Sean Fenske, Editor-in-Chief09.28.20

Prior to the pandemic, healthcare-acquired infections were a serious concern. With insurance companies changing how such issues were reimbursed should patients get sick as a result (i.e., they weren’t reimbursing for it), it became even more critical for healthcare facilities to determine best practices for eliminating the risk as much as possible.

Enter the COVID-19 pandemic. Disinfecting surfaces in the age of the pandemic brought about an even greater need. Hospitals had to not only prevent spread of the coronavirus among patients, but also had to ensure its own staff were safe. Demand for technologies that could eliminate the virus grew exponentially.

UV-Concepts began offering UV-based disinfection technologies well before the pandemic hit, but in the face of coronavirus, their solution certain gained attention. Taking time to speak with MPO about the system, UV technologies, and infection control was Jeremy Starkweather, the president of UV-Concepts Inc.

Sean Fenske: Can you please explain your UV technology and generally how it works?

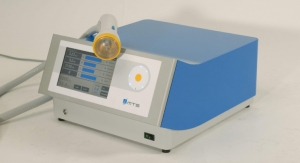

By completely surrounding portable medical equipment within a fully-enclosed, highly-reflective space the size of a photo booth, the UVE delivers a very precise dose into areas that would normally be challenging for traditional UV light systems. Image courtesy of UV-Concepts.

Jeremy Starkweather: For its size, the UV-C Enclosure (UVE) is the fastest and most powerful UV-C technology in healthcare due to the dosage of UV light it delivers within a 60-second disinfection cycle. UV light is only effective if you can deliver the correct dosage to a surface, and that’s what the UVE does well. By completely surrounding portable medical equipment within a fully-enclosed, highly-reflective space the size of a photo booth, the UVE delivers a very precise dose into areas that would normally be challenging for traditional UV light systems.

Due to the novel design, the UVE requires a shorter cycle time vs. other disinfection technologies, such as chemical disinfectants, hydrogen peroxide vapor, misting units, or electrostatic spraying units. These are effective platforms for certain applications but require much longer cycle times and chemical dwell times.

Another distinction of the purpose built UVE platform: It can be used directly within an active work environment without disrupting daily workflow because it protects the outside environment from the disinfecting technology during the 60-second, automated cycle. A lot of other techniques either require you to seal off a room, or have special ventilation, plumbing, or electricity. That creates downtime in workflow efficiency because you may need to keep a room free of anything or any living person for an extended period of time.

Fenske: Pre-COVID, what was the appeal of using UV technology in a healthcare setting?

Starkweather: Well before the emergence of the pandemic, there were recognized risks and challenges with the disinfection of high touch surfaces and portable medical equipment (PME) in the healthcare setting.

As early as the 1980s, infection control experts linked pathogens on the wheels of a wheelchair as the vector of transmission from one hospital ward to another Their observation was then quantified into two separate studies published in 2014 and 2018, which showed high rates of contamination on wheelchairs in a hospital environment. The first study found as much as 47 percent of the wheelchairs harbored C. difficile and MRSA—two strains of bacteria that can cause difficult-to-treat, if not life-threatening, infections in humans. Other researchers have identified multiple variabilities associated with the manual disinfection of PME; and following the results of another analysis, a team in Canada recommended improved management and protocols with dedicated personnel working on process management.

Wheelchairs are just one example of the many high-touch pieces of equipment that move from multiple treatment areas and sensitive environments that can be a potential vector of transmission for infectious pathogens.

Based on the clear evidence that a problem existed with the disinfection of PME, our team at UV-Concepts spent years developing an ecosystem solution comprised of the UVE, digital tags, and a cloud-based process management program. We’ve developed a broader strategy for the process and quality improvement of PME disinfection protocols that, before the pandemic, had unique utility, has tremendous utility now for the disinfection of PPE during the pandemic, and will continue to have utility well after the pandemic.

Fenske: What has the interest been in the technology since the start of the pandemic?

Starkweather: Since the start of the pandemic, interest in the UVE system has grown exponentially from our existing installation base of hospital customers. We’ve seen our current hospital clients expand their use of the UVE system to broader disinfection applications of medical equipment and personal protection equipment (PPE). We’re also now seeing an uptick in interest from non-healthcare sectors, such as first responders, professional sports teams, and corporations looking to protect their employees by disinfecting high touch surfaces and packages coming in and out of the office environment.

Fenske: How effective is UV on surfaces exposed to COVID?

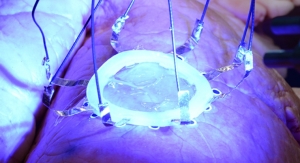

Starkweather: Direct exposure to UV light is essential for disinfecting equipment, but the most important areas that need to receive light are the ones that are touched by hands, such as the handles on medical equipment or keyboards. The UVE exposes these high-touch areas of equipment with a UV-C dose that is powerful enough to kill even the most drug-resistant microorganisms, and on non-porous surfaces, the UVE delivers 20 times the energy needed to completely inactive coronaviruses.

The UVE delivers about 380 mJ/cm2 of UV-C at 60 seconds, and in about 200 seconds, it delivers 1,000 mJ/cm2 of UV-C. We measure the UV-C dose from the middle of the UVE, which is the furthest distance away from the light sources. So, we know the exact dosage in the center of the UVE, and that gives us the confidence that anything closer to the lamps is receiving potentially an even higher dose.

Fenske: Are there settings/technologies in a healthcare setting where UV can’t be used?

Starkweather: UV-C is highly effective for the disinfection of non-porous, hard surfaces, but is less effective in disinfecting porous surfaces, such as fabrics. Other considerations are ensuring there’s a clear line of sight with UV-C to have a disinfecting effect.

Fenske: Are medical device manufacturers looking to use UV technologies within their facilities? If so, how and why?

Starkweather: We are talking to medical device companies and their equipment manufacturers about the compatibility of their device surfaces with UV-C disinfection, in terms of preserving the integrity of surfaces without degradation. One nice thing about UV light on hard surfaces is the depth of penetration of UV light is minimal. So pathogens are killed, without deeply going into the surface. We believe the UVE will have less of an impact on surface degradation than chemical disinfectants, which can have a hard impact on human skin and be especially harsh on surfaces.

Fenske: Are there opportunities to incorporate UV technologies into medical devices?

Starkweather: I think there are opportunities as UV-C LED technologies continue to develop. There are some UV-C LED companies that are pursuing niche application paths. As of now, UV-Concepts does not have plans underway.

Fenske: What’s ahead for UV technologies? What do you foresee in five to ten years?

Starkweather: What's ahead for UV-C light disinfection is the recognition that it's highly effective for many broad applications. Up until the last 10 years, it was primarily just used in air and water, and in the last 10 years, there’s been greater recognition of surface contamination and the effectiveness of UV-C disinfection. So, I think we’ll see greater adoption by many markets with healthcare being the most prominent one. Hopefully, that brings new ideas and new inventions to the table.

Fenske: Do you have any additional comments or thoughts you’d like to share?

Starkweather: UV-Concepts has the most powerful UV-C disinfecting platform in healthcare that is purpose built for medical equipment but has even broader applications in non-healthcare markets.

The UVE has a robust protocol management platform that brings a level of automation, repeatability, and absolute consistency to the disinfection process. The system has an automated means of keeping track of disinfecting protocols for specific equipment, which has led to broader use and applications within hospitals, such as burn wards, transplant centers, and facilities where the most immune-compromised patients are surrounded by portable medical equipment for interventional and diagnostic use.

The beauty about UVE is you can train hundreds of people to use it, and they will use it the exact same way every single time. So you don't have to be an expert in environmental cleaning to use our product. You need to be able to walk up and swipe your badge to start the unit.

Enter the COVID-19 pandemic. Disinfecting surfaces in the age of the pandemic brought about an even greater need. Hospitals had to not only prevent spread of the coronavirus among patients, but also had to ensure its own staff were safe. Demand for technologies that could eliminate the virus grew exponentially.

UV-Concepts began offering UV-based disinfection technologies well before the pandemic hit, but in the face of coronavirus, their solution certain gained attention. Taking time to speak with MPO about the system, UV technologies, and infection control was Jeremy Starkweather, the president of UV-Concepts Inc.

Sean Fenske: Can you please explain your UV technology and generally how it works?

By completely surrounding portable medical equipment within a fully-enclosed, highly-reflective space the size of a photo booth, the UVE delivers a very precise dose into areas that would normally be challenging for traditional UV light systems. Image courtesy of UV-Concepts.

Due to the novel design, the UVE requires a shorter cycle time vs. other disinfection technologies, such as chemical disinfectants, hydrogen peroxide vapor, misting units, or electrostatic spraying units. These are effective platforms for certain applications but require much longer cycle times and chemical dwell times.

Another distinction of the purpose built UVE platform: It can be used directly within an active work environment without disrupting daily workflow because it protects the outside environment from the disinfecting technology during the 60-second, automated cycle. A lot of other techniques either require you to seal off a room, or have special ventilation, plumbing, or electricity. That creates downtime in workflow efficiency because you may need to keep a room free of anything or any living person for an extended period of time.

Fenske: Pre-COVID, what was the appeal of using UV technology in a healthcare setting?

Starkweather: Well before the emergence of the pandemic, there were recognized risks and challenges with the disinfection of high touch surfaces and portable medical equipment (PME) in the healthcare setting.

As early as the 1980s, infection control experts linked pathogens on the wheels of a wheelchair as the vector of transmission from one hospital ward to another Their observation was then quantified into two separate studies published in 2014 and 2018, which showed high rates of contamination on wheelchairs in a hospital environment. The first study found as much as 47 percent of the wheelchairs harbored C. difficile and MRSA—two strains of bacteria that can cause difficult-to-treat, if not life-threatening, infections in humans. Other researchers have identified multiple variabilities associated with the manual disinfection of PME; and following the results of another analysis, a team in Canada recommended improved management and protocols with dedicated personnel working on process management.

Wheelchairs are just one example of the many high-touch pieces of equipment that move from multiple treatment areas and sensitive environments that can be a potential vector of transmission for infectious pathogens.

Based on the clear evidence that a problem existed with the disinfection of PME, our team at UV-Concepts spent years developing an ecosystem solution comprised of the UVE, digital tags, and a cloud-based process management program. We’ve developed a broader strategy for the process and quality improvement of PME disinfection protocols that, before the pandemic, had unique utility, has tremendous utility now for the disinfection of PPE during the pandemic, and will continue to have utility well after the pandemic.

Fenske: What has the interest been in the technology since the start of the pandemic?

Starkweather: Since the start of the pandemic, interest in the UVE system has grown exponentially from our existing installation base of hospital customers. We’ve seen our current hospital clients expand their use of the UVE system to broader disinfection applications of medical equipment and personal protection equipment (PPE). We’re also now seeing an uptick in interest from non-healthcare sectors, such as first responders, professional sports teams, and corporations looking to protect their employees by disinfecting high touch surfaces and packages coming in and out of the office environment.

Fenske: How effective is UV on surfaces exposed to COVID?

Starkweather: Direct exposure to UV light is essential for disinfecting equipment, but the most important areas that need to receive light are the ones that are touched by hands, such as the handles on medical equipment or keyboards. The UVE exposes these high-touch areas of equipment with a UV-C dose that is powerful enough to kill even the most drug-resistant microorganisms, and on non-porous surfaces, the UVE delivers 20 times the energy needed to completely inactive coronaviruses.

The UVE delivers about 380 mJ/cm2 of UV-C at 60 seconds, and in about 200 seconds, it delivers 1,000 mJ/cm2 of UV-C. We measure the UV-C dose from the middle of the UVE, which is the furthest distance away from the light sources. So, we know the exact dosage in the center of the UVE, and that gives us the confidence that anything closer to the lamps is receiving potentially an even higher dose.

Fenske: Are there settings/technologies in a healthcare setting where UV can’t be used?

Starkweather: UV-C is highly effective for the disinfection of non-porous, hard surfaces, but is less effective in disinfecting porous surfaces, such as fabrics. Other considerations are ensuring there’s a clear line of sight with UV-C to have a disinfecting effect.

Fenske: Are medical device manufacturers looking to use UV technologies within their facilities? If so, how and why?

Starkweather: We are talking to medical device companies and their equipment manufacturers about the compatibility of their device surfaces with UV-C disinfection, in terms of preserving the integrity of surfaces without degradation. One nice thing about UV light on hard surfaces is the depth of penetration of UV light is minimal. So pathogens are killed, without deeply going into the surface. We believe the UVE will have less of an impact on surface degradation than chemical disinfectants, which can have a hard impact on human skin and be especially harsh on surfaces.

Fenske: Are there opportunities to incorporate UV technologies into medical devices?

Starkweather: I think there are opportunities as UV-C LED technologies continue to develop. There are some UV-C LED companies that are pursuing niche application paths. As of now, UV-Concepts does not have plans underway.

Fenske: What’s ahead for UV technologies? What do you foresee in five to ten years?

Starkweather: What's ahead for UV-C light disinfection is the recognition that it's highly effective for many broad applications. Up until the last 10 years, it was primarily just used in air and water, and in the last 10 years, there’s been greater recognition of surface contamination and the effectiveness of UV-C disinfection. So, I think we’ll see greater adoption by many markets with healthcare being the most prominent one. Hopefully, that brings new ideas and new inventions to the table.

Fenske: Do you have any additional comments or thoughts you’d like to share?

Starkweather: UV-Concepts has the most powerful UV-C disinfecting platform in healthcare that is purpose built for medical equipment but has even broader applications in non-healthcare markets.

The UVE has a robust protocol management platform that brings a level of automation, repeatability, and absolute consistency to the disinfection process. The system has an automated means of keeping track of disinfecting protocols for specific equipment, which has led to broader use and applications within hospitals, such as burn wards, transplant centers, and facilities where the most immune-compromised patients are surrounded by portable medical equipment for interventional and diagnostic use.

The beauty about UVE is you can train hundreds of people to use it, and they will use it the exact same way every single time. So you don't have to be an expert in environmental cleaning to use our product. You need to be able to walk up and swipe your badge to start the unit.