Mark Crawford05.19.10

A market decline in 2009 and increased inventory levels at all major OEMs created challenging times for implant manufacturers and their supply chains. Driven by increased vigilance by the U.S. Food and Drug Administration (FDA) and the need for lower costs, OEMs are looking for value-added suppliers who can take time and cost out of the entire manufacturing process.

"OEMs can usually manage through an economic downturn okay," said Joe Zuzula, director of sales and marketing for Orchid Orthopedic Solutions in Holt, Mich. "The spine and extremity markets have done fairly well. A lot of OEMs seem to have positive sales, but they aren't seeing double-digit growth like they used to."

That decrease has, of course, hurt contract manufacturers. Most experienced significant decreases in sales last year, with some being down 15 percent or more for 2009.

"OEMs look at their businesses and see areas where they can reduce waste on their own, such as excess inventory," Zuzula continued. "If they also have manufacturing capability, they can keep their people busy by pulling in work from vendors. Recently, however, there has been an uptick in the positive direction. We also know more about the healthcare bill, which eases some concerns in the industry. However, there are still some questions about the device tax and its impact on our industry."

Stephen Cowen, vice president of sales and marketing for Sandvik MedTech in Sheffield, England, told Orthopedic Design & Technology that the "de-stocking" by the major OEMs negatively impacted the market and contract manufacturing output during 2009.

"OEM stock days peaked at 293," he noted.

Contract manufacturers also have to deal with increased scrutiny from the FDA on OEMs and their supply chain, especially regarding quality control and compliance. "The FDA continues to increase the level of focus, control and audit pressure on manufacturers around the world," said Cowen. "OEMs are eager to consolidate their supply chains to better upstream raw material traceability. They want to find suppliers who embrace this and can relieve some of the supply chain management burden."

It's no surprise that dealing with more audits and validation procedures adds more time to the production process.

"More OEMs are demanding total process and equipment validation from suppliers, which can take months to complete," said Joe Davis, executive vice president of 3D Medical Manufacturing in Riviera Beach, Fla.

The recent OEM and tier-one FDA scrutiny has increased the level of enforcement at the supply base and beyond. Issues such as validations, special process, supplier control and change control have the potential to slow down the pace at which products can be commercialized.

Although audit frequency has not necessarily increased, the depth of the audit or process review is much more detailed and extensive than in the past.

"Controls are driven down to every level of the supply chain," said Rick Stetler, vice president of North American operations for Paragon Medical in Pierceton, Ind. "Controls and risk mitigation must be in place before projects can move forward. To address this, we have increased our regulatory staff and integrated more risk mitigation tools into our new product introduction process."

It's pretty simple. OEMs want everything to be better and faster-higher quality, shorter lead times and on-time delivery-all for a lower price.

"They want suppliers who can step up and take on more of the value stream for their products," said Zuzula.

This varies from vendor-managed inventory systems for reducing lead times to providing engineering resources, warehousing and full supply-chain management services. Vendors who can provide better characterization and control of raw material sources, as well as robust, well-coordinated global quality control systems that help ease the regulatory pressure on OEMs, will be in high demand.

"One of the biggest trends we continue to see as a manufacturer is the need to provide a complete product that OEMs can put directly on their shelf," said Casey Tuller, director of development for Advantage Manufacturing Technologies (AMT) in Monroe, Wash. "The key to making this work smoothly is being committed to meeting the OEMs' needs and being a trusted business partner. OEMs are typically very helpful in getting you up to speed on what they need and giving you time to put the necessary tools in place. We use a combination of an enterprise resource planning (ERP) system and a statistical process control system to collect as much data electronically as we can, such as scanning parts and documents."

Rapid tooling, rapid design and short launch times increasingly are important to meet OEM expectations. Rapid prototyping is another key step in getting new products to market quickly.

"OEMs use rapid prototyping to confirm design intent," said Ken Tuchel, senior vice president for implant sales for Symmetry Medical in Warsaw, Ind. "There are several unique processes that can be used to prototype product. When confirming the design and functionality of the implant, it is important to understand the design and the process outputs that can affect functionality. Prior to building tooling, gauging and related fixtures-which can exceed $100,000-we want to make sure we are working closely with the OEM to produce the end product per the design intent."

Cost, time and speed are all related to efficiency. It goes without saying that cost is a major driver for OEMs. In order for suppliers to be competitive they must have a developed and functioning cost-reduction program.

"The optimal way to garner large savings is to evaluate the entire value stream, including customers and suppliers," said Stetler. "This broad approach aligns organizational goals and can achieve win/win results."

Delivery schedules often fluctuate, according to the capacity and demand the OEM is experiencing. To be as cost-efficient as possible, contract manufacturers must be able to establish a production schedule that matches the ebb and flow of the OEM.

"In order to do this, suppliers must be able to respond quickly," said Zuzula. "Therefore communication is huge. It's imperative to have constant communication so you can understand what OEMs are seeing in the market and how they are planning to deal with it."

The best way to be prepared to meet the next OEM challenge is to be as lean and efficient as possible. The application of Lean manufacturing principles removes waste from all levels of the operation so manufacturing time is as short as possible-throughout the supply chain. "Lean is a great way to save thousands of dollars in the logistics of shipping, handling, procurement and inspection costs," said Zuzula.

Stetler said his company's approach to leveraging Lean and cost reduction is one of close partnership with clients.

"At any one time we have multiple projects going on between divisions and in partnership with our clients or supply base," he said. "With dedicated staff we are able to improve large portions of the value stream very quickly."

It's best to have the value stream tied to the end user, if possible, experts said.

"In a perfect Lean scenario, for example, if a hospital pulls a kit for a surgery, that action would send a signal to the OEM to replace that kit, while at the same time signal the contract manufacturer and raw material supplier that another one needs to be made. This would happen instantaneously, so all partners involved could replace the kit in the shortest possible lead time," said Zuzula. "It also allows everyone in the value stream to see what the actual need is so unnecessary inventory is not built."

Excess inventory can waste resources and material, which, in turn, can increase costs. Forward-thinking contract manufacturers work to build lean enterprises with their customers and vendors. Zuzula said when companies take on more of the value stream, they become more vertically integrated and have more control.

"This kind of system gives us the capability to do more for the OEM, either in-house or through an outside subcontractor," he said. "Customers are looking for vendors who can manage more of the value stream-if you can help an OEM drop from 20 vendors to just one to produce an instrument/implant kit, you're saving that OEM time and money and becoming a valued partner."

Materials in greatest demand by OEMs continue to be titanium, PEEK, stainless steel, cobalt/ chrome, ultra high molecular weight polyethylene (UHMWPE) and zirconium. Stronger and tougher ceramics also are being sought for next-generation orthopedic implants.

"There has been a progressive move towards the use of ceramic composite materials like zirconia-toughened alumina that provide the excellent biocompatability and tribology of alumina, but have enhanced strengths and fracture resistance due to zirconia," said Steve Hughes, orthopedic product manager for C5 Medicalwerks in Grand Junction, Colo., a company that manufactures ceramic medical implants for the orthopedic, dental, spinal and electroimplant markets.

Hughes also noted a trend toward larger-diameter components for hips. He said that to give the maximum range of sizes on acetabulum components, a relatively thin-walled ceramic is required, which necessitates tougher properties.

"There is also an interest for ceramic knee components for patients who have metal ion allergies, and these require higher-strength materials," Hughes said.

One way that companies are able to reduce costs through improved efficiency is by using automation.

According to Advantage Manufacturing Technologies' Tuller said his firm continues to look at machines that produce more products with fewer operators, as well as consolidating processes where possible along the way.

"A good example would be machining bone plates in multiple steps and set-ups on a 3-axis vertical mill versus using a 5-axis mill, or even a Horizontal mill with a pallet pool system making the parts-one machine and one operator," Tuller said. We do both depending on the design of the implant."

AMT currently is focused on 5-axis milling and Swiss gun drilling. Due to the difficulty of obtaining cannulated material, AMT invested in new Swiss machines and retrofitted older machines with gun drilling capability.

"In the end we discovered we can manufacture a higher-quality part, with cheaper solid-bar stock, and have total control of the process in-house," said Tuller. "Our goal is to match practical, well-designed equipment with the product we're making. We can get a reputable 5-axis mill that will cover most of our implant needs for $150,000-$200,000. Swiss lathe gun drilling is now coming from the machine tool manufacturers and dealers as an option and can be really cost-effective. The set-up we run adds approximately $15,000-$20,000 to a $200,000 Star CNC machine. Our business model is to go after the higher-tolerance work where there is less competition anyway. Sure it's hard, but it's worth it."

Robotic forge technology is another advanced process that helps keep costs down by increasing efficiency and throughput.

"We have invested considerable time and money to develop this technology," said Tuchel. "There are very few orthopedic forging suppliers using this unique method. The biggest advantages are consistency in loading and unloading, producing a better product and the efficacy gains with robotics."

Validation/quality enforcement is more restrictive today than ever before. OEMs are clearly looking for suppliers that can embrace (and pass) the increased regulatory scrutiny from OEMs and the FDA. Although regulation often is regarded as a complication that burns up time and increases costs, it also can be a valuable strategic advantage. "A robust regulatory compliance system reduces risk for the supplier and the OEM, yielding an efficient commercialization process," said Stetler. "There is a tremendous amount of work associated with such a step function change, which presents various challenges on its own. Strong regulatory control offers OEMs assurance that their supply chains are viable and will remain intact during an FDA audit."

Because of increased FDA scrutiny, OEMs are auditing their vendors' validation activities more frequently.

"We are getting increases in audits from our customers," said Zuzula. "We have assembled a quality management team, drawing from all our divisions. Its mission is to make certain our validation/ standardization procedures meet the good manufacturing practices (GMPs) established by the FDA. If you don't have these processes in place already, it will be costly to get up to speed. However, it has become the ante-if you don't meet or exceed the GMPs you're basically out of the game. Quality must be measurable and predictable in all your equipment, operations and processes at all times if you want to stay in the implant business."

David said medical device companies increasingly are "getting onboard" with complete master validation plan requirements.

"3D Medical is seeing more upfront validation study requirements prior to production from our customers," he said.

Such enforcement efforts require organizations to become more responsive to particular project needs and identify potential validation issues sooner. OEMs that allow suppliers to engage earlier in the development process will shorten their time to market as they allow suppliers to execute validation protocols in advance of design transfer.

"This type of sourcing will change the way the industry interacts with its supply base, improving the process in the long run," said Stetler.

The FDA also recently has heightened its scope of new product and 510(k) acceptance levels. Significant testing may be required to claim equivalency rather than using another product's testing results already on the market.

"Customer validation requirements continue to increase as process capability and requirements tighten and further emphasis on process controls are put in place," said Tuchel.

Zuzula said the increased vigilance by FDA means contract manufacturers need to offer products and services that are better than they did before.

"The core purpose of lean manufacturing is continuous improvement, removing waste, streamlining processes and always getting better," Zuzula said. "Ultimately you want a complete lean enterprise that is linked to the vendors in your supply chain-this is the best way to add value and be positioned to meet the newest OEM expectations."

The biggest challenge for contract manufacturers is to improve on all fronts, at all times, to keep OEMs satisfied. To accomplish this, continual improvement must be part of corporate culture. Waste must be stripped and value added wherever possible. Value-added services include automated in-process inspection, increased documentation and administration, design and engineering services, packaging/ cleaning, inventory management, distribution and total supply chain management, from "dock to stock." Long-term agreements that focus on reducing overall supply chain costs also are reassuring to OEMs.

Forecasting fluctuations always is challenging in an uneven economy. As a hedge against fluctuations, OEMs are requesting more managed inventory systems from their vendors. Managing this ebb and flow of customer orders as their outsourcing needs vary is part art and part science. Flexible manufacturing schedules are helpful for accommodating growth and capacity changes; outstanding communication, via software and frequent phone interactions, is essential to launch nimble responses.

Balancing Lean manufacturing principles with what seems like ever-changing (sometimes weekly) customer needs depends on developing and maintaining the critical relationship between the OEM buyer and the contract manufacturer's planners. The same principles apply for supply chain relationships.

"We meet with our main titanium resource at least four to five times a year, who really has the same values we do, so we are very fortunate to be working with people who are equally aligned with our mission and values," said Tuller.

Customers' implant design and manufacturing requirements continue to evolve, which may depend on new materials that need different machining techniques.

"With the advances made in minimally invasive and computer-aided surgeries, we see implant designs bringing new challenges to our teams, such as increasing longevity and being able to insert the implant in a smaller area within the wound site," said Tuchel. "This usually requires tighter tolerance machining."

And, of course, there always will be regulatory challenges. "In my opinion, the biggest challenges faced by suppliers today relate to the multiple interpretations of the regulatory agencies by the OEMs," said Stetler. "Each OEM interprets and initiates actions to satisfy their organization's requirements. These interpretations can vary greatly from OEM to OEM, forcing the supply base to have extremely customizable systems adaptable to each need, while still offering cost and lead time advantages. Success depends on outstanding communication. It's a constant effort to keep all key managers in synch with customer and business needs. It's very easy to make things complex; it is very difficult to keep them simple."

"OEMs can usually manage through an economic downturn okay," said Joe Zuzula, director of sales and marketing for Orchid Orthopedic Solutions in Holt, Mich. "The spine and extremity markets have done fairly well. A lot of OEMs seem to have positive sales, but they aren't seeing double-digit growth like they used to."

That decrease has, of course, hurt contract manufacturers. Most experienced significant decreases in sales last year, with some being down 15 percent or more for 2009.

"OEMs look at their businesses and see areas where they can reduce waste on their own, such as excess inventory," Zuzula continued. "If they also have manufacturing capability, they can keep their people busy by pulling in work from vendors. Recently, however, there has been an uptick in the positive direction. We also know more about the healthcare bill, which eases some concerns in the industry. However, there are still some questions about the device tax and its impact on our industry."

Stephen Cowen, vice president of sales and marketing for Sandvik MedTech in Sheffield, England, told Orthopedic Design & Technology that the "de-stocking" by the major OEMs negatively impacted the market and contract manufacturing output during 2009.

"OEM stock days peaked at 293," he noted.

Contract manufacturers also have to deal with increased scrutiny from the FDA on OEMs and their supply chain, especially regarding quality control and compliance. "The FDA continues to increase the level of focus, control and audit pressure on manufacturers around the world," said Cowen. "OEMs are eager to consolidate their supply chains to better upstream raw material traceability. They want to find suppliers who embrace this and can relieve some of the supply chain management burden."

It's no surprise that dealing with more audits and validation procedures adds more time to the production process.

"More OEMs are demanding total process and equipment validation from suppliers, which can take months to complete," said Joe Davis, executive vice president of 3D Medical Manufacturing in Riviera Beach, Fla.

The recent OEM and tier-one FDA scrutiny has increased the level of enforcement at the supply base and beyond. Issues such as validations, special process, supplier control and change control have the potential to slow down the pace at which products can be commercialized.

Although audit frequency has not necessarily increased, the depth of the audit or process review is much more detailed and extensive than in the past.

"Controls are driven down to every level of the supply chain," said Rick Stetler, vice president of North American operations for Paragon Medical in Pierceton, Ind. "Controls and risk mitigation must be in place before projects can move forward. To address this, we have increased our regulatory staff and integrated more risk mitigation tools into our new product introduction process."

What OEMs Want

It's pretty simple. OEMs want everything to be better and faster-higher quality, shorter lead times and on-time delivery-all for a lower price.

"They want suppliers who can step up and take on more of the value stream for their products," said Zuzula.

This varies from vendor-managed inventory systems for reducing lead times to providing engineering resources, warehousing and full supply-chain management services. Vendors who can provide better characterization and control of raw material sources, as well as robust, well-coordinated global quality control systems that help ease the regulatory pressure on OEMs, will be in high demand.

"One of the biggest trends we continue to see as a manufacturer is the need to provide a complete product that OEMs can put directly on their shelf," said Casey Tuller, director of development for Advantage Manufacturing Technologies (AMT) in Monroe, Wash. "The key to making this work smoothly is being committed to meeting the OEMs' needs and being a trusted business partner. OEMs are typically very helpful in getting you up to speed on what they need and giving you time to put the necessary tools in place. We use a combination of an enterprise resource planning (ERP) system and a statistical process control system to collect as much data electronically as we can, such as scanning parts and documents."

Rapid tooling, rapid design and short launch times increasingly are important to meet OEM expectations. Rapid prototyping is another key step in getting new products to market quickly.

"OEMs use rapid prototyping to confirm design intent," said Ken Tuchel, senior vice president for implant sales for Symmetry Medical in Warsaw, Ind. "There are several unique processes that can be used to prototype product. When confirming the design and functionality of the implant, it is important to understand the design and the process outputs that can affect functionality. Prior to building tooling, gauging and related fixtures-which can exceed $100,000-we want to make sure we are working closely with the OEM to produce the end product per the design intent."

Meeting OEM Demands

|

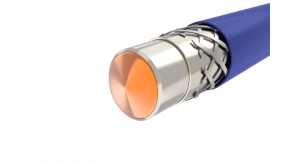

Orthopedic manufacturers should strive for a complete lean enterprise that is linked to suppliers for ultimate value. Photo courtesy of Orchid Orthopedic Solutions. |

"The optimal way to garner large savings is to evaluate the entire value stream, including customers and suppliers," said Stetler. "This broad approach aligns organizational goals and can achieve win/win results."

Delivery schedules often fluctuate, according to the capacity and demand the OEM is experiencing. To be as cost-efficient as possible, contract manufacturers must be able to establish a production schedule that matches the ebb and flow of the OEM.

"In order to do this, suppliers must be able to respond quickly," said Zuzula. "Therefore communication is huge. It's imperative to have constant communication so you can understand what OEMs are seeing in the market and how they are planning to deal with it."

The best way to be prepared to meet the next OEM challenge is to be as lean and efficient as possible. The application of Lean manufacturing principles removes waste from all levels of the operation so manufacturing time is as short as possible-throughout the supply chain. "Lean is a great way to save thousands of dollars in the logistics of shipping, handling, procurement and inspection costs," said Zuzula.

Stetler said his company's approach to leveraging Lean and cost reduction is one of close partnership with clients.

"At any one time we have multiple projects going on between divisions and in partnership with our clients or supply base," he said. "With dedicated staff we are able to improve large portions of the value stream very quickly."

It's best to have the value stream tied to the end user, if possible, experts said.

"In a perfect Lean scenario, for example, if a hospital pulls a kit for a surgery, that action would send a signal to the OEM to replace that kit, while at the same time signal the contract manufacturer and raw material supplier that another one needs to be made. This would happen instantaneously, so all partners involved could replace the kit in the shortest possible lead time," said Zuzula. "It also allows everyone in the value stream to see what the actual need is so unnecessary inventory is not built."

Excess inventory can waste resources and material, which, in turn, can increase costs. Forward-thinking contract manufacturers work to build lean enterprises with their customers and vendors. Zuzula said when companies take on more of the value stream, they become more vertically integrated and have more control.

"This kind of system gives us the capability to do more for the OEM, either in-house or through an outside subcontractor," he said. "Customers are looking for vendors who can manage more of the value stream-if you can help an OEM drop from 20 vendors to just one to produce an instrument/implant kit, you're saving that OEM time and money and becoming a valued partner."

Machine & Material Matters

Materials in greatest demand by OEMs continue to be titanium, PEEK, stainless steel, cobalt/ chrome, ultra high molecular weight polyethylene (UHMWPE) and zirconium. Stronger and tougher ceramics also are being sought for next-generation orthopedic implants.

|

Hip components made from ceramic composite materials such as zirconia-toughened alumina are stronger and more fracture-resistant than other substances. Photo courtesy of C5 Medicalwerks. |

Hughes also noted a trend toward larger-diameter components for hips. He said that to give the maximum range of sizes on acetabulum components, a relatively thin-walled ceramic is required, which necessitates tougher properties.

"There is also an interest for ceramic knee components for patients who have metal ion allergies, and these require higher-strength materials," Hughes said.

One way that companies are able to reduce costs through improved efficiency is by using automation.

According to Advantage Manufacturing Technologies' Tuller said his firm continues to look at machines that produce more products with fewer operators, as well as consolidating processes where possible along the way.

"A good example would be machining bone plates in multiple steps and set-ups on a 3-axis vertical mill versus using a 5-axis mill, or even a Horizontal mill with a pallet pool system making the parts-one machine and one operator," Tuller said. We do both depending on the design of the implant."

AMT currently is focused on 5-axis milling and Swiss gun drilling. Due to the difficulty of obtaining cannulated material, AMT invested in new Swiss machines and retrofitted older machines with gun drilling capability.

"In the end we discovered we can manufacture a higher-quality part, with cheaper solid-bar stock, and have total control of the process in-house," said Tuller. "Our goal is to match practical, well-designed equipment with the product we're making. We can get a reputable 5-axis mill that will cover most of our implant needs for $150,000-$200,000. Swiss lathe gun drilling is now coming from the machine tool manufacturers and dealers as an option and can be really cost-effective. The set-up we run adds approximately $15,000-$20,000 to a $200,000 Star CNC machine. Our business model is to go after the higher-tolerance work where there is less competition anyway. Sure it's hard, but it's worth it."

Robotic forge technology is another advanced process that helps keep costs down by increasing efficiency and throughput.

"We have invested considerable time and money to develop this technology," said Tuchel. "There are very few orthopedic forging suppliers using this unique method. The biggest advantages are consistency in loading and unloading, producing a better product and the efficacy gains with robotics."

Regulatory Control

Validation/quality enforcement is more restrictive today than ever before. OEMs are clearly looking for suppliers that can embrace (and pass) the increased regulatory scrutiny from OEMs and the FDA. Although regulation often is regarded as a complication that burns up time and increases costs, it also can be a valuable strategic advantage. "A robust regulatory compliance system reduces risk for the supplier and the OEM, yielding an efficient commercialization process," said Stetler. "There is a tremendous amount of work associated with such a step function change, which presents various challenges on its own. Strong regulatory control offers OEMs assurance that their supply chains are viable and will remain intact during an FDA audit."

Because of increased FDA scrutiny, OEMs are auditing their vendors' validation activities more frequently.

"We are getting increases in audits from our customers," said Zuzula. "We have assembled a quality management team, drawing from all our divisions. Its mission is to make certain our validation/ standardization procedures meet the good manufacturing practices (GMPs) established by the FDA. If you don't have these processes in place already, it will be costly to get up to speed. However, it has become the ante-if you don't meet or exceed the GMPs you're basically out of the game. Quality must be measurable and predictable in all your equipment, operations and processes at all times if you want to stay in the implant business."

David said medical device companies increasingly are "getting onboard" with complete master validation plan requirements.

"3D Medical is seeing more upfront validation study requirements prior to production from our customers," he said.

Such enforcement efforts require organizations to become more responsive to particular project needs and identify potential validation issues sooner. OEMs that allow suppliers to engage earlier in the development process will shorten their time to market as they allow suppliers to execute validation protocols in advance of design transfer.

"This type of sourcing will change the way the industry interacts with its supply base, improving the process in the long run," said Stetler.

The FDA also recently has heightened its scope of new product and 510(k) acceptance levels. Significant testing may be required to claim equivalency rather than using another product's testing results already on the market.

"Customer validation requirements continue to increase as process capability and requirements tighten and further emphasis on process controls are put in place," said Tuchel.

Zuzula said the increased vigilance by FDA means contract manufacturers need to offer products and services that are better than they did before.

"The core purpose of lean manufacturing is continuous improvement, removing waste, streamlining processes and always getting better," Zuzula said. "Ultimately you want a complete lean enterprise that is linked to the vendors in your supply chain-this is the best way to add value and be positioned to meet the newest OEM expectations."

Challenges Ahead

The biggest challenge for contract manufacturers is to improve on all fronts, at all times, to keep OEMs satisfied. To accomplish this, continual improvement must be part of corporate culture. Waste must be stripped and value added wherever possible. Value-added services include automated in-process inspection, increased documentation and administration, design and engineering services, packaging/ cleaning, inventory management, distribution and total supply chain management, from "dock to stock." Long-term agreements that focus on reducing overall supply chain costs also are reassuring to OEMs.

Forecasting fluctuations always is challenging in an uneven economy. As a hedge against fluctuations, OEMs are requesting more managed inventory systems from their vendors. Managing this ebb and flow of customer orders as their outsourcing needs vary is part art and part science. Flexible manufacturing schedules are helpful for accommodating growth and capacity changes; outstanding communication, via software and frequent phone interactions, is essential to launch nimble responses.

Balancing Lean manufacturing principles with what seems like ever-changing (sometimes weekly) customer needs depends on developing and maintaining the critical relationship between the OEM buyer and the contract manufacturer's planners. The same principles apply for supply chain relationships.

"We meet with our main titanium resource at least four to five times a year, who really has the same values we do, so we are very fortunate to be working with people who are equally aligned with our mission and values," said Tuller.

Customers' implant design and manufacturing requirements continue to evolve, which may depend on new materials that need different machining techniques.

"With the advances made in minimally invasive and computer-aided surgeries, we see implant designs bringing new challenges to our teams, such as increasing longevity and being able to insert the implant in a smaller area within the wound site," said Tuchel. "This usually requires tighter tolerance machining."

And, of course, there always will be regulatory challenges. "In my opinion, the biggest challenges faced by suppliers today relate to the multiple interpretations of the regulatory agencies by the OEMs," said Stetler. "Each OEM interprets and initiates actions to satisfy their organization's requirements. These interpretations can vary greatly from OEM to OEM, forcing the supply base to have extremely customizable systems adaptable to each need, while still offering cost and lead time advantages. Success depends on outstanding communication. It's a constant effort to keep all key managers in synch with customer and business needs. It's very easy to make things complex; it is very difficult to keep them simple."