Dave Sheppard, Chief Operating Officer and Principal, MedWorld Advisors 04.03.17

“I am fed up seeing all the metrics from my head of Supply Chain on efficiency. I want to hear about what we’re doing to get new customers [and] get to market faster. I don’t want to hear about efficiency. I want to hear about growth.”—Fortune 500 company CEO, from DHL’s November 2016 whitepaper, “The Plug and Play Supply Chain: Beyond Efficiency to Growth.”

In working with supply chain professionals worldwide, I am often interested in learning how they create value in their organizations through the supply chain. Experienced professionals are aware that there are many avenues to success through supply chain processes. The key, however, lies in the delivery of the value proposition.

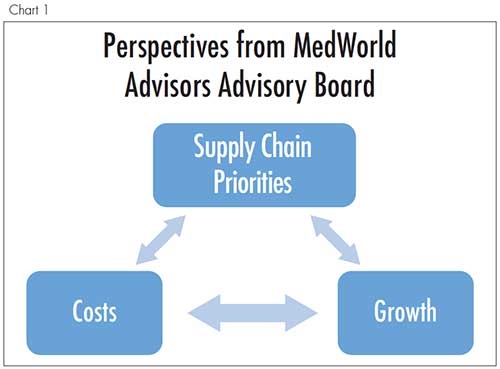

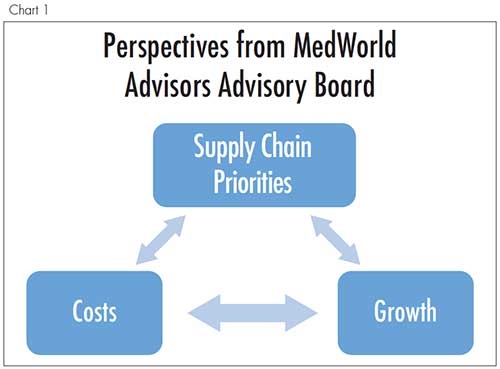

Does the supply chain bring value by focusing solely on cost, or does it create value through revenue growth? Moreover, does the supply chain consider ways to create success for all stakeholders—employees, management, shareholders, and customers alike?

A supply chain with a revenue growth-centered focus understands its role in helping to grow the company. Indeed, the supply chain is integral to the strategic development of any well-run organization. The supply chain is a key corporate stakeholder that can help the business expand its customer base, which, in turn, increases revenue. As stakeholders, supply chains must decide whether they can add value to their organizations by prioritizing activities that lead to sustainable growth.

Despite its role in corporate revenue growth, cost is still important to the sourcing team. In fact, creating true cost competitiveness is a growth driver in every organization.

Many companies expertly utilize their supply chains to improve their bottom lines. Amazon is an excellent example: While the online retailer obviously controls costs, its supply chains’ focus on the customer is one of its main growth engines. As Amazon founder and CEO Jeff Bezos once said, “There are two ways to extend a business. Take inventory of what you’re good at and extend out from your skills. Or determine what your customers need and work backward, even if it requires learning new skills. Kindle is an example of working backward.” Some might wonder how Bezos’ philosophy applies to the supply chain. The answer is quite simple—Amazon uses its supply chain to innovate and meet its customers’ needs.

Many companies expertly utilize their supply chains to improve their bottom lines. Amazon is an excellent example: While the online retailer obviously controls costs, its supply chains’ focus on the customer is one of its main growth engines. As Amazon founder and CEO Jeff Bezos once said, “There are two ways to extend a business. Take inventory of what you’re good at and extend out from your skills. Or determine what your customers need and work backward, even if it requires learning new skills. Kindle is an example of working backward.” Some might wonder how Bezos’ philosophy applies to the supply chain. The answer is quite simple—Amazon uses its supply chain to innovate and meet its customers’ needs.

Nike also uses its supply chain wisely. According to November 2013 research from the Stanford Initiative for the Study of Supply Chain Responsibility, “...innovation is helping Nike achieve its ultimate destination: ‘A truly sustainable supply chain.’” In Nike’s case, innovation contributes to both sustainable product innovation to meet customers’ needs, as well as new manufacturing methods that benefit its stakeholders’ ecosystem.

Walmart is legendary in regard to supply chain cost efficiencies. Over a five-year period, the company grew from $408 billion in sales to $486 billion in sales in fiscal 2015, according to The Wall Street Journal’s MarketWatch. Was that growth due to “efficiencies” or was it driven by the ability to invent products that meet customers’ needs? An interesting question.

There aren’t many medical technology companies that use the supply chain to drive innovation and growth. According to the “Gartner Supply Chain Top 25” for 2016, only five of the top 25 supply chain firms were in the healthcare industry, and they were either consumer and/or pharmaceutical-focused institutions. In order of listed performance, the companies included Proctor & Gamble, Colgate-Palmolive, Johnson & Johnson, GlaxoSmithKline, and Kimberly-Clark. In their life sciences category ranking, only Abbott Laboratories and Cardinal Health made the top 10 as medical device manufacturers. The remaining firms were mostly pharmaceutical or drug-focused.

Despite this dearth in medtech supply chain innovation, there are some device manufacturers that have mastered the strategy. But there is always room for improvement at the OEM or OEM supplier level.

Let’s consider the key focus required for a growth-centered approach in healthcare supply chain management.

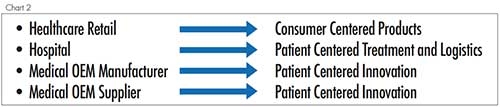

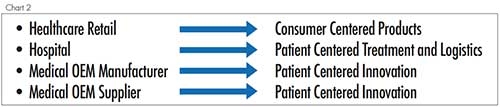

As illustrated in Chart 2, healthcare retailers can generate sustainable growth through supply chain innovation that creates cost-competitive, consumer-centered products marketed in an accessible manner.

As illustrated in Chart 2, healthcare retailers can generate sustainable growth through supply chain innovation that creates cost-competitive, consumer-centered products marketed in an accessible manner.

Hospitals’ paths to successful growth is through better patient care—i.e., supply chain innovation that ensures both services and products (devices, goods, drugs, etc.) are readily available for diagnosis and treatment.

Medtech manufacturers can create a winning growth strategy by using their supply chains to develop and procure products that meet patients’ clinical needs. There is no other way to sustainable long-term growth. It is critical for OEMs to help their customer base (hospitals, clinics, surgery centers, etc.) succeed. Such victories are occurring in unique and meaningful ways, including new devices for revolutionary treatments and new sales strategies (namely, risk-sharing models for positive patient outcomes).

OEM suppliers may wonder why patient-centered innovation is so important to the supply chain. The answer, though, is obvious once the thought is vocalized. In today’s global environment, the medical OEM supplier is the oil that keeps the medtech industry engine running smoothly. OEM suppliers are now not only used for obtaining materials and components—many highly valued firms are also an integral part of the manufacturer’s NPI cycle. Patient-centered innovation can help OEM suppliers and their customers achieve success in the market. In my experience, the best way to sustain a growing business is to be a key part of your customers’ success. When your customers win, you win.

Good OEM suppliers are involved in the research and development cycle with their customers. They listen to their customers’ needs and find ways to deliver products and solutions to meet (or exceed) their requirements.

Good OEM suppliers are involved in the research and development cycle with their customers. They listen to their customers’ needs and find ways to deliver products and solutions to meet (or exceed) their requirements.

Great OEM suppliers bring new innovation to their customers. Sourcing leaders are obligated to understand their company’s strategy and how their products, solutions, etc., fit into their customers’ requirements. While innovations will most likely come from the OEM supplier’s engineering department, opportunities often originate from the sourcing team. Sometimes, it is simply (or not so simply, as experienced sourcing professionals know) finding new materials, components, services, or other requested solutions.

A more effective success strategy occurs when the sourcing team originates novel ideas for the OEM supplier’s marketing and engineering teams to develop for their customers. Proactive participation in helping the company win is a great way for the supply chain to demonstrate its value to the organization it serves.

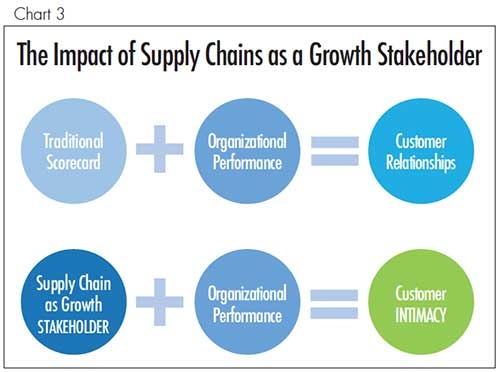

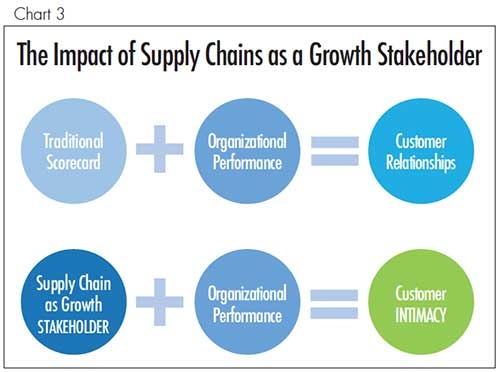

There are obviously many sourcing professionals who are very good at using all traditional supply chain principles to leverage both their own and their team’s activities to reduce product costs. I’d like those same professionals to think about how they’d answer the question from the Fortune 500 CEO quoted in DHL’s whitepaper. What would they say to that CEO? Demonstrating additional benefit to the organization beyond product costs, supply chain logistics, and standard scorecard metrics—by truly participating as a stakeholder in the growth of a company, supply chains immeasurably increase their business value.

Perhaps it may even lead from competence to confidence to promotion. Proactive leadership is a sought-after skill in many companies. Thus, when sourcing professionals arrive at work each day, I suggest they ask themselves, “What am I doing to help my company’s customers win?” As established in this discussion, when customers are successful, so are their suppliers.

Dave Sheppard is a former Fortune 500 executive and is now a principal at MedWorld Advisors. He can be reached at davesheppard@medworldadvisors.com

In working with supply chain professionals worldwide, I am often interested in learning how they create value in their organizations through the supply chain. Experienced professionals are aware that there are many avenues to success through supply chain processes. The key, however, lies in the delivery of the value proposition.

Does the supply chain bring value by focusing solely on cost, or does it create value through revenue growth? Moreover, does the supply chain consider ways to create success for all stakeholders—employees, management, shareholders, and customers alike?

A supply chain with a revenue growth-centered focus understands its role in helping to grow the company. Indeed, the supply chain is integral to the strategic development of any well-run organization. The supply chain is a key corporate stakeholder that can help the business expand its customer base, which, in turn, increases revenue. As stakeholders, supply chains must decide whether they can add value to their organizations by prioritizing activities that lead to sustainable growth.

Despite its role in corporate revenue growth, cost is still important to the sourcing team. In fact, creating true cost competitiveness is a growth driver in every organization.

Nike also uses its supply chain wisely. According to November 2013 research from the Stanford Initiative for the Study of Supply Chain Responsibility, “...innovation is helping Nike achieve its ultimate destination: ‘A truly sustainable supply chain.’” In Nike’s case, innovation contributes to both sustainable product innovation to meet customers’ needs, as well as new manufacturing methods that benefit its stakeholders’ ecosystem.

Walmart is legendary in regard to supply chain cost efficiencies. Over a five-year period, the company grew from $408 billion in sales to $486 billion in sales in fiscal 2015, according to The Wall Street Journal’s MarketWatch. Was that growth due to “efficiencies” or was it driven by the ability to invent products that meet customers’ needs? An interesting question.

There aren’t many medical technology companies that use the supply chain to drive innovation and growth. According to the “Gartner Supply Chain Top 25” for 2016, only five of the top 25 supply chain firms were in the healthcare industry, and they were either consumer and/or pharmaceutical-focused institutions. In order of listed performance, the companies included Proctor & Gamble, Colgate-Palmolive, Johnson & Johnson, GlaxoSmithKline, and Kimberly-Clark. In their life sciences category ranking, only Abbott Laboratories and Cardinal Health made the top 10 as medical device manufacturers. The remaining firms were mostly pharmaceutical or drug-focused.

Despite this dearth in medtech supply chain innovation, there are some device manufacturers that have mastered the strategy. But there is always room for improvement at the OEM or OEM supplier level.

Let’s consider the key focus required for a growth-centered approach in healthcare supply chain management.

Hospitals’ paths to successful growth is through better patient care—i.e., supply chain innovation that ensures both services and products (devices, goods, drugs, etc.) are readily available for diagnosis and treatment.

Medtech manufacturers can create a winning growth strategy by using their supply chains to develop and procure products that meet patients’ clinical needs. There is no other way to sustainable long-term growth. It is critical for OEMs to help their customer base (hospitals, clinics, surgery centers, etc.) succeed. Such victories are occurring in unique and meaningful ways, including new devices for revolutionary treatments and new sales strategies (namely, risk-sharing models for positive patient outcomes).

OEM suppliers may wonder why patient-centered innovation is so important to the supply chain. The answer, though, is obvious once the thought is vocalized. In today’s global environment, the medical OEM supplier is the oil that keeps the medtech industry engine running smoothly. OEM suppliers are now not only used for obtaining materials and components—many highly valued firms are also an integral part of the manufacturer’s NPI cycle. Patient-centered innovation can help OEM suppliers and their customers achieve success in the market. In my experience, the best way to sustain a growing business is to be a key part of your customers’ success. When your customers win, you win.

Great OEM suppliers bring new innovation to their customers. Sourcing leaders are obligated to understand their company’s strategy and how their products, solutions, etc., fit into their customers’ requirements. While innovations will most likely come from the OEM supplier’s engineering department, opportunities often originate from the sourcing team. Sometimes, it is simply (or not so simply, as experienced sourcing professionals know) finding new materials, components, services, or other requested solutions.

A more effective success strategy occurs when the sourcing team originates novel ideas for the OEM supplier’s marketing and engineering teams to develop for their customers. Proactive participation in helping the company win is a great way for the supply chain to demonstrate its value to the organization it serves.

There are obviously many sourcing professionals who are very good at using all traditional supply chain principles to leverage both their own and their team’s activities to reduce product costs. I’d like those same professionals to think about how they’d answer the question from the Fortune 500 CEO quoted in DHL’s whitepaper. What would they say to that CEO? Demonstrating additional benefit to the organization beyond product costs, supply chain logistics, and standard scorecard metrics—by truly participating as a stakeholder in the growth of a company, supply chains immeasurably increase their business value.

Perhaps it may even lead from competence to confidence to promotion. Proactive leadership is a sought-after skill in many companies. Thus, when sourcing professionals arrive at work each day, I suggest they ask themselves, “What am I doing to help my company’s customers win?” As established in this discussion, when customers are successful, so are their suppliers.

Dave Sheppard is a former Fortune 500 executive and is now a principal at MedWorld Advisors. He can be reached at davesheppard@medworldadvisors.com