Mark Bos, National Bearings Company04.06.16

Aleading, U.S.-based medical device manufacturer was experiencing significant product failure. A plastic gear in a disposable surgical device was melting during surgery, requiring the surgeon to use two separate devices during each procedure. Not only was this diminishing the surgeon’s desire to use the product, it was significantly increasing hospital costs due to the need for more than one device. At approximately $1,000 per device, this was a very expensive premature failure issue. If this type of failure could be eliminated, the cost and duration of the surgery could be reduced considerably and the manufacturer would have the opportunity to gain significant market share.

The manufacturer suspected that part of the problem was due to friction created between the plastic gear and the device housing. It was determined that one potential solution could be realized by adding a bearing, reducing friction and eliminating the product failure. The product engineer sought a bearing manufacturer to determine if the current design could be modified accordingly.

The Challenge

National Bearings Company, the only bearing manufacturer that willingly took on the project, began a series of design evolutions to solve the primary problem—preventing the gear from melting.

First evolution: Create a plain bearing from a thermally conductive plastic to reduce friction and shunt heat from the plastic gear. The result—failure. The design was inadequate and the gear melted.

Second evolution: Create a stainless steel bearing with balls to significantly reduce friction and prevent heat from building up in the plastic gear. The result ended in failure again. The bearing worked well, but the plastic gear failed. The shoulders of the gear had to be reduced in diameter significantly in order to accommodate the new bearing. This reduction in diameter caused the gear to become structurally unstable.

Third evolution: The nuclear option—replace the plastic gear with a traditional metal gear and bearing assembly that would be easily capable of long and stable performance. The result was a success, to a degree.

The Solution

After realizing the original design was insufficient for the application, the manufacturer specified a more expensive metal gear with high performance stainless steel bearings.

Specifying this metal gear and stainless steel bearing brought about a new issue for the product’s design. Once the product longevity had been addressed, component cost became the new priority.

The new metal gear design was approximately $20 per assembly, as compared to less than $1 for the original, inadequate design. The heavy-duty gear and high-precision bearings would last forever, but they were also enormously expensive. National Bearings needed to find a balance that provided enough performance to complete the surgery and a cost that did not unnecessarily exceed the budget.

Gear hobbing is a traditional manufacturing method for gears that requires a cutting tool (hob) and a special milling machine. The process is highly precise and slow, so hobbing is typically very expensive. Due to the high costs, this manufacturing method for the gear had to be abandoned.

Instead, National Bearings developed an aluminum extrusion with an exaggerated tooth profile as gear stock. National Bearings then had the option to machine the gear stock to the tight tolerances necessary to mount the bearings and finally grind the tooth profile to the precise dimensions required to mate with the drive belt. Not only was National Bearings able to mount the bearings, it achieved the required gear tooth shape and dramatically reduced costs.

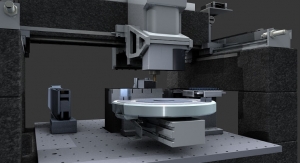

Finally, National Bearings built a robotic assembly machine, working in a clean environment, to build and inspect the assembly prior to packaging.

The Result

After more than a year of highly collaborative development, including weekly meetings, dozens of design iterations, and a rigorous production qualification process, National Bearings succeeded in developing a gear assembly that worked for the entire duration of the surgical procedure. This solution also saved the manufacturer money—the custom-designed gear assembly cost less than $8 per unit.

In addition, premature product failure is no longer an issue and National Bearings proved its ability to troubleshoot and resolve significant design issues through a highly collaborative design process.

A Collaborative Approach

The National Bearings engineers applied their knowledge of materials and manufacturing processes to help the manufacturer achieve a workable design. The engineering team collaborated with the manufacturer’s product designer to identify problems and possible solutions. Only through close collaboration and the tireless application of knowledge could this challenge have been solved.

Mark Bos is a manufacturing professional with extensive experience in custom bearings, assembly design, and manufacturing. In his current position with National Bearings, Bos serves as VP of business development, and is actively involved in product development, engineering, marketing, and sales management.

The manufacturer suspected that part of the problem was due to friction created between the plastic gear and the device housing. It was determined that one potential solution could be realized by adding a bearing, reducing friction and eliminating the product failure. The product engineer sought a bearing manufacturer to determine if the current design could be modified accordingly.

The Challenge

National Bearings Company, the only bearing manufacturer that willingly took on the project, began a series of design evolutions to solve the primary problem—preventing the gear from melting.

First evolution: Create a plain bearing from a thermally conductive plastic to reduce friction and shunt heat from the plastic gear. The result—failure. The design was inadequate and the gear melted.

Second evolution: Create a stainless steel bearing with balls to significantly reduce friction and prevent heat from building up in the plastic gear. The result ended in failure again. The bearing worked well, but the plastic gear failed. The shoulders of the gear had to be reduced in diameter significantly in order to accommodate the new bearing. This reduction in diameter caused the gear to become structurally unstable.

Third evolution: The nuclear option—replace the plastic gear with a traditional metal gear and bearing assembly that would be easily capable of long and stable performance. The result was a success, to a degree.

The Solution

After realizing the original design was insufficient for the application, the manufacturer specified a more expensive metal gear with high performance stainless steel bearings.

Specifying this metal gear and stainless steel bearing brought about a new issue for the product’s design. Once the product longevity had been addressed, component cost became the new priority.

The new metal gear design was approximately $20 per assembly, as compared to less than $1 for the original, inadequate design. The heavy-duty gear and high-precision bearings would last forever, but they were also enormously expensive. National Bearings needed to find a balance that provided enough performance to complete the surgery and a cost that did not unnecessarily exceed the budget.

Gear hobbing is a traditional manufacturing method for gears that requires a cutting tool (hob) and a special milling machine. The process is highly precise and slow, so hobbing is typically very expensive. Due to the high costs, this manufacturing method for the gear had to be abandoned.

Instead, National Bearings developed an aluminum extrusion with an exaggerated tooth profile as gear stock. National Bearings then had the option to machine the gear stock to the tight tolerances necessary to mount the bearings and finally grind the tooth profile to the precise dimensions required to mate with the drive belt. Not only was National Bearings able to mount the bearings, it achieved the required gear tooth shape and dramatically reduced costs.

Finally, National Bearings built a robotic assembly machine, working in a clean environment, to build and inspect the assembly prior to packaging.

The Result

After more than a year of highly collaborative development, including weekly meetings, dozens of design iterations, and a rigorous production qualification process, National Bearings succeeded in developing a gear assembly that worked for the entire duration of the surgical procedure. This solution also saved the manufacturer money—the custom-designed gear assembly cost less than $8 per unit.

In addition, premature product failure is no longer an issue and National Bearings proved its ability to troubleshoot and resolve significant design issues through a highly collaborative design process.

A Collaborative Approach

The National Bearings engineers applied their knowledge of materials and manufacturing processes to help the manufacturer achieve a workable design. The engineering team collaborated with the manufacturer’s product designer to identify problems and possible solutions. Only through close collaboration and the tireless application of knowledge could this challenge have been solved.

Mark Bos is a manufacturing professional with extensive experience in custom bearings, assembly design, and manufacturing. In his current position with National Bearings, Bos serves as VP of business development, and is actively involved in product development, engineering, marketing, and sales management.