Matt Sand, President, 3DEO05.30.19

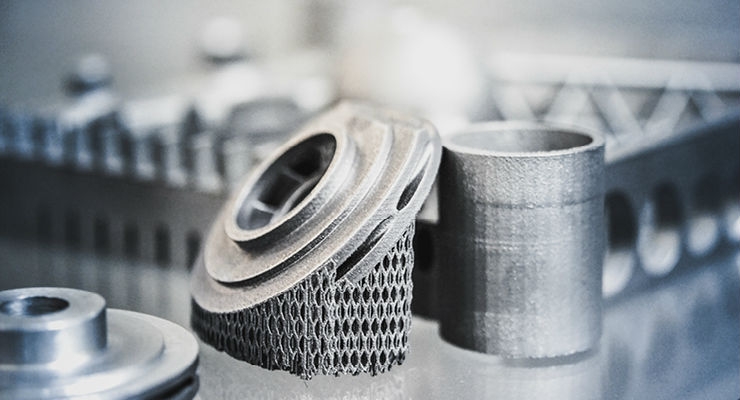

3D printing has left behind its days as an obscure, fledgling technology of dubious real-world value. In nearly all corners of the modern manufacturing environment, additive manufacturing (AM) is now recognized as a powerful manufacturing technology, particularly when it comes to complex designs and streamlining the supply chain. Still, the perception lingers that 3D printing is impractical for most companies, at least from a cost perspective.

While the business case for AM (and particularly metal AM) remains situation specific, there are certain fields in which the advantages of the technique shine through. Medical devices—and medtech more broadly—is one of those fields.

This article shows how medtech companies can leverage 3D metal printing to make better products more efficiently.

Why Metal 3D Printing and Medtech Are a Natural Match

The development requirements of medical devices play right into the strengths of 3D printing. This is due to the inherently complex, unique geometries combined with the low quantities of products required in medicine.

Many medical situations are unique, or at least nearly unique. Generally speaking, these situations call for products that perform highly specialized tasks—and perform them extraordinarily well. Human lives are at stake and the outcome of operations can hinge on the tiniest of details. Therefore, a part that is even marginally more effective at performing its task may be extremely valuable.

The trouble in the past has not been that such incremental improvements in performance are impossible to dream up. Rather, it’s that the best ideas of biomedical engineers have been difficult-to-impossible to execute upon. Physical manufacturing capabilities have lagged behind the creativity of designers.

Even more challenging than actually fabricating devices that are better at performing medical functions has been justifying their cost. More than one decision maker in a major healthcare organization has found themselves facing a tough problem. Sure, a machine designed this way might decrease the failure rate of a given surgery by 1 percent, but is it really worth it if the unit costs 10 times more?

The advent of next generation metal AM technologies has made the answers to these questions much more obvious. On a cost-per-part basis, the technology excels in applications where a relatively low volume of small, complex components are needed. Medtech, which often calls for parts either completely customized or replicated only in small amounts, is an ideal match.

3D Printed Medical Devices in Today’s World

This alignment is best illustrated using real examples. Consider, for instance, the world of ventricular assist devices (VADs). These components are literally designed to keep the hearts of patients with advanced heart failure beating. That’s a high-leverage situation that demands a precision-engineered, highly reliable product. The industry-leading HeartWare HVAD system from Medtronic is correspondingly complex, featuring a passive maglev pump system, dual motor stators, and a patented impeller in the world’s smallest VAD package.

A component that small and intricate would be extremely hard, if not impossible, to produce using traditional methods like CNC machining or metal injection molding (MIM). The set-up and tooling costs would be extreme, and wasted material would likely be a significant proportion of the total. Further, these disadvantages would not be offset by volume—the market-leading device is only used by 15,000 patients worldwide.

Metal AM, on the other hand, has no tooling costs, and adding significant design complexity does not add significantly to the cost of production. The extra costs associated with AM may be worth it because the process is able to eliminate extra costs associated with labor, molds, and fixtures.

3D printing means the absence of demand for a million HVADs is not an economic disqualifier. It allows an extremely detailed, superior product to be cost-effectively manufactured at whatever unit volume is required.

Brass Tacks: Breaking Down Final Part Cost

Does the example portend a future in which all medical technology is produced using AM? Answering that question requires a detailed understanding of the business case for this rapidly evolving manufacturing technique.

Perhaps no metric is more crucial to the long-term viability of any manufacturing situation than final part cost. Arriving at this figure involves tallying every expense associated with production of a given number of components and distributing that expense across whatever amount of components is ultimately produced. Whether the healthcare sector begins producing (or even just using) primarily 3D printed components depends on the final part cost associated with hundreds of thousands of unique manufacturing situations.

Lots of variables matter. Part complexity, ease of access to the technology itself, volume, location—all these factors play a role at the micro-level.

Final part cost of 3D printed components can be divided into four categories: machine amortization, materials, labor, and post-processing.

The math behind machine amortization is fairly simple. 3D printers, particularly those suited for industrial metals printing, can be very expensive. The facilities and infrastructure required to operate them are also expensive. And these machines incur wear and tear with each use, just as any factory equipment would.

Most estimates amortize metal AM equipment at a rate of $150-$300 per hour. The exact amount depends on the printer, material being processed, and necessary infrastructure. Depending on throughput, this expense can account for a significant proportion of final part cost.

The materials that ultimately make up 3D-printed components are a more obvious cost. This is especially true for many medtech applications that require metals safe for use on (and in) humans. The cost of the raw material, usually in powder form, plays a clear role in determining a batch’s unit cost. Also factored into material cost is waste material that cannot be recycled and reused in the process.

Labor is an aspect of the metal AM process that often goes overlooked by industry outsiders. The fact is finding and/or training talent that can operate increasingly sophisticated printing systems isn’t easy. Some processes may even require two operators. Total hourly labor inputs are often lower in metal AM than more conventional methods, but the expense still exists.

Finally, it’s crucial to account for post processing and secondary operations. This is everything that happens to the parts after the print. This also includes what remains AM’s greatest weakness: surface finish. Many parts—particularly those used in medical applications—demand extremely tight tolerances or smooth finishes to perform their functions. With the loose tolerances of today’s printers, many (if not most) tolerances cannot be hit with the printer alone. As such, the job is often unfinished when the printer gets through. Grinding, heat treatment, and other secondary operations may all be necessary. This adds time, labor, and equipment expense to the whole process. This is not an area in which 3D printing excels against the standards of CNC machining or injection molding.

By and large, the post-processing requirements fall into three main categories, dimensional tolerances, surface finish, and heat treatment.

Calculating Final Part Cost

Final part cost is the sum of these four cost categories pro-rated across the unit volume of a given batch. The following is obvious but not well understood in the 3D printing community: the cost of 3D printed parts—even a marginally better 3D printed part—must be cost competitive with traditionally manufactured parts to gain traction in the marketplace. When it comes to production, cost is king. Finding AM applications that meet these criteria is the key to unlocking the potential of additive manufacturing in the medical technology space.

How Organizations Can Use AM and Avoid a Risky Capital Outlay

Medical device makers that want to incorporate AM into their processes face an uphill battle. Printers themselves are often 7-figure investments, not including ancillary equipment, facilities, and labor required to operate them.

As new market entrants, medtech companies are necessarily dealing with lower volumes of materials, rendering them unable to leverage economies of scale to bring down their input costs. The labor market is tight, making it tough to find skilled operators. And post processing is a separate battle unto itself, requiring large investments in space, machinery, and labor apart from those associated with the printing process.

Given these barriers to entry, some organizations have had to invest upwards of $5 million before the first commercial sale. That can be an impossible business case to make. Fortunately, there’s another option—working with an AM service bureau.

3D printing service bureaus are equipped to handle all the challenges outlined above for a simple reason—they specialize in AM. Service bureaus are able to justify the enormous investment required more readily because they can spread the fixed costs across many customers, lowering costs for all customers. Further, they deal in sufficient volumes to unlock the cost advantages that come with scale. A medtech company that wants to 3D print its new design has an easy solution—let someone else print it.

Matt Sand is the president of 3DEO (www.3DEO.co), an innovative metal 3D printing company based in Los Angeles. 3DEO is the go-to supplier of low-cost metal 3D printed serial production components. Leveraging its proprietary technology, 3DEO competes head-to-head with conventional manufacturing in terms of quality, cost, and turnaround time.

While the business case for AM (and particularly metal AM) remains situation specific, there are certain fields in which the advantages of the technique shine through. Medical devices—and medtech more broadly—is one of those fields.

This article shows how medtech companies can leverage 3D metal printing to make better products more efficiently.

Why Metal 3D Printing and Medtech Are a Natural Match

The development requirements of medical devices play right into the strengths of 3D printing. This is due to the inherently complex, unique geometries combined with the low quantities of products required in medicine.

Many medical situations are unique, or at least nearly unique. Generally speaking, these situations call for products that perform highly specialized tasks—and perform them extraordinarily well. Human lives are at stake and the outcome of operations can hinge on the tiniest of details. Therefore, a part that is even marginally more effective at performing its task may be extremely valuable.

The trouble in the past has not been that such incremental improvements in performance are impossible to dream up. Rather, it’s that the best ideas of biomedical engineers have been difficult-to-impossible to execute upon. Physical manufacturing capabilities have lagged behind the creativity of designers.

Even more challenging than actually fabricating devices that are better at performing medical functions has been justifying their cost. More than one decision maker in a major healthcare organization has found themselves facing a tough problem. Sure, a machine designed this way might decrease the failure rate of a given surgery by 1 percent, but is it really worth it if the unit costs 10 times more?

The advent of next generation metal AM technologies has made the answers to these questions much more obvious. On a cost-per-part basis, the technology excels in applications where a relatively low volume of small, complex components are needed. Medtech, which often calls for parts either completely customized or replicated only in small amounts, is an ideal match.

3D Printed Medical Devices in Today’s World

This alignment is best illustrated using real examples. Consider, for instance, the world of ventricular assist devices (VADs). These components are literally designed to keep the hearts of patients with advanced heart failure beating. That’s a high-leverage situation that demands a precision-engineered, highly reliable product. The industry-leading HeartWare HVAD system from Medtronic is correspondingly complex, featuring a passive maglev pump system, dual motor stators, and a patented impeller in the world’s smallest VAD package.

A component that small and intricate would be extremely hard, if not impossible, to produce using traditional methods like CNC machining or metal injection molding (MIM). The set-up and tooling costs would be extreme, and wasted material would likely be a significant proportion of the total. Further, these disadvantages would not be offset by volume—the market-leading device is only used by 15,000 patients worldwide.

Metal AM, on the other hand, has no tooling costs, and adding significant design complexity does not add significantly to the cost of production. The extra costs associated with AM may be worth it because the process is able to eliminate extra costs associated with labor, molds, and fixtures.

3D printing means the absence of demand for a million HVADs is not an economic disqualifier. It allows an extremely detailed, superior product to be cost-effectively manufactured at whatever unit volume is required.

Brass Tacks: Breaking Down Final Part Cost

Does the example portend a future in which all medical technology is produced using AM? Answering that question requires a detailed understanding of the business case for this rapidly evolving manufacturing technique.

Perhaps no metric is more crucial to the long-term viability of any manufacturing situation than final part cost. Arriving at this figure involves tallying every expense associated with production of a given number of components and distributing that expense across whatever amount of components is ultimately produced. Whether the healthcare sector begins producing (or even just using) primarily 3D printed components depends on the final part cost associated with hundreds of thousands of unique manufacturing situations.

Lots of variables matter. Part complexity, ease of access to the technology itself, volume, location—all these factors play a role at the micro-level.

Final part cost of 3D printed components can be divided into four categories: machine amortization, materials, labor, and post-processing.

The math behind machine amortization is fairly simple. 3D printers, particularly those suited for industrial metals printing, can be very expensive. The facilities and infrastructure required to operate them are also expensive. And these machines incur wear and tear with each use, just as any factory equipment would.

Most estimates amortize metal AM equipment at a rate of $150-$300 per hour. The exact amount depends on the printer, material being processed, and necessary infrastructure. Depending on throughput, this expense can account for a significant proportion of final part cost.

The materials that ultimately make up 3D-printed components are a more obvious cost. This is especially true for many medtech applications that require metals safe for use on (and in) humans. The cost of the raw material, usually in powder form, plays a clear role in determining a batch’s unit cost. Also factored into material cost is waste material that cannot be recycled and reused in the process.

Labor is an aspect of the metal AM process that often goes overlooked by industry outsiders. The fact is finding and/or training talent that can operate increasingly sophisticated printing systems isn’t easy. Some processes may even require two operators. Total hourly labor inputs are often lower in metal AM than more conventional methods, but the expense still exists.

Finally, it’s crucial to account for post processing and secondary operations. This is everything that happens to the parts after the print. This also includes what remains AM’s greatest weakness: surface finish. Many parts—particularly those used in medical applications—demand extremely tight tolerances or smooth finishes to perform their functions. With the loose tolerances of today’s printers, many (if not most) tolerances cannot be hit with the printer alone. As such, the job is often unfinished when the printer gets through. Grinding, heat treatment, and other secondary operations may all be necessary. This adds time, labor, and equipment expense to the whole process. This is not an area in which 3D printing excels against the standards of CNC machining or injection molding.

By and large, the post-processing requirements fall into three main categories, dimensional tolerances, surface finish, and heat treatment.

Calculating Final Part Cost

Final part cost is the sum of these four cost categories pro-rated across the unit volume of a given batch. The following is obvious but not well understood in the 3D printing community: the cost of 3D printed parts—even a marginally better 3D printed part—must be cost competitive with traditionally manufactured parts to gain traction in the marketplace. When it comes to production, cost is king. Finding AM applications that meet these criteria is the key to unlocking the potential of additive manufacturing in the medical technology space.

How Organizations Can Use AM and Avoid a Risky Capital Outlay

Medical device makers that want to incorporate AM into their processes face an uphill battle. Printers themselves are often 7-figure investments, not including ancillary equipment, facilities, and labor required to operate them.

As new market entrants, medtech companies are necessarily dealing with lower volumes of materials, rendering them unable to leverage economies of scale to bring down their input costs. The labor market is tight, making it tough to find skilled operators. And post processing is a separate battle unto itself, requiring large investments in space, machinery, and labor apart from those associated with the printing process.

Given these barriers to entry, some organizations have had to invest upwards of $5 million before the first commercial sale. That can be an impossible business case to make. Fortunately, there’s another option—working with an AM service bureau.

3D printing service bureaus are equipped to handle all the challenges outlined above for a simple reason—they specialize in AM. Service bureaus are able to justify the enormous investment required more readily because they can spread the fixed costs across many customers, lowering costs for all customers. Further, they deal in sufficient volumes to unlock the cost advantages that come with scale. A medtech company that wants to 3D print its new design has an easy solution—let someone else print it.

Matt Sand is the president of 3DEO (www.3DEO.co), an innovative metal 3D printing company based in Los Angeles. 3DEO is the go-to supplier of low-cost metal 3D printed serial production components. Leveraging its proprietary technology, 3DEO competes head-to-head with conventional manufacturing in terms of quality, cost, and turnaround time.