Virtual Human Modeling for Tailor-Made Implants

By Sam Brusco, Associate Editor | 11.20.23

Computer-assisted, functional tests and human modeling aim to design patient-specific implants and orthoses.

Researchers at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA are developing a new software platform for virtual clinical in silico studies for hip and knee replacements. The workflow-based simulation environment was on display at this year’s MEDICA trade fair.

The computer-assisted, functional tests and human modeling aim to design implants and orthoses specifically for an individual to minimize later complications. The group is digitizing numerous manual production steps and transferring them to a virtual process to use the simulation software to manufacture all types of joint replacements, prostheses, and orthoses.

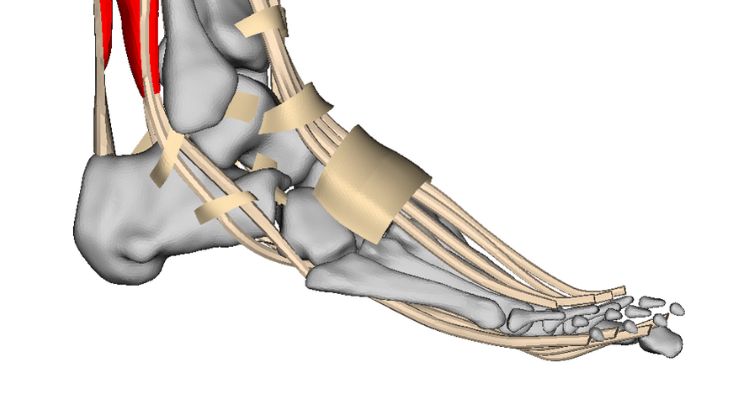

The muscle-tendon system is modeled with a huge amount of detail to create a digital twin.

“Our software platform supports surgeons in planning procedures. Using the realistic simulations, they are able to see precisely what effect each change has,” Dr. Okan Avci, head of the Virtual Orthopedic Lab at Fraunhofer IPA told the press. “This preserves the knowledge of experienced doctors. Surgeons with little experience can use the software to learn. It is also a way to improve standards, since we are establishing a system that is easy to understand.”

Virtual clinical trials are another possible application for the software. Patient-specific analyses of implant functionality and effectiveness are currently not used much in clinical trials because they’re too costly and complex. Putting together suitable patient groups (cohorts) can prove difficult—it’s rare to find more than 50 trial subjects.

“Currently, implants can only be tested on standard testing machines and clinical trials with few subjects do not serve as sufficient evidence. With our human modeling and the simulations, it’s possible to put together multiple virtual patient cohorts and calculate a range of implant variations. Numerous factors such as the size of the prosthesis, muscle strength and many more can be factored in,” explained the engineer. “This will increase evidence because it is possible to analyze the effects.” In the future, medical technology businesses and clinics will be able to license the human modeling that they need for further research and development.”

The researcher and his team are currently working with an implant manufacturer on human modeling for simulating and analyzing a knee replacement used in cases of bone tumors.

The computer-assisted, functional tests and human modeling aim to design implants and orthoses specifically for an individual to minimize later complications. The group is digitizing numerous manual production steps and transferring them to a virtual process to use the simulation software to manufacture all types of joint replacements, prostheses, and orthoses.

The muscle-tendon system is modeled with a huge amount of detail to create a digital twin.

“Our software platform supports surgeons in planning procedures. Using the realistic simulations, they are able to see precisely what effect each change has,” Dr. Okan Avci, head of the Virtual Orthopedic Lab at Fraunhofer IPA told the press. “This preserves the knowledge of experienced doctors. Surgeons with little experience can use the software to learn. It is also a way to improve standards, since we are establishing a system that is easy to understand.”

Virtual clinical trials are another possible application for the software. Patient-specific analyses of implant functionality and effectiveness are currently not used much in clinical trials because they’re too costly and complex. Putting together suitable patient groups (cohorts) can prove difficult—it’s rare to find more than 50 trial subjects.

“Currently, implants can only be tested on standard testing machines and clinical trials with few subjects do not serve as sufficient evidence. With our human modeling and the simulations, it’s possible to put together multiple virtual patient cohorts and calculate a range of implant variations. Numerous factors such as the size of the prosthesis, muscle strength and many more can be factored in,” explained the engineer. “This will increase evidence because it is possible to analyze the effects.” In the future, medical technology businesses and clinics will be able to license the human modeling that they need for further research and development.”

The researcher and his team are currently working with an implant manufacturer on human modeling for simulating and analyzing a knee replacement used in cases of bone tumors.