Steve Maylish and Mike White, Fusion Biotec11.07.17

The most successful innovators throughout history used a process called ideation in order to create products that make our lives better and more enjoyable. Thoughtful ideation shortens the development cycle, improves performance, and reduces cost. It aids creation of simple, elegant designs that meet user needs in the most direct way. Applying ideation during medical device design is a critical step toward creating a successful product.

Historically, ideation has been the domain of industrial designers. The word “ideation” originates as the combination of idea and creation. It’s the creative process of developing and communicating new ideas. Designers approach this process by using sketching and drawing, mock-up, and model-making in order to develop and visualize a concept for their own study.

This same approach is used to communicate ideas, innovations, and designs to others, and as such, ideation is one of the oldest forms of communication. Early man sketched ideas before he could write them. One might imagine a group of hunters designing a plan to capture dinner. Visual imagery was as important to these hunters as it is to designers; both used drawing skills to solve problems and document ideas.

Flash forward, and we find ideation at the core of the most iconic products and designs of our era. Harley Earl pioneered the modern automobile as the first design executive at General Motors in the 1930s. IDEO is the firm responsible for the original digital mouse. Frog Design and Jonathan Ive at Apple use this process to generate innovative products.

The main theme an industrial designer brings to the table is “the human comes first.” Industrial designers are taught and most often have a natural instinct and empathy toward the user. Early in design school, students are introduced to critical thinking and the design process, or “design methodology.”

Some tools industrial designers employ to better understand the user are: real-time observation of the user in the user’s environment, workflow mapping, quick execution or rapid visualization sketches (to create good ideas and flush out bad ones), and mock-up studies (to give an idea in 3D form of the impact of size, shape, and volume). The mock-up will also start to define the arrangement or hierarchy of buttons, handles, switches, doors, displays, etc. (For more, see the column “The Human Factor” in the May 2017 edition of MPO).

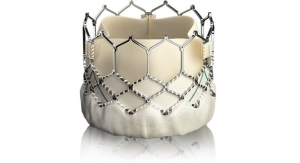

While ideation originated in consumer products, it is equally important and perhaps more impactful to medical devices. Three core elements in medtech benefit from a robust ideation process: driving technological innovation, reducing cost of care, and maintaining a high level of product quality. Despite these significant benefits, there is a natural resistance to this unstructured, creative process in an industry dominated by a highly structured regulatory framework. Yet when applied well, ideation accelerates product development and dovetails nicely with U.S. Food and Drug Administration (FDA) design controls. The FDA has issued guidance on the importance of designing a user experience that reduces the risk of human error creating hazards. (See “FDA Guidance on Applying Human Factors and Usability Engineering to Medical Devices.”)

There are five key steps to ideation:

1. Teaming

Most critical to the ideation process is choosing the right team. Start by establishing a team with relevant knowledge and skills. It’s very helpful to have teammate diversity in education, thought process, etc. Team members with different training and backgrounds approach solutions from different angles, and often, the intersection of their perspectives creates a result that is greater than the sum of the parts.

Open with an icebreaker to get creativity and interaction flowing. In one example, each team member stated their name, job, and location, and then—if they won the lottery—shared how much money they would want and what they would do with it.

It’s important to promote an atmosphere focused on inspiration and creativity. Sometimes it’s necessary to exclude a member stifling this process. Ideation focuses on making things go right, rather than preventing things from going wrong. No team ever created anything new or great by focusing on what might go wrong.

There are some practical guidelines to follow in forming a team. The ideal size is three to eight people. It’s critical the entire team blocks out the time. Sessions can last from a few hours to days depending on scope. Finally, the team leader should be experienced in ideation. (Hint: if they don’t have foam core, hot glue, and X-acto knives at their desk, look elsewhere!)

2. Scoping

Next, ensure everyone moves in the same direction. The scope discussion should clearly establish “must-haves” and “nice-to-haves.” An unstructured discussion or asking scripted “How Might We” questions can accomplish this. For example, when developing a home-use diagnostic instrument, we would ask, “How might we create an instrument that anyone can easily use at home to find out if they have an infectious disease?” In establishing scope, focus on needs and functionality. Ensure everyone shares an understanding of what the product must do, while deferring design solutions and constraints stifling creativity.

3. Brainstorming

In brainstorming, the main rule is “Don’t kill ideas.” There’s no need for perfection; in fact, the wilder the better! Get comfortable with failure. A dumb idea could be the goose that lays the golden egg. A winning idea is often inspired by a wacky one.

Start generating ideas individually, then regroup and share. At the end of this phase, put all the post-its on a wall, have each person describe their idea, and group like ideas together, giving each group a name. For example, in a sample mixing design ideation, the team developed four concept sketches resembling a martini shaker, so that grouping was labeled “Cocktail Shaker.” It’s always a great idea to bring in props like similar products, drawings, pictures, or objects. If a brainstorming idea is comparable to an existing product, take a trip to the store, buy one, and bring it back.

Brainstorming summary:

In try-storming, ideas are built to see if they work, or even better, if they are hopeless. If there’s endless debate over the quality of an idea, quickly build it and test it out of foam core, glue, and found parts.

When a Fortune 500 diagnostics company was developing a new protein analyzer, the team performed ideation on the pneumatics. One idea was a direct pump to replace pressure and vacuum canisters. This would save $2,500 per instrument and improve reliability; however, a debate ensued over capacity or response time. Rather than waste time debating or kill the idea due to “high risk,” the team built a very rough prototype using pumps from another instrument. The prototype functioned well enough to bolster confidence and later became the mainstream design.

The key is speed, and as with brainstorming, failure is expected and even celebrated when done quickly. Failing fast and often is the name of the game. An iteration should take a day or less. If there is lead time to order or make parts, find another way. The more iterations at this stage, the lower the risk to the final design. This is also helpful to unearth problems unseen in drawings or CAD.

5. Summarizing

After try-storming the most promising ideas, gather the team and settle on one or two winning concepts. Document them with enough detail to capture critical features. There should be a refined sketch and mock-up of the final concept. If a foam core model can be made functional, it encourages the company that the design is robust. It’s also good to think in terms of design inputs for FDA design controls. What are the critical requirements and specifications? How would we test them?

Lessons Learned and Pitfalls to Avoid

It can be difficult for a seasoned medical device engineering staff to embrace the fact that failing early, fast, and often is the best road to a robust design. After many years of conditioning to abhor failure, engineers often design for perfection. While this may be comforting, it runs a high risk of creating a product that meets specifications, but misses the forest for the trees.

One company developed a breast biopsy system that functioned well, but the sound frightened patients so much that they switched doctors. One patient said, “...it sounded just like a drill, and that freaked me out.” This could have been identified and corrected during try-storming; however, it is often too late to make these changes once prototypes have been built and tested.

Ideation is a tried and true process to innovate and develop simple, elegant designs. Applied to medical devices, it can be the secret weapon that improves quality, reduces cost, drives customer adoption, and accelerates time-to-market. It’s important to start with a motivated, open-minded team organized by a hot-glue-gun-wielding leader. Following these simple guidelines can help businesses innovate rapidly and create the next great product.

Steve Maylish has been part of the medical device community for over 30 years. He is currently chief commercial officer for Fusion Biotec, an Orange, Calif.-based contract engineering firm that brings together art, science, and engineering to create medical devices. Early in his career, Maylish held positions at Fortune 100 corporations such as Johnson & Johnson, Shiley, Sorin Group, Baxter Healthcare, and Edwards Lifesciences.

Mike White is chief technical officer of Fusion Biotec. He has 24 years of experience in engineering and medical device product development. Formerly director of product development and value engineering at Beckman Coulter, Mike learned about foam core and hot glue in ME101 at Stanford where he received a B.S. and M.S. in Mechanical Engineering and an MBA at MIT Sloan.

Historically, ideation has been the domain of industrial designers. The word “ideation” originates as the combination of idea and creation. It’s the creative process of developing and communicating new ideas. Designers approach this process by using sketching and drawing, mock-up, and model-making in order to develop and visualize a concept for their own study.

This same approach is used to communicate ideas, innovations, and designs to others, and as such, ideation is one of the oldest forms of communication. Early man sketched ideas before he could write them. One might imagine a group of hunters designing a plan to capture dinner. Visual imagery was as important to these hunters as it is to designers; both used drawing skills to solve problems and document ideas.

Flash forward, and we find ideation at the core of the most iconic products and designs of our era. Harley Earl pioneered the modern automobile as the first design executive at General Motors in the 1930s. IDEO is the firm responsible for the original digital mouse. Frog Design and Jonathan Ive at Apple use this process to generate innovative products.

The main theme an industrial designer brings to the table is “the human comes first.” Industrial designers are taught and most often have a natural instinct and empathy toward the user. Early in design school, students are introduced to critical thinking and the design process, or “design methodology.”

Some tools industrial designers employ to better understand the user are: real-time observation of the user in the user’s environment, workflow mapping, quick execution or rapid visualization sketches (to create good ideas and flush out bad ones), and mock-up studies (to give an idea in 3D form of the impact of size, shape, and volume). The mock-up will also start to define the arrangement or hierarchy of buttons, handles, switches, doors, displays, etc. (For more, see the column “The Human Factor” in the May 2017 edition of MPO).

While ideation originated in consumer products, it is equally important and perhaps more impactful to medical devices. Three core elements in medtech benefit from a robust ideation process: driving technological innovation, reducing cost of care, and maintaining a high level of product quality. Despite these significant benefits, there is a natural resistance to this unstructured, creative process in an industry dominated by a highly structured regulatory framework. Yet when applied well, ideation accelerates product development and dovetails nicely with U.S. Food and Drug Administration (FDA) design controls. The FDA has issued guidance on the importance of designing a user experience that reduces the risk of human error creating hazards. (See “FDA Guidance on Applying Human Factors and Usability Engineering to Medical Devices.”)

There are five key steps to ideation:

1. Teaming

Most critical to the ideation process is choosing the right team. Start by establishing a team with relevant knowledge and skills. It’s very helpful to have teammate diversity in education, thought process, etc. Team members with different training and backgrounds approach solutions from different angles, and often, the intersection of their perspectives creates a result that is greater than the sum of the parts.

Open with an icebreaker to get creativity and interaction flowing. In one example, each team member stated their name, job, and location, and then—if they won the lottery—shared how much money they would want and what they would do with it.

It’s important to promote an atmosphere focused on inspiration and creativity. Sometimes it’s necessary to exclude a member stifling this process. Ideation focuses on making things go right, rather than preventing things from going wrong. No team ever created anything new or great by focusing on what might go wrong.

There are some practical guidelines to follow in forming a team. The ideal size is three to eight people. It’s critical the entire team blocks out the time. Sessions can last from a few hours to days depending on scope. Finally, the team leader should be experienced in ideation. (Hint: if they don’t have foam core, hot glue, and X-acto knives at their desk, look elsewhere!)

2. Scoping

Next, ensure everyone moves in the same direction. The scope discussion should clearly establish “must-haves” and “nice-to-haves.” An unstructured discussion or asking scripted “How Might We” questions can accomplish this. For example, when developing a home-use diagnostic instrument, we would ask, “How might we create an instrument that anyone can easily use at home to find out if they have an infectious disease?” In establishing scope, focus on needs and functionality. Ensure everyone shares an understanding of what the product must do, while deferring design solutions and constraints stifling creativity.

3. Brainstorming

In brainstorming, the main rule is “Don’t kill ideas.” There’s no need for perfection; in fact, the wilder the better! Get comfortable with failure. A dumb idea could be the goose that lays the golden egg. A winning idea is often inspired by a wacky one.

Start generating ideas individually, then regroup and share. At the end of this phase, put all the post-its on a wall, have each person describe their idea, and group like ideas together, giving each group a name. For example, in a sample mixing design ideation, the team developed four concept sketches resembling a martini shaker, so that grouping was labeled “Cocktail Shaker.” It’s always a great idea to bring in props like similar products, drawings, pictures, or objects. If a brainstorming idea is comparable to an existing product, take a trip to the store, buy one, and bring it back.

Brainstorming summary:

- Don’t kill ideas.

- Encourage weirdness and wacky ideas.

- Build on other ideas.

- Go for quantity (seven to 10 ideas per person).

- Be open. Take 20-30 minutes to generate ideas individually, then share with the group.

- Stay on scope.

- Capture ideas visually by using drawings, pictures, and objects rather than words.

In try-storming, ideas are built to see if they work, or even better, if they are hopeless. If there’s endless debate over the quality of an idea, quickly build it and test it out of foam core, glue, and found parts.

When a Fortune 500 diagnostics company was developing a new protein analyzer, the team performed ideation on the pneumatics. One idea was a direct pump to replace pressure and vacuum canisters. This would save $2,500 per instrument and improve reliability; however, a debate ensued over capacity or response time. Rather than waste time debating or kill the idea due to “high risk,” the team built a very rough prototype using pumps from another instrument. The prototype functioned well enough to bolster confidence and later became the mainstream design.

The key is speed, and as with brainstorming, failure is expected and even celebrated when done quickly. Failing fast and often is the name of the game. An iteration should take a day or less. If there is lead time to order or make parts, find another way. The more iterations at this stage, the lower the risk to the final design. This is also helpful to unearth problems unseen in drawings or CAD.

5. Summarizing

After try-storming the most promising ideas, gather the team and settle on one or two winning concepts. Document them with enough detail to capture critical features. There should be a refined sketch and mock-up of the final concept. If a foam core model can be made functional, it encourages the company that the design is robust. It’s also good to think in terms of design inputs for FDA design controls. What are the critical requirements and specifications? How would we test them?

Lessons Learned and Pitfalls to Avoid

It can be difficult for a seasoned medical device engineering staff to embrace the fact that failing early, fast, and often is the best road to a robust design. After many years of conditioning to abhor failure, engineers often design for perfection. While this may be comforting, it runs a high risk of creating a product that meets specifications, but misses the forest for the trees.

One company developed a breast biopsy system that functioned well, but the sound frightened patients so much that they switched doctors. One patient said, “...it sounded just like a drill, and that freaked me out.” This could have been identified and corrected during try-storming; however, it is often too late to make these changes once prototypes have been built and tested.

Ideation is a tried and true process to innovate and develop simple, elegant designs. Applied to medical devices, it can be the secret weapon that improves quality, reduces cost, drives customer adoption, and accelerates time-to-market. It’s important to start with a motivated, open-minded team organized by a hot-glue-gun-wielding leader. Following these simple guidelines can help businesses innovate rapidly and create the next great product.

Steve Maylish has been part of the medical device community for over 30 years. He is currently chief commercial officer for Fusion Biotec, an Orange, Calif.-based contract engineering firm that brings together art, science, and engineering to create medical devices. Early in his career, Maylish held positions at Fortune 100 corporations such as Johnson & Johnson, Shiley, Sorin Group, Baxter Healthcare, and Edwards Lifesciences.

Mike White is chief technical officer of Fusion Biotec. He has 24 years of experience in engineering and medical device product development. Formerly director of product development and value engineering at Beckman Coulter, Mike learned about foam core and hot glue in ME101 at Stanford where he received a B.S. and M.S. in Mechanical Engineering and an MBA at MIT Sloan.