Videos

Mount Sinai Establishes 3D Printing Services for Clinicians and Researchers

Mount Sinai Establishes 3D Printing Services for Clinicians and Researchers

Rapid Prototyping Center utilizes four 3D printers as well as a laser cutter to produce patient-specific neuroanatomy.

By The Mount Sinai Hospital/Mount Sinai School of Medicine12.07.16

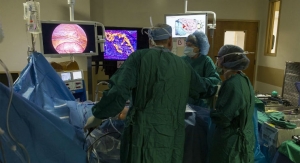

Mount Sinai Health System announced the creation of the Medical Modeling Core, a collaboration led by the Department of Neurosurgery, where clinicians can confer and order 3D models for their cases. Virtual reality, simulation, and 3D printing services will be provided on a low-cost fee-for-service basis with quick turnaround times. This resource will be the first of its kind catering to the unique patient-specific modeling requirements of clinicians at Mount Sinai.

"Our simulation, prototyping, and 3D printing resources developed here at Mount Sinai are rare for a medical institution," said Joshua Bederson, MD, Professor and System Chair for the Department of Neurosurgery at Mount Sinai Health System and Clinical Director of the Neurosurgery Simulation Core. "These models are used in the planning stages for minimally invasive approaches and can be a trial run for the surgery. In conjunction with simulation, they also play an important role in the patient consultation process."

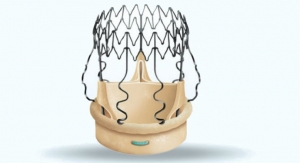

The team handling 3D printing services is led by Anthony Costa, PhD, Assistant Professor for the Department of Neurosurgery and Scientific Director of the Neurosurgery Simulation Core at the Icahn School of Medicine at Mount Sinai. Dr. Costa has developed segmentation tools and computer code to expedite the process of turning radiological data into models appropriate for 3D printing and modeling. Recent prints include skull-base tumors with surrounding vasculature and cranial nerves, spine modeling for the correction of severe scoliosis, and pelvic models for the planning of arthroplasty. More than half a dozen interdisciplinary collaborations have been established between the Medical Modeling Core and Mount Sinai clinical departments, including neurosurgery, orthopedics, surgery, otolaryngology and cardiology.

"We're unique because we can leverage our technological tools with the expertise of radiology and the printing lab to complete projects on a rapid time scale," said Dr. Costa. "We're talking about days as opposed to weeks. Mount Sinai is a large institution with a high volume of cases and our patients will benefit from 3D modeling."

In-house design and production of the 3D models also leads to significant cost savings for Mount Sinai physicians. For example, a print that would cost $500 to model at the hospital could cost ten times that through a vendor.

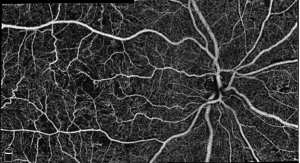

The Rapid Prototyping Center utilizes four 3D printers as well as a laser cutter to produce patient-specific neuroanatomy for pre-operative planning with exceptionally high resolution. Materials range from gypsum powder base made of plastic, polyamide (nylon), epoxy resin, wax, photopolymers, and polycarbonate. Engineers can fabricate models and functional parts for a wide range of applications.

Related Searches: