Mark Crawford, Contributing Writer01.29.18

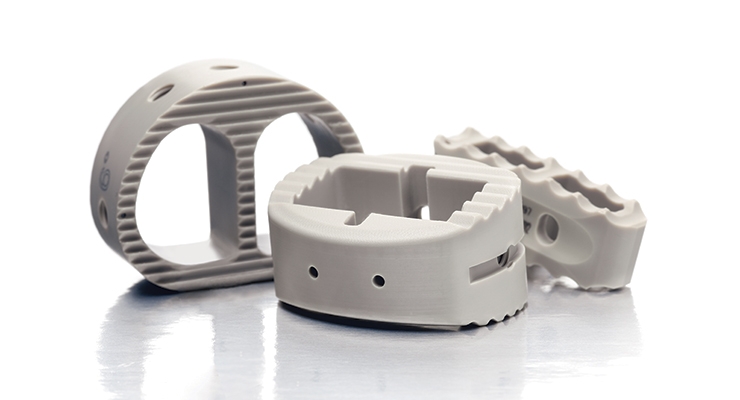

As medical devices get smaller and more complex, and include more advanced or sensitive materials, machinists must have the technology and know-how to deliver the high-precision, tight-tolerance machining these components and parts require. OEM engineers continue to design products with finer features (for example, laser cuts as narrow as 0.0007 inches), which means machinists must stay ahead of the technology curve and be able to deliver the machining solution that wins the next project.

These complex geometries do, of course, create machining challenges. For example, “laser beam size or ‘kerf’ for cutting precision geometries must run at 0.0015-inch diameter or smaller to effectively create some of these components,” said David Philbrick, tech sales/business development manager for Economy Spring , an MW Industries company and Southington, Conn.-based manufacturer of precision products used in medical device instruments and surgical implants. “However, smaller certainly does not mean easier.”

To stay competitive, machine partners must invest in the technology advancements in the machining/laser processing world, such as smaller cutting tools for computer numerical control (CNC) machining, laser improvements, and hybrid machines, which combine lasers with conventional machining equipment. Depending on client needs, some companies even develop their own proprietary equipment in-house.

OEMs also demand efficiency, speed, and lower costs, from concept/design all the way through production. The best way to meet these expectations is through a lifecycle OEM-supplier partnership, with collaborative development at all stages of development.

“We collaborate with the customer to find part design areas that may be slightly altered to significantly reduce cycle time, yet still meet the customer’s design intent,” said Ryan Haferbecker, engineering manager for LISI Medical Remmele, a Big Lake, Minn.-based manufacturer of precision components and implants for minimally invasive surgical, spine, and urology applications. “Our teams work collaboratively, reviewing dimensions and tolerances to optimize the inspection process and open up tolerance zones when possible. Our strategic partnerships with our customers allow us to work interactively at all phases of the project and offer machine and technology solutions that optimize costs for current volume need.”

Dennis Norwich, director of engineering for Wytech Industries, a Rahway, N.J.-based manufacturer of wire and tubing components and assemblies for the medical industry, agreed it is best to get that machining input early on in a project, to avoid costly mistakes as the project matures. For example, OEMs often want features that are not specified on the print, which can create delays. Tighter tolerances and better surface finishes that are not called out on the print are often requested after the first round of sample parts are made. “These changes often have a cost impact,” said Norwich. “We find ourselves questioning many of the ‘defined’ features in the quoting stage, so we can produce the product that the customer really wants, with fewer surprises or iterations.”

In addition to better efficiency, shorter lead times, and lower costs, OEMs seek efficient management of all the validation processes. This is especially true for more complex parts that require extreme precision, utilize advanced (and sometimes sensitive) materials, or are made with newer technologies.

“Increasingly, OEMs require fully PPAP-approved [Production Part Approval Process] parts with stringent tolerances and statistically sound processes,” said Joshua Chaffee, sales engineer for ARCOR Laser Services, a Suffield, Conn.-based contract manufacturer that specializes in laser processing services, machining, and assembly. “The OEMs are not dictating exactly how to achieve the desired results; instead they are relying on the supplier’s expertise to meet the design and part intent. This puts much of the process engineering responsibility on the service provider. The OEMs rely on the supplier to be the true expert and have the appropriate processes in place.”

The Latest in Lasers

Laser wavelength, pulse width, size, and beam delivery continue to evolve at an impressive rate—and at lower price points. This dynamic allows for growth in applicable materials, material thicknesses, and potential design geometries. Improved precision laser power controls, closed-loop feedback mechanisms, and stringent process qualifications lead to finer cuts, better welds, and improved laser-based surface treatments such as texturing and edge rounding. “Automation, including robotic load and unload, also continues to improve efficiency and throughput,” said Chaffee. “Multiple laser processing stations can be fed by one robot while being monitored by a cell leader.”

With complex devices being made from advanced materials that include thin metals, transparent materials, and heat-sensitive materials (including bioabsorbables), there is increased demand for picosecond and femtosecond lasers that can provide high-precision micromachining. These systems provide better quality and higher throughput, at lower cost per watt. For example, their short pulse width minimizes heat input, making them a “cold” process. This allows for the cutting of thin materials, non-metallic materials, and/or complicated geometries such as stents. The resulting cut edge from these lasers is burr-free, which can eliminate or reduce the need for post processing. Heat-affected zones (HAZ) can also be significantly reduced for specific types of alloys by flooding the product in coolant during the cutting operation. “Our laser-cutting systems operate in aqueous coolants that reduce the heat absorption of the alloys and eliminate metal re-melt, improving edge conditions with less micro-cracking,” said Philbrick. “These edge conditions are a radical shift from the oxygen/nitrogen gas-assist processes of laser systems in the past.”

“In addition,” added Mike Treleaven, vice president of Tegra Medical, a Franklin, Mass.-based contract manufacturer of medical device components and finished devices, “femtosecond lasers make cuts with less dross and oxide, reducing the need for cleaning and increasing the ability to process more materials.”

Because shorter laser wavelengths and higher delivery frequencies make laser cutting possible over a wider range of materials, they give engineers more creative freedom for designing functionality into their products. For example, the medical device industry is pushing to get more functionality from standard stainless steel hypo-tubes. Medical device manufacturers (MDMs) want combined features such as flexibility and repeatable articulation, variable flexibility to improve maneuverability throughout the device, location and locking features to secure other device components, and other features such as cutting edges, puncturing elements, and rawl functions.

“A good example of increased functionality would be five-foot-long hypo-tube of 1.3 mm outer diameter, with variable flexibility along 90 percent of the total length, a bend radius decreasing from initial four inches at proximal end down to 0.3 inches at distal tip,” said Richard Hurst, business development director at West Chester, Pa.-based XL Precision Technologies—a manufacturer of components and sub-assemblies for medical devices. “Several locking tangs would be located at various positions along the length with three rotating deployment features for graft stent delivery and re-positioning, a piercing distal tip, followed by a lateral cutting blade, laser cut behind the distal end.”

The latest technological advancement at Laser Light Technologies, a Hermann, Mo.-based service provider of laser micromachining, is the capability to machine to depth laminates of various polymer materials. Today’s lab-on-chip and microfluidic devices are designed for low cost/high-volume production. To achieve this, they use multiple layers of laminate material, where each layer is initially laser machined with individual features, and then individual layers are combined into final laminate. “Our laser system allows adjustment of pulse energy, repetition, and feed rate for each polymer material used in a laminate,” said Alex Pozdin, vice president of R&D for Laser Light Technologies. “The system is used to machine all layers of laminate in a sheet form and can be updated for efficient roll-to-roll processing.”

An increasing variety of polymers and fluoropolymers are extruded into tubing of many shapes. Polyolefin, polyetheretherketone (PEEK), polytetrafluoroethylene (PTFE), and fluorinated ethylene propylene (FEP) are often used to make single or multi-lumen tubing that can be used for a variety of products, such as electro-surgical tools and instruments. The ability to machine these instrument components/polymers requires various laser capabilities that can cut the polymers without leaving any carbon footprint or residues that need to be cleaned after machining.

“This concern is less of an issue today because laser systems can machine these polymers effectively without damaging the metal components underneath the polymers,” said Philbrick. “Creative manufacturing teams can integrate the motion control elements needed that allow uniquely shaped components and polymers to be laser-machined for precision applications. Whether it be on rods, wire, or even multi-faceted bars, this expanded design creativity facilitates the launch of new and innovative products and services to market.”

Traditional Machining Steps Up

With the rapid development of laser-processing capabilities, traditional machining is under pressure to improve speed, precision, and tolerances, with minimal heat-affected zones and fewer machining/post-processing steps. One way to do this is through automation—for example, CNC centers are becoming more automated, especially for part handling at load/unload, inspection, and secondary part-finishing processes. In some cases, additive manufacturing can also be accomplished in a single step, with no secondary operations required.

“We’ve definitely seen increased competition from non-machining manufacturing processes, which drives the need to aggressively find innovative ways to reduce traditional machined part manufacturing costs,” said Haferbecker. Although additive manufacturing is a competitive process, “our main competition for high-volume medical products is typically low-cost labor regions and combinations of non-machining manufacturing processes such as stamping, coining, and metal injection molding.”

New offerings in the automation and software markets such as more versatile and easy-to-implement robotics, smart technologies to aid in part recognition, point-of-use data collection and decision making, as well as increased speed, accuracy, and versatility, keep CNC machinery competitive. “These investments allow us to maintain our focus on low-touch production and reduce the cost of a machining minute,” said Haferbecker.

Speed is always a top consideration for winning a machining contract and CNC equipment continues to improve throughput volume. Faster speed also means cleaner cutting, with fewer secondary steps needed—another way to reduce costs and get products to market faster.

“The pure speed of the newer CNC machining centers is amazing,” said Norwich. “Both linear and spindle speeds are so fast that the newer machines are producing smaller medical devices faster than you could have imagined a few years ago. Our most recent CNC miller purchase has spindle speeds up to 20,000 RPM and a rapid traverse of 2,400 inches per minute. This gives us much cleaner burr-free cutting, which eliminates secondary operations such as hand deburring. We have also greatly reduced cycle times. We reduced the cycle time of one particular orthopedic product from 25 minutes for a pallet of parts to six minutes with high-speed machining.”

LISI Medical Remmele recently invested in precision electrochemical machining (PECM) equipment, which gives the company a competitive edge against coining. PECM offers low per-part cost with high accuracy and top-level part finishes. It also optimizes low attendance rates, reduces set-up times, and streamlines inspection processes. “Realizing these efficiencies allows us to consider what was once regarded as high-volume pricing as feasible for mid-volume mixed model products, and customers as well,” said Haferbecker. “PECM can speed up throughput time by 25 percent or more and reduce labor needs by about 50 percent.”

Another solution for keeping CNC machining competitive is the combination of multiple technologies to create a hybrid machine with enhanced functionality. For example, LaserSwiss machines combine laser cutting and welding with traditional Swiss turning. These machines can perform multiple processes with a single set-up, which also streamlines the validation process. This trend is also driving down costs by shortening lead times for prototyping and production volumes.

“The addition of LaserSwiss technology allows us to manufacture complete components with machined features, laser cut features, and formed features in a single manufacturing pass, without losing registration of the part,” said Joseph Lovotti, director of laser technologies for Okay Industries, a Berlin, Conn.-based manufacturer of components and subassemblies for medical device companies. “The result is better process capability, along with the cost savings of one work cell doing the work of three processes.”

A popular LaserSwiss line is Tsugami’s S205, S206, and SS207-5AX Swiss-type lathe series that comes equipped with integrated 250W and 400W SPI fiber laser cutting systems. The smaller footprint frees up floor space and expands design options. The S206 provides up to 36 tools and the laser; the SS207-5AX has seven axes and includes a B-axis tool block containing the laser. Other advantages include full Swiss turning capability, through-part coolant, and automatic part handling options.

Economy Spring utilizes several Citizen L20 CNC LaserSwiss machining centers, a CNC/laser welding platform for metal parts, a CO2 and fiber laser for plastics, and a plastic printer to help with model and fixture construction. “The combination of multiple laser platforms gives our engineering team the freedom to create very diverse products and assemblies, allowing our customers to get all of their metal products and assemblies from one source,” said Philbrick. “This improves speed to market for our customers and reduces their reliance on additional suppliers to complete a project when multiple technology disciplines are required, saving them time and money.”

In-House, Custom-Made

Sometimes contract manufacturers must come up with their own innovative ways to meet the product requirements and capabilities, while still holding down costs. They can buy equipment, combine equipment to eliminate steps and improve efficiency, co-develop a machine with an equipment manufacturer, or design their own in-house proprietary equipment to meet unique customer needs. For example, ARCOR Laser Services has developed intellectual property, including a seven-axis machine interface and watertight cutting/welding head design. “This advance allows part features and process speeds that are difficult, or impossible, to achieve with traditional milling tools,” stated Chaffee. “Parts with flexible features are now easily achievable, since the raw tube stock is bar-fed through the spindle and the laser is simply cutting as the material is presented. Helical or spiral cutting is now common and can be cut anywhere along the part length.”

Wytech Industries recently built a four-axis CNC trocar grinding machine that can handle very complex multi-step grinds; this could not have previously been accomplished with commercial needle pointing machines. This solution is ideal for lower-volume or high-complexity (and high price) products. Wytech also developed a custom six-axis laser cutter for a specific family of orthopedic devices, which could not be made with off-the-shelf equipment.

Sometimes it is the unique combination of machining technologies that does the trick. XLPT combines both lasers and spark erosion to create highly sophisticated designs and economic production solutions, with no-contact technologies. “Spark erosion, combined with laser cutting, provides unique capability with zero burr generation,” said Hurst. “A good example would be reducing wall thickness on the inside of stainless steel tubes after laser cutting flexibility.”

Okay Industries has developed, through its machine tool partners, five-, six-, and even eight-axis specialized laser tube cutting work cells to accommodate the most exotic of spherical customer part geometries. It is also integrating vision with robotics for positioning the part as well as inspection and data collection during production. “This provides statistical process control and real-time feedback to make machine adjustments automatically,” said Lovotti. “We also use automated vision inspection on completed parts. The advantage of integrating vision into robotics with laser processing is a true one-pass approach to manufacturing. This process ensures consistency, quality, and accuracy of medical device products, which is critical to end-use performance.”

A variety of wattage/types of laser systems on the market today provide more in-house options. As a result, more companies are creating their own motion control systems with closed-loop logic and integrating the lasers themselves, which they receive directly from the laser manufacturer. “This activity continues to accelerate new laser development methodology that allows companies to create unique autonomous platforms that continue to expand on these new ideas,” said Philbrick. “These new machining approaches to laser manufacturing will continue to grow the market.”

After three years of feasibility review and many successful customer development projects, XLPT recently purchased a metal 3D additive manufacturing system with 0.0005-inch layer capability to provide micro features and high accuracy. “New programming developments are reducing the need for secondary operations, but removal from the substrate is always required,” said Hurst. “Material properties are almost identical to stock bar material. In many applications, we find the process is competitive with traditionally machined, and even molded, components.” Current projects are now combining 3D printing, laser cutting, spark erosion, and laser welding to provide unique product realization.

And sometimes it isn’t the combination of technologies that turns a project into a winner, but the material.

Low-density polyethylene (LDPE) is a popular thermoplastic used in various industrial applications. Due to low melting temperatures, laser hole drilling shows significant hole-diameter variation related to re-solidification of molten material. This variation increases with increased thickness of material. For a customer application that required LDPE to be drilled with an array of 0.175-mm holes to provide consistent flow in a filter of a bioreactor, Laser Light Technologies used a laminate material consisting of 0.33 mm of LDPE and 0.025 mm of polyester (PET).

“The laser beam enters material laying horizontally from the LDPE side,” said Pozdin. “We then use the trepanning technique to drill the holes. First, the laser beam melts the LDPE, then drills the hole in the PET. With the beam on, molten material re-flows through the hole in PET and re-solidifies on the opposite side of laminate. Gravity and capillary forces then form the hole with the size of the hole drilled in PET. As a result, filters that contain around 1,000 holes provide variation of the opening area less than 1 percent.”

Advanced OEMs trust the vendor’s ability to understand when to utilize certain technologies in a cost-effective manner for their products, noted Philbrick. This results in the elimination of unnecessary operations or components, which in turn reduces component/assembly costs and improves their bottom line. “The goal is to create less validation activity at different component suppliers, which results in faster speed to market,” said Philbrick. “The manufacturers of tomorrow must re-invent themselves to create new processes and ideas that reduce customer involvement. Good suppliers involve the customer less in the supply chain and assume more of the project management role. That is the goal of many OEMs as they continue to consolidate their supply base with companies that can do more.”

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.

These complex geometries do, of course, create machining challenges. For example, “laser beam size or ‘kerf’ for cutting precision geometries must run at 0.0015-inch diameter or smaller to effectively create some of these components,” said David Philbrick, tech sales/business development manager for Economy Spring , an MW Industries company and Southington, Conn.-based manufacturer of precision products used in medical device instruments and surgical implants. “However, smaller certainly does not mean easier.”

To stay competitive, machine partners must invest in the technology advancements in the machining/laser processing world, such as smaller cutting tools for computer numerical control (CNC) machining, laser improvements, and hybrid machines, which combine lasers with conventional machining equipment. Depending on client needs, some companies even develop their own proprietary equipment in-house.

OEMs also demand efficiency, speed, and lower costs, from concept/design all the way through production. The best way to meet these expectations is through a lifecycle OEM-supplier partnership, with collaborative development at all stages of development.

“We collaborate with the customer to find part design areas that may be slightly altered to significantly reduce cycle time, yet still meet the customer’s design intent,” said Ryan Haferbecker, engineering manager for LISI Medical Remmele, a Big Lake, Minn.-based manufacturer of precision components and implants for minimally invasive surgical, spine, and urology applications. “Our teams work collaboratively, reviewing dimensions and tolerances to optimize the inspection process and open up tolerance zones when possible. Our strategic partnerships with our customers allow us to work interactively at all phases of the project and offer machine and technology solutions that optimize costs for current volume need.”

Dennis Norwich, director of engineering for Wytech Industries, a Rahway, N.J.-based manufacturer of wire and tubing components and assemblies for the medical industry, agreed it is best to get that machining input early on in a project, to avoid costly mistakes as the project matures. For example, OEMs often want features that are not specified on the print, which can create delays. Tighter tolerances and better surface finishes that are not called out on the print are often requested after the first round of sample parts are made. “These changes often have a cost impact,” said Norwich. “We find ourselves questioning many of the ‘defined’ features in the quoting stage, so we can produce the product that the customer really wants, with fewer surprises or iterations.”

In addition to better efficiency, shorter lead times, and lower costs, OEMs seek efficient management of all the validation processes. This is especially true for more complex parts that require extreme precision, utilize advanced (and sometimes sensitive) materials, or are made with newer technologies.

“Increasingly, OEMs require fully PPAP-approved [Production Part Approval Process] parts with stringent tolerances and statistically sound processes,” said Joshua Chaffee, sales engineer for ARCOR Laser Services, a Suffield, Conn.-based contract manufacturer that specializes in laser processing services, machining, and assembly. “The OEMs are not dictating exactly how to achieve the desired results; instead they are relying on the supplier’s expertise to meet the design and part intent. This puts much of the process engineering responsibility on the service provider. The OEMs rely on the supplier to be the true expert and have the appropriate processes in place.”

The Latest in Lasers

Laser wavelength, pulse width, size, and beam delivery continue to evolve at an impressive rate—and at lower price points. This dynamic allows for growth in applicable materials, material thicknesses, and potential design geometries. Improved precision laser power controls, closed-loop feedback mechanisms, and stringent process qualifications lead to finer cuts, better welds, and improved laser-based surface treatments such as texturing and edge rounding. “Automation, including robotic load and unload, also continues to improve efficiency and throughput,” said Chaffee. “Multiple laser processing stations can be fed by one robot while being monitored by a cell leader.”

With complex devices being made from advanced materials that include thin metals, transparent materials, and heat-sensitive materials (including bioabsorbables), there is increased demand for picosecond and femtosecond lasers that can provide high-precision micromachining. These systems provide better quality and higher throughput, at lower cost per watt. For example, their short pulse width minimizes heat input, making them a “cold” process. This allows for the cutting of thin materials, non-metallic materials, and/or complicated geometries such as stents. The resulting cut edge from these lasers is burr-free, which can eliminate or reduce the need for post processing. Heat-affected zones (HAZ) can also be significantly reduced for specific types of alloys by flooding the product in coolant during the cutting operation. “Our laser-cutting systems operate in aqueous coolants that reduce the heat absorption of the alloys and eliminate metal re-melt, improving edge conditions with less micro-cracking,” said Philbrick. “These edge conditions are a radical shift from the oxygen/nitrogen gas-assist processes of laser systems in the past.”

“In addition,” added Mike Treleaven, vice president of Tegra Medical, a Franklin, Mass.-based contract manufacturer of medical device components and finished devices, “femtosecond lasers make cuts with less dross and oxide, reducing the need for cleaning and increasing the ability to process more materials.”

Because shorter laser wavelengths and higher delivery frequencies make laser cutting possible over a wider range of materials, they give engineers more creative freedom for designing functionality into their products. For example, the medical device industry is pushing to get more functionality from standard stainless steel hypo-tubes. Medical device manufacturers (MDMs) want combined features such as flexibility and repeatable articulation, variable flexibility to improve maneuverability throughout the device, location and locking features to secure other device components, and other features such as cutting edges, puncturing elements, and rawl functions.

“A good example of increased functionality would be five-foot-long hypo-tube of 1.3 mm outer diameter, with variable flexibility along 90 percent of the total length, a bend radius decreasing from initial four inches at proximal end down to 0.3 inches at distal tip,” said Richard Hurst, business development director at West Chester, Pa.-based XL Precision Technologies—a manufacturer of components and sub-assemblies for medical devices. “Several locking tangs would be located at various positions along the length with three rotating deployment features for graft stent delivery and re-positioning, a piercing distal tip, followed by a lateral cutting blade, laser cut behind the distal end.”

The latest technological advancement at Laser Light Technologies, a Hermann, Mo.-based service provider of laser micromachining, is the capability to machine to depth laminates of various polymer materials. Today’s lab-on-chip and microfluidic devices are designed for low cost/high-volume production. To achieve this, they use multiple layers of laminate material, where each layer is initially laser machined with individual features, and then individual layers are combined into final laminate. “Our laser system allows adjustment of pulse energy, repetition, and feed rate for each polymer material used in a laminate,” said Alex Pozdin, vice president of R&D for Laser Light Technologies. “The system is used to machine all layers of laminate in a sheet form and can be updated for efficient roll-to-roll processing.”

An increasing variety of polymers and fluoropolymers are extruded into tubing of many shapes. Polyolefin, polyetheretherketone (PEEK), polytetrafluoroethylene (PTFE), and fluorinated ethylene propylene (FEP) are often used to make single or multi-lumen tubing that can be used for a variety of products, such as electro-surgical tools and instruments. The ability to machine these instrument components/polymers requires various laser capabilities that can cut the polymers without leaving any carbon footprint or residues that need to be cleaned after machining.

“This concern is less of an issue today because laser systems can machine these polymers effectively without damaging the metal components underneath the polymers,” said Philbrick. “Creative manufacturing teams can integrate the motion control elements needed that allow uniquely shaped components and polymers to be laser-machined for precision applications. Whether it be on rods, wire, or even multi-faceted bars, this expanded design creativity facilitates the launch of new and innovative products and services to market.”

Traditional Machining Steps Up

With the rapid development of laser-processing capabilities, traditional machining is under pressure to improve speed, precision, and tolerances, with minimal heat-affected zones and fewer machining/post-processing steps. One way to do this is through automation—for example, CNC centers are becoming more automated, especially for part handling at load/unload, inspection, and secondary part-finishing processes. In some cases, additive manufacturing can also be accomplished in a single step, with no secondary operations required.

“We’ve definitely seen increased competition from non-machining manufacturing processes, which drives the need to aggressively find innovative ways to reduce traditional machined part manufacturing costs,” said Haferbecker. Although additive manufacturing is a competitive process, “our main competition for high-volume medical products is typically low-cost labor regions and combinations of non-machining manufacturing processes such as stamping, coining, and metal injection molding.”

New offerings in the automation and software markets such as more versatile and easy-to-implement robotics, smart technologies to aid in part recognition, point-of-use data collection and decision making, as well as increased speed, accuracy, and versatility, keep CNC machinery competitive. “These investments allow us to maintain our focus on low-touch production and reduce the cost of a machining minute,” said Haferbecker.

Speed is always a top consideration for winning a machining contract and CNC equipment continues to improve throughput volume. Faster speed also means cleaner cutting, with fewer secondary steps needed—another way to reduce costs and get products to market faster.

“The pure speed of the newer CNC machining centers is amazing,” said Norwich. “Both linear and spindle speeds are so fast that the newer machines are producing smaller medical devices faster than you could have imagined a few years ago. Our most recent CNC miller purchase has spindle speeds up to 20,000 RPM and a rapid traverse of 2,400 inches per minute. This gives us much cleaner burr-free cutting, which eliminates secondary operations such as hand deburring. We have also greatly reduced cycle times. We reduced the cycle time of one particular orthopedic product from 25 minutes for a pallet of parts to six minutes with high-speed machining.”

LISI Medical Remmele recently invested in precision electrochemical machining (PECM) equipment, which gives the company a competitive edge against coining. PECM offers low per-part cost with high accuracy and top-level part finishes. It also optimizes low attendance rates, reduces set-up times, and streamlines inspection processes. “Realizing these efficiencies allows us to consider what was once regarded as high-volume pricing as feasible for mid-volume mixed model products, and customers as well,” said Haferbecker. “PECM can speed up throughput time by 25 percent or more and reduce labor needs by about 50 percent.”

Another solution for keeping CNC machining competitive is the combination of multiple technologies to create a hybrid machine with enhanced functionality. For example, LaserSwiss machines combine laser cutting and welding with traditional Swiss turning. These machines can perform multiple processes with a single set-up, which also streamlines the validation process. This trend is also driving down costs by shortening lead times for prototyping and production volumes.

“The addition of LaserSwiss technology allows us to manufacture complete components with machined features, laser cut features, and formed features in a single manufacturing pass, without losing registration of the part,” said Joseph Lovotti, director of laser technologies for Okay Industries, a Berlin, Conn.-based manufacturer of components and subassemblies for medical device companies. “The result is better process capability, along with the cost savings of one work cell doing the work of three processes.”

A popular LaserSwiss line is Tsugami’s S205, S206, and SS207-5AX Swiss-type lathe series that comes equipped with integrated 250W and 400W SPI fiber laser cutting systems. The smaller footprint frees up floor space and expands design options. The S206 provides up to 36 tools and the laser; the SS207-5AX has seven axes and includes a B-axis tool block containing the laser. Other advantages include full Swiss turning capability, through-part coolant, and automatic part handling options.

Economy Spring utilizes several Citizen L20 CNC LaserSwiss machining centers, a CNC/laser welding platform for metal parts, a CO2 and fiber laser for plastics, and a plastic printer to help with model and fixture construction. “The combination of multiple laser platforms gives our engineering team the freedom to create very diverse products and assemblies, allowing our customers to get all of their metal products and assemblies from one source,” said Philbrick. “This improves speed to market for our customers and reduces their reliance on additional suppliers to complete a project when multiple technology disciplines are required, saving them time and money.”

In-House, Custom-Made

Sometimes contract manufacturers must come up with their own innovative ways to meet the product requirements and capabilities, while still holding down costs. They can buy equipment, combine equipment to eliminate steps and improve efficiency, co-develop a machine with an equipment manufacturer, or design their own in-house proprietary equipment to meet unique customer needs. For example, ARCOR Laser Services has developed intellectual property, including a seven-axis machine interface and watertight cutting/welding head design. “This advance allows part features and process speeds that are difficult, or impossible, to achieve with traditional milling tools,” stated Chaffee. “Parts with flexible features are now easily achievable, since the raw tube stock is bar-fed through the spindle and the laser is simply cutting as the material is presented. Helical or spiral cutting is now common and can be cut anywhere along the part length.”

Wytech Industries recently built a four-axis CNC trocar grinding machine that can handle very complex multi-step grinds; this could not have previously been accomplished with commercial needle pointing machines. This solution is ideal for lower-volume or high-complexity (and high price) products. Wytech also developed a custom six-axis laser cutter for a specific family of orthopedic devices, which could not be made with off-the-shelf equipment.

Sometimes it is the unique combination of machining technologies that does the trick. XLPT combines both lasers and spark erosion to create highly sophisticated designs and economic production solutions, with no-contact technologies. “Spark erosion, combined with laser cutting, provides unique capability with zero burr generation,” said Hurst. “A good example would be reducing wall thickness on the inside of stainless steel tubes after laser cutting flexibility.”

Okay Industries has developed, through its machine tool partners, five-, six-, and even eight-axis specialized laser tube cutting work cells to accommodate the most exotic of spherical customer part geometries. It is also integrating vision with robotics for positioning the part as well as inspection and data collection during production. “This provides statistical process control and real-time feedback to make machine adjustments automatically,” said Lovotti. “We also use automated vision inspection on completed parts. The advantage of integrating vision into robotics with laser processing is a true one-pass approach to manufacturing. This process ensures consistency, quality, and accuracy of medical device products, which is critical to end-use performance.”

A variety of wattage/types of laser systems on the market today provide more in-house options. As a result, more companies are creating their own motion control systems with closed-loop logic and integrating the lasers themselves, which they receive directly from the laser manufacturer. “This activity continues to accelerate new laser development methodology that allows companies to create unique autonomous platforms that continue to expand on these new ideas,” said Philbrick. “These new machining approaches to laser manufacturing will continue to grow the market.”

After three years of feasibility review and many successful customer development projects, XLPT recently purchased a metal 3D additive manufacturing system with 0.0005-inch layer capability to provide micro features and high accuracy. “New programming developments are reducing the need for secondary operations, but removal from the substrate is always required,” said Hurst. “Material properties are almost identical to stock bar material. In many applications, we find the process is competitive with traditionally machined, and even molded, components.” Current projects are now combining 3D printing, laser cutting, spark erosion, and laser welding to provide unique product realization.

And sometimes it isn’t the combination of technologies that turns a project into a winner, but the material.

Low-density polyethylene (LDPE) is a popular thermoplastic used in various industrial applications. Due to low melting temperatures, laser hole drilling shows significant hole-diameter variation related to re-solidification of molten material. This variation increases with increased thickness of material. For a customer application that required LDPE to be drilled with an array of 0.175-mm holes to provide consistent flow in a filter of a bioreactor, Laser Light Technologies used a laminate material consisting of 0.33 mm of LDPE and 0.025 mm of polyester (PET).

“The laser beam enters material laying horizontally from the LDPE side,” said Pozdin. “We then use the trepanning technique to drill the holes. First, the laser beam melts the LDPE, then drills the hole in the PET. With the beam on, molten material re-flows through the hole in PET and re-solidifies on the opposite side of laminate. Gravity and capillary forces then form the hole with the size of the hole drilled in PET. As a result, filters that contain around 1,000 holes provide variation of the opening area less than 1 percent.”

Advanced OEMs trust the vendor’s ability to understand when to utilize certain technologies in a cost-effective manner for their products, noted Philbrick. This results in the elimination of unnecessary operations or components, which in turn reduces component/assembly costs and improves their bottom line. “The goal is to create less validation activity at different component suppliers, which results in faster speed to market,” said Philbrick. “The manufacturers of tomorrow must re-invent themselves to create new processes and ideas that reduce customer involvement. Good suppliers involve the customer less in the supply chain and assume more of the project management role. That is the goal of many OEMs as they continue to consolidate their supply base with companies that can do more.”

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books.