Michael Barbella, Managing Editor07.27.21

Materials science has played a key role in the global battle against COVID-19.

Triiodide, salt, copper, nano-silver, polyimide, and graphene are just a few of the recruits drafted thus far in the 18-month coronavirus war. Sodium chloride, a natural anti-bacterial agent, is adept at filtering air and decontaminating surfaces, while copper “foam” can effectively capture tiny aerosol droplets carrying virus particles (diameters between 0.1 and 0.4 micrometers). Moreover, graphene has been used as a protective coating on face masks (the material’s sharp edges damage viruses), and Vyon porous plastic filters are helping a University of Cambridge (U.K.) spinout company diagnose COVID-19 infections in less than 90 minutes.

A research team at Northeastern University, meanwhile, has adopted a virus “mentality” to defeat SARS-CoV-2. The institution’s “Nano-Medicine Lab” created an injectable nano-molecular material that could prevent bacterial infection spread and also help reduce inflammation.

“What we are creating in the lab are molecules that are about 80,000 times smaller than the diameter of a strand of your hair,” Thomas Webster, the lab’s head, said in an interview posted on the school’s website. “In order to kill the viruses, you have to make a nano-meter material to disrupt their function.”

The technology Webster’s lab is researching as a potential coronavirus weapon actually was developed eight years ago as an injectable to help regenerate tissue and cartilage. The material was licensed by Concord, Mass.-based Audax Medical Inc. and has been commercialized for several regenerative medicine applications.

“We quickly hypothesized, when this COVID-19 situation came up,” Webster explained, “that these molecules are great at healing tissue, they’re great at reducing infections, exceptional at inhibiting inflammation that often comes from microbes, and perhaps it could be used to kill viruses.”

Such hypotheses were not uncommon over the last year as scientists, virologists, and medical professionals frantically searched for COVID-19’s molecular Achilles Heel. The pandemic, in fact, underscored the importance of materials science in developing tools and technologies for anti-viral research and treatment.

MPO’s March feature, Resourceful Resources, details the various pandemic response efforts of more than a half-dozen materials suppliers and manufacturers. The story also examines the challenges associated with developing wearable materials, and the impact AI and digital health has had on the space. Mark Denning, Medical Market Business Manager at Sekisui Kydex, was among the experts interviewed for the story. His full input is provided in the following Q&A.

Michael Barbella: In what ways has the global pandemic spurred material innovation?

Mark Denning: KYDEX ION Technology

Denning: We supported two major ventilator programs, including the Ford/GE Healthcare ventilator program and the CAE Healthcare CAEAir1 Mechanical Ventilator.

Ford Program:

Barbella: What lessons from the pandemic will materials developers/suppliers carry forward in a post-COVID-19 world?

Denning: Medical equipment housing materials must have excellent chemical resistance:

Barbella: With the growing importance of sustainability and recyclability in the industry, can medtech materials be made more sustainable? If so, how?

Denning: Yes, and we prioritize making sustainable materials:

Barbella: Please discuss an instance (example) of an innovative material solution(s) your company came up with to meet challenging customer requests.

Denning: KYDEX ION Technology

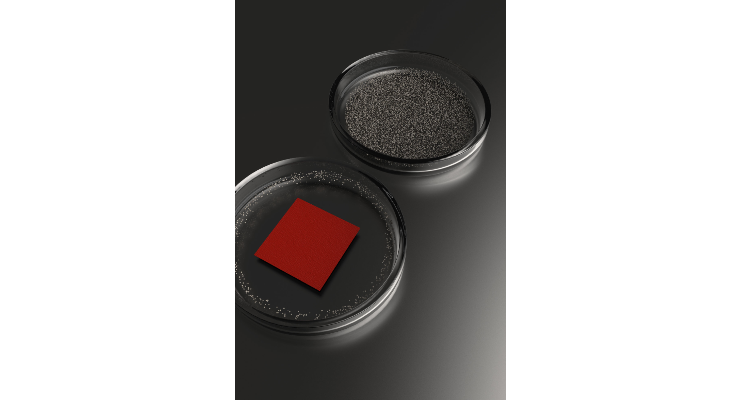

Triiodide, salt, copper, nano-silver, polyimide, and graphene are just a few of the recruits drafted thus far in the 18-month coronavirus war. Sodium chloride, a natural anti-bacterial agent, is adept at filtering air and decontaminating surfaces, while copper “foam” can effectively capture tiny aerosol droplets carrying virus particles (diameters between 0.1 and 0.4 micrometers). Moreover, graphene has been used as a protective coating on face masks (the material’s sharp edges damage viruses), and Vyon porous plastic filters are helping a University of Cambridge (U.K.) spinout company diagnose COVID-19 infections in less than 90 minutes.

A research team at Northeastern University, meanwhile, has adopted a virus “mentality” to defeat SARS-CoV-2. The institution’s “Nano-Medicine Lab” created an injectable nano-molecular material that could prevent bacterial infection spread and also help reduce inflammation.

“What we are creating in the lab are molecules that are about 80,000 times smaller than the diameter of a strand of your hair,” Thomas Webster, the lab’s head, said in an interview posted on the school’s website. “In order to kill the viruses, you have to make a nano-meter material to disrupt their function.”

The technology Webster’s lab is researching as a potential coronavirus weapon actually was developed eight years ago as an injectable to help regenerate tissue and cartilage. The material was licensed by Concord, Mass.-based Audax Medical Inc. and has been commercialized for several regenerative medicine applications.

“We quickly hypothesized, when this COVID-19 situation came up,” Webster explained, “that these molecules are great at healing tissue, they’re great at reducing infections, exceptional at inhibiting inflammation that often comes from microbes, and perhaps it could be used to kill viruses.”

Such hypotheses were not uncommon over the last year as scientists, virologists, and medical professionals frantically searched for COVID-19’s molecular Achilles Heel. The pandemic, in fact, underscored the importance of materials science in developing tools and technologies for anti-viral research and treatment.

MPO’s March feature, Resourceful Resources, details the various pandemic response efforts of more than a half-dozen materials suppliers and manufacturers. The story also examines the challenges associated with developing wearable materials, and the impact AI and digital health has had on the space. Mark Denning, Medical Market Business Manager at Sekisui Kydex, was among the experts interviewed for the story. His full input is provided in the following Q&A.

Michael Barbella: In what ways has the global pandemic spurred material innovation?

Mark Denning: KYDEX ION Technology

- R&D team reacted quickly to the needs of our customers at the onset of the pandemic and pivoted their efforts towards materials that held up to harsh chemicals and bacteria. They developed Premium KYDEX ION Technology that is 99 percent effective at inhibiting the growth of stain and odor causing bacteria on KYDEX Thermoplastics.

- Health and safety are at the forefront of the patient experience, requiring materials that are chemical resistant, inherently antimicrobial, and will not be stained by harsh cleaning agents.

- While this isn’t a solution to eliminate the disinfection process, its intention is to keep surfaces cleaner between disinfection processes with quantifiable results.

- The industry had to react quickly to fulfill material needs to service equipment manufacturers. Our material lead times went from three weeks to produce and ship a normal order, to two to five days for COVID-19 identified orders. As an essential manufacturer, speed was imperative to help our customers get life-saving devices to medical facilities.

Denning: We supported two major ventilator programs, including the Ford/GE Healthcare ventilator program and the CAE Healthcare CAEAir1 Mechanical Ventilator.

Ford Program:

- Backed by the power of Ford Motor Company in collaboration with GE Healthcare, the mission was clear: Produce 50,000 life-saving medical devices in response to the COVID-19 pandemic. Revere Plastics was named Ford’s supplier with assistance from SEKISUI KYDEX, manufacturer of KYDEX Thermoplastics. The goal was set. The clock was ticking. Lives were on the line and time was of the essence. What happened next is a testament to Quick Response Manufacturing (QRM) and the power of rapid prototyping.

- SEKISUI KYDEX does not simply manufacture sheet that is later cut into plastic rectangles. Fueled by 400 dedicated professionals, SEKISUI KYDEX is committed to delivering more than their customers can imagine, including stepping in when needed to produce fully finished, ready-to-use parts. This was a complete change from the traditional model, where a typical customer purchase is considered complete after the sale of thermoplastic sheet—a journey from extruder to integrator. This opportunity was one to try something new and help Ford Motor Company and GE Healthcare meet their aggressive timelines.

- Prints were developed, parts were quoted, quality documents were developed and put into place, accounts were set up with our finance team, go/no-go gauges were developed, POs were cut, material was produced, material was shipped, first articles were made and approved, all over a period of one week.

- The SEKISUI KYDEX team and I collaborated with Revere Plastics on material requirements for both internal and external parts, first utilizing SEKISUI KYDEX’s ALLEN ABS sheet and KYDEX T-MB (antimicrobial) sheet. Later, the teams also added KYDEX T-IM injection molding resin to the mix. Along with being the first time Revere Plastics and SEKISUI KYDEX had ever worked together, this was also the first project where all three SEKISUI KYDEX materials were harmonized in a single application.

- Airon’s simplified ventilator design—the pNeuton A— is responsive to the needs of most COVID-19 patients and operates on air pressure without the need for electricity, which helps speed up production times.

Barbella: What lessons from the pandemic will materials developers/suppliers carry forward in a post-COVID-19 world?

Denning: Medical equipment housing materials must have excellent chemical resistance:

- In today’s medical environment, the use of aggressive disinfectant agents is critical in eliminating surface bacteria and viruses to reduce the risk of infection. Understanding what materials stand up to healthcare grade disinfectants is a critical step in material selection, to avoid degradation and discoloration, and ensure device’s longevity. Materials that don’t hold up to the chemicals and disinfectants can also cause micro fissures in the product, which can not only harbor bacteria, but cause the product to become brittle and fail.

- Collaborated with outside manufacturers to confirm this information. A variety of samples underwent contact testing with PDI Sani-Cloth disinfecting wipes: stressed tensile bar, submersion, continuous contact, and wipe down. SEKISUI KYDEX and PDI conducted testing based on ASTM D543, Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents.

- Testing results confirmed that KYDEX Thermoplastics are not adversely affected by hospital-grade CDC recognized disinfectants and perform without loss of surface finish, color fastness, or degradation of mechanical and physical properties

- We’ve seen an increased interest in UV-C disinfection, vapor disinfection, and heavier utilization of traditional wipes and sprays. Materials are exposed to heavy doses of quaternary ammonium compounds, sodium hypochlorite, and hydrogen peroxide regularly to prevent disease spread. Efficacy rate is standard part of conversations now, and how these chemicals effect materials used to house and enclose devices is now becoming more apparent.

Barbella: With the growing importance of sustainability and recyclability in the industry, can medtech materials be made more sustainable? If so, how?

Denning: Yes, and we prioritize making sustainable materials:

- Many would be surprised to know that KYDEX Thermoplastics are already developed through an environmentally conscious process. They are a recyclable plastic material because of the PVC's properties, and combined with internal initiatives that create a sustainable lifecycle.

- KYDEX Thermoplastics do not contain plasticizers, brominated halogen flame retardants, phthalates or BPAs, and are fully RoHS, REACH, and CA Prop 65 compliant.

- Throughout the KYDEX Thermoplastics production process, scrap material is collected internally, and from our customers, for recycling by our in-house recycling partner, Ultra-Poly. Inside our South Campus facility, Ultra-Poly has recycled over 15 million pounds of PVC material in 2020.

- The scrap material can also be converted to our recycled grade product, KYDEX V103, or sold to the market to be made into products like warehouse trays, etc.

- SEKISUI KYDEX is continuing the journey of sustainability by prioritizing the next phase of implementing recycling streams for end-use materials at the end of their lifecycle.

- To eliminate or minimize the need to paint which creates harmful VOCs, we put a huge emphasis on color creation and ability to maintain color accuracy.

- SEKISUI KYDEX is ISO 14001:2015 Certified and a Zero Waste to Landfill manufacturer.

Barbella: Please discuss an instance (example) of an innovative material solution(s) your company came up with to meet challenging customer requests.

Denning: KYDEX ION Technology

- Our appLab quickly innovated KYDEX ION Technology at the beginning of the pandemic, due to our aviation interiors customers looking for a solution to instill confidence in passengers. This quickly transitioned to the medical market for high touch surfaces.

- New KYDEX ION Technology is 99 percent effective at inhibiting the growth of stain and odor causing bacteria on KYDEX Thermoplastics. KYDEX ION Technology interferes with bacteria DNA, which prevents stain and odor causing bacteria from multiplying on the treated thermoplastic sheet.

- KYDEX ION Technology is an antimicrobial treatment incorporated into the sheet, which helps keep the treated surface cleaner between cleanings.

- Customers were also looking materials with the physical performance properties of KYDEX Thermoplastics, utilizing injection molding for large runs of small parts with tight tolerances.

- This is why we developed KYDEX Injection Moldable resins. We are also on the cusp of some other solutions that I’m not at liberty to share at this point.

- KYDEX Injection Molding materials are a specialty formulated thermoplastic alloy and share the same physical properties as KYDEX Thermoplastic sheet.

- When parts for medical device housings are from different sources, achieving visual consistency among materials can be difficult. Because KYDEX IM materials are specifically engineered to match KYDEX thermoformed parts, they contribute to the overall seamless aesthetic and are as durable, chemical- and stain- resistant. They are easy to disinfect and are ideal for high traffic areas such as healthcare furniture and medical devices.