Lars Thording, VP of Marketing & Public Affairs at Innovative Health LLC07.09.20

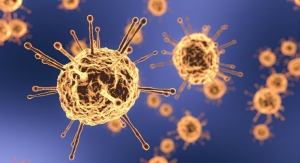

Catheter ablation is one of the fastest growing service lines in U.S. healthcare. More and more patients are diagnosed with atrial fibrillation (AFib) and similar conditions, and electrophysiology (EP) labs are treating them as fast as they can diagnose them.

Improvements in catheter ablation technology and methodology are not only having a great impact on patients and their quality of life, but are also making a mark financially: A new economic analysis estimates that $2.5 billion will be spent in 2020 on medical devices used for catheter ablation. At the level of the individual procedure, an AFib procedure absorbs about $10,500 in medical device costs alone. Commercial reimbursement for the procedure averages $33,417, while Centers for Medicare and Medicaid Services (CMS) reimburses catheter ablation as an outpatient procedure at about $20,700. This means catheter ablations are an important driver of profits where the payer mix is favorable – and that the financial sustainability of catheter ablation procedures is questionable where it is not.

For device manufacturers, this delicate cost balance is going to become more important than ever going forward, as hospitals become less tolerant of higher costs for new technology, as well as the waste associated with single-use devices.

When device costs are 50 percent of reimbursement, the financial equation is tough. And while CMS reimbursement has been going up in recent years, the constant and frequent roll-out of new catheter ablation technology is driving device costs up.

This makes catheter ablation critically important from a financial perspective for many hospitals that offer EP procedures. This has become even more apparent after April and May, where hospitals experienced a mandatory shut-down of elective procedures. While catheter ablation procedures are among the procedures that usually present the hospital with a net profit, patient care and ICU units that take care of COVID-19 patients are less profitable. So, the shut-down stopped the profitable procedures and ramped up unprofitable activities. Modern Healthcare reported that hospital revenue fell 40-60 percent and YTD March operating income across U.S. hospitals was -8.1 percent. By May, this number was -18 percent.

Lessons from the Pandemic

To remain competitive in the future, device manufacturers need an appreciation of the challenges facing today’s hospitals. As hospitals take stock of their situations and evaluate how to manage costs, demand, and service line activities in a prolonged COVID-19 crisis, they need to look more fundamentally at technology utilization. Elective surgeries such as catheter ablation have opened up, although not yet at 100 percent. There are three important lessons to be learned from the COVID-19 pandemic:

1. “Elective” procedures may threaten public health in a pandemic in the short term, but in the long term, elective procedures are necessary for the financial sustainability of the hospital – and therefore for public health. Hospitals need to find a way to continue elective procedures during a pandemic, by leaning out and better controlling the supply chain, and by finding an operational “fix” to a situation where very sick people as well as less sick people have to enter the hospital. Pent up demand for catheter ablations from the shut-down presents both a financial opportunity and a public health issue. This puzzle needs to be solved.

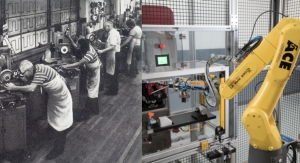

2. Technology adoption needs to be managed from a combined patient care and financial perspective. The ultra-thin margins on which hospitals operate will no longer tolerate blind adoption of new technology just because it is “new technology,” or even if such technology offers marginally better patient outcomes. This is because new technology is almost always more expensive than “old technology,” and hospitals need resilience and reserve in their supply chain to be able to address pandemic-style demand shifts.

3. Healthcare in general needs to adopt a different view on how technology is used. The environmental movement has created markets for recycling, repair services, and new products to embrace the idea that “things shouldn’t be used and thrown away.” The mantra of “reduce, reuse, recycle” has altered many industries, but healthcare, which is the second-largest generator of garbage in our economy, has not caught up. Instead, more and more devices are labeled “single-use,” and garbage truck after garbage truck hauls away medical and hospital waste from the hospital every day.

Financial and Environmental Drivers in Healthcare

During the Spring months of the pandemic where hospitals experienced a surge in critically ill patients, personal protective equipment (PPE) was in short supply, and hospitals, desperate to protect staff as well as patients, had to change the way they looked at face masks, gloves, shields, and gowns. Hospital staff was employed to sew face masks and asked to reuse them. Emergency Use Authorizations (EUAs) created a pathway for reprocessing and reusing PPE, at standards that were different and lower than normal standards for such practices. Essentially, a mindset change was demanded: “This is not garbage, this is an asset.”

Reusing medical devices is not a new idea for hospitals that clean thousands of devices in their Sterile Processing Department (SPD) every day, but all of a sudden, the scope has changed, and broader reform of technology utilization is now on the agenda.

The COVID-19 pandemic has created a confluence of the environmental and financial change drivers in healthcare. Reusing medical devices drives the cost savings necessary to stay resilient and prepared from a supply chain perspective, and it reduces costs to ensure that elective procedures drive profits for the hospital. It also ensures that fewer garbage trucks leave the hospital every day, and that environmental damage is reduced. In Europe and elsewhere, the term “circular economy” has become popular to represent this confluence of the values behind financial and environmental sustainability: If hospitals don’t throw away devices, but re-use them, they save the environment, and they reduce costs. “Circular economy” has indeed become a rallying cry behind efforts to redirect resource utilization in general and make it more sustainable.

For manufacturers in healthcare, this represents a problem and an opportunity. American MedTech companies are driven by patient care demand to constantly launch new technologies (that are more expensive), to ensure these technologies drive the largest possible revenue, and to aggressively sell these new technologies to physicians and other healthcare professionals. American MedTech companies are not operating from a circular economy perspective, but there is an opportunity for companies to embrace the concept of the circular economy.

They can do this by:

In the specific case of catheter ablation, the circular economy mindset serves to address all three lessons learned from the pandemic. Single-use device reprocessing has been a common practice in most U.S. hospitals for decades, but recently, a surge in clearances for devices used in catheter ablations has shined a light on electrophysiology as an area of opportunity for cost savings. Single-use device reprocessing companies must go through an extensive, strict clearance process with FDA prior to being able to reprocess single-use devices and bring them back to the hospital for another use. This clearance process mirrors what other manufacturers have to go through, and clearance is only granted when data has demonstrated that reprocessed devices are functionally the same as new and do not present any added patient risk.

Reprocessed devices are typically about half the price of new devices, and EP labs that embrace reprocessing can save almost 30 percent in device costs per catheter ablation procedure, equivalent to more than $3,000. This can change the equation for hospitals whose patient populations are largely CMS reimbursed and make catheter ablation a stronger profit contributor to hospitals struggling financially with the conditions of a pandemic. This also frees the extra resources hospitals need to juggle supply chain demands in the era of specific supply shortages.

It would benefit manufacturers in the catheter ablation space to take a circular economy approach to their technology development and launches. This includes embracing reprocessing as a much-needed extension of the single-use lifetime of so many devices, so that hospitals can reduce waste and adopt new technologies with less impact on profitability. Based on current FDA clearances, fully leveraging single-use device reprocessing can save U.S. healthcare more than $700 million, reducing device spend from $2.5 billion to $1.8 billion.

In addition to embracing single-use device reprocessing, the future will favor manufacturers that deliberately design technologies for re-use and balance the lure of new technology with the need for hospitals to remain financially stable.

Lars Thording, PhD, has a background in academia, consulting and industry leadership. He has been responsible for the launch of numerous market-disrupting solutions across healthcare, insurance and technology. Originally from Denmark, Thording has taught at universities in Denmark, Ireland and the United States. He currently serves as the vice president of marketing and public affairs at Innovative Health, a medical device reprocessing company specializing in electrophysiology and cardiology technology. Thording currently serves on the board of the Association of Medical Device Reprocessors.

Improvements in catheter ablation technology and methodology are not only having a great impact on patients and their quality of life, but are also making a mark financially: A new economic analysis estimates that $2.5 billion will be spent in 2020 on medical devices used for catheter ablation. At the level of the individual procedure, an AFib procedure absorbs about $10,500 in medical device costs alone. Commercial reimbursement for the procedure averages $33,417, while Centers for Medicare and Medicaid Services (CMS) reimburses catheter ablation as an outpatient procedure at about $20,700. This means catheter ablations are an important driver of profits where the payer mix is favorable – and that the financial sustainability of catheter ablation procedures is questionable where it is not.

For device manufacturers, this delicate cost balance is going to become more important than ever going forward, as hospitals become less tolerant of higher costs for new technology, as well as the waste associated with single-use devices.

When device costs are 50 percent of reimbursement, the financial equation is tough. And while CMS reimbursement has been going up in recent years, the constant and frequent roll-out of new catheter ablation technology is driving device costs up.

This makes catheter ablation critically important from a financial perspective for many hospitals that offer EP procedures. This has become even more apparent after April and May, where hospitals experienced a mandatory shut-down of elective procedures. While catheter ablation procedures are among the procedures that usually present the hospital with a net profit, patient care and ICU units that take care of COVID-19 patients are less profitable. So, the shut-down stopped the profitable procedures and ramped up unprofitable activities. Modern Healthcare reported that hospital revenue fell 40-60 percent and YTD March operating income across U.S. hospitals was -8.1 percent. By May, this number was -18 percent.

Lessons from the Pandemic

To remain competitive in the future, device manufacturers need an appreciation of the challenges facing today’s hospitals. As hospitals take stock of their situations and evaluate how to manage costs, demand, and service line activities in a prolonged COVID-19 crisis, they need to look more fundamentally at technology utilization. Elective surgeries such as catheter ablation have opened up, although not yet at 100 percent. There are three important lessons to be learned from the COVID-19 pandemic:

1. “Elective” procedures may threaten public health in a pandemic in the short term, but in the long term, elective procedures are necessary for the financial sustainability of the hospital – and therefore for public health. Hospitals need to find a way to continue elective procedures during a pandemic, by leaning out and better controlling the supply chain, and by finding an operational “fix” to a situation where very sick people as well as less sick people have to enter the hospital. Pent up demand for catheter ablations from the shut-down presents both a financial opportunity and a public health issue. This puzzle needs to be solved.

2. Technology adoption needs to be managed from a combined patient care and financial perspective. The ultra-thin margins on which hospitals operate will no longer tolerate blind adoption of new technology just because it is “new technology,” or even if such technology offers marginally better patient outcomes. This is because new technology is almost always more expensive than “old technology,” and hospitals need resilience and reserve in their supply chain to be able to address pandemic-style demand shifts.

3. Healthcare in general needs to adopt a different view on how technology is used. The environmental movement has created markets for recycling, repair services, and new products to embrace the idea that “things shouldn’t be used and thrown away.” The mantra of “reduce, reuse, recycle” has altered many industries, but healthcare, which is the second-largest generator of garbage in our economy, has not caught up. Instead, more and more devices are labeled “single-use,” and garbage truck after garbage truck hauls away medical and hospital waste from the hospital every day.

Financial and Environmental Drivers in Healthcare

During the Spring months of the pandemic where hospitals experienced a surge in critically ill patients, personal protective equipment (PPE) was in short supply, and hospitals, desperate to protect staff as well as patients, had to change the way they looked at face masks, gloves, shields, and gowns. Hospital staff was employed to sew face masks and asked to reuse them. Emergency Use Authorizations (EUAs) created a pathway for reprocessing and reusing PPE, at standards that were different and lower than normal standards for such practices. Essentially, a mindset change was demanded: “This is not garbage, this is an asset.”

Reusing medical devices is not a new idea for hospitals that clean thousands of devices in their Sterile Processing Department (SPD) every day, but all of a sudden, the scope has changed, and broader reform of technology utilization is now on the agenda.

The COVID-19 pandemic has created a confluence of the environmental and financial change drivers in healthcare. Reusing medical devices drives the cost savings necessary to stay resilient and prepared from a supply chain perspective, and it reduces costs to ensure that elective procedures drive profits for the hospital. It also ensures that fewer garbage trucks leave the hospital every day, and that environmental damage is reduced. In Europe and elsewhere, the term “circular economy” has become popular to represent this confluence of the values behind financial and environmental sustainability: If hospitals don’t throw away devices, but re-use them, they save the environment, and they reduce costs. “Circular economy” has indeed become a rallying cry behind efforts to redirect resource utilization in general and make it more sustainable.

For manufacturers in healthcare, this represents a problem and an opportunity. American MedTech companies are driven by patient care demand to constantly launch new technologies (that are more expensive), to ensure these technologies drive the largest possible revenue, and to aggressively sell these new technologies to physicians and other healthcare professionals. American MedTech companies are not operating from a circular economy perspective, but there is an opportunity for companies to embrace the concept of the circular economy.

They can do this by:

- Focusing on sustainable technology development – combining financial sustainability with technology advancement (launching technologies that are both better and cheaper), so that technology is adopted faster by hospitals that operate under financial strain.

- Developing reusable products – MedTech has been going in the opposite direction, increasingly launching “single-use” devices to drive revenue through new product sales; a return to reusable products could drive market share.

- Leveraging reprocessing – combining existing or new technology solutions with the ability to “reprocess” the devices in controlled, safe facilities; this could drive market share and show a commitment to the financial sustainability of hospitals.

In the specific case of catheter ablation, the circular economy mindset serves to address all three lessons learned from the pandemic. Single-use device reprocessing has been a common practice in most U.S. hospitals for decades, but recently, a surge in clearances for devices used in catheter ablations has shined a light on electrophysiology as an area of opportunity for cost savings. Single-use device reprocessing companies must go through an extensive, strict clearance process with FDA prior to being able to reprocess single-use devices and bring them back to the hospital for another use. This clearance process mirrors what other manufacturers have to go through, and clearance is only granted when data has demonstrated that reprocessed devices are functionally the same as new and do not present any added patient risk.

Reprocessed devices are typically about half the price of new devices, and EP labs that embrace reprocessing can save almost 30 percent in device costs per catheter ablation procedure, equivalent to more than $3,000. This can change the equation for hospitals whose patient populations are largely CMS reimbursed and make catheter ablation a stronger profit contributor to hospitals struggling financially with the conditions of a pandemic. This also frees the extra resources hospitals need to juggle supply chain demands in the era of specific supply shortages.

It would benefit manufacturers in the catheter ablation space to take a circular economy approach to their technology development and launches. This includes embracing reprocessing as a much-needed extension of the single-use lifetime of so many devices, so that hospitals can reduce waste and adopt new technologies with less impact on profitability. Based on current FDA clearances, fully leveraging single-use device reprocessing can save U.S. healthcare more than $700 million, reducing device spend from $2.5 billion to $1.8 billion.

In addition to embracing single-use device reprocessing, the future will favor manufacturers that deliberately design technologies for re-use and balance the lure of new technology with the need for hospitals to remain financially stable.

Lars Thording, PhD, has a background in academia, consulting and industry leadership. He has been responsible for the launch of numerous market-disrupting solutions across healthcare, insurance and technology. Originally from Denmark, Thording has taught at universities in Denmark, Ireland and the United States. He currently serves as the vice president of marketing and public affairs at Innovative Health, a medical device reprocessing company specializing in electrophysiology and cardiology technology. Thording currently serves on the board of the Association of Medical Device Reprocessors.