Sam Brusco, Associate Editor11.07.16

In the heart of Atlanta—midtown, to be precise—sits a somewhat unassuming building that many commuters on their way downtown might not even glance at during their drive. It’s one story tall, has a slight nondescript flavor, and doesn’t overtly advertise itself to oncoming traffic.

It’s also the site of breakthrough, yet unheard of medical device development projects—about 70 in the last 3 years, in fact. Courtesy of the Georgia Department of Economic Development, I was privileged enough to tour this facility, which is known as the Global Center for Medical Innovation, or GCMI.

For those yet unaware, GCMI isn’t an engineering, prototyping, device testing, quality assurance, or consulting facility, nor is it an incubator. More aptly put, it’s not just any of those; it’s all of them. Since opening its doors in April 2012, GCMI has partnered with over 50 different startups, clinicians, university tech transfer offices, and academic researchers to bring their medical devices from concept to market, offering a variety resources along the way.

A lean, non-profit facility that takes on high-risk medical device ventures that corporations tend to shy away from, GCMI seeks to lend a commercial eye to innovation. It’s part of a medtech “value chain” that exists in Georgia that includes nearby universities like Georgia Tech and Emory; industry pioneers like C.R. Bard, Elekta, and Stryker; and start-ups like CardioMEMS. (The latter of these actually passed through the GCMI before being acquired by St. Jude Medical in 2014 for a cool $455 million.) GCMI stands in the gap between innovation and industry, offering medical device developers a helping hand—and an impressively well-equipped facility—for eventually getting their products into the hands of patients.

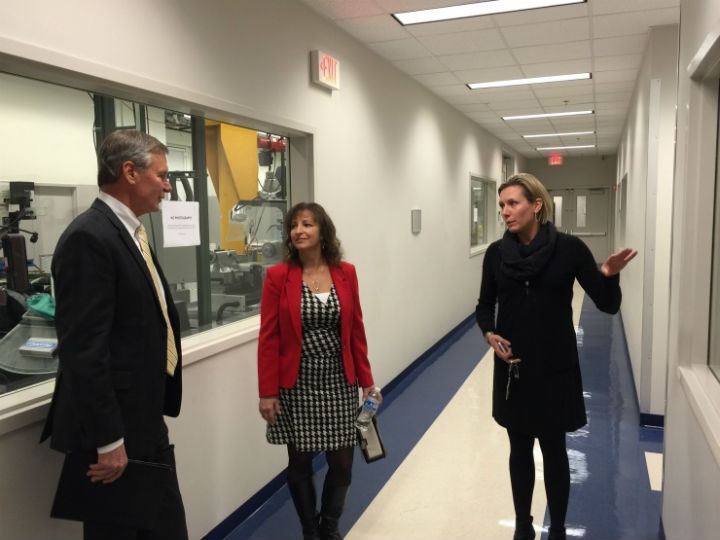

Georgia Tech President G.P. “Bud” Peterson (left) shares his insights on medical device innovation with Julie Lenzer Kirk (center), the director of U.S. Commerce Department's Office of Innovation and Entrepreneurship and GCMI CEO Tiffany Wilson (right). GCMI is a Georgia Tech affiliate. (Courtesy of Georgia Tech)

In order to gain some insight on how GCMI assists fledgling medical device developers in getting their projects to market, MPO spoke with Tiffany Wilson, chief executive officer of GCMI and T3 Labs, a preclinical testing and training services facility that GCMI acquired in late July.

Sam Brusco: What are your criteria for accepting a project into the GCMI?

Tiffany Wilson: We operate on a fee for service basis, so at a minimum innovators should have some level of funding for us to accept a project. We then assess projects on our ability to add value and help the innovator or startup achieve value added milestones to reach go/no-go decisions. Ideally, the startup team embraces a collaborative spirit and is ready to actively work with our team to move the project forward.

Brusco: Where in the product development cycle does GCMI usually get involved?

Wilson: The earlier the better—but we can get involved as early as an idea or an unmet clinical need that needs to be addressed, or as late as a product on the market that needs to be re-designed. Our goal is to help accelerate the development and commercialization of new medical technologies so patients can benefit and the medtech startup industry can thrive, so we jump in where we can to help make that happen.

Brusco: Which in-house services (engineering, prototyping, testing, consulting, etc.) does GCMI offer to startups? Do you offer financial consulting as well?

Wilson: Through GCMI and T3 Labs, we have an in-house team of design/biomedical engineers, medtech product development expertise, clinical evaluation, and preclinical testing. Our "ecosystem" includes a broad range of experts and consultants across the continuum, including legal, patent, material properties, electronics, software, regulatory, quality, reimbursement, clinical, and investors. We build project teams based on the critical needs and pathway for the startup. We work with investors to help startups make sure they are investor ready and can address key points in the due diligence process.

Brusco: Though GCMI is a non-profit, how do you accrue the funding to keep the wheels turning?

Wilson: While we got off the ground with tremendously helpful grant dollars from the U.S. Department of Commerce and the Georgia Research Alliance, both GCMI and T3 Labs operate on a fee for service basis. We have been able to do this and grow by providing excellent customer service, quality work, and being able to do what we said we could do. Moving forward, there are a number of new programs we are launching in 2017 that will grow the level of funding required to expand our capabilities, hire additional expertise, and support the most innovative technologies and startups on their journey from concept to commercialization.

Brusco: What challenges are involved in bringing university-born medtech innovations to market?

Wilson: The main challenge we see is that university innovators do not always appreciate the complexity of taking an invention or an initial prototype and turning that into a regulated product. There is usually a lot of education and discussion around that process. We also see university innovations developed in a vacuum vs. based on customer-based feedback and specifications—i.e., technology looking for a problem to solve rather than addressing true unmet clinical needs. Finally, the technology transfer process and finding the right business partner can be tricky.

Brusco: How does GCMI assist university-born startups in entering the medtech market?

Wilson: At the most basic level, we can help take IP and quickly develop basic market assessment and proof-of-concept prototypes to see if the startup pathway looks promising. We can then put together a product development strategy and help build a team around the startup to help identify critical milestones and quality plan that will be required as the startup moves from grant funding that is available to university spinouts to early stage investors and venture capital.

Brusco: When would you consider a project to be “ready” to leave the GCMI?

Wilson: It depends on the technology and the team. We see a project as a success if we can provide a way for an innovator or entrepreneur to fail quickly and inexpensively or move out of the incubator so they can scale—or anywhere in between. If we can help someone hit a milestone or answer a question quickly, easily, and in a capital efficient way, that's a win.

Brusco: Lastly, what are the 3 most common bits of advice you offer startups passing through the GCMI?

Wilson: Start thinking about design controls and your quality system. Now.

Understand your customer(s) and keep them in the loop throughout.

Plan. Hit the pause button for a moment to do your homework, understand what milestones investors are going to want to see, what data FDA and CMS need to see, and what specifications are critical for customers to see.

It’s also the site of breakthrough, yet unheard of medical device development projects—about 70 in the last 3 years, in fact. Courtesy of the Georgia Department of Economic Development, I was privileged enough to tour this facility, which is known as the Global Center for Medical Innovation, or GCMI.

For those yet unaware, GCMI isn’t an engineering, prototyping, device testing, quality assurance, or consulting facility, nor is it an incubator. More aptly put, it’s not just any of those; it’s all of them. Since opening its doors in April 2012, GCMI has partnered with over 50 different startups, clinicians, university tech transfer offices, and academic researchers to bring their medical devices from concept to market, offering a variety resources along the way.

A lean, non-profit facility that takes on high-risk medical device ventures that corporations tend to shy away from, GCMI seeks to lend a commercial eye to innovation. It’s part of a medtech “value chain” that exists in Georgia that includes nearby universities like Georgia Tech and Emory; industry pioneers like C.R. Bard, Elekta, and Stryker; and start-ups like CardioMEMS. (The latter of these actually passed through the GCMI before being acquired by St. Jude Medical in 2014 for a cool $455 million.) GCMI stands in the gap between innovation and industry, offering medical device developers a helping hand—and an impressively well-equipped facility—for eventually getting their products into the hands of patients.

Georgia Tech President G.P. “Bud” Peterson (left) shares his insights on medical device innovation with Julie Lenzer Kirk (center), the director of U.S. Commerce Department's Office of Innovation and Entrepreneurship and GCMI CEO Tiffany Wilson (right). GCMI is a Georgia Tech affiliate. (Courtesy of Georgia Tech)

In order to gain some insight on how GCMI assists fledgling medical device developers in getting their projects to market, MPO spoke with Tiffany Wilson, chief executive officer of GCMI and T3 Labs, a preclinical testing and training services facility that GCMI acquired in late July.

Sam Brusco: What are your criteria for accepting a project into the GCMI?

Tiffany Wilson: We operate on a fee for service basis, so at a minimum innovators should have some level of funding for us to accept a project. We then assess projects on our ability to add value and help the innovator or startup achieve value added milestones to reach go/no-go decisions. Ideally, the startup team embraces a collaborative spirit and is ready to actively work with our team to move the project forward.

Brusco: Where in the product development cycle does GCMI usually get involved?

Wilson: The earlier the better—but we can get involved as early as an idea or an unmet clinical need that needs to be addressed, or as late as a product on the market that needs to be re-designed. Our goal is to help accelerate the development and commercialization of new medical technologies so patients can benefit and the medtech startup industry can thrive, so we jump in where we can to help make that happen.

Brusco: Which in-house services (engineering, prototyping, testing, consulting, etc.) does GCMI offer to startups? Do you offer financial consulting as well?

Wilson: Through GCMI and T3 Labs, we have an in-house team of design/biomedical engineers, medtech product development expertise, clinical evaluation, and preclinical testing. Our "ecosystem" includes a broad range of experts and consultants across the continuum, including legal, patent, material properties, electronics, software, regulatory, quality, reimbursement, clinical, and investors. We build project teams based on the critical needs and pathway for the startup. We work with investors to help startups make sure they are investor ready and can address key points in the due diligence process.

Brusco: Though GCMI is a non-profit, how do you accrue the funding to keep the wheels turning?

Wilson: While we got off the ground with tremendously helpful grant dollars from the U.S. Department of Commerce and the Georgia Research Alliance, both GCMI and T3 Labs operate on a fee for service basis. We have been able to do this and grow by providing excellent customer service, quality work, and being able to do what we said we could do. Moving forward, there are a number of new programs we are launching in 2017 that will grow the level of funding required to expand our capabilities, hire additional expertise, and support the most innovative technologies and startups on their journey from concept to commercialization.

Brusco: What challenges are involved in bringing university-born medtech innovations to market?

Wilson: The main challenge we see is that university innovators do not always appreciate the complexity of taking an invention or an initial prototype and turning that into a regulated product. There is usually a lot of education and discussion around that process. We also see university innovations developed in a vacuum vs. based on customer-based feedback and specifications—i.e., technology looking for a problem to solve rather than addressing true unmet clinical needs. Finally, the technology transfer process and finding the right business partner can be tricky.

Brusco: How does GCMI assist university-born startups in entering the medtech market?

Wilson: At the most basic level, we can help take IP and quickly develop basic market assessment and proof-of-concept prototypes to see if the startup pathway looks promising. We can then put together a product development strategy and help build a team around the startup to help identify critical milestones and quality plan that will be required as the startup moves from grant funding that is available to university spinouts to early stage investors and venture capital.

Brusco: When would you consider a project to be “ready” to leave the GCMI?

Wilson: It depends on the technology and the team. We see a project as a success if we can provide a way for an innovator or entrepreneur to fail quickly and inexpensively or move out of the incubator so they can scale—or anywhere in between. If we can help someone hit a milestone or answer a question quickly, easily, and in a capital efficient way, that's a win.

Brusco: Lastly, what are the 3 most common bits of advice you offer startups passing through the GCMI?

Wilson: Start thinking about design controls and your quality system. Now.

Understand your customer(s) and keep them in the loop throughout.

Plan. Hit the pause button for a moment to do your homework, understand what milestones investors are going to want to see, what data FDA and CMS need to see, and what specifications are critical for customers to see.