Emily Peck, Senior Chemist, MicroCare LLC06.02.21

Outsourcing is an essential practice within medical device manufacturing, and sustainability is a crucial part of this process. Manufacturers who control standards and sources in a supply chain must not only meet customer expectations and cost implications, but must also be ethically and environmentally responsible. It is therefore important to address sustainability and ensure procedures are being followed. This means developing both long-term and short-term production strategies that balance profits with environmental protection and safety.

Businesses must decrease emissions, improve energy efficiency, protect natural resources, reduce waste, and protect their workers’ health and well-being. Sustainability’s objective is to meet today’s short-term goal of commercial success without overlooking the long-term impact operations might have on the workforce and planet.

When considering green manufacturing processes, it’s integral to address the triple bottom line (TBL). Companies should not just focus on profit but also environmental and social concerns. The three P’s—planet, people, profit—should be the long-term goal for a responsible organization.

When it comes to sustainable practices in the manufacture of medical components, the cleaning method and fluids used during the production process should be considered.

Medical device manufacturing has very strict requirements for production cleanliness and product quality. The industry is consistently under pressure from a growing number of regulatory agencies and governments increasing legislation and enforcing green laws in an effort to reduce any negative environmental impact. Companies must look for more responsible and sustainable cleaning solutions to address this.

Finding a cleaning process that is successful in reliably cleaning all contamination from medical components and tackles the three P’s is the ultimate package. So what steps should companies take?

Stipulating a Green Cleaning Process

Medical devices can be complex assemblies and include intricate shapes and delicate parts, all of which makes cleaning during manufacturing particularly difficult. Despite this challenge, the requirement for absolute cleanliness is critical. Complete removal of particulate, oils, or inorganic contaminates introduced during manufacturing processes must be removed. If this isn’t achieved successfully, lack of device reliability may be the outcome. In medical device manufacturing, that can be catastrophic.

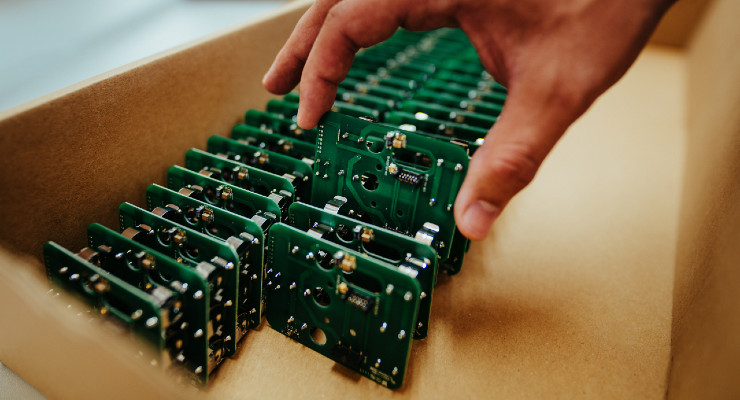

Whether it is production of high-reliability medical electronics (which often includes dense circuitry within very small, complex packages) or multifaceted assemblies with intricate shapes and delicate parts, both must be cleaned to meet reliability and quality standards.

For medical manufacturers today it is no longer sufficient to produce high-quality parts at competitive prices; they must get there by following the path of sustainability. Vapor degreasing is a long-term economically-sound cleaning process that helps minimize negative environmental impact and keeps medical device manufacturers following the right path. This cleaning method both conserves energy and natural resources and leaves components exceptionally clean.

A vapor degreaser is a closed-loop system that uses specific low-boiling non-flammable fluid as the cleaning agent. Solvent-based cleaning fluids contain a mixture of compounds that can be combined or custom-formulated to successfully remove contaminants. They are also engineered to ensure they are compatible with the substrate and materials of the part being cleaned to maximize effectiveness.

A vapor degreaser is not only a parts cleaner, but also a continuous recovery and recycling system. The system contains two chambers: the boil sump and the rinse sump. In the boil sump, the solvent is heated and parts are immersed and cleaned in the fluid. Once cleaned, parts are mechanically transferred to the rinse sump for final cleaning in a pure, uncontaminated fluid. The cleaning fluid condenses and drips back into the vapor degreaser, from which it can be reused for many hundreds of times before requiring refreshment or replacement. It does not produce wastewater—which must be filtered, distilled, deionized, and osmosis prepped prior to disposal. The vapor degreaser simply concentrates the soils as it works. This reduces waste generation and lowers hazardous waste disposal costs.

Sustainable Cleaning Fluids

Vapor degreasing is a winning method for sustainable cleaning, but the cleaning fluid used in it makes the process even greener.

Modern cleaning fluids used in a vapor degreaser have outstanding ecological and safety profiles. They are more environmentally acceptable and highly effective cleaning options that outperform older fluids and alternate processes like aqueous cleaning.

These fluids are engineered with the correct characteristics such as high densities, low surface tensions, and low viscosities to wet every surface. This means they can penetrate the most complex shapes to completely dissolve contaminants and remove the most stubborn particulate. They are also compatible with a range of metals and plastics, and clean a variety of soils with ease. Parts come out of a vapor degreaser clean, dry, spot-free, and cool enough for immediate further processing or packaging.

Modern cleaning formulations have been developed to clean very effectively inside a vapor degreaser without using harmful chemicals like hydrochlorofluorocarbons (HCFCs), nPB (n-Propyl Bromide), perchloroethylene (Perc), and trichloroethylene (TCE). These high-solvency chlorinated and brominated solvents have groundwater contamination and air quality concerns and are either banned, restricted, or under scrutiny in some countries—including the United States.

Significant advancements in medical device cleaning make vapor degreasing cleaning fluids a safe, sustainable, regulatory-compliant option. There are some modern cleaning fluids that now use hydrofluoroolefin (HFO) chemicals in formulations with very low Global Warming Potential (GWP).

A substance’s climate impact, commonly expressed as GWP, is the amount of greenhouse gas it emits and becomes trapped in the high atmosphere. The longer a trapped gas absorbs infrared radiation in the atmosphere, the more it may contribute to global warming and climate change. New cleaning fluids offer improved environmental properties without compromising performance. They are safe, non-flammable, and environmentally progressive fluids with a low GWP. The lower the GWP number, the more climate-friendly the substance. Therefore, by comparison to traditional cleaning solvents like HFCs (hydrofluorocarbons) that have an average GWP ratings in the thousands, new vapor degreasing fluids are more eco-friendly. Additionally, the Ozone Depleting Potential (ODP) ratings of many of the new sustainable cleaning fluids is zero, meeting all strict air quality emission regulations.

Increased Worker Safety

When it comes to the three P’s, we have seen how planet and profit have been achieved through vapor degreasers and the cleaning fluids used in them. The final P—people—is also addressed through this method.

Next-generation vapor degreasing fluids are both environmentally safer and safer for people. The properties of new cleaning fluids ensure they are compositionally stable and safe to use. Their non-flammable properties improve workplace safety. Furthermore, many of the substitutes for nPB, PERC, or TCE have improved HAP (hazardous air pollutant) and human toxicity profiles and higher, better TLVs (Threshold Limit Values) than legacy solvents.

Expressed in parts-per-million (ppm), a TLV helps evaluate the amount of exposure allowed in the workplace over time without adverse effects to the employee. Chemicals with high numbers, for example 1,000 ppm, indicates a safer chemistry with a higher exposure threshold. Lower threshold numbers indicate a greater risk.

In the U.S., several government agencies recommended 10-ppm minimum for nPB exposure limits. Separately, California adopted a 5-ppm limit. In 2014, the American Conference of Governmental Industrial Hygienists (ACGIH) lowered their recommended nPB exposure rating to just 0.1 ppm. In 2020, the EPA announced nPB presents an unreasonable risk to human health when used as a cleaner inside all vapor degreasers including open-top, in-line, and closed-loop models. Today, it is unknown exactly when a complete nPB ban will happen in the U.S., but many experts agree an eventual ban is certain and coming soon.

Meeting the Three Ps with Sustainable Cleaning

Vapor degreasing, when used with environmentally progressive cleaning fluids, is playing an important role in meeting green manufacturing requirements. It is helping address the triple bottom line and manage the three P’s principle.

Medical product outsourcers must create a sustainable model by choosing a partner who recognizes the need for green standards and can also guarantee components are cleaned to the highest standard to ensure reliability and quality. Additionally, they must also address the strict regulations that must be complied with in the medical industry. This will ensure long-term functionality as well as improve worker safety credentials, environmental impact, and adherence to regulatory compliance.

Emily Peck is a senior chemist at MicroCare LLC, which offers benchtop and vapor degreasing cleaning solutions. She has been in the industry more than six years and holds a MS in chemistry from Tufts University. Peck researches, develops, and tests cleaning-related products that are used on a daily basis in electronics, medical, and precision cleaning applications. For more information, visit www.microcare.com.

Businesses must decrease emissions, improve energy efficiency, protect natural resources, reduce waste, and protect their workers’ health and well-being. Sustainability’s objective is to meet today’s short-term goal of commercial success without overlooking the long-term impact operations might have on the workforce and planet.

When considering green manufacturing processes, it’s integral to address the triple bottom line (TBL). Companies should not just focus on profit but also environmental and social concerns. The three P’s—planet, people, profit—should be the long-term goal for a responsible organization.

When it comes to sustainable practices in the manufacture of medical components, the cleaning method and fluids used during the production process should be considered.

Medical device manufacturing has very strict requirements for production cleanliness and product quality. The industry is consistently under pressure from a growing number of regulatory agencies and governments increasing legislation and enforcing green laws in an effort to reduce any negative environmental impact. Companies must look for more responsible and sustainable cleaning solutions to address this.

Finding a cleaning process that is successful in reliably cleaning all contamination from medical components and tackles the three P’s is the ultimate package. So what steps should companies take?

Stipulating a Green Cleaning Process

Medical devices can be complex assemblies and include intricate shapes and delicate parts, all of which makes cleaning during manufacturing particularly difficult. Despite this challenge, the requirement for absolute cleanliness is critical. Complete removal of particulate, oils, or inorganic contaminates introduced during manufacturing processes must be removed. If this isn’t achieved successfully, lack of device reliability may be the outcome. In medical device manufacturing, that can be catastrophic.

Whether it is production of high-reliability medical electronics (which often includes dense circuitry within very small, complex packages) or multifaceted assemblies with intricate shapes and delicate parts, both must be cleaned to meet reliability and quality standards.

For medical manufacturers today it is no longer sufficient to produce high-quality parts at competitive prices; they must get there by following the path of sustainability. Vapor degreasing is a long-term economically-sound cleaning process that helps minimize negative environmental impact and keeps medical device manufacturers following the right path. This cleaning method both conserves energy and natural resources and leaves components exceptionally clean.

A vapor degreaser is a closed-loop system that uses specific low-boiling non-flammable fluid as the cleaning agent. Solvent-based cleaning fluids contain a mixture of compounds that can be combined or custom-formulated to successfully remove contaminants. They are also engineered to ensure they are compatible with the substrate and materials of the part being cleaned to maximize effectiveness.

A vapor degreaser is not only a parts cleaner, but also a continuous recovery and recycling system. The system contains two chambers: the boil sump and the rinse sump. In the boil sump, the solvent is heated and parts are immersed and cleaned in the fluid. Once cleaned, parts are mechanically transferred to the rinse sump for final cleaning in a pure, uncontaminated fluid. The cleaning fluid condenses and drips back into the vapor degreaser, from which it can be reused for many hundreds of times before requiring refreshment or replacement. It does not produce wastewater—which must be filtered, distilled, deionized, and osmosis prepped prior to disposal. The vapor degreaser simply concentrates the soils as it works. This reduces waste generation and lowers hazardous waste disposal costs.

Sustainable Cleaning Fluids

Vapor degreasing is a winning method for sustainable cleaning, but the cleaning fluid used in it makes the process even greener.

Modern cleaning fluids used in a vapor degreaser have outstanding ecological and safety profiles. They are more environmentally acceptable and highly effective cleaning options that outperform older fluids and alternate processes like aqueous cleaning.

These fluids are engineered with the correct characteristics such as high densities, low surface tensions, and low viscosities to wet every surface. This means they can penetrate the most complex shapes to completely dissolve contaminants and remove the most stubborn particulate. They are also compatible with a range of metals and plastics, and clean a variety of soils with ease. Parts come out of a vapor degreaser clean, dry, spot-free, and cool enough for immediate further processing or packaging.

Modern cleaning formulations have been developed to clean very effectively inside a vapor degreaser without using harmful chemicals like hydrochlorofluorocarbons (HCFCs), nPB (n-Propyl Bromide), perchloroethylene (Perc), and trichloroethylene (TCE). These high-solvency chlorinated and brominated solvents have groundwater contamination and air quality concerns and are either banned, restricted, or under scrutiny in some countries—including the United States.

Significant advancements in medical device cleaning make vapor degreasing cleaning fluids a safe, sustainable, regulatory-compliant option. There are some modern cleaning fluids that now use hydrofluoroolefin (HFO) chemicals in formulations with very low Global Warming Potential (GWP).

A substance’s climate impact, commonly expressed as GWP, is the amount of greenhouse gas it emits and becomes trapped in the high atmosphere. The longer a trapped gas absorbs infrared radiation in the atmosphere, the more it may contribute to global warming and climate change. New cleaning fluids offer improved environmental properties without compromising performance. They are safe, non-flammable, and environmentally progressive fluids with a low GWP. The lower the GWP number, the more climate-friendly the substance. Therefore, by comparison to traditional cleaning solvents like HFCs (hydrofluorocarbons) that have an average GWP ratings in the thousands, new vapor degreasing fluids are more eco-friendly. Additionally, the Ozone Depleting Potential (ODP) ratings of many of the new sustainable cleaning fluids is zero, meeting all strict air quality emission regulations.

Increased Worker Safety

When it comes to the three P’s, we have seen how planet and profit have been achieved through vapor degreasers and the cleaning fluids used in them. The final P—people—is also addressed through this method.

Next-generation vapor degreasing fluids are both environmentally safer and safer for people. The properties of new cleaning fluids ensure they are compositionally stable and safe to use. Their non-flammable properties improve workplace safety. Furthermore, many of the substitutes for nPB, PERC, or TCE have improved HAP (hazardous air pollutant) and human toxicity profiles and higher, better TLVs (Threshold Limit Values) than legacy solvents.

Expressed in parts-per-million (ppm), a TLV helps evaluate the amount of exposure allowed in the workplace over time without adverse effects to the employee. Chemicals with high numbers, for example 1,000 ppm, indicates a safer chemistry with a higher exposure threshold. Lower threshold numbers indicate a greater risk.

In the U.S., several government agencies recommended 10-ppm minimum for nPB exposure limits. Separately, California adopted a 5-ppm limit. In 2014, the American Conference of Governmental Industrial Hygienists (ACGIH) lowered their recommended nPB exposure rating to just 0.1 ppm. In 2020, the EPA announced nPB presents an unreasonable risk to human health when used as a cleaner inside all vapor degreasers including open-top, in-line, and closed-loop models. Today, it is unknown exactly when a complete nPB ban will happen in the U.S., but many experts agree an eventual ban is certain and coming soon.

Meeting the Three Ps with Sustainable Cleaning

Vapor degreasing, when used with environmentally progressive cleaning fluids, is playing an important role in meeting green manufacturing requirements. It is helping address the triple bottom line and manage the three P’s principle.

Medical product outsourcers must create a sustainable model by choosing a partner who recognizes the need for green standards and can also guarantee components are cleaned to the highest standard to ensure reliability and quality. Additionally, they must also address the strict regulations that must be complied with in the medical industry. This will ensure long-term functionality as well as improve worker safety credentials, environmental impact, and adherence to regulatory compliance.

Emily Peck is a senior chemist at MicroCare LLC, which offers benchtop and vapor degreasing cleaning solutions. She has been in the industry more than six years and holds a MS in chemistry from Tufts University. Peck researches, develops, and tests cleaning-related products that are used on a daily basis in electronics, medical, and precision cleaning applications. For more information, visit www.microcare.com.