More Content From Master Bond Inc.

-

Thermally Conductive, Electrically Insulative Epoxy for Medical Device Applications

Product: EP40TCMedPress Releases Released on 07.31.2023

-

Non-Cytotoxic Epoxy Withstands Multiple Methods of Medical Sterilization

Product: EP41S-5MedPress Releases Released on 02.08.2023

-

Ultra-Low Viscosity, Biocompatible Epoxy Offers Optical Clarity

Product: EP4CL-80MedPress Releases Released on 09.07.2022

-

Biocompatible UV Curable Adhesive Formulated for TPU Bonding

Master Bond UV17Med is a one part, no mix, UV curable system.Press Releases Released on 07.26.2022

-

LED405Med: How Do You Use an LED Curing Adhesive?

Learn how to properly apply and cure an LED curable adhesive system using a portable LED light source in this demonstration video.Videos Released on 02.14.2022

-

Non-Cytotoxic Epoxy Resists Sterilization by Autoclaving, Radiation and Chemicals

Master Bond EP62-1HTMed is a two part epoxy that meets the requirements of ISO 10993-5 for non-cytotoxicity.Press Releases Released on 02.14.2022

-

Chemically Resistant, NASA Low Outgassing, Non-Drip Epoxy System

Master Bond EP41S-5ND Black is a two part, NASA low outgassing rated epoxy, with outstanding chemical resistance to acids, bases, alcohols and fuels.Press Releases Released on 06.24.2021

-

Fast Setting, Two Component Epoxy Color Coded for Proper Mixing

Master Bond EP51CC is a two component, fast setting epoxy with a color coding system where Part A is white and Part B is black.Press Releases Released on 02.10.2021

-

Nanosilica Filled, Electrically Insulative Epoxy Features Abrasion Resistance

Product: EP21NSPress Releases Released on 01.06.2021

-

Highly Flexible UV Curable Adhesive Meets ISO 10993-5 Standard for Cytotoxicity

Product: UV15X-6Med-2LVPress Releases Released on 11.24.2020

-

One Part Fast Curing Epoxy for Bonding and Small Encapsulation Applications

Product: EP4EN-80Press Releases Released on 10.29.2020

-

Silver Conductive Silicone Adhesive Meets NASA Low Outgassing Specifications

Product: MasterSil 151SPress Releases Released on 10.06.2020

-

Low Viscosity Epoxy Coating Features Acid Resistance

Product: EP21ARLVPress Releases Released on 09.11.2020

-

Thermally Conductive Epoxy for Large Potting Applications Features Low Exotherm

Product: EP29LPAOHTPress Releases Released on 08.18.2020

-

Medical Grade Epoxy Offers Thermal Conductivity and Electrical Insulation

Product: EP42HT-4AOMed BlackPress Releases Released on 07.13.2020

Related Content

-

Fast Setting, Two Component Epoxy Color Coded for Proper Mixing

Master Bond EP51CC is a two component, fast setting epoxy with a color coding system where Part A is white and Part B is black.

-

-

Highly Flexible UV Curable Adhesive Meets ISO 10993-5 Standard for Cytotoxicity

Product: UV15X-6Med-2LV

-

-

Silver Conductive Silicone Adhesive Meets NASA Low Outgassing Specifications

Product: MasterSil 151S

-

Freudenberg Expands Medical Balloon Development

Establishes the Balloon Development Center of Excellence.Freudenberg Medical 11.04.19

-

Thermally Conductive, Chemically Resistant Epoxy Sealant

Product: EP62-1AO

-

Diagnostics

Beckman Coulter Receives BARDA Funding

Is developing an algorithm to aid in the early detection of sepsis.Beckman Coulter 10.30.19

-

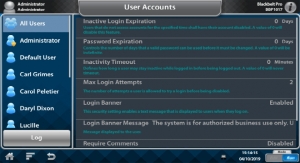

Q & A: Understanding the UL 1203 Standard

Venkat Nandivada answers questions about the UL1203 Standard.

-

-

Materials

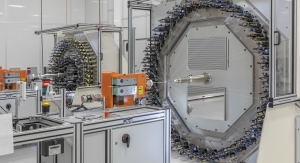

Cortland Biomedical Opens State-of-the-Art Facility

Strategically designed by textile engineers.Cortland Biomedical 09.17.19

-

Materials

Biocoat Opens New State of the Art Facility

Launches on-site contract coating service business unit.Biocoat Inc. 09.17.19

-

-

Contract Manufacturing

Medical Murray Opens New Facility

Increases regional footprint in South East.Medical Murray 08.29.19

-

UV Curing Adhesive Passes NASA Low Outgassing Specifications

Product: UV10TK40M

-

Contract Manufacturing

Turning a Regulatory Headache into a Competitive Advantage

Understanding 21 CFR Part 11 and EU Annex 11 compliance.David Kralovetz, Cincinnati Test Systems 07.23.19

-

Toughened Epoxy Polysulfide Hybrid Offers Advanced Chemical Resistance

Product: EP21TP-2NV

-

Contract Manufacturing | Packaging & Sterilization

Selecting the Right Manufacturer to Ensure Reduced Sterilization Risk

Having strict hygienic procedures isn’t just the duty of the hospitals; it begins with the manufacturer.John MacDonald, President, AIP Precision Machining 07.08.19

-

R&D & Design

7 Tips to Ensure You Embrace Risk for Safer Medical Devices

Embrace the idea or concept of risk to ensure your product is safer and better overall.Rilind Elezaj , Founder, Probleme.me 07.01.19

-

Testing

Automated Assembly with The Arthur G. Russell Company at ATX East

William Mis of The Arthur G. Russell Company talks about the company's high-speed assembly and test systems for disposable medical devices.Sam Brusco, Associate Editor

-

-

Toughened, Low Outgassing, One Component Epoxy Features Thermal Cycling Resistance

Product: Supreme 17HT

-

-