Dawn A. Lissy, President & Founder, Empirical01.30.18

There are two basic types of people: Those who make sweeping generalizations, and those who don’t. (Actually, there’s a third type—one who opens columns with corny jokes and strains to hear the laugh track over the lonely cricket in the corner.)

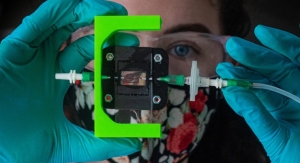

Jokes aside, we do find two primary types of clients relating to the prototyping phase of medical device development. I like to think of them as “additive” or “subtractive” types. Not to be confused with the physical processes to generate a prototype, these are people who either have a solid concept of what a prototype should be, or customers who need to see a wide range of options before knowing what they do or don’t like.

It helps the Empirical Machine staff to ascertain at the start which type we’re dealing with. It aids the client as well, because it’s two very different approaches to supporting their device development.

Developers with a clear idea of what they want can potentially create a functional prototype faster than the client who needs to see 9,999 ways to not make an implant because we’re adding minor changes to a fairly solid concept. However, the “additive” customer might be fixated on an idea that doesn’t necessarily address all the other prototyping aspects we consider at Empirical.

For the “subtractive” set, we often find ourselves generating multiple versions of the same prototype because these clients won’t know if we’re on the right track until it’s in front of them. This type of open discovery process can become especially time-consuming. However, it also allows greater flexibility and input from outsiders with expertise on the big picture of getting a medical device to market.

Richard Brown, senior engineer at Engineering & Quality Solutions Inc. (EQS), knows each client type well. We frequently partner with EQS on projects for which Empirical provides testing and small-batch manufacturing and EQS supplies product development or engineering analysis. Richard has over 30 years of experience in the design and manufacturing world and has prototyped hundreds of parts. Engineering & Quality Solutions Inc. offers FEA and engineering analysis, product development support, and FDA and quality systems expertise. He said before beginning the prototype phase, make a thorough, honest assessment of your goals, budget, and the project’s scope.

“To get the most out of doing a prototype, you really need to understand what the need for the prototype is,” he said. “You might just need a quick couple of ‘touchy-feely’ parts to put into someone’s hands. You might not need all of the geometry or even all of the function out of it yet.”

You also need to determine if the prototype better lends itself to traditional manufacturing, 3D printing, or a combination, Brown said.

“Cost, material, geometry, purpose of prototype, and type of part are all considerations,” he said. “Just about any traditionally manufactured part can be 3D printed, but does it need to be?”

3D printing is almost always going to offer faster and, in many cases, cheaper prototyping. But those prototypes may not have full function, proper cosmetics, etc. Traditional machining can produce a fully functioning part. If it is likely to be the final manufacturing process, prototyping with traditional machining can be a critical test run to reveal potential device production issues and unforeseen costs.

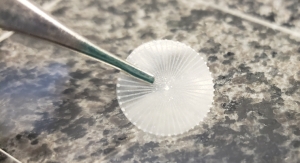

A prototype with functional threads may be an issue for additive processes. The prototype’s build size may be better suited for traditional manufacturing. Porous structures often work better with additive manufacturing so the device’s density can be adjusted based on clinical need. Materials can be an issue as well. While material variety is certainly expanding in the additive manufacturing industry, there are still some limitations. It also used to be considerably more expensive to opt for 3D printing, but now that’s not necessarily the case.

“You’re getting to the point [where] I think it’s a definite quote process,” Brown said. “Additive can give traditional a good run for the money, depending on material type, size of the part, type of part, things like that.”

If your goal is a functional prototype and/or to gain insight into the long-term manufacturing outlook, there are a couple of deal-breaker questions to address with your vendor: Is the shop ISO 13485 certified, and are they registered with the FDA and operating according to regulation 21 CFR part 820?

“That is the absolutely the first thing you need to ask,” Brown said. “If they don’t know what that is, you need to go elsewhere. You have a lot of people and a lot of machine shops that are doing medical implants that I will say probably shouldn’t be because they don’t realize all of the concerns related to the FDA.”

If the answers are yes and yes, show that vendor your drawings before commencing in order to unearth whether anything in the design requires special tools or unexpected customization.

“You’re looking for any information you can get out of the shop at this point,” Brown said. “Find out if they’re seeing anything that can save money or that might help improve cost and manufacturability.”

When working with a 3D printer, determine if that particular shop uses materials necessary for your prototype and whether they use electron beam or laser sintering. Outsourcing additive manufacturing can be especially tricky in our industry because the FDA is still developing standards for these newer manufacturing technologies. We have yet to find a vendor actually specializing in medical devices. (See “3D Printing: Third Industrial Revolution or Productivity Stalemate?” in the October 2016 issue of MPO). That will likely change as developers continue to more frequently and aptly use this manufacturing process. Expect a learning curve—most 3D printing vendors are still learning about our industry and requirements as they take on projects.

Whenever possible, think with the final product in mind. Work out whatever issues exist with regard to ease of manufacturing to scale in the prototype phase before reaching mass production.

“Ask your vendor or machine shop, ‘What are you seeing here that I can change that might make your life easier?’” Brown said. “Have I designed something special into this where they’re going to need a special tool or material size to manufacture what I need?”

Sometimes a simple design tweak so the device can be produced with standard tools or a change to a standard material size will save considerable time, money, and regulatory questions.

Consider overall tolerances. If you have a mating part, designing a standard-sized hole means standard-sized tools can shape that part. Even 0.001 inches can have an impact on your timeline and budget, and a nonstandard hole may not be important for that version of prototype.

“As we get closer and nearer to final prototype, we’re hoping it’s perfect,” Brown said.

We all hope for “perfect,” but I’m happy with “really freakin’ close”—safe, reproducible, on time, and on budget. Approaching the prototype phase with equal commitment to thorough due diligence as to your entire project and asking the right questions of the right partner will get you there.

Dawn Lissy is a biomedical engineer, entrepreneur, and innovator. Since 1998, the Empirical family of companies (Empirical Testing Corp., Empirical Consulting, LLC, and Empirical Machine, LLC) has operated under Lissy’s direction. Empirical offers the full range of regulatory and quality systems consulting, testing, small batch and prototype manufacturing, and validations services to bring a medical device to market. Empirical is very active within standards development organization ASTM International and has one of the widest scopes of test methods of any accredited independent lab in the United States. Because Lissy was a member of the U.S. Food and Drug Administration’s Entrepreneur-in-Residence program, she has first-hand, in-depth knowledge of the regulatory landscape. Lissy holds an inventor patent for the Stackable Cage System for corpectomy and vertebrectomy. Her M.S. in biomedical engineering is from The University of Akron, Ohio.

Jokes aside, we do find two primary types of clients relating to the prototyping phase of medical device development. I like to think of them as “additive” or “subtractive” types. Not to be confused with the physical processes to generate a prototype, these are people who either have a solid concept of what a prototype should be, or customers who need to see a wide range of options before knowing what they do or don’t like.

It helps the Empirical Machine staff to ascertain at the start which type we’re dealing with. It aids the client as well, because it’s two very different approaches to supporting their device development.

Developers with a clear idea of what they want can potentially create a functional prototype faster than the client who needs to see 9,999 ways to not make an implant because we’re adding minor changes to a fairly solid concept. However, the “additive” customer might be fixated on an idea that doesn’t necessarily address all the other prototyping aspects we consider at Empirical.

For the “subtractive” set, we often find ourselves generating multiple versions of the same prototype because these clients won’t know if we’re on the right track until it’s in front of them. This type of open discovery process can become especially time-consuming. However, it also allows greater flexibility and input from outsiders with expertise on the big picture of getting a medical device to market.

Richard Brown, senior engineer at Engineering & Quality Solutions Inc. (EQS), knows each client type well. We frequently partner with EQS on projects for which Empirical provides testing and small-batch manufacturing and EQS supplies product development or engineering analysis. Richard has over 30 years of experience in the design and manufacturing world and has prototyped hundreds of parts. Engineering & Quality Solutions Inc. offers FEA and engineering analysis, product development support, and FDA and quality systems expertise. He said before beginning the prototype phase, make a thorough, honest assessment of your goals, budget, and the project’s scope.

“To get the most out of doing a prototype, you really need to understand what the need for the prototype is,” he said. “You might just need a quick couple of ‘touchy-feely’ parts to put into someone’s hands. You might not need all of the geometry or even all of the function out of it yet.”

You also need to determine if the prototype better lends itself to traditional manufacturing, 3D printing, or a combination, Brown said.

“Cost, material, geometry, purpose of prototype, and type of part are all considerations,” he said. “Just about any traditionally manufactured part can be 3D printed, but does it need to be?”

3D printing is almost always going to offer faster and, in many cases, cheaper prototyping. But those prototypes may not have full function, proper cosmetics, etc. Traditional machining can produce a fully functioning part. If it is likely to be the final manufacturing process, prototyping with traditional machining can be a critical test run to reveal potential device production issues and unforeseen costs.

A prototype with functional threads may be an issue for additive processes. The prototype’s build size may be better suited for traditional manufacturing. Porous structures often work better with additive manufacturing so the device’s density can be adjusted based on clinical need. Materials can be an issue as well. While material variety is certainly expanding in the additive manufacturing industry, there are still some limitations. It also used to be considerably more expensive to opt for 3D printing, but now that’s not necessarily the case.

“You’re getting to the point [where] I think it’s a definite quote process,” Brown said. “Additive can give traditional a good run for the money, depending on material type, size of the part, type of part, things like that.”

If your goal is a functional prototype and/or to gain insight into the long-term manufacturing outlook, there are a couple of deal-breaker questions to address with your vendor: Is the shop ISO 13485 certified, and are they registered with the FDA and operating according to regulation 21 CFR part 820?

“That is the absolutely the first thing you need to ask,” Brown said. “If they don’t know what that is, you need to go elsewhere. You have a lot of people and a lot of machine shops that are doing medical implants that I will say probably shouldn’t be because they don’t realize all of the concerns related to the FDA.”

If the answers are yes and yes, show that vendor your drawings before commencing in order to unearth whether anything in the design requires special tools or unexpected customization.

“You’re looking for any information you can get out of the shop at this point,” Brown said. “Find out if they’re seeing anything that can save money or that might help improve cost and manufacturability.”

When working with a 3D printer, determine if that particular shop uses materials necessary for your prototype and whether they use electron beam or laser sintering. Outsourcing additive manufacturing can be especially tricky in our industry because the FDA is still developing standards for these newer manufacturing technologies. We have yet to find a vendor actually specializing in medical devices. (See “3D Printing: Third Industrial Revolution or Productivity Stalemate?” in the October 2016 issue of MPO). That will likely change as developers continue to more frequently and aptly use this manufacturing process. Expect a learning curve—most 3D printing vendors are still learning about our industry and requirements as they take on projects.

Whenever possible, think with the final product in mind. Work out whatever issues exist with regard to ease of manufacturing to scale in the prototype phase before reaching mass production.

“Ask your vendor or machine shop, ‘What are you seeing here that I can change that might make your life easier?’” Brown said. “Have I designed something special into this where they’re going to need a special tool or material size to manufacture what I need?”

Sometimes a simple design tweak so the device can be produced with standard tools or a change to a standard material size will save considerable time, money, and regulatory questions.

Consider overall tolerances. If you have a mating part, designing a standard-sized hole means standard-sized tools can shape that part. Even 0.001 inches can have an impact on your timeline and budget, and a nonstandard hole may not be important for that version of prototype.

“As we get closer and nearer to final prototype, we’re hoping it’s perfect,” Brown said.

We all hope for “perfect,” but I’m happy with “really freakin’ close”—safe, reproducible, on time, and on budget. Approaching the prototype phase with equal commitment to thorough due diligence as to your entire project and asking the right questions of the right partner will get you there.

Dawn Lissy is a biomedical engineer, entrepreneur, and innovator. Since 1998, the Empirical family of companies (Empirical Testing Corp., Empirical Consulting, LLC, and Empirical Machine, LLC) has operated under Lissy’s direction. Empirical offers the full range of regulatory and quality systems consulting, testing, small batch and prototype manufacturing, and validations services to bring a medical device to market. Empirical is very active within standards development organization ASTM International and has one of the widest scopes of test methods of any accredited independent lab in the United States. Because Lissy was a member of the U.S. Food and Drug Administration’s Entrepreneur-in-Residence program, she has first-hand, in-depth knowledge of the regulatory landscape. Lissy holds an inventor patent for the Stackable Cage System for corpectomy and vertebrectomy. Her M.S. in biomedical engineering is from The University of Akron, Ohio.