” said Drew Summerville, vice president of marketing for Harland Medical Systems, an Eden Prairie, Minn.-based provider of medical device coatings and automated coating and testing equipment. “Now, however, because of the adoption of radial access procedures, coated introducers are quite common. This trend puts pressure on the economics of adding a hydrophilic coating.”

According to MarketWatch, cardiovascular devices accounted for the largest share of the coatings market in the U.S. in 2015—about 35 percent. This segment is expected to grow at a compound annual growth (CAGR) rate of 3.22 percent from 2016 to 2021. Orthopedics was the second-largest application market in 2015, capturing 21.84 percent volume share, growing at a slightly faster rate of 5 percent.

“Devices for structural heart, peripheral vascular, robotic surgery, and diagnostics are among the highest-growth segments,” said Bill Ellerkamp, president of Precision Coating, a Hudson, Mass.-based provider of fluoropolymer, anodic, and hydrophilic coating application services for the medical device industry. “These segments are looking for a range of functionality from specialty coatings including life cycle integrity, substrate compatibility and adhesion, conformance, and precision and accuracy of application. Biocompatibility is a must, of course. Bioeffectiveness is critical for active coatings, which promote or inhibit biodynamic activity such as drug elution, osseointegration, coagulation, and anti-bacterial/anti-microbial functionality.”

According to Nader Kalkhoran, vice president of business development and global sales for N2 Biomedical, a Bedford, Mass.-based provider of coating and surface treatment services for a wide range of medical and industrial applications, orthopedic OEMs are highly aware of patient sensitivity to metal ion release and infection rate. “Therefore coatings and surface treatment options addressing these issues are gaining more attention in the industry,” he said. “There is also increased emphasis on surface texturing of medical devices on nanoscale to enhance tissue attachment and growth, as well as inhibit bacterial colonization.”

As more catheter-based procedures are developed for brain procedures, the neuro-interventional market is also expanding. “The rapid growth of structural heart devices also makes hydrophilic coatings a necessity for these delivery systems,” said Summerville.

OEMs also want durable, long-lasting products with coatings that can withstand multiple cleaning and sterilization cycles. In addition, “we have noticed the progression of minimally invasive and robotic procedures has produced an upturn in insulative and abrasion-resistant coatings,” said James Morris, president and CEO of Surgical Coatings, a Sedalia, Colo.-based provider of surface coating services for the medical device industry.

What OEMs Want

Using safe, cost-effective coatings is a top priority for any MDM. Well-established, off-the-shelf coatings and materials are preferred because they are low risk and have an established cost. However, more expensive proprietary coating formulas, specific to a single device or application, are often required for many advanced devices. This higher degree of customization for advanced devices often presents unique coating challenges.

“Coatings may be required to cover the entire complex structure, or just part of the complex structure, and must adhere to the variety of materials used within the device,” said Khristine Carroll, executive vice president for AdvanSource Biomaterials, a Wilmington, Mass.-based material technology company specializing in material formulation and synthesis for custom coatings and coating process applications. “This requires a combination of various coating techniques to achieve the best results. With a wide range of customizable coating materials, and an expansive range of customizable coating techniques, including plasma polymerization, coatings can be optimized for complex devices.”

Other common OEM requests include low particle generation, more abrasion resistance, increased durability, infection resistance, reduced friction, and efficient curing systems. MDMs are also asking for thinner coatings that add minimal additional thickness to coated devices—for example, those that navigate small and tortuous pathways inside the body.

The bottom line, however, is that MDMs want long-lasting coatings with improved properties at the lowest possible price.

“There is no question that manufacturers want high-quality, durable, and long-lasting products,” said David Wayne, director of sales and marketing for Vapor Technologies, a Longmont, Colo.-based manufacturer of physical vapor deposition (PVD) coating equipment. “But they also want to be able to coat parts for $20 a batch instead of $20 a part.”

With cost always top of mind, OEMs are eager to find ways to reduce expenses. One way is by overhauling supply chains and reducing the number of approved vendors. Coating applicators that can handle multiple tasks—such as sourcing, procuring, and managing raw materials—are preferred. “OEMs want their coating applicators to manage more of the value stream activities associated with the parts they need coated,” said Ellerkamp. “These can include cleaning, surface preparation, marking and printing, secondary operations, packaging, and Kanban/inventory management.”

Technology Advances

New materials and substrates are constantly being developed for the demands of the medical device industry. Medical device design engineers, working collaboratively with plastics engineers, are constantly pushing the technology envelope to develop new materials that enhance the functionality of their medical device designs. For example, coatings that can self-heal after being damaged are actively being developed.

Multi-functionality—for example, designing integrated chemistry and process solutions which optimize competing design criteria (such as example abrasion resistance and lubricity in a fluoropolymer coating, or hardness and chemical resistance in an anodic coating)—is in high demand. Another example is the combination of selective conductive/non-conductive coatings and identification and traceability markers.

AdvanSource Biomaterials Corporation continues to expand upon options associated with solution use or combination solutions using its core material platforms. By targeting specific formulation adaptations to create certain solubility and associated properties, “we can offer materials with a greater range of characteristics, such as able hardening or damping, insolation or conductivity, increased visibility under multiple sources, and targeted delivery mechanisms as well as diffusion rates,” said Carroll.

For the implanted and wearable biosensor segments, there is an increasing need for precision coatings that not only improve the biocompatibility of the sensors, but also protect the enzyme sensing layer so the biosensor can function longer in the body and regulate the flux analytes in and out of the sensors. Several challenges exist for this type of coating—for example, the coating needs to be thin enough to allow the permeation of the analytes, the thickness needs to be very well controlled to ensure consistency from device to device, and the coating process must be gentle enough to preserve the functionality of the enzyme-sensing layer.

“Plasma polymerization is an excellent coating technology platform for creating highly customizable and precise ultrathin coatings for biosensors,” said Kevin Chen, chief technology officer for Medical Surface, a Natick, Mass.-based medical device coating company specializing in plasma surface treatment, plasma polymerization coating, and plasma-enhanced chemical vapor deposition. “This process allows us to create ultrathin [nanometer] coatings, while using a quartz crystal microbalance during the coating process to control the thickness accurately.”

A challenge for many of the new plastics being developed is that very little will adhere to the substrate, including medical grade inks. Such specialty plastics require pre-treatment to promote ink adhesion. CI Medical has formulated specialty gases that, by adjusting the volume of the component gases and exposure time of the components to the gases, can promote superior ink adhesion on many of these challenging surfaces. “Our proprietary coatings can be used on a variety of substrates and enable the device to be seen under fluoroscopy and x-ray,” said Mahan.

“Combining surface treatments and coatings have yielded new opportunities to coat materials that previously resisted adhesion,” agreed Carroll. “For example, plasma polymerization or alternate surface conditioning can activate surfaces that were previously very difficult to coat.”

Application Approaches

Areas that are coating-free are mission-critical in electrosurgical devices. Surgical Coatings utilizes a proprietary “virtual masking” process to ensure perfectly defined coating-free areas and eliminate poor edge quality, boosting overall surface quality. Virtual masking processes have continued to advance over the last two decades. “Using automated laser systems, we can remove the coating from substrates in very specific and tight-tolerance areas, producing a perfect quality edge surrounding coating-free areas,” said Morris. “This ensures flake-free edges and allows us to apply coatings on complex geometries. The automation behind these systems is critical to high-volume production and allows us to focus on coating applications, without wasting time on traditional masking procedures.”

Surgical Coatings has also developed a tunable corona discharge for electrostatic powder coatings. Although several powder-coating equipment manufacturers offer corona discharges to reduce back-ionization, orange peel, and other typical Faraday effects, “we found they did not perform well for the complex geometries and unique materials we often see in the medical device industry,” said Morris. “Using our tunable corona discharge, we have been able to coat difficult materials onto especially complex geometries, while maintaining coating thickness tolerances ±0.0005” in some cases.”

An increasing number of MDMs seek out durable color options for stainless steel and other non-anodizable alloys for product differentiation or aesthetics. N2 Biomedical recently developed a durable ceramic-based color-coating process called Spectrum that serves as an alternative or supplement to the color anodizing process. Spectrum coatings can be applied to any metal alloy including stainless steel, cobalt-chromium, nickel-titanium, and copper-nickel-titanium, providing many more color tones than currently available from anodized titanium.

Chemical vapor deposition and plasma-enhanced chemical vapor deposition (PECVD) have been widely used for electronic devices, such as application of water-proof coatings. In recent years there has been increased interest in coating carbon nanotube and graphene materials, which have attractive properties such as surface conductivity and transparency. “Plasma polymerization methods can be used to create surface functional groups on carbon nanotube and graphene materials, making them even more attractive in a variety of applications,” said Chen.

Manufacturers have known for decades about the benefits of in-house PVD (physical vapor deposition) coating: time savings, quality control, and customized thin film coatings that differentiate products by improving function and appearance. The process can sidestep the use of hexavalent chromium and concentrated acids common in traditional chrome plating. In the past, however, this equipment was too expensive for lower-volume operations and too difficult to integrate into existing manufacturing facilities. There was also the misconception that PVD-based techniques could only process a limited number of parts in a single batch over a relatively long processing time. Today, however, there exists both batch-based and in-line high throughput PVD systems that can process parts at high volumes as cost-effectively as non-vacuum-based coating techniques.

“PVD can deposit a durable decorative, pure chromium coating without toxic components,” said Wayne. “The addition of elements such as nitrogen can also produce even more durable chrome alternatives such as chromium nitride that greatly improve performance in high-wear applications.”

PVD systems are also now available in compact, affordable systems that are easy to install and use. “We recommend that smaller operations that send their parts out to coating services look at the in-house alternative,” continued Wayne. “If it makes financial sense, a smaller operation can get all the benefits that large-scale operations get from investing in a coating machine.”

For sandblasting surface treatments, many OEMs don’t realize how precisely micro-abrasive blasting (or precision sandblasting) can be controlled. For example, equipment made by Comco, a Burbank, Calif.-based manufacturer of micro-precision sandblasting equipment, can create consistent surface finishes that meet tightly defined surface texture parameters of Ra, Sa, and Sdr. “The AccuFlo abrasive blaster uses a patented method of mixing air and abrasive to ensure the consistent flow necessary to achieve such exacting results,” said Colin Weightman, director of technology for Comco. “For example, we can achieve an Ra [arithmetical mean height of a line] of 5-150 μin with a standard deviation of less than 5.0 μin. No masking is necessary to achieve a sharp delineation between the blasted and unblasted surface—we can achieve a transition zone of less than 0.007 inches.”

A key area of innovation and advancement in quality control is automation and inspection. Manual coating and human error have typically been the biggest source of scrap in coating applications and services. Automated coating equipment with a computer interface allows operators to design and apply customized coatings to a greater variety of complex devices, especially when the process is coupled with 3D printing.

“Significant investments in robotics enable us to achieve very thin and highly consistent process control [8 Sigma] against increasingly tight tolerances,” said Ellerkamp. “This has required significant changes in the manufacturing process as well as manufacturing support and process engineering. Advances in machine learning systems are enabling us to automate inspection of critical attributes.”

The Challenges of Additive Manufacturing

Parts constructed using additive manufacturing (AM) methods typically require coatings. Implantable devices often need a surface that isolates the materials used in the AM process from the patient. Perhaps the biggest challenge for coating AM parts is the substrate itself. For example, 3D-printed plastics have unique mesh patterns that present varying levels of surface roughness and porosity. Liquid coating a surface that presents irregular or uneven levels of porosity and surface roughness usually requires some adaptive and reactive automation techniques to achieve success. AM devices often require a thicker coating to smooth out uneven surfaces. The surface adhesion properties of 3D-printed devices may also be different from molded devices, even when the substrate material is similar. “Therefore coatings optimized for molded devices may need to be re-optimized for 3D printed devices,” said Chen.

New raw materials for AM, especially for metal additive manufacturing, typically contain binders which may inhibit certain coatings from adhering effectively and/or change the porosity of the finished substrate. This may also require the coatings and/or application process to be re-engineered.

In addition, many AM plastics cannot withstand the process or curing temperatures required by even the lowest cure temperature powder coatings, therefore limiting the available application options. “These additive substrates limit and challenge the coating selection process, especially in the medical device industry, where particular materials and ingredients are off limits for biocompatibility reasons,” said Morris. “Adapting to these new substrates will likely result in the development of new and coating materials that will specifically address these challenges.

Nonstop Innovation

Forward-thinking coating providers will stay ahead of the technology curve and integrate new technologies such as advanced laser processing, automation, and machine learning into their core processes, thereby being able to meet challenging OEM demands when others cannot. OEMs now regularly design more complex or customized devices made from new substrates that often don’t “take” to existing coating methods. Finding the right coatings for these products, which meet their highly specific performance requirements, often pushes material science to the limits to find an innovative solution.

“Some of the newer treatments utilize coatings as a carrier for drugs or biologics, permitting localized and controlled release of therapeutics to overcome problems associated with systemic administration,” said Kalkhoran. “Although this concept is not new and has been applied to several devices such as drug-eluting stents and balloons, there are few such coated products currently on the market and the breadth of research continues to expand.”

For example, researchers at Stevens Institute of Technology have developed a “self-defensive surface” for joint implants. The implants are dipped first into microgel flecks and then covered with a charged solution. The resulting coating can release micro-doses of antibiotics when bacteria approach, using antibiotics tailored to the patient’s specific risk factors. In another study, scientists at Boston University School of Medicine have studied the intrinsic structure of drug coatings from balloon catheters under a scanning electron microscope. They discovered that some of the microscopic particles in the coatings are shaped like needles and others are round, which create differences in the amount and rate of drug transfer. The researchers hope they will be able to homogenize the structure of the coating to optimize drug release, leading to better outcomes for people suffering with arterial disease.

A new antibacterial polyurethane coating for intravascular catheters has been developed at Brown University. The coating gradually releases a drug called auranofin that can kill both planktonic (free-floating) bacteria and prevent colonization of bacteria on device surfaces, a big step toward reducing catheter-related bloodstream infections. Finally, a research team from Chalmers University of Technology in Sweden has developed a novel coating whose surface is covered with vertical graphene flakes that slice up any bacteria that try to take hold, killing them.

As medical devices become smaller and more complex, and utilize advanced materials with tighter dimensional constraints, the need for specialized coatings and innovative surface treatments will grow. “This, coupled with continuing enhancements in design opportunities and material advancements, will continue to create high-growth opportunities and a pressing market need for an increasing array of coating options,” said Carroll.

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.

|

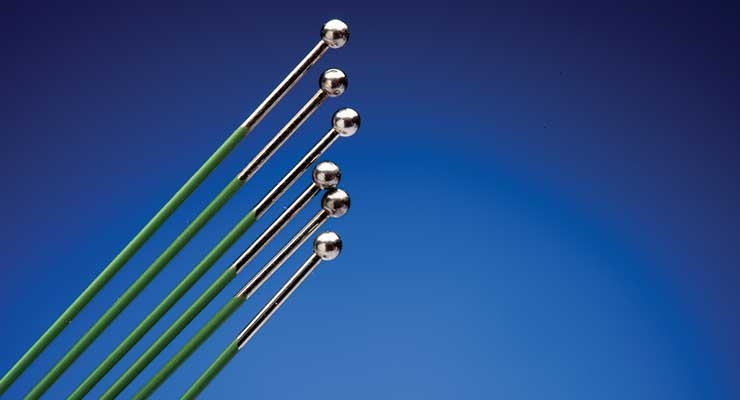

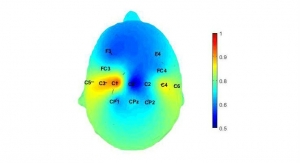

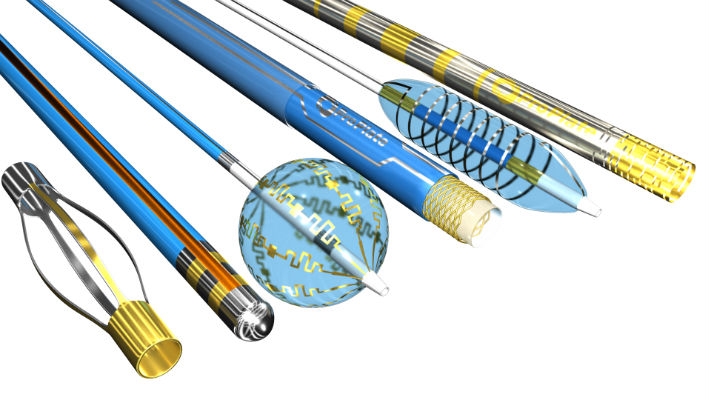

Ross Peterson • Vice President, Business Development, ProPlate Craig Ingalls • President and CEO, ProPlate Catheters are long, flexible, thin-walled, extruded polymer tubes—often with braid reinforcements—that can be navigated and guided through the body’s veins or arteries to enable access to areas in need of treatment. This minimally invasive approach allows for reduced trauma to the patient’s body and faster recovery from surgery. Balloon catheters are often utilized in procedures including angioplasty, stent placement, and those that utilize heating or cooling. Further, they are used in the treatment of peripheral artery disease, atrial fibrillation (AF), and neural and other endovascular conditions. During most of these procedures, once the balloon is deployed, it inflates, pressing and conforming to the surrounding tissue to open blood vessels or valves. Catheters may also be used to contact tissue for other application-specific purposes, such as tissue ablation or stimulation. Today’s catheter ablation and stimulation procedures can take up to several hours. Current balloon catheter designs in the market have a variety of limitations, from both a functional and manufacturability standpoint. For example, a critical drawback is associated with designs delivering a constant temperature across the entire surface of the balloon. This approach leaves little room for the differences in tissue walls and other anatomy being ablated or stimulated, and can lead to over- or under-ablation/stimulation. This is directly tied to the current design and manufacturing processes for these devices. Traditionally, catheter ablation has a success rate in AF procedures of about 60 percent. Further, it is not uncommon for patients to undergo multiple ablation procedures in order to achieve a successful treatment. According to the CDC, an estimated 2.7 million to 6.1 million people in the United States have AF, which can lead to blood clots, stroke, heart failure, and other heart-related complications. This disease alone drives a greater need for further catheter technology advancement in order to best help patients in need of more effective treatments. Until recently, thermal management designs for balloons have primarily involved hot or cold liquids or gases circulating within the balloon and supplied via two or more lumens within the catheter shaft. As previously mentioned, a constant temperature distributed along the entire surface of the balloon will, in many instances, limit the effectiveness or functionality of the device. A new coating process technology allows for discrete and high temperature variation at localized points of contact on the balloon surface. This is accomplished with the application of multiple, electrically independent electrodes metallized directly onto the outside surface of off-the-shelf catheter balloons made of various polymers. These conductive surface patterns can be used in high-temperature applications where an external RF energy source is employed. This patterned metalizing process offers companies an alternative design and manufacturing option aimed to optimize functionality and versatility for electrophysiology (EP) balloon catheter devices. Through the use of this novel metallization technology, interventional cardiologists can deploy robust electrical energy through multiple paths and to multiple discrete locations via minimally invasive catheter-based components. This enables more sophisticated and effective treatment of diseases and disorders such as, but not limited to, arrhythmias. Over the past few years, ProPlate’s team of physicists, chemists, material scientists, and electrical/mechanical engineers have successfully integrated metal electrode and radiopaque materials, as well as electrical lead paths, directly onto standard balloon catheters. The technology has also been successfully demonstrated on ceramic components, thin-walled polymer tubing, metallic stents, and other miniature catheter components.  Through the use of a novel metallization technology, interventional cardiologists can deploy robust electrical energy through multiple paths and to multiple discrete locations via minimally invasive catheter-based components. Image courtesy of ProPlate. Medical device manufacturers can utilize this flexible, ultra-thin metallization technology to precisely and selectively install electrodes, electrical leads, and radiopaque markers directly onto catheter components. Potential application areas include diagnostics, detection, sensing, ablation, stimulation, guidance, and mapping. The novel, patent-pending process technology provides for selective metallization, which is attached intimately to the polymer surface, and demonstrates excellent adhesion and flexibility without fracturing, lead separation, or delamination. The process accommodates high-inflation pressure, high balloon expansion multiples, folding, twisting, and bending over a broad range of balloon dimensions and geometries. Until now, placing such electrical components on an extensible surface was not possible using traditional manufacturing methods. Advances in balloon catheter design and functionality via utilization of this coating technology offer enhanced treatment possibilities. In sensing and mapping applications, for example, the process facilitates transmission of multiple data streams over small-diameter catheter tubing and components, allowing for mapping of electrophysiological activity with high resolution while also eliminating, or greatly reducing, the requirement for multiple and discrete lead wires. It also eliminates the need for extensive lead insulation and the associated “wasted diameters” from the dimensional growth. This diameter-reducing technology will allow for increased functionality for ever-shrinking catheters. The large size, 2D-geometry and rigid mechanical properties of standard conventional electronics—such as PCB flex circuitry or nanoparticle conductive inks (which can be prone to cracking and delamination)—integrated into medical devices can result in many drawbacks and procedural challenges with soft biological tissue. Through this advancement in manufacturing, device engineers can construct electronics that can readily integrate with the soft, irregular curvilinear surfaces of the human body. Through this proprietary process, expandable circuitry is selectively applied onto the complex 3D geometry of a balloon catheter and/or its subcomponents. Further, it can be made to be extensible without tensile or compressive cracking failures by utilizing non-linear geometrical layouts. High adhesion strength and robust flexibility enable multiple dynamic inflation and deflation cycles during use. Employing this novel coating technology on catheter shafts can significantly reduce the size of catheter lumens, enabling reach to biological locations not previously accessible, while dramatically enhancing sensing possibilities. Similar concepts are also made possible when applied to other substrates, such as ceramics, industry standard metals, and in some cases, bioabsorbable materials. The unique capabilities of this technology create new opportunities for doctors and physicians studying tissues, improving surgical procedures, and monitoring patient wellness by driving further valuable medical device application innovations. |