Mark Crawford, Contributing Writer11.08.16

In vitro diagnostic (IVD) devices are used to perform tests in clinical or over-the-counter settings on biological samples such as blood, saliva, and tissue collected from the human body. IVD products include analytical equipment, chemicals and reagents, disposables, and the software that supports analytical processes in medical laboratories and research facilities. IVD processes can range from simple, at-home tests to high-precision genomic tests that are used to diagnose the presence of infections and disease, as well as monitoring at-home care and drug therapy compliance.

According to BCC Research’s November 2015 report entitled “In Vitro Diagnostics: Technologies and Global Markets (HLC186A),” the global market for IVD products was valued at $57.3 billion in 2014 and is expected to grow to $81.1 billion by 2020 at a steady compound annual growth rate (CAGR) of 6.1 percent from 2015 to 2020.

It is also a very dynamic market that is quickly evolving and reacting to market trends, OEM needs, and emerging markets in developing countries that are likely to see double-digit growth in the coming years.

“Fifty percent of new global business is in emerging markets such as China and South America,” said Jim Hill, North American sales manager for Diba Industries Inc., a Danbury, Conn.-based provider of precision fluid handling solutions for diagnostics, life sciences, and medical device manufacturers. “Although many experts thought that much of this growth would be serviced by home-grown companies in these markets, we are seeing large U.S. IVD companies be very successful in selling refurbished machines, or re-designs of old product lines, that would have otherwise gone end-of-life, in these new markets.”

Another influencer on this trend is cost control. Healthcare has been under pressure to reduce costs for several years—and using standard equipment, or re-designed equipment that incorporates technological improvements to expand capabilities such as accuracy and speed, is one way to keep costs down.

“New technologies have emerged and are finding their ways to the clinic,” said Michael Kallelis, head of business development for KMC Systems Inc., a Merrimack, N.H.-based contract manufacturer for instrument companies. “These events have enabled OEM platform providers to look at their current instrument designs and refresh them to achieve lower costs and menu expansion. As a result, instrument design and development activities have increased over the last few years.”

On the technology front, point of care (POC) is rapidly driving IVD innovation. Demand is high for accurate, over-the-counter tests that provide instant results. POC is increasingly used for disease management, self-testing, and drug therapy monitoring. Speed is always of the essence—quicker test results can be acted upon sooner by medical staff, sometimes even in mid-procedure. Medical device companies also want technologies that are smaller, lighter weight, and easier to use. Analytical laboratories look for fast, efficient equipment that can do more tests and provide higher processing throughput, another way to drive down costs.

“DNA-based methods, including the adoption of sequencing in diagnostics, are driving new insights in monitoring disease and wellness,” said Richard Rubin, vice president of sales and marketing for Accel Biotech Inc., a Los Gatos, Calif.-based Ximedica company that provides full design and development services for IVD and life science systems. “Other technology trends are simultaneously driving increased access of diagnostics to point of care via compact, foolproof operation instruments, while large, highly automated, central lab systems continue to evolve and drive the cost per test down through volume.”

Glenn Ogura, senior vice president of market development for Resonetics, a Boston, Mass.-based supplier of laser micro manufacturing services and systems for the life sciences industry, has observed the same trend.

“The in vitro diagnostic market is seeing a transformational change, going from large instruments in the central laboratories that carry out tests for clinical chemistry, immunology, and hematology to tabletop and hand-held diagnostic instruments, especially in the areas of next generation sequencing, molecular diagnostics, and point of care,” he said. “The trend is to move the diagnostic test from the hospital to the physician’s office and, ultimately, to the home.”

All this activity within the IVD industry has created a high level of volatility, as evidenced by the number of large acquisitions and mergers that have occurred over the last 12 months. Large consolidations are expected to continue as long as there is a healthy ecosystem for start-ups (for example, business incubators associated with university research). Although there is intense pressure to control cost because of constrained reimbursement and other factors, the fundamental value of IVD testing still represents a bargain in the overall scheme of healthcare economics and expansion of the market will continue.

Recent Technology Trends

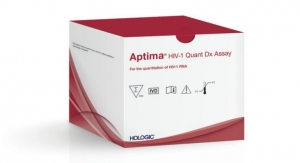

There is a great deal of effort in transitioning from time-consuming central lab tests to POC testing. Most companies want to achieve Clinical Laboratory Improvement Amendments (CLIA)-waived status in the United States, which would allow certain technologies to be sold and used by a nurse or other non-expert operator already involved in providing patient care. Tests developed for POC need to be “sample-to-answer”—meaning the operator takes the fluid or tissue sample and applies it directly to the instrument, which will then generate an accurate, simple-to-interpret result within 30 minutes or less. Medical device manufacturers (MDMs) and their end-user clients also seek expanded onboard assay menus, which saves time, reduces the number of samples needed, and improves efficiency.

Rubin noted that, although DNA tests based on the invention of polymerase chain reaction (PCR) have driven the bulk of the IVD market evolution in the last 20 years, immunoassays have changed relatively little given the lack of a parallel method to amplify low-concentration protein signals. “However, a number of companies are currently developing novel alternative methods for signal amplification to provide greater sensitivity and specificity to immunoassays,” he said. Examples include recent platforms developed by Singulex, Aushon Biosystems Inc., and PerkinElmer Inc.

The emphasis on molecular assays continues to advance existing technologies, such as rapid PCR, as well as overall processing times and time-to-result specifications. “These attributes are increasing instrument throughput and walk-away time for modern clinical instruments,” said Kallelis. “Faster, smaller, and less expensive is now a reality, where it was only a desire a few years ago.”

As equipment gets smaller and lighter in weight, so must components such as microfluidic chips, biochips, and biosensors, in both polymers and glass. As the sample and reagent volumes decrease, the feature sizes of the devices also decrease, opening up new opportunities for laser micro manufacturing. A key advantage of this process is that it is an immediately available, single-step process for drilling, cutting, and etching polymers, glass, metal, and ceramic down to the micron level. “This is unlike other polymer microfabrication processes such as multi-step lithographic processes or molding,” said Ogura, “which require a mold to be fabricated first, or glass microfabrication processes such as wet etching or particle bead blasting that require a mask overlay.”

What OEMs Want

MDMs and end-users of IVD equipment are laser-focused on reducing costs and generating highly accurate and consistent results. In response, technology is advancing so that assays are increasingly more sensitive and accurate, with improved medical results (for example, early detection). However, this also requires that analytical systems run better and cleaner, which means investing in new or upgraded equipment. MDMs are asking for both larger, faster, higher-throughput instruments and also smaller, focused, POC instruments—which is why instrumentation at both ends of the operating scale is often the topic of discussion at tradeshows, seminars, and symposia.

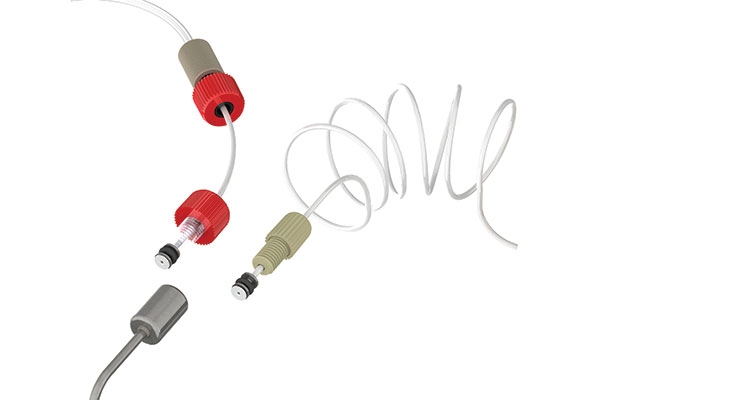

Sample sizes continue to get smaller as larger companies increase the array of tests their systems can perform. “Each new test is a new revenue stream,” said Hill. “Therefore, they need to be able to test a smaller amount of patient sample to stretch what they have across more tests.” Smaller sample sizes also require smaller system components, such as Diba’s Click-N-Seal fittings for the smallest fitting sizes used in IVD systems. As the fittings are hand-tightened, the resistance of the cap increases until the correct torque is reached, at which point, the cap clicks and the clinician knows the fitting has created a secure seal, without damaging the port through over-tightening.

With the Affordable Care Act’s emphasis on addressing chronic care conditions and disease management through accountable care reimbursement models, IVD companies and their customers are extremely interested in remote and ongoing health monitoring, such as continuous glucose monitoring, complete with alerts, data trends, and technology integration. “As a result of these trends,” said Richard Hartman, director of medical sales for Boyd Corporation, a Modesto, Calif.-based global provider of precision-engineered, specialty material-based energy management and sealing solutions, “MDMs are moving from test strips to wearables, and patient care is moving away from the acute and ambulatory settings.”

Not only do clients want the benefits of more advanced technologies in their IVD equipment, they also seek simplicity and ease of use. “Clients want products that are intuitive and simple to use,” indicated Ravi Narayanan, global product manager for Nordson Medical, a Loveland, Colo.-based manufacturer of single-use fluid connection components.

This includes materials that are chemically resistant to the various reagents used. USP Class VI compliant materials, materials that can withstand gamma irradiation, and products with a larger flow path diameter are favored. OEMs and end-users also want instruments that are easier and faster to service and maintain. Therefore, more emphasis is being placed on incorporating easy-to-use instrument components.

“OEM instrument and equipment designers are looking for products that can be plug-and-play, reducing the time of a field service call,” added Narayanan. “Customers also seek the ability to perform multiple tests faster, especially in emergency conditions, in order to detect/diagnose emerging diseases.”

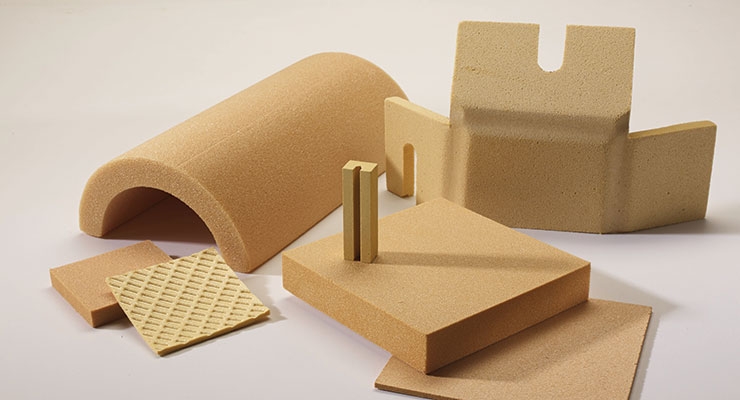

Working within the advanced flexible materials market, Brianna Sporbert, director of Sourcebook engineering for Boyd Technologies, a Lee, Mass.-based precision converter in the medical device, life science, and electronic markets, has noticed an increase in requests from customers for single-use diagnostic materials for single-use or home-care devices. “These products are used for both diagnosis and ongoing monitoring and treatment,” she said. “Personal care products and preventative medicine have expanded the need for simple-to-use, but accurate, medical devices.”

Younger companies, particularly new entrants into the IVD market, are especially vulnerable to market forces. They often lack capital, certain critical expertise, and sound business leadership. They have the great idea, but are uncertain how to develop it and get it through the approval process. They may also hope to be bought out by a larger company, if their product is a success. To navigate this landscape, startups often team up with an experienced IVD partner to help them through the product development process. For example, a growing customer base for Accel Biotech is venture capital-backed startups that count on outside resources to help develop their instrument systems. Capabilities in opto-electro-mechanical software-controlled hardware, for example, along with single-use cartridges, are in strong demand by these entrepreneurs because they provide a single source for most of their product development needs.

“These clients typically emerge from universities with some core biochemical intellectual property or possibly a novel microelectromechanical systems sensor concept, but need help on all aspects of device development around these starting blocks,” said Rubin. “For both start-ups and established companies, a frequent challenge is integrating the sample preparation. We employ both automated liquid handling and cartridge-based strategies, which allows us to advise companies on an optimal approach for their application and proceed with rapid development.”

Advancements and Innovations

Most of the recent advancements in the IVD industry pertain to assay technologies. The advent of molecular assays, as well as next-generation sequencing, is changing the landscape of IVD testing more rapidly than in prior decades. To produce these higher-sensitivity assays, instrumentation must evolve as quickly as the chemistry. For cartridge-based systems, cartridges are becoming smaller and more sophisticated, which has generated a design challenge for refining materials and manufacturing techniques. Cartridge designers and manufacturers with deep material science understanding are becoming critical to the development of advanced cartridge-based systems.

Over the last few years, assays have been developed that can detect more indicators using lower levels of reagents, enabling earlier detection of diseases and increasing the ability of patients or caregivers to manage home care. This has become particularly relevant in the oncology industry, where early stage cancer detection has dramatically decreased the mortality rate of cancer patients.

“As more assays are discovered to address cancer and other diseases, the development becomes limited by the performance of the materials,” said Sporbert. “Some of these investigative procedures demand very complicated and precise material configurations, or are very sensitive to environmental conditions. This leads to a heightened emphasis on stability and exactness of the finished products, resulting in a demand for increased performance from converters and material manufacturers.”

As an example, laser-drilled thin polymer films of hole diameters of a few microns or greater are used as PCR emulsion filters for sequencing and to trap/isolate circulating tumor cell and circulating tumor DNA for liquid biopsy applications. These micropore filters are also used for diagnostic instruments for the detection of pathogens (bacteria, viruses) that cause infectious diseases.

“There is also an integration of multiple material types such as polymer, glass, and silicon as the diagnostic devices become active, not just passive,” said Ogura. “Laser-machined polymer and glass interposers are used to bridge the gap. Lasers are also used to drill analyte inlet and outlet vias in polymer and glass cover slides. Laser ablation of polymer coatings is also an effective way to expose metal electrodes for electrochemical reactions or for the attachment of DNA probes.”

Cutting (dicing) and drilling of glass and sapphire wafers also become more challenging as the feature sizes become smaller and features are packed closer together, necessitating processes that can cut glass with straight sidewalls. Putting sensitive chemistries closer to the edge of the wafer requires a cutting process that does not generate debris. And as glass wafers become thinner (100 microns thick), they are more susceptible to breaking.

“To overcome all these limitations, Resonetics has developed ‘zero kerf’ technology that produces zero taper cut edges, an absence of surface debris, no kerf (cut) width, and is an order of magnitude faster than traditional ablation methods,” said Ogura. “The laser creates micro-fissures that propagate along the vertical direction to create these ultra-clean-looking cuts. Initially we developed the process to handle external cuts of glass wafers and slides ranging from 100 microns to 1 mm thick.”

Regulatory and Reimbursement Challenges

The new CE directive in the European Union (EU) is starting to influence the behavior of MDMs and how they will implement the new guidelines. Other regulatory areas, such as Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), are now common requirements in the design and development process for IVDs, along with systems to ensure compliance with those regulations. Even so, many U.S. companies struggled to get their systems compliant in time with the new RoHS compliance deadline in Europe. After several extensions of the deadline date, some companies were taken by surprise and dropped systems from their European line card so they could concentrate on getting their leading systems certified.

“REACH compliance continues to be a challenge for many companies—it’s complicated, convoluted, and constantly being changed every few months, making it a regulatory nightmare,” said Hill.

Tiffany Roberts, director at ImmucorDX Laboratory, an Atlanta, Ga.-based provider of transfusion and transplantation diagnostic products, indicates that because the U.S. Food and Drug Administration (FDA) treats an IVD product like a medical device, it can be more challenging to receive approval. “It is becoming cost-prohibitive to perform all the studies that the FDA requires,” she said. “In addition, if you do get FDA approval, the IVD is then ‘locked down,’ which makes it difficult to continue to innovate or improve that product. And, of course, it is cost-prohibitive to have an advanced design of that IVD product be re-approved.”

CMS/Medicare is another challenge. CMS is usually the largest payer, especially for transplants, but covering/reimbursing a new test/new technology is nearly impossible in the current environment, she added. “It’s not unreasonable that they want proof of clinical utility, but that’s difficult to obtain when you can’t get clinicians to adopt, which they won’t do unless the test is paid for,” Roberts said. “It’s a vicious cycle that means the IVD company must essentially do the test for free, for a number of years, and not many can afford to do that.”

3D Printing and Beyond

MDMs are historically slow to change their ways, and prefer to use tested and verified methods and materials. Where they do tend to let loose a bit, however, is in the early development stages, where technologies like 3D printing can be fully considered, including taking advantage of being able to test new design concepts and prototypes in a matter of hours, instead of weeks.

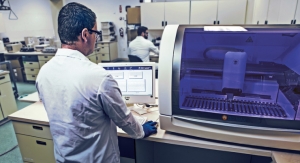

“3D printing is an interesting topic, but at a high level we shouldn’t ignore the proliferation of laboratory automation into almost every aspect of the clinical workflow,” stated Kallelis. “A good example of this can be seen at trade shows where companies are exhibiting complex automation of microbiology, hematology, and molecular assays. Tasks that were normally performed by trained medical technologists are transitioning to highly automated platforms. These ‘smart’ platforms minimize operator errors, maximize throughput, and provide consistent results. This is a move up the automation technology ladder that has benefited other industries, and is now a reality for the clinical environment.”

Resonetics has established an internal initiative to develop 3D printing and other types of additive manufacturing. “Given the current feature size limit of 3D printing, we have adopted a hybrid approach to use 3D printing to create the device, layer by layer, and then use a subtractive technology such as laser ablation to selectively remove layers to create smaller features,” said Ogura.

Emerging markets—especially China, India, and elsewhere in Asia—will continue to drive demand for IVD products, creating a highly competitive marketplace where technology advancements in IVD could create enough differentiation to expand market share. This is in contrast to the EU market, which has slowed, mostly due to cost constraints over public health expenditure. Latin America, Africa, and the Middle East are also potentially attractive markets for IVD that may emerge soon.

IVD manufacturers seek and obtain innovation support for their new product introductions from key partners within their supply chains. This spurs greater design creativity, device multi-functionality, improved precision, and higher throughput—all of which improve customer satisfaction and brand reputation. OEMs count on their partners for critical assets such as cleanrooms, medical material selection expertise, and rapid prototyping capabilities. For example, in vitro diagnostic wearables can require precision die cutting, skin contact adhesives, electromagnetic interference, and radio frequency interference shielding, spacers, and electrodes.

“The emergence of new in vitro diagnostic device technologies is a win for patients and providers through improved care, a win for insurance companies and employers through reduced costs, and a win for manufacturers by giving us the ability to support the evolution of the healthcare industry,” said Hartman.

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books. Contact him at mark.crawford@charter.net

According to BCC Research’s November 2015 report entitled “In Vitro Diagnostics: Technologies and Global Markets (HLC186A),” the global market for IVD products was valued at $57.3 billion in 2014 and is expected to grow to $81.1 billion by 2020 at a steady compound annual growth rate (CAGR) of 6.1 percent from 2015 to 2020.

It is also a very dynamic market that is quickly evolving and reacting to market trends, OEM needs, and emerging markets in developing countries that are likely to see double-digit growth in the coming years.

“Fifty percent of new global business is in emerging markets such as China and South America,” said Jim Hill, North American sales manager for Diba Industries Inc., a Danbury, Conn.-based provider of precision fluid handling solutions for diagnostics, life sciences, and medical device manufacturers. “Although many experts thought that much of this growth would be serviced by home-grown companies in these markets, we are seeing large U.S. IVD companies be very successful in selling refurbished machines, or re-designs of old product lines, that would have otherwise gone end-of-life, in these new markets.”

Another influencer on this trend is cost control. Healthcare has been under pressure to reduce costs for several years—and using standard equipment, or re-designed equipment that incorporates technological improvements to expand capabilities such as accuracy and speed, is one way to keep costs down.

“New technologies have emerged and are finding their ways to the clinic,” said Michael Kallelis, head of business development for KMC Systems Inc., a Merrimack, N.H.-based contract manufacturer for instrument companies. “These events have enabled OEM platform providers to look at their current instrument designs and refresh them to achieve lower costs and menu expansion. As a result, instrument design and development activities have increased over the last few years.”

On the technology front, point of care (POC) is rapidly driving IVD innovation. Demand is high for accurate, over-the-counter tests that provide instant results. POC is increasingly used for disease management, self-testing, and drug therapy monitoring. Speed is always of the essence—quicker test results can be acted upon sooner by medical staff, sometimes even in mid-procedure. Medical device companies also want technologies that are smaller, lighter weight, and easier to use. Analytical laboratories look for fast, efficient equipment that can do more tests and provide higher processing throughput, another way to drive down costs.

“DNA-based methods, including the adoption of sequencing in diagnostics, are driving new insights in monitoring disease and wellness,” said Richard Rubin, vice president of sales and marketing for Accel Biotech Inc., a Los Gatos, Calif.-based Ximedica company that provides full design and development services for IVD and life science systems. “Other technology trends are simultaneously driving increased access of diagnostics to point of care via compact, foolproof operation instruments, while large, highly automated, central lab systems continue to evolve and drive the cost per test down through volume.”

Glenn Ogura, senior vice president of market development for Resonetics, a Boston, Mass.-based supplier of laser micro manufacturing services and systems for the life sciences industry, has observed the same trend.

“The in vitro diagnostic market is seeing a transformational change, going from large instruments in the central laboratories that carry out tests for clinical chemistry, immunology, and hematology to tabletop and hand-held diagnostic instruments, especially in the areas of next generation sequencing, molecular diagnostics, and point of care,” he said. “The trend is to move the diagnostic test from the hospital to the physician’s office and, ultimately, to the home.”

All this activity within the IVD industry has created a high level of volatility, as evidenced by the number of large acquisitions and mergers that have occurred over the last 12 months. Large consolidations are expected to continue as long as there is a healthy ecosystem for start-ups (for example, business incubators associated with university research). Although there is intense pressure to control cost because of constrained reimbursement and other factors, the fundamental value of IVD testing still represents a bargain in the overall scheme of healthcare economics and expansion of the market will continue.

Recent Technology Trends

There is a great deal of effort in transitioning from time-consuming central lab tests to POC testing. Most companies want to achieve Clinical Laboratory Improvement Amendments (CLIA)-waived status in the United States, which would allow certain technologies to be sold and used by a nurse or other non-expert operator already involved in providing patient care. Tests developed for POC need to be “sample-to-answer”—meaning the operator takes the fluid or tissue sample and applies it directly to the instrument, which will then generate an accurate, simple-to-interpret result within 30 minutes or less. Medical device manufacturers (MDMs) and their end-user clients also seek expanded onboard assay menus, which saves time, reduces the number of samples needed, and improves efficiency.

Rubin noted that, although DNA tests based on the invention of polymerase chain reaction (PCR) have driven the bulk of the IVD market evolution in the last 20 years, immunoassays have changed relatively little given the lack of a parallel method to amplify low-concentration protein signals. “However, a number of companies are currently developing novel alternative methods for signal amplification to provide greater sensitivity and specificity to immunoassays,” he said. Examples include recent platforms developed by Singulex, Aushon Biosystems Inc., and PerkinElmer Inc.

The emphasis on molecular assays continues to advance existing technologies, such as rapid PCR, as well as overall processing times and time-to-result specifications. “These attributes are increasing instrument throughput and walk-away time for modern clinical instruments,” said Kallelis. “Faster, smaller, and less expensive is now a reality, where it was only a desire a few years ago.”

As equipment gets smaller and lighter in weight, so must components such as microfluidic chips, biochips, and biosensors, in both polymers and glass. As the sample and reagent volumes decrease, the feature sizes of the devices also decrease, opening up new opportunities for laser micro manufacturing. A key advantage of this process is that it is an immediately available, single-step process for drilling, cutting, and etching polymers, glass, metal, and ceramic down to the micron level. “This is unlike other polymer microfabrication processes such as multi-step lithographic processes or molding,” said Ogura, “which require a mold to be fabricated first, or glass microfabrication processes such as wet etching or particle bead blasting that require a mask overlay.”

What OEMs Want

MDMs and end-users of IVD equipment are laser-focused on reducing costs and generating highly accurate and consistent results. In response, technology is advancing so that assays are increasingly more sensitive and accurate, with improved medical results (for example, early detection). However, this also requires that analytical systems run better and cleaner, which means investing in new or upgraded equipment. MDMs are asking for both larger, faster, higher-throughput instruments and also smaller, focused, POC instruments—which is why instrumentation at both ends of the operating scale is often the topic of discussion at tradeshows, seminars, and symposia.

Sample sizes continue to get smaller as larger companies increase the array of tests their systems can perform. “Each new test is a new revenue stream,” said Hill. “Therefore, they need to be able to test a smaller amount of patient sample to stretch what they have across more tests.” Smaller sample sizes also require smaller system components, such as Diba’s Click-N-Seal fittings for the smallest fitting sizes used in IVD systems. As the fittings are hand-tightened, the resistance of the cap increases until the correct torque is reached, at which point, the cap clicks and the clinician knows the fitting has created a secure seal, without damaging the port through over-tightening.

With the Affordable Care Act’s emphasis on addressing chronic care conditions and disease management through accountable care reimbursement models, IVD companies and their customers are extremely interested in remote and ongoing health monitoring, such as continuous glucose monitoring, complete with alerts, data trends, and technology integration. “As a result of these trends,” said Richard Hartman, director of medical sales for Boyd Corporation, a Modesto, Calif.-based global provider of precision-engineered, specialty material-based energy management and sealing solutions, “MDMs are moving from test strips to wearables, and patient care is moving away from the acute and ambulatory settings.”

Not only do clients want the benefits of more advanced technologies in their IVD equipment, they also seek simplicity and ease of use. “Clients want products that are intuitive and simple to use,” indicated Ravi Narayanan, global product manager for Nordson Medical, a Loveland, Colo.-based manufacturer of single-use fluid connection components.

This includes materials that are chemically resistant to the various reagents used. USP Class VI compliant materials, materials that can withstand gamma irradiation, and products with a larger flow path diameter are favored. OEMs and end-users also want instruments that are easier and faster to service and maintain. Therefore, more emphasis is being placed on incorporating easy-to-use instrument components.

“OEM instrument and equipment designers are looking for products that can be plug-and-play, reducing the time of a field service call,” added Narayanan. “Customers also seek the ability to perform multiple tests faster, especially in emergency conditions, in order to detect/diagnose emerging diseases.”

Working within the advanced flexible materials market, Brianna Sporbert, director of Sourcebook engineering for Boyd Technologies, a Lee, Mass.-based precision converter in the medical device, life science, and electronic markets, has noticed an increase in requests from customers for single-use diagnostic materials for single-use or home-care devices. “These products are used for both diagnosis and ongoing monitoring and treatment,” she said. “Personal care products and preventative medicine have expanded the need for simple-to-use, but accurate, medical devices.”

Younger companies, particularly new entrants into the IVD market, are especially vulnerable to market forces. They often lack capital, certain critical expertise, and sound business leadership. They have the great idea, but are uncertain how to develop it and get it through the approval process. They may also hope to be bought out by a larger company, if their product is a success. To navigate this landscape, startups often team up with an experienced IVD partner to help them through the product development process. For example, a growing customer base for Accel Biotech is venture capital-backed startups that count on outside resources to help develop their instrument systems. Capabilities in opto-electro-mechanical software-controlled hardware, for example, along with single-use cartridges, are in strong demand by these entrepreneurs because they provide a single source for most of their product development needs.

“These clients typically emerge from universities with some core biochemical intellectual property or possibly a novel microelectromechanical systems sensor concept, but need help on all aspects of device development around these starting blocks,” said Rubin. “For both start-ups and established companies, a frequent challenge is integrating the sample preparation. We employ both automated liquid handling and cartridge-based strategies, which allows us to advise companies on an optimal approach for their application and proceed with rapid development.”

Advancements and Innovations

Most of the recent advancements in the IVD industry pertain to assay technologies. The advent of molecular assays, as well as next-generation sequencing, is changing the landscape of IVD testing more rapidly than in prior decades. To produce these higher-sensitivity assays, instrumentation must evolve as quickly as the chemistry. For cartridge-based systems, cartridges are becoming smaller and more sophisticated, which has generated a design challenge for refining materials and manufacturing techniques. Cartridge designers and manufacturers with deep material science understanding are becoming critical to the development of advanced cartridge-based systems.

Over the last few years, assays have been developed that can detect more indicators using lower levels of reagents, enabling earlier detection of diseases and increasing the ability of patients or caregivers to manage home care. This has become particularly relevant in the oncology industry, where early stage cancer detection has dramatically decreased the mortality rate of cancer patients.

“As more assays are discovered to address cancer and other diseases, the development becomes limited by the performance of the materials,” said Sporbert. “Some of these investigative procedures demand very complicated and precise material configurations, or are very sensitive to environmental conditions. This leads to a heightened emphasis on stability and exactness of the finished products, resulting in a demand for increased performance from converters and material manufacturers.”

As an example, laser-drilled thin polymer films of hole diameters of a few microns or greater are used as PCR emulsion filters for sequencing and to trap/isolate circulating tumor cell and circulating tumor DNA for liquid biopsy applications. These micropore filters are also used for diagnostic instruments for the detection of pathogens (bacteria, viruses) that cause infectious diseases.

“There is also an integration of multiple material types such as polymer, glass, and silicon as the diagnostic devices become active, not just passive,” said Ogura. “Laser-machined polymer and glass interposers are used to bridge the gap. Lasers are also used to drill analyte inlet and outlet vias in polymer and glass cover slides. Laser ablation of polymer coatings is also an effective way to expose metal electrodes for electrochemical reactions or for the attachment of DNA probes.”

Cutting (dicing) and drilling of glass and sapphire wafers also become more challenging as the feature sizes become smaller and features are packed closer together, necessitating processes that can cut glass with straight sidewalls. Putting sensitive chemistries closer to the edge of the wafer requires a cutting process that does not generate debris. And as glass wafers become thinner (100 microns thick), they are more susceptible to breaking.

“To overcome all these limitations, Resonetics has developed ‘zero kerf’ technology that produces zero taper cut edges, an absence of surface debris, no kerf (cut) width, and is an order of magnitude faster than traditional ablation methods,” said Ogura. “The laser creates micro-fissures that propagate along the vertical direction to create these ultra-clean-looking cuts. Initially we developed the process to handle external cuts of glass wafers and slides ranging from 100 microns to 1 mm thick.”

Regulatory and Reimbursement Challenges

The new CE directive in the European Union (EU) is starting to influence the behavior of MDMs and how they will implement the new guidelines. Other regulatory areas, such as Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), are now common requirements in the design and development process for IVDs, along with systems to ensure compliance with those regulations. Even so, many U.S. companies struggled to get their systems compliant in time with the new RoHS compliance deadline in Europe. After several extensions of the deadline date, some companies were taken by surprise and dropped systems from their European line card so they could concentrate on getting their leading systems certified.

“REACH compliance continues to be a challenge for many companies—it’s complicated, convoluted, and constantly being changed every few months, making it a regulatory nightmare,” said Hill.

Tiffany Roberts, director at ImmucorDX Laboratory, an Atlanta, Ga.-based provider of transfusion and transplantation diagnostic products, indicates that because the U.S. Food and Drug Administration (FDA) treats an IVD product like a medical device, it can be more challenging to receive approval. “It is becoming cost-prohibitive to perform all the studies that the FDA requires,” she said. “In addition, if you do get FDA approval, the IVD is then ‘locked down,’ which makes it difficult to continue to innovate or improve that product. And, of course, it is cost-prohibitive to have an advanced design of that IVD product be re-approved.”

CMS/Medicare is another challenge. CMS is usually the largest payer, especially for transplants, but covering/reimbursing a new test/new technology is nearly impossible in the current environment, she added. “It’s not unreasonable that they want proof of clinical utility, but that’s difficult to obtain when you can’t get clinicians to adopt, which they won’t do unless the test is paid for,” Roberts said. “It’s a vicious cycle that means the IVD company must essentially do the test for free, for a number of years, and not many can afford to do that.”

3D Printing and Beyond

MDMs are historically slow to change their ways, and prefer to use tested and verified methods and materials. Where they do tend to let loose a bit, however, is in the early development stages, where technologies like 3D printing can be fully considered, including taking advantage of being able to test new design concepts and prototypes in a matter of hours, instead of weeks.

“3D printing is an interesting topic, but at a high level we shouldn’t ignore the proliferation of laboratory automation into almost every aspect of the clinical workflow,” stated Kallelis. “A good example of this can be seen at trade shows where companies are exhibiting complex automation of microbiology, hematology, and molecular assays. Tasks that were normally performed by trained medical technologists are transitioning to highly automated platforms. These ‘smart’ platforms minimize operator errors, maximize throughput, and provide consistent results. This is a move up the automation technology ladder that has benefited other industries, and is now a reality for the clinical environment.”

Resonetics has established an internal initiative to develop 3D printing and other types of additive manufacturing. “Given the current feature size limit of 3D printing, we have adopted a hybrid approach to use 3D printing to create the device, layer by layer, and then use a subtractive technology such as laser ablation to selectively remove layers to create smaller features,” said Ogura.

Emerging markets—especially China, India, and elsewhere in Asia—will continue to drive demand for IVD products, creating a highly competitive marketplace where technology advancements in IVD could create enough differentiation to expand market share. This is in contrast to the EU market, which has slowed, mostly due to cost constraints over public health expenditure. Latin America, Africa, and the Middle East are also potentially attractive markets for IVD that may emerge soon.

IVD manufacturers seek and obtain innovation support for their new product introductions from key partners within their supply chains. This spurs greater design creativity, device multi-functionality, improved precision, and higher throughput—all of which improve customer satisfaction and brand reputation. OEMs count on their partners for critical assets such as cleanrooms, medical material selection expertise, and rapid prototyping capabilities. For example, in vitro diagnostic wearables can require precision die cutting, skin contact adhesives, electromagnetic interference, and radio frequency interference shielding, spacers, and electrodes.

“The emergence of new in vitro diagnostic device technologies is a win for patients and providers through improved care, a win for insurance companies and employers through reduced costs, and a win for manufacturers by giving us the ability to support the evolution of the healthcare industry,” said Hartman.

Mark Crawford is a full-time freelance business and marketing/communications writer based in Madison, Wis. His clients range from startups to global manufacturing leaders. He also writes a variety of feature articles for regional and national publications and is the author of five books. Contact him at mark.crawford@charter.net