Diagnosing the IVD Market: An Interview with TEAM Technologies

By Sam Brusco, Associate Editor | 03.30.21

Chief revenue officer Steve Lents discusses the in-vitro diagnostic market and manufacturing rapid antigen POC COVID-19 tests.

The SARS-CoV-2 pandemic’s extreme disruption was by no means limited to the medical device industry; virtually every industry floundered as they struggled to cope with travel restrictions, social distancing guidelines, skeleton crews of employees on site, and anxiety about how long the pandemic would rage on.

The medical device industry, however, was uniquely impacted for a number of reasons. Procedures considered elective were cancelled or postponed to free up critical hospital beds. Medtech makers who provided technologies used in elective procedures—orthopedic manufacturers, for example—watched their revenue plummet as hospitals purchased far less of their products.

Though some sectors were handcuffed, the pandemic has also spurred the mission-critical diagnostics industry into action. A race promptly began to develop novel and rapid diagnostics kits to detect coronavirus. During health crises, the U.S. Food and Drug Administration (FDA) often approves integral pharmaceuticals, medtech, and diagnostic tests under its far less stringent emergency use authorization (EUA).

To gain more insight about the pandemic’s impact and other industry headwinds, trends, and challenges affecting the in-vitro diagnostic testing market, I spoke with Steve Lents, chief revenue officer of TEAM Technologies, a a Morristown, Tenn.-based end-to-end manufacturing solutions provider for medical and dental products. Lents was quoted in the March issue feature article “Diagnostic Desperation: A Look at IVD Trends During COVID-19”. The entirety of our interview is included below.

Sam Brusco: What are the dominant market forces at play in the IVD industry at present?

Steve Lents: In today’s market, and particularly over the past 10 months, the ability to scale-up production and maintain a robust and reliable supply chain has emerged as a big challenge for those providing medical devices and healthcare services. In particular, the desire for many companies to minimize reliance on overseas supply lines and manufacture either OEM or finished products here in the United States has come front and center.

The COVID-19 pandemic has stressed many of these healthcare and medical supply chains with the increased demand for critical in-vitro diagnostic devices to detect COVID-19 and for personal protective equipment (PPE) to prevent the spread of the disease. All of this has strained many manufacturing and logistics networks and meeting those needs head on has become a priority.

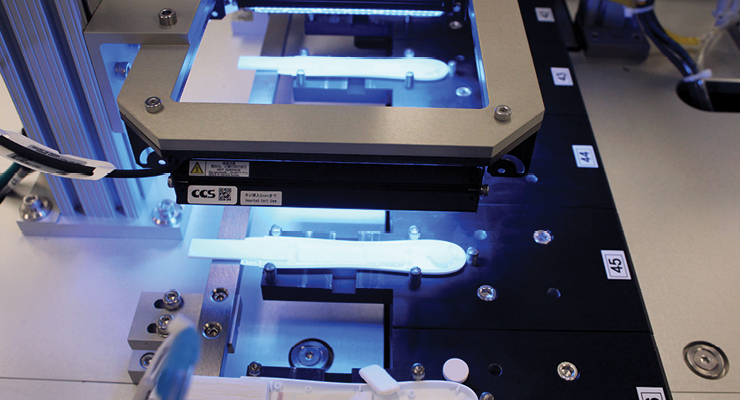

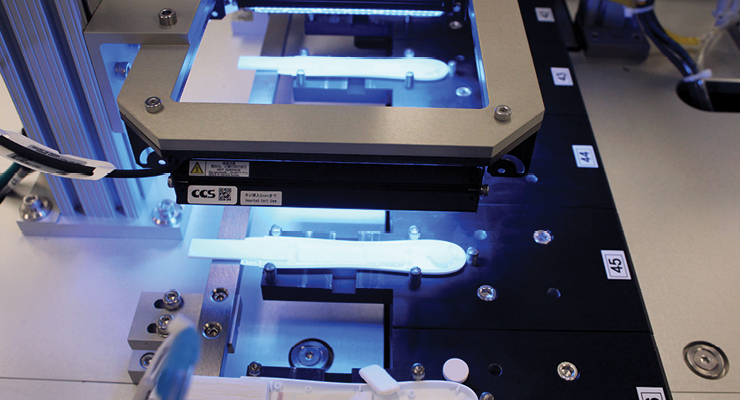

Partnering at the concept stage can determine the success and quality of a diagnostic test.

Brusco: How has the COVID-19 pandemic affected your business? What adjustments had to be made as a result?

Lents: We have been able to adapt quickly to meet the needs of the healthcare market during the pandemic. As a U.S.-based medical device manufacturer, we’ve been able to rapidly scale production. This past year, we partnered with Maxim Biomedical to begin production of SARS-CoV-2 rapid antigen point-of-care (POC) tests to assist organizations seeking the benefits of rapid testing. The test kits are lateral flow assays (LFAs) that offer a streamlined workflow and a closed-tube format that eliminates the need for expensive equipment or a reader to perform. This initiative will produce much-needed testing solutions for a variety of markets and industries.

Our philosophy of ONE TEAM, MANY Technologies has served us well. We have an extensive lineup of manufacturing processes throughout the U.S., which has allowed us to quickly allocate resources to provide critical healthcare products. Our Haverhill, Conn. location partnered with a high-volume PPE manufacturer, as the need increased due to COVID-19. As a result, over eight million NIOSH-approved, N95 respirator masks have been produced for frontline healthcare workers since July 2020. Our ICP Medical business unit is working diligently with hospitals and surgery centers to meet the increased demands for masks, gowns, booties, and privacy curtains.

Of course, in all our facilities, we have protected our ability to meet client needs and ensure uptime by adhering to CDC guidelines to maintain the safety and health of our workers, suppliers, and customers.

Brusco: What benefits come from partnering with a firm like TEAM Technologies for IVD projects?

Lents: To aid in meeting the challenges facing our clients, we’ve made adjustments where appropriate to supply and demand processes to ensure their products continue to flow to market on time and without disruption. These have included the development of comprehensive risk management programs and crisis response plans to help avoid downtime and ensure worker safety.

We’ve invested in additional capacity within our facilities to ensure timely delivery and meet quality standards. This includes the addition and expansion of cleanroom capabilities within the United States and a focus on improving quality control and reducing product lead times.

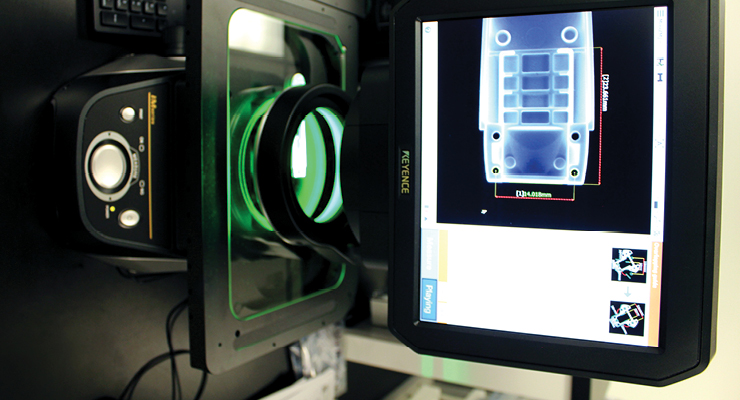

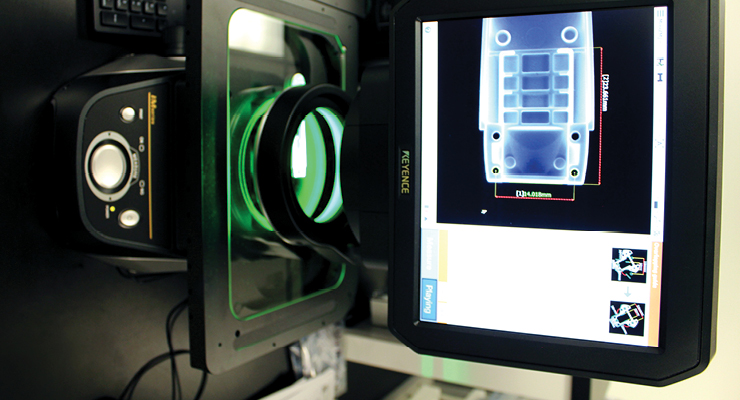

An expert R&D team engages with a manufacturing partner at every stage to move the project along the path to commercialization.

Brusco: What trends, challenges, and opportunities do you expect for the IVD market in the near future?

Lents: With the expected continued demand for IVDs, particularly rapid test devices, it will be important for manufacturers and suppliers to have flexibility while maintaining quality in their outputs. Developing and executing strategies aligned with customer and market needs will require the ability to incorporate external sources to guide firms in dealing with new threats and capitalizing on new market opportunities.

Adjusting internal policies and procedures and making investments in technology are critical steps we’ve made and will continue to take to meet the needs of what many are calling “the new normal,” not just in manufacturing, but also in nearly every industry and market today.

The medical device industry, however, was uniquely impacted for a number of reasons. Procedures considered elective were cancelled or postponed to free up critical hospital beds. Medtech makers who provided technologies used in elective procedures—orthopedic manufacturers, for example—watched their revenue plummet as hospitals purchased far less of their products.

Though some sectors were handcuffed, the pandemic has also spurred the mission-critical diagnostics industry into action. A race promptly began to develop novel and rapid diagnostics kits to detect coronavirus. During health crises, the U.S. Food and Drug Administration (FDA) often approves integral pharmaceuticals, medtech, and diagnostic tests under its far less stringent emergency use authorization (EUA).

To gain more insight about the pandemic’s impact and other industry headwinds, trends, and challenges affecting the in-vitro diagnostic testing market, I spoke with Steve Lents, chief revenue officer of TEAM Technologies, a a Morristown, Tenn.-based end-to-end manufacturing solutions provider for medical and dental products. Lents was quoted in the March issue feature article “Diagnostic Desperation: A Look at IVD Trends During COVID-19”. The entirety of our interview is included below.

Sam Brusco: What are the dominant market forces at play in the IVD industry at present?

Steve Lents: In today’s market, and particularly over the past 10 months, the ability to scale-up production and maintain a robust and reliable supply chain has emerged as a big challenge for those providing medical devices and healthcare services. In particular, the desire for many companies to minimize reliance on overseas supply lines and manufacture either OEM or finished products here in the United States has come front and center.

The COVID-19 pandemic has stressed many of these healthcare and medical supply chains with the increased demand for critical in-vitro diagnostic devices to detect COVID-19 and for personal protective equipment (PPE) to prevent the spread of the disease. All of this has strained many manufacturing and logistics networks and meeting those needs head on has become a priority.

Partnering at the concept stage can determine the success and quality of a diagnostic test.

Brusco: How has the COVID-19 pandemic affected your business? What adjustments had to be made as a result?

Lents: We have been able to adapt quickly to meet the needs of the healthcare market during the pandemic. As a U.S.-based medical device manufacturer, we’ve been able to rapidly scale production. This past year, we partnered with Maxim Biomedical to begin production of SARS-CoV-2 rapid antigen point-of-care (POC) tests to assist organizations seeking the benefits of rapid testing. The test kits are lateral flow assays (LFAs) that offer a streamlined workflow and a closed-tube format that eliminates the need for expensive equipment or a reader to perform. This initiative will produce much-needed testing solutions for a variety of markets and industries.

Our philosophy of ONE TEAM, MANY Technologies has served us well. We have an extensive lineup of manufacturing processes throughout the U.S., which has allowed us to quickly allocate resources to provide critical healthcare products. Our Haverhill, Conn. location partnered with a high-volume PPE manufacturer, as the need increased due to COVID-19. As a result, over eight million NIOSH-approved, N95 respirator masks have been produced for frontline healthcare workers since July 2020. Our ICP Medical business unit is working diligently with hospitals and surgery centers to meet the increased demands for masks, gowns, booties, and privacy curtains.

Of course, in all our facilities, we have protected our ability to meet client needs and ensure uptime by adhering to CDC guidelines to maintain the safety and health of our workers, suppliers, and customers.

Brusco: What benefits come from partnering with a firm like TEAM Technologies for IVD projects?

Lents: To aid in meeting the challenges facing our clients, we’ve made adjustments where appropriate to supply and demand processes to ensure their products continue to flow to market on time and without disruption. These have included the development of comprehensive risk management programs and crisis response plans to help avoid downtime and ensure worker safety.

We’ve invested in additional capacity within our facilities to ensure timely delivery and meet quality standards. This includes the addition and expansion of cleanroom capabilities within the United States and a focus on improving quality control and reducing product lead times.

An expert R&D team engages with a manufacturing partner at every stage to move the project along the path to commercialization.

Brusco: What trends, challenges, and opportunities do you expect for the IVD market in the near future?

Lents: With the expected continued demand for IVDs, particularly rapid test devices, it will be important for manufacturers and suppliers to have flexibility while maintaining quality in their outputs. Developing and executing strategies aligned with customer and market needs will require the ability to incorporate external sources to guide firms in dealing with new threats and capitalizing on new market opportunities.

Adjusting internal policies and procedures and making investments in technology are critical steps we’ve made and will continue to take to meet the needs of what many are calling “the new normal,” not just in manufacturing, but also in nearly every industry and market today.