Michael Barbella, Managing Editor03.31.21

Last spring, Vexos Inc. received a federal contract to produce 10,000 mechanical ventilators for COVID-19 patients in Canada. The global electronics manufacturing services (EMS) and custom material solutions provider was part of a consortium that worked to ensure the Land of Maple Syrup had a sufficient ventilator supply for its hospitalized patients.

Vexos worked with Elemaster Group and JMP Solutions to manufacture the Mechanical Ventilator Milano (MVM), an electrically operated, microprocessor-controlled, pneumatically driven machine. The project truly was a collaborative effort: Elemaster designed the ventilator, JPM Solutions made the mechanical sub-assembly, and Vexos provided the electronics (and tested the device).

“We recognized the need to partner with an experienced EMS organization with strong manufacturing and supply chain presence in the medical sector, and the ability to meet U.S. and Canadian regulatory requirements,” Elemaster President/CEO Gabriele Cogliati said. “In Vexos, we have a partner that aligns with us and our goal, to provide the MVM Ventilator globally.”

Such partnerships were commonplace in the pandemic’s early days as companies from all walks of life (including healthcare) turned to EMS providers for help in navigating COVID-19-induced supply chain challenges and equipment shortages. Their expertise particularly was crucial in maintaining device connectivity and meeting the skyrocketing demand for telehealth services and remote patient monitoring technology.

Medical Product Outsourcing’s January/February feature, Virtual Allies, examines the key role EMS providers played in helping address the medtech industry’s quickly-changing needs. Thomas Allen, vice president at Elgin, Ill.-based TRICOR Systems Inc., was among the experts interviewed for the story. His full input is provided in the following Q&A.

Michael Barbella: Please discuss the latest trends in EMS outsourcing.

Thomas Allen: What are customers demanding of their EMS providers? OEMs are looking for on time delivery, reliable quality systems and ISO certification with FDA-registered facilities.

Barbella: What qualities do OEMs look for in selecting EMS providers? How has this changed over the last five years (if at all)?

Allen: When selecting an EMS provider, OEMs are looking for companies that will not only build their product but offer suggestions for product design improvement, cost savings and repairs. In the last five years U.S. OEM have started reshoring their products as tariffs have been imposed. With the recent pandemic there has been another shift to reshoring as the uncertainty of producibility and delivery due to government shut downs and parts availability have impacted manufacturing.

Barbella: Please discuss the biggest challenges EMS providers face regarding technology in the next 5 years. How is your company addressing these challenges?

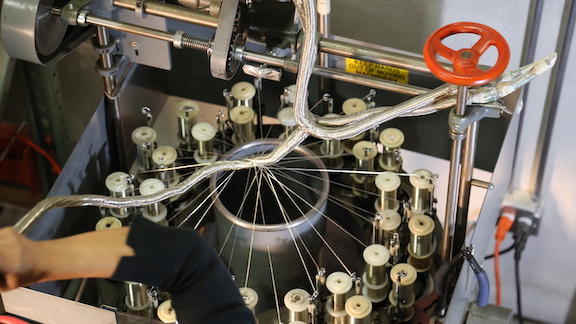

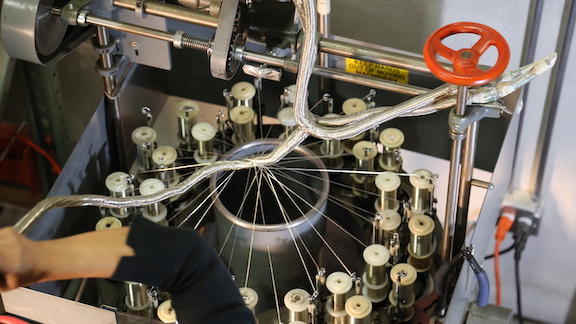

Allen: I don’t really think we know what our biggest challenge is going to be, in 2019 if this question was asked, I would not have replied a worldwide pandemic. But here we are a year later and a lot wiser. The challenges we face as EMS providers will remain similar to what we have faced in the past. Number one will always be a talented labor pool. If you are making something on an assembly line and one person’s job is to tighten screws, you will find someone, but if you are making something that requires a person to read a drawing, create a cable, wire a system, and install it into a medical product you will have a much more difficult time. TRICOR is always on the lookout for talented electrical assemblers and utilizes several companies in the search.

Skilled electrical assemblers for medical products are a valuable asset to EMS providers. Image courtesy of TRICOR Systems Inc.

Barbella: There has been a big push in many areas of healthcare for environmentally-friendly (“green”) manufacturing and products. Is this also true in the EMS space? If so, how are EMS providers helping customers be more green in their product development and/or manufacturing?

Allen: EMS manufactures continue to design with more lead-free parts and solder. When possible, recycled and recyclable packaging material is utilized and an effort to reduce waste by better packaging design.

Barbella: How has the OEM-EMS provider relationship changed in the wake of COVID-19?

Allen: For TRICOR the change has been minimal. OEMs still want their products on time but are understanding regarding delays due to material shortages

Barbella: What lessons—if any—have EMS providers learned from the pandemic that they can carry forward once the virus is brought under control?

Allen: Shut downs and slow production equals price increases. We continue to get notices of price increases due to material shortages and lack of time to manufacture. This has also affected lead times for certain components with deliveries pushed to a year away or longer.

Barbella: How were EMS providers’ supply chain management skills tested by the pandemic? How did your company respond to the challenge?

Allen: In the February/March [2020] time frame TRICOR started looking at daily usage supplies that were necessary to continue operation to identify where shortages were sure to be. Two such items were isopropyl alcohol used daily and disinfecting wipes used to clean medical equipment. These items were quickly ordered. Other component parts for equipment builds became more challenging, so we reach out more frequently to vendors to get a better understanding of their ability to deliver. This helped not only in scheduling but in providing our customers realistic delivery schedules sooner rather than later.

Vexos worked with Elemaster Group and JMP Solutions to manufacture the Mechanical Ventilator Milano (MVM), an electrically operated, microprocessor-controlled, pneumatically driven machine. The project truly was a collaborative effort: Elemaster designed the ventilator, JPM Solutions made the mechanical sub-assembly, and Vexos provided the electronics (and tested the device).

“We recognized the need to partner with an experienced EMS organization with strong manufacturing and supply chain presence in the medical sector, and the ability to meet U.S. and Canadian regulatory requirements,” Elemaster President/CEO Gabriele Cogliati said. “In Vexos, we have a partner that aligns with us and our goal, to provide the MVM Ventilator globally.”

Such partnerships were commonplace in the pandemic’s early days as companies from all walks of life (including healthcare) turned to EMS providers for help in navigating COVID-19-induced supply chain challenges and equipment shortages. Their expertise particularly was crucial in maintaining device connectivity and meeting the skyrocketing demand for telehealth services and remote patient monitoring technology.

Medical Product Outsourcing’s January/February feature, Virtual Allies, examines the key role EMS providers played in helping address the medtech industry’s quickly-changing needs. Thomas Allen, vice president at Elgin, Ill.-based TRICOR Systems Inc., was among the experts interviewed for the story. His full input is provided in the following Q&A.

Michael Barbella: Please discuss the latest trends in EMS outsourcing.

Thomas Allen: What are customers demanding of their EMS providers? OEMs are looking for on time delivery, reliable quality systems and ISO certification with FDA-registered facilities.

Barbella: What qualities do OEMs look for in selecting EMS providers? How has this changed over the last five years (if at all)?

Allen: When selecting an EMS provider, OEMs are looking for companies that will not only build their product but offer suggestions for product design improvement, cost savings and repairs. In the last five years U.S. OEM have started reshoring their products as tariffs have been imposed. With the recent pandemic there has been another shift to reshoring as the uncertainty of producibility and delivery due to government shut downs and parts availability have impacted manufacturing.

Barbella: Please discuss the biggest challenges EMS providers face regarding technology in the next 5 years. How is your company addressing these challenges?

Allen: I don’t really think we know what our biggest challenge is going to be, in 2019 if this question was asked, I would not have replied a worldwide pandemic. But here we are a year later and a lot wiser. The challenges we face as EMS providers will remain similar to what we have faced in the past. Number one will always be a talented labor pool. If you are making something on an assembly line and one person’s job is to tighten screws, you will find someone, but if you are making something that requires a person to read a drawing, create a cable, wire a system, and install it into a medical product you will have a much more difficult time. TRICOR is always on the lookout for talented electrical assemblers and utilizes several companies in the search.

Skilled electrical assemblers for medical products are a valuable asset to EMS providers. Image courtesy of TRICOR Systems Inc.

Barbella: There has been a big push in many areas of healthcare for environmentally-friendly (“green”) manufacturing and products. Is this also true in the EMS space? If so, how are EMS providers helping customers be more green in their product development and/or manufacturing?

Allen: EMS manufactures continue to design with more lead-free parts and solder. When possible, recycled and recyclable packaging material is utilized and an effort to reduce waste by better packaging design.

Barbella: How has the OEM-EMS provider relationship changed in the wake of COVID-19?

Allen: For TRICOR the change has been minimal. OEMs still want their products on time but are understanding regarding delays due to material shortages

Barbella: What lessons—if any—have EMS providers learned from the pandemic that they can carry forward once the virus is brought under control?

Allen: Shut downs and slow production equals price increases. We continue to get notices of price increases due to material shortages and lack of time to manufacture. This has also affected lead times for certain components with deliveries pushed to a year away or longer.

Barbella: How were EMS providers’ supply chain management skills tested by the pandemic? How did your company respond to the challenge?

Allen: In the February/March [2020] time frame TRICOR started looking at daily usage supplies that were necessary to continue operation to identify where shortages were sure to be. Two such items were isopropyl alcohol used daily and disinfecting wipes used to clean medical equipment. These items were quickly ordered. Other component parts for equipment builds became more challenging, so we reach out more frequently to vendors to get a better understanding of their ability to deliver. This helped not only in scheduling but in providing our customers realistic delivery schedules sooner rather than later.