Michael Barbella, Managing Editor01.30.17

Kevin J. Tracey decided to become a neurosurgeon when his mother died. He was 5 years old at the time.

Too young to truly comprehend the loss, Tracey sought solace with his maternal grandfather, then a pediatrics professor at Yale University. He wasn’t looking for kind words from the man, a shoulder to cry on, or even a peck on the cheek.

All he wanted was an explanation.

“I climbed onto his lap and asked what happened,” Tracey recalled to The New York Times in a 2014 interview. “He [grandfather] explained that surgeons tried to take it [brain tumor] out but couldn’t separate the tumor tissue from the normal neurons. I remember saying to him, ‘Somebody should do something about that.’ That was when I decided to be a neurosurgeon. I wanted to solve problems that were insolvable.”

Tracey’s personal vendetta against the unsolvable would eventually define his medical career, beginning with the 1985 death of an infant burn victim at New York Hospital. Accidentally doused with boiling pasta water, the girl died suddenly in Tracey’s arms just a few days before her scheduled discharge, and only 24 hours after her first birthday.

The case haunted Tracey for years. He found himself wrestling with a familiar question from childhood: What happened?

He wanted an explanation. Again.

This time, however, Tracey answered his own question. He suspected sepsis, a condition caused by the human immune system’s overwhelming and life-threatening response to an infection. The illness can lead to tissue damage, organ failure, and ultimately, death.

Confounding Tracey’s theory, though, was the lack of bacteria and/or signs of infection anywhere in the victim’s body upon death.

“The more I looked into the problem, the more I realized that basic science lacked a fundamental understanding of why septic shock occurs,” Tracey, now president of The Feinstein Institute for Medical Research (Manhasset, N.Y.) and professor of molecular medicine and neurosurgery at the Hofstra Northwell School of Medicine, told a TEDMED audience last May. “Thirty years ago, I decided to go into the lab and study that problem and my labs have been pursuing that question ever since. What we found changed the way the world thinks about how the body responds to infection.”

Indeed, Tracey’s research changed the way the medical world thinks about organic infection defenses. Specifically, he discovered an interface between nerves and the immune system, disproving a deep-seated scientific consensus that long regarded communication between the two impossible. The conduit for this interplay is the vagus nerve, which helps control and regulate inflammation. Through a series of experiments, Tracey showed that the human nervous system works similarly to a computer terminal, through which commands can be delivered to stop problems like acute inflammation before it begins, or repair the body after an illness.

Tracey’s efforts to better understand the body’s immunological responses has helped establish the emerging new field of bioelectronics, a promising area of medicine that has proven successful in treating acute and chronic immune system disorders (i.e., rheumatoid arthritis, diabetes, psoriasis, inflammatory bowel disease, multiple sclerosis, heart disease, etc.).

The idea of interrupting the vagus nerve-brain conduit with electrical pulses is not an entirely new concept. Vagus nerve stimulation has been used since 1997 to control epileptic seizures and has also been effective at treating drug-resistant cases of clinical depression. But advancements in immunology—due largely to Tracey’s groundbreaking research—are prompting clinicians to test the technique on other difficult-to-manage diseases.

And the results have been encouraging.

Clinical trial subjects implanted with bioelectronic nerve stimulators in their necks have reported significant improvements in rheumatoid arthritis and Crohn’s disease symptoms. Arthritis sufferers, according to study data, experienced fewer swollen joints and pain, while several Crohn’s disease patients achieved complete remission.

Such notable turnarounds are inspiring quests for additional therapies as well: Purdue University researchers, for instance, are investigating bioelectronic therapies for epilepsy, a brain disorder that costs the U.S. healthcare system $15.5 billion annually. Johns Hopkins University scholars, on the other hand, are studying the ways nerve signals affect obesity, diabetes, and gastrointestinal-motility disorders. “What we’re doing today,” Johns Hopkins Medicine and Neurosciences Professor Jay Pasricha said, “is like the precursor to the Model T.”

Only this Model N has more savvy backers.

Last summer, pharmaceutical giant GSK (GlaxoSmithKline) and Verily Life Sciences LLC (formerly Google Life Sciences) formed a company specially tasked with researching, developing, and commercializing bioelectronic therapies. The two partners will contribute 540 million British pounds ($714 million) over seven years to operate Galvani Bioelectronics, aptly named after the 18th century scientist best known for his experiments animating severed frogs’ legs with jolts of electricity.

GSK considers the joint venture with Verily a natural “next step” in its four-year crusade to establish a firm foothold in bioelectronic medicine. The company has invested roughly 45 million euros ($50 million) since 2012 on bioelectronic technology, including a million-dollar prize in 2013 to encourage research into “electroceuticals.”

GSK first unveiled its bioelectronics ambitions three years ago in the journal Nature, and believes it is ahead of its big pharma rivals in developing medical treatments to use electrical impulses rather than traditional chemicals or proteins. Galvani executives expect the first bioelectronic devices to be ready for government inspection in six years.

“This is an ambitious collaboration, allowing GSK and Verily to combine forces and have a huge impact on an emerging field,” Brian Otis, chief technology officer at Verily, said when the partnership was announced. “Bioelectronic medicine is a new area of therapeutic exploration, and we know that success will require the confluence of deep disease biology expertise and new highly miniaturized technologies.”

Not to mention electronics manufacturing and design prowess. As electrophysiology and neuroscience yield promising new treatments for age-old diseases, companies like Galvani will need to work closely with electronics manufacturing services (EMS) providers to bring their products to market.

“The medical device industry is at a point of significant change,” noted John Carlson, president of Flex Medical Solutions, a division of Flex Ltd., a global provider of sketch-to-scale design, engineering, manufacturing, supply chain insight, and logistics services to various industries, including medical. “There’s a growing recognition that in order for medtech companies to compete, they’re going to have to be much better at collaboration and partnership in certain areas than they’ve historically had to be. We’ve seen ongoing consolidation in the industry, and as a result, companies’ portfolios have become bigger. Consequently, the number of products they’re having to produce has grown almost exponentially. Therefore, the consolidation, the bigger portfolios, and the products’ naturally long lifecycles have forced companies to look at partnering with EMS suppliers in a very different way than in the past.”

One alternate view is beget by a reassessment of core capabilities. Companies with diverse product portfolios are almost never adept in all markets and/or healthcare technologies in which they operate, and thus must outsource with trusted partners to remain competitive.

Privately held biotech firm Ichor Medical Systems adopted this approach in collaborating with Flex on its TriGrid DNA Delivery System, an electroportation device used to deliver DNA vaccines and treatments for various diseases. TriGrid uses electrical fields to increase DNA drug delivery efficiency up to 1,000-fold as compared to conventional injection. The product is comprised of a small, hand-held device that contains a syringe needle and four recessed electrodes arranged in a diamond shape around the central syringe. The design, according to Ichor, is necessary to encompass the tissue in which the drug is administered.

Ichor turned to Flex to incorporate multiple layers of switches in the device, including mechanical, senseless rotational, and optical for accurate drug dose delivery. Flex also developed a special algorithm to compensate for minor deviations in delivery.

“There’s a growing awareness across large and small companies that the pathway to success is collaborative development or partnerships,” Carlson said. “The old outsourcing model of ‘I give you the spec and you go make this’—those kinds of relationships don’t work out well on the OEM side or the EMS provider side. The collaborative efforts tend to be the best ones, and we’re seeing increased recognition from large and small companies of the need to partner.”

That need has partly been driven by the advent of digital health and the shift from service- to value-based reimbursement models. Digital health entrepreneurs are approaching medicine largely from a data perspective, crafting personalized solutions based on new ways of gathering, viewing, manipulating, and analyzing patient information. Their strategies are blurring industry lines and inspiring new technologies like wearable health devices and activity trackers that put data into users’ hands.

Among the flood of wearables saturating the market are two wireless smart patches from Silicon Valley startup VitalConnect—the VitalPatch, a disposable biosensor developed in partnership with Flex, and HealthPatch MD, a reusable cardiac monitor.

Both patches continuously measure heart rate, respiratory rate, heart rate variability, skin temperature, posture, and step count, and they’re powered by zinc-air batteries that can last up to four days before requiring replacement. Both devices also are designed to detect falls.

The patches have been certified and cleared for use in the United States, European Union, Japan, and Canada. They are produced in different adhesive grades based on activity and perspiration levels.

“From a medical standpoint, historically we’ve been partnering [with companies] on the manufacturing end,” Carlson explained. “But more and more, we’re helping customers understand how partnering on the innovation side of things can really help them gain a competitive differentiation in the marketplace and allow them to move much faster than they would otherwise do on their own. Many of our newest engagements have really been on the innovation side of things, where we’ve helped customers move into new technology spaces and bridge the different industries much faster and better than they would have without our help.”

Crossovers can be overwhelming, though. Medtech firms unfamiliar with the consumer space are often dumbfounded at the fast pace of product development and amount of risk-taking associated with new innovations. Medical devices require significant understanding of the target audience and are subject to stringent regulatory scrutiny whereas consumer products are more nimble and can be commercialized in a matter of months.

Such an abbreviated product development timeline can be a major stumbling block for healthcare companies traversing the consumer market. Incorporating wireless connectivity into a medical device requires knowledge of WiFi, Bluetooth, radio-frequency identification, near-field communications, and other connective technologies, as well as IEEE standards for information technology and telecommunications/information exchange.

New York City-based startup AdhereTech Inc., for example, leveraged the wireless communications expertise of full-service design firm Intelligent Product Solutions (IPS) to develop a smart, wireless pill bottle that electronically reminds patients to take their medications and alerts caregivers to missed doses. The company estimates that medication non-adherence costs the United States roughly $100 billion and contributes to 100,000 deaths annually.

AdhereTech’s Smart Pill Bottle is basically a standard drug vial with a cellphone radio and prescription inside that occasionally beeps and lights up to remind its owners to take their medications. The bottle requires no syncing or programming, and its battery can last up to 90 days on a full charge.

AdhereTech executives chose wisely in partnering with IPS on the Smart Pill Bottle, as they tapped into a knowledge base of former Symbol Technologies and Motorola experts with experience in all forms of wireless communications—from low-level languages like Zigbee, Bluetooth, and near field to the longer-range protocols of WiFi, GPS, and wide area radio communications.

Certainly, electronics design and wireless communication expertise are important ingredients for any EMS outsourcing partnership, but they comprise only a small part of the full recipe for success. Quality, of course, is at the top of every device manufacturer’s list of selection criteria, but it’s also imperative to consider location, product complexity, test procedures, circuit board cleanliness, and cost containment, among other factors.

Geography can easily become a deciding factor, depending on whether companies want to manufacture a product near their headquarters or somewhere within the distribution market. “We are seeing increased interest in regional manufacturing as an outsourcing strategy,” said Curtis Campbell, vice president of West Coast sales for SigmaTron International Inc., a full-service EMS provider based in Elk Grove, Ill. “We have U.S. customers that select a specific U.S. or Mexico facility for its proximity to their engineering team or manufacturing locations. In China, we’ve seen increased interest from medical customers for manufacturing support in China to support sales in China. We’ve added ISO 13485:2008 certification to our Suzhou, PRC facility to support that, and we are expanding our support capabilities in the United States as well.”

Naturally, cost is a major consideration when determining location. Manufacturing a product far from home—on another continent or a different hemisphere, perhaps—is significantly more expensive than local assembly, particularly when problems arise. Long-distance production can also be complicated by conflicting time zones, language barriers, and divergent cultures.

Costs can be reasonably mitigated, though, through design for manufacturability (DFM). Incorporating this proactive technique from the start of the product development process not only helps control expenses, but also improves device reliability and sustainability.

“Medical device OEMs have a good knowledge of electronics but they generally don’t have the capability to make a device manufacturable,” said Dave Busch, vice president of Medical, NEO Technology Solutions, at NEO Tech, a Chatsworth, Calif.-based supplier of electronic product design, engineering, and manufacturing services for the medical, defense/aerospace, and industrial markets. “The OEM’s expertise is in leveraging technology to create a solution to a medical problem. The contract manufacturer’s expertise is in making the solution manufacturable.”

Indeed, contract electronics manufacturers can help their partners ensure that designs are practical to make from a cost or materials standpoint, and that those solutions suit the end user. In addition, a closely integrated team can reduce the risk of a “silo” approach and an overemphasis of any one element, while other design considerations are overlooked.

EMS providers can offer the most value to their partners, however, through component obsolescence management. An inevitable and unavoidable by-product of the digital health revolution, antiquated parts can add cost and complexity to any project. At fault is medtech’s long product development lifecycle, which can hamper companies’ abilities to incorporate the latest hardware/software in finished devices. Upgrades can further complicate the development process, as product changes or modifications typically require regulatory recertification.

Component obsolescence can be managed in various ways, though many EMS providers have chosen to tackle the challenge through component monitoring software programs. Such courseware can help identify the timing of part antiquity as well as inventory levels and source reduction.

“When customers design a product, they put a bill of materials together. We take that BOM and buy all the parts and put everything together. Many times, we’ll get a bill of materials and go out to buy the part only to find out that one of the parts is obsolete or will be obsolete in the next year. That already puts you behind the eight ball,” said Michael Goeringer, president of Elk Grove Village, Ill.-based Arc-Tronics Inc., a designer and manufacturer of custom-printed circuit boards, and electromechanical and cable/harness assembly products. “We have some software tools to help customers in this area. We load up their BOM, it goes out to the Web, and it does a risk analysis. There’s an algorithm built into the software program that calculates when a particular part will become obsolete. The report will say, ‘This part is not recommended for design,’ or ‘This part will be obsolete in two years.’ We can help customers avoid these problems if we get involved with them up front. We’re building MRI machines—they’re expensive pieces of equipment that are going to be around for a long time. You need to be able to support those machines for 20 or 30 years. You can’t sell a machine for seven figures and two years later say, ‘That part went bad and there’s no replacement for it.’ That’s not going to be good for the customer. Obsolescence is a huge factor in the design of a product.”

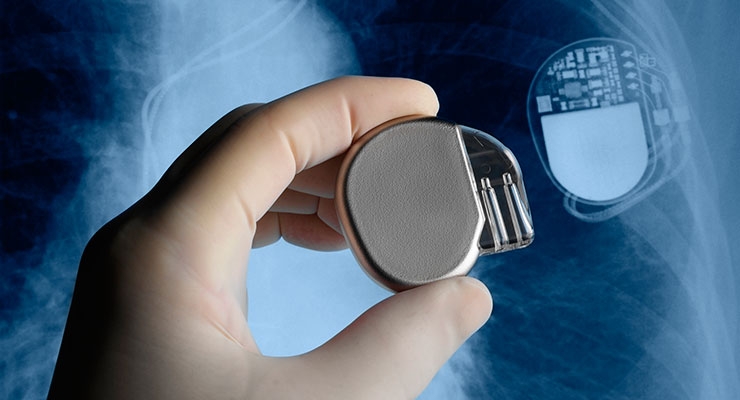

So is cybersecurity. Earlier this year, the U.S. Food and Drug Administration (FDA) confirmed hacking vulnerabilities in St. Jude Medical Inc.’s pacemakers and implantable heart defibrillators, though regulators insisted the hacking risk never endangered patients.

Nevertheless, the confirmation was unsettling, as it highlighted the growing risk posed by mobile health devices and wireless communication networks. A Brookings Institute report issued last year detailed the disturbing extent of that risk, finding that 23 percent of all data breaches occur in the healthcare industry, and nearly 90 percent of healthcare organizations experienced a data breach between 2013 and 2015, costing the industry $6.2 billion.

In late December (2016), the FDA released cybersecurity recommendations for medical device manufacturers, suggesting that device makers monitor their devices and associated software for bugs, and patch any problems that occur.

“One of the challenges EMS providers face in designing connectivity and intelligence into medical products is to have effective cybersecurity management,” noted Wayne Meng, founder, president, and CEO of Sanbor Medical, a medical device contract manufacture company in Allentown, Pa. “Developing a set of cybersecurity control [measures] should include limiting access to devices through the authentication of users, ensuring the data transfer to and from the device using encryption methods, and implementing features that allow for security compromises to be detected, recognized, logged, timed, and acted upon during normal use.”

***

Kevin Tracey envisions a future without drugs.

In that world, medicine and Mother Nature speak the same language, courtesy of infinitesimal microprocessors that can communicate with and control the body’s nervous system. “A patient gets a device implanted once for disease, and they’re done,” he fancied to the Times. “No prescriptions, no medicines, no injections. That’s the future...”

To achieve that future, though, Tracey will need the support of electronics manufacturing service providers, who hold the key to deciphering the body’s biological brogue. Collaborating with these companies can help turn Tracey’s vision into a reality, as they possess both the expertise and service flexibility to become trusted partners.

“Many companies are expert at understanding the market need, but not experts in manufacturing. We continue to see a desire for medical device manufacturers and many of our other customers to look for service delivery flexibility,” said Adrian Nishimoto, operations manager at Spectrum Assembly Inc., a vertically-integrated contract manufacturing firm in Carlsbad, Calif. “San Diego is a medical product development hub and we see many startup clients who have very specific support needs that don’t always fit the typical electronics contract manufacturing model. There is often a ‘gap’ period where they aren’t doing high enough volume manufacturing to attract larger EMS companies, but the complexity of their needs goes beyond what most job shops can offer. We’ve found our ability to listen to their requirements and then fill the gaps in their documentation and materials strategy, plus optimize their assembly processes addresses that issue well.”

Too young to truly comprehend the loss, Tracey sought solace with his maternal grandfather, then a pediatrics professor at Yale University. He wasn’t looking for kind words from the man, a shoulder to cry on, or even a peck on the cheek.

All he wanted was an explanation.

“I climbed onto his lap and asked what happened,” Tracey recalled to The New York Times in a 2014 interview. “He [grandfather] explained that surgeons tried to take it [brain tumor] out but couldn’t separate the tumor tissue from the normal neurons. I remember saying to him, ‘Somebody should do something about that.’ That was when I decided to be a neurosurgeon. I wanted to solve problems that were insolvable.”

Tracey’s personal vendetta against the unsolvable would eventually define his medical career, beginning with the 1985 death of an infant burn victim at New York Hospital. Accidentally doused with boiling pasta water, the girl died suddenly in Tracey’s arms just a few days before her scheduled discharge, and only 24 hours after her first birthday.

The case haunted Tracey for years. He found himself wrestling with a familiar question from childhood: What happened?

He wanted an explanation. Again.

This time, however, Tracey answered his own question. He suspected sepsis, a condition caused by the human immune system’s overwhelming and life-threatening response to an infection. The illness can lead to tissue damage, organ failure, and ultimately, death.

Confounding Tracey’s theory, though, was the lack of bacteria and/or signs of infection anywhere in the victim’s body upon death.

“The more I looked into the problem, the more I realized that basic science lacked a fundamental understanding of why septic shock occurs,” Tracey, now president of The Feinstein Institute for Medical Research (Manhasset, N.Y.) and professor of molecular medicine and neurosurgery at the Hofstra Northwell School of Medicine, told a TEDMED audience last May. “Thirty years ago, I decided to go into the lab and study that problem and my labs have been pursuing that question ever since. What we found changed the way the world thinks about how the body responds to infection.”

Indeed, Tracey’s research changed the way the medical world thinks about organic infection defenses. Specifically, he discovered an interface between nerves and the immune system, disproving a deep-seated scientific consensus that long regarded communication between the two impossible. The conduit for this interplay is the vagus nerve, which helps control and regulate inflammation. Through a series of experiments, Tracey showed that the human nervous system works similarly to a computer terminal, through which commands can be delivered to stop problems like acute inflammation before it begins, or repair the body after an illness.

Tracey’s efforts to better understand the body’s immunological responses has helped establish the emerging new field of bioelectronics, a promising area of medicine that has proven successful in treating acute and chronic immune system disorders (i.e., rheumatoid arthritis, diabetes, psoriasis, inflammatory bowel disease, multiple sclerosis, heart disease, etc.).

The idea of interrupting the vagus nerve-brain conduit with electrical pulses is not an entirely new concept. Vagus nerve stimulation has been used since 1997 to control epileptic seizures and has also been effective at treating drug-resistant cases of clinical depression. But advancements in immunology—due largely to Tracey’s groundbreaking research—are prompting clinicians to test the technique on other difficult-to-manage diseases.

And the results have been encouraging.

Clinical trial subjects implanted with bioelectronic nerve stimulators in their necks have reported significant improvements in rheumatoid arthritis and Crohn’s disease symptoms. Arthritis sufferers, according to study data, experienced fewer swollen joints and pain, while several Crohn’s disease patients achieved complete remission.

Such notable turnarounds are inspiring quests for additional therapies as well: Purdue University researchers, for instance, are investigating bioelectronic therapies for epilepsy, a brain disorder that costs the U.S. healthcare system $15.5 billion annually. Johns Hopkins University scholars, on the other hand, are studying the ways nerve signals affect obesity, diabetes, and gastrointestinal-motility disorders. “What we’re doing today,” Johns Hopkins Medicine and Neurosciences Professor Jay Pasricha said, “is like the precursor to the Model T.”

Only this Model N has more savvy backers.

Last summer, pharmaceutical giant GSK (GlaxoSmithKline) and Verily Life Sciences LLC (formerly Google Life Sciences) formed a company specially tasked with researching, developing, and commercializing bioelectronic therapies. The two partners will contribute 540 million British pounds ($714 million) over seven years to operate Galvani Bioelectronics, aptly named after the 18th century scientist best known for his experiments animating severed frogs’ legs with jolts of electricity.

GSK considers the joint venture with Verily a natural “next step” in its four-year crusade to establish a firm foothold in bioelectronic medicine. The company has invested roughly 45 million euros ($50 million) since 2012 on bioelectronic technology, including a million-dollar prize in 2013 to encourage research into “electroceuticals.”

GSK first unveiled its bioelectronics ambitions three years ago in the journal Nature, and believes it is ahead of its big pharma rivals in developing medical treatments to use electrical impulses rather than traditional chemicals or proteins. Galvani executives expect the first bioelectronic devices to be ready for government inspection in six years.

“This is an ambitious collaboration, allowing GSK and Verily to combine forces and have a huge impact on an emerging field,” Brian Otis, chief technology officer at Verily, said when the partnership was announced. “Bioelectronic medicine is a new area of therapeutic exploration, and we know that success will require the confluence of deep disease biology expertise and new highly miniaturized technologies.”

Not to mention electronics manufacturing and design prowess. As electrophysiology and neuroscience yield promising new treatments for age-old diseases, companies like Galvani will need to work closely with electronics manufacturing services (EMS) providers to bring their products to market.

“The medical device industry is at a point of significant change,” noted John Carlson, president of Flex Medical Solutions, a division of Flex Ltd., a global provider of sketch-to-scale design, engineering, manufacturing, supply chain insight, and logistics services to various industries, including medical. “There’s a growing recognition that in order for medtech companies to compete, they’re going to have to be much better at collaboration and partnership in certain areas than they’ve historically had to be. We’ve seen ongoing consolidation in the industry, and as a result, companies’ portfolios have become bigger. Consequently, the number of products they’re having to produce has grown almost exponentially. Therefore, the consolidation, the bigger portfolios, and the products’ naturally long lifecycles have forced companies to look at partnering with EMS suppliers in a very different way than in the past.”

One alternate view is beget by a reassessment of core capabilities. Companies with diverse product portfolios are almost never adept in all markets and/or healthcare technologies in which they operate, and thus must outsource with trusted partners to remain competitive.

Privately held biotech firm Ichor Medical Systems adopted this approach in collaborating with Flex on its TriGrid DNA Delivery System, an electroportation device used to deliver DNA vaccines and treatments for various diseases. TriGrid uses electrical fields to increase DNA drug delivery efficiency up to 1,000-fold as compared to conventional injection. The product is comprised of a small, hand-held device that contains a syringe needle and four recessed electrodes arranged in a diamond shape around the central syringe. The design, according to Ichor, is necessary to encompass the tissue in which the drug is administered.

Ichor turned to Flex to incorporate multiple layers of switches in the device, including mechanical, senseless rotational, and optical for accurate drug dose delivery. Flex also developed a special algorithm to compensate for minor deviations in delivery.

“There’s a growing awareness across large and small companies that the pathway to success is collaborative development or partnerships,” Carlson said. “The old outsourcing model of ‘I give you the spec and you go make this’—those kinds of relationships don’t work out well on the OEM side or the EMS provider side. The collaborative efforts tend to be the best ones, and we’re seeing increased recognition from large and small companies of the need to partner.”

That need has partly been driven by the advent of digital health and the shift from service- to value-based reimbursement models. Digital health entrepreneurs are approaching medicine largely from a data perspective, crafting personalized solutions based on new ways of gathering, viewing, manipulating, and analyzing patient information. Their strategies are blurring industry lines and inspiring new technologies like wearable health devices and activity trackers that put data into users’ hands.

Among the flood of wearables saturating the market are two wireless smart patches from Silicon Valley startup VitalConnect—the VitalPatch, a disposable biosensor developed in partnership with Flex, and HealthPatch MD, a reusable cardiac monitor.

Both patches continuously measure heart rate, respiratory rate, heart rate variability, skin temperature, posture, and step count, and they’re powered by zinc-air batteries that can last up to four days before requiring replacement. Both devices also are designed to detect falls.

The patches have been certified and cleared for use in the United States, European Union, Japan, and Canada. They are produced in different adhesive grades based on activity and perspiration levels.

“From a medical standpoint, historically we’ve been partnering [with companies] on the manufacturing end,” Carlson explained. “But more and more, we’re helping customers understand how partnering on the innovation side of things can really help them gain a competitive differentiation in the marketplace and allow them to move much faster than they would otherwise do on their own. Many of our newest engagements have really been on the innovation side of things, where we’ve helped customers move into new technology spaces and bridge the different industries much faster and better than they would have without our help.”

Crossovers can be overwhelming, though. Medtech firms unfamiliar with the consumer space are often dumbfounded at the fast pace of product development and amount of risk-taking associated with new innovations. Medical devices require significant understanding of the target audience and are subject to stringent regulatory scrutiny whereas consumer products are more nimble and can be commercialized in a matter of months.

Such an abbreviated product development timeline can be a major stumbling block for healthcare companies traversing the consumer market. Incorporating wireless connectivity into a medical device requires knowledge of WiFi, Bluetooth, radio-frequency identification, near-field communications, and other connective technologies, as well as IEEE standards for information technology and telecommunications/information exchange.

New York City-based startup AdhereTech Inc., for example, leveraged the wireless communications expertise of full-service design firm Intelligent Product Solutions (IPS) to develop a smart, wireless pill bottle that electronically reminds patients to take their medications and alerts caregivers to missed doses. The company estimates that medication non-adherence costs the United States roughly $100 billion and contributes to 100,000 deaths annually.

AdhereTech’s Smart Pill Bottle is basically a standard drug vial with a cellphone radio and prescription inside that occasionally beeps and lights up to remind its owners to take their medications. The bottle requires no syncing or programming, and its battery can last up to 90 days on a full charge.

AdhereTech executives chose wisely in partnering with IPS on the Smart Pill Bottle, as they tapped into a knowledge base of former Symbol Technologies and Motorola experts with experience in all forms of wireless communications—from low-level languages like Zigbee, Bluetooth, and near field to the longer-range protocols of WiFi, GPS, and wide area radio communications.

Certainly, electronics design and wireless communication expertise are important ingredients for any EMS outsourcing partnership, but they comprise only a small part of the full recipe for success. Quality, of course, is at the top of every device manufacturer’s list of selection criteria, but it’s also imperative to consider location, product complexity, test procedures, circuit board cleanliness, and cost containment, among other factors.

Geography can easily become a deciding factor, depending on whether companies want to manufacture a product near their headquarters or somewhere within the distribution market. “We are seeing increased interest in regional manufacturing as an outsourcing strategy,” said Curtis Campbell, vice president of West Coast sales for SigmaTron International Inc., a full-service EMS provider based in Elk Grove, Ill. “We have U.S. customers that select a specific U.S. or Mexico facility for its proximity to their engineering team or manufacturing locations. In China, we’ve seen increased interest from medical customers for manufacturing support in China to support sales in China. We’ve added ISO 13485:2008 certification to our Suzhou, PRC facility to support that, and we are expanding our support capabilities in the United States as well.”

Naturally, cost is a major consideration when determining location. Manufacturing a product far from home—on another continent or a different hemisphere, perhaps—is significantly more expensive than local assembly, particularly when problems arise. Long-distance production can also be complicated by conflicting time zones, language barriers, and divergent cultures.

Costs can be reasonably mitigated, though, through design for manufacturability (DFM). Incorporating this proactive technique from the start of the product development process not only helps control expenses, but also improves device reliability and sustainability.

“Medical device OEMs have a good knowledge of electronics but they generally don’t have the capability to make a device manufacturable,” said Dave Busch, vice president of Medical, NEO Technology Solutions, at NEO Tech, a Chatsworth, Calif.-based supplier of electronic product design, engineering, and manufacturing services for the medical, defense/aerospace, and industrial markets. “The OEM’s expertise is in leveraging technology to create a solution to a medical problem. The contract manufacturer’s expertise is in making the solution manufacturable.”

Indeed, contract electronics manufacturers can help their partners ensure that designs are practical to make from a cost or materials standpoint, and that those solutions suit the end user. In addition, a closely integrated team can reduce the risk of a “silo” approach and an overemphasis of any one element, while other design considerations are overlooked.

EMS providers can offer the most value to their partners, however, through component obsolescence management. An inevitable and unavoidable by-product of the digital health revolution, antiquated parts can add cost and complexity to any project. At fault is medtech’s long product development lifecycle, which can hamper companies’ abilities to incorporate the latest hardware/software in finished devices. Upgrades can further complicate the development process, as product changes or modifications typically require regulatory recertification.

Component obsolescence can be managed in various ways, though many EMS providers have chosen to tackle the challenge through component monitoring software programs. Such courseware can help identify the timing of part antiquity as well as inventory levels and source reduction.

“When customers design a product, they put a bill of materials together. We take that BOM and buy all the parts and put everything together. Many times, we’ll get a bill of materials and go out to buy the part only to find out that one of the parts is obsolete or will be obsolete in the next year. That already puts you behind the eight ball,” said Michael Goeringer, president of Elk Grove Village, Ill.-based Arc-Tronics Inc., a designer and manufacturer of custom-printed circuit boards, and electromechanical and cable/harness assembly products. “We have some software tools to help customers in this area. We load up their BOM, it goes out to the Web, and it does a risk analysis. There’s an algorithm built into the software program that calculates when a particular part will become obsolete. The report will say, ‘This part is not recommended for design,’ or ‘This part will be obsolete in two years.’ We can help customers avoid these problems if we get involved with them up front. We’re building MRI machines—they’re expensive pieces of equipment that are going to be around for a long time. You need to be able to support those machines for 20 or 30 years. You can’t sell a machine for seven figures and two years later say, ‘That part went bad and there’s no replacement for it.’ That’s not going to be good for the customer. Obsolescence is a huge factor in the design of a product.”

So is cybersecurity. Earlier this year, the U.S. Food and Drug Administration (FDA) confirmed hacking vulnerabilities in St. Jude Medical Inc.’s pacemakers and implantable heart defibrillators, though regulators insisted the hacking risk never endangered patients.

Nevertheless, the confirmation was unsettling, as it highlighted the growing risk posed by mobile health devices and wireless communication networks. A Brookings Institute report issued last year detailed the disturbing extent of that risk, finding that 23 percent of all data breaches occur in the healthcare industry, and nearly 90 percent of healthcare organizations experienced a data breach between 2013 and 2015, costing the industry $6.2 billion.

In late December (2016), the FDA released cybersecurity recommendations for medical device manufacturers, suggesting that device makers monitor their devices and associated software for bugs, and patch any problems that occur.

“One of the challenges EMS providers face in designing connectivity and intelligence into medical products is to have effective cybersecurity management,” noted Wayne Meng, founder, president, and CEO of Sanbor Medical, a medical device contract manufacture company in Allentown, Pa. “Developing a set of cybersecurity control [measures] should include limiting access to devices through the authentication of users, ensuring the data transfer to and from the device using encryption methods, and implementing features that allow for security compromises to be detected, recognized, logged, timed, and acted upon during normal use.”

***

Kevin Tracey envisions a future without drugs.

In that world, medicine and Mother Nature speak the same language, courtesy of infinitesimal microprocessors that can communicate with and control the body’s nervous system. “A patient gets a device implanted once for disease, and they’re done,” he fancied to the Times. “No prescriptions, no medicines, no injections. That’s the future...”

To achieve that future, though, Tracey will need the support of electronics manufacturing service providers, who hold the key to deciphering the body’s biological brogue. Collaborating with these companies can help turn Tracey’s vision into a reality, as they possess both the expertise and service flexibility to become trusted partners.

“Many companies are expert at understanding the market need, but not experts in manufacturing. We continue to see a desire for medical device manufacturers and many of our other customers to look for service delivery flexibility,” said Adrian Nishimoto, operations manager at Spectrum Assembly Inc., a vertically-integrated contract manufacturing firm in Carlsbad, Calif. “San Diego is a medical product development hub and we see many startup clients who have very specific support needs that don’t always fit the typical electronics contract manufacturing model. There is often a ‘gap’ period where they aren’t doing high enough volume manufacturing to attract larger EMS companies, but the complexity of their needs goes beyond what most job shops can offer. We’ve found our ability to listen to their requirements and then fill the gaps in their documentation and materials strategy, plus optimize their assembly processes addresses that issue well.”