5 Questions from the Booth: Qosina

By MPO Staff | 11.12.17

Medical device component supplier offers disposable OEM components to the medical and pharmaceutical industries.

The editorial team of Medical Product Outsourcing reached out to several companies who were exhibiting at Medica or Compamed in case you’re unable to see them at the event or are not headed to Germany this year. Review the following questions we served up to Scott Herskovitz, VP of sales and marketing of Qosina and see if the company is a potential contract manufacturing partner for you.

MPO: What technology or service are you emphasizing at Medica this year?

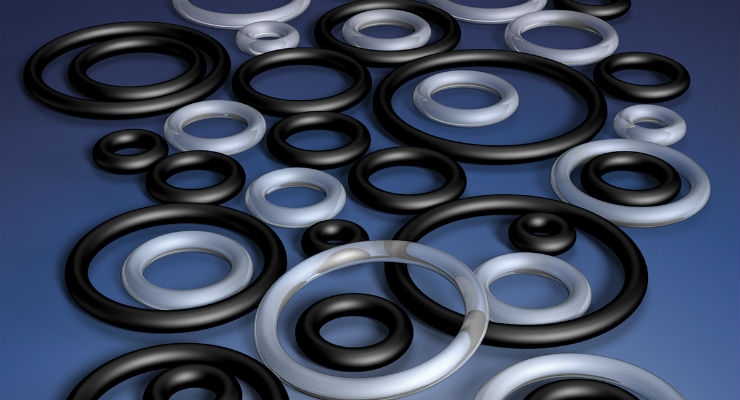

Scott Herskovitz: We’re pleased to debut our newest product line: medical-grade O-rings. Qosina’s O-rings are unique in that they are made from medical-grade EPDM and silicone, clean room manufactured and packaged, they help to minimize component design costs, and speed up the product development process. Additionally, our O-rings are in stock and ready for immediate delivery. Customers can request free samples for their evaluation and testing before they order.

MPO: What’s the most common challenge customers inquire about and how do you address it?

Scott Herskovitz: One question that frequently comes up is “How do I find the right component for my application?” Qosina has the largest selection of stock components for medical device manufacturing. And most design engineers know that we offer free samples of our medical OEM components. Engineers experiment with many different products while determining what to spec into a design. They evaluate size, color, materials, and pricing, all of which are considered pivotal to the decision-making process. Qosina’s components are perfect for building prototypes, testing different sterilization methods, and validating bonding agents.

MPO: If you could give one piece of advice to companies seeking a manufacturing partner before they make a decision, what would it be?

Scott Herskovitz: Qosina can source a product that already exists, preventing you from having to reinvent the wheel. Before companies began offering stock components, product designers had to design the various components they would use, in addition to the core product. Tooling had to be created and the components manufactured, which is a costly process. Designers can utilize Qosina as their one-stop-shop for components without having the hassle of using several different sources for one project, therefore, easily streamlining their vendor lists. We welcome sourcing requests for tool modifications, hard-to-find items, subassemblies, or tubing. Customers can also request an item that is not already in our inventory, and we will work to develop the part to exact specifications.

MPO: What are the forces driving medical device manufacturers to seek your technology/services over doing it in-house?

Scott Herskovitz: Qosina’s philosophy has always been to address customers’ need for selection and speed with thousands of stock components. Our customers’ time is valuable, so we want to help them efficiently manage their production system. We offer many solutions for inventory management, and one such tool is the Kanban blanket order. With Kanban, inventory levels align with actual consumption. We release the parts when our customers need them, minimizing their inventory investment and freeing up space for more productive activity. Kanban also reduces overhead costs by consolidating purchases and suppliers with one order.

MPO: In what ways is your company able to aid in getting a product (project) to market faster?

Scott Herskovitz: As I mentioned earlier, Qosina’s products are in stock and available for immediate delivery. We provide complimentary samples on most products so they can be tested during prototyping and research and development, which reduces time to market.

If you're interested in following up with Qosina at the event, you’ll find them in Medica at hall/booth 6/J27 or in Compamed at hall/booth 8A/L16.

MPO: What technology or service are you emphasizing at Medica this year?

Scott Herskovitz: We’re pleased to debut our newest product line: medical-grade O-rings. Qosina’s O-rings are unique in that they are made from medical-grade EPDM and silicone, clean room manufactured and packaged, they help to minimize component design costs, and speed up the product development process. Additionally, our O-rings are in stock and ready for immediate delivery. Customers can request free samples for their evaluation and testing before they order.

MPO: What’s the most common challenge customers inquire about and how do you address it?

Scott Herskovitz: One question that frequently comes up is “How do I find the right component for my application?” Qosina has the largest selection of stock components for medical device manufacturing. And most design engineers know that we offer free samples of our medical OEM components. Engineers experiment with many different products while determining what to spec into a design. They evaluate size, color, materials, and pricing, all of which are considered pivotal to the decision-making process. Qosina’s components are perfect for building prototypes, testing different sterilization methods, and validating bonding agents.

MPO: If you could give one piece of advice to companies seeking a manufacturing partner before they make a decision, what would it be?

Scott Herskovitz: Qosina can source a product that already exists, preventing you from having to reinvent the wheel. Before companies began offering stock components, product designers had to design the various components they would use, in addition to the core product. Tooling had to be created and the components manufactured, which is a costly process. Designers can utilize Qosina as their one-stop-shop for components without having the hassle of using several different sources for one project, therefore, easily streamlining their vendor lists. We welcome sourcing requests for tool modifications, hard-to-find items, subassemblies, or tubing. Customers can also request an item that is not already in our inventory, and we will work to develop the part to exact specifications.

MPO: What are the forces driving medical device manufacturers to seek your technology/services over doing it in-house?

Scott Herskovitz: Qosina’s philosophy has always been to address customers’ need for selection and speed with thousands of stock components. Our customers’ time is valuable, so we want to help them efficiently manage their production system. We offer many solutions for inventory management, and one such tool is the Kanban blanket order. With Kanban, inventory levels align with actual consumption. We release the parts when our customers need them, minimizing their inventory investment and freeing up space for more productive activity. Kanban also reduces overhead costs by consolidating purchases and suppliers with one order.

MPO: In what ways is your company able to aid in getting a product (project) to market faster?

Scott Herskovitz: As I mentioned earlier, Qosina’s products are in stock and available for immediate delivery. We provide complimentary samples on most products so they can be tested during prototyping and research and development, which reduces time to market.

If you're interested in following up with Qosina at the event, you’ll find them in Medica at hall/booth 6/J27 or in Compamed at hall/booth 8A/L16.