Bucking the Incremental Innovation Trend

By Sean Fenske, Editor | 11.21.16

Not everyone makes a big splash at Medica, but these companies certainly made a great impression.

Medica—the event organizers bill as the “world’s biggest medical trade fair”—wrapped up last week, posting figures of over 125,000 visitors interacting with a record 5,000-plus exhibitors. Commenting on the high international participation in regard to the growing export business, Joachim Schäfer, managing director of Messe Düsseldorf, stated, “Medica, as a place for global business and creating contacts in all important markets, is simply an event not to be missed. Our specialist visitors came from 135 different countries, with Asian emerging countries particularly well represented. Around 60 percent were international visitors, which is a new high.”

While the impressive figures boasted by the show were a sight to see, slightly less impressive were the advancements in medical technology innovation (or, more appropriately, lack thereof). Medical devices are fantastic pieces of technology, but when one attends an event like Medica, the concept of incremental innovation really begins to materialize. Advancements from one year to the next are subtle—colors are sharper, devices are more powerful, certain tools are smarter, etc. But the true breakthrough technologies are more challenging to find. Medica 2016 did offer a few examples, however, of technologies and companies making an impact with impressive innovation.

Nelipak

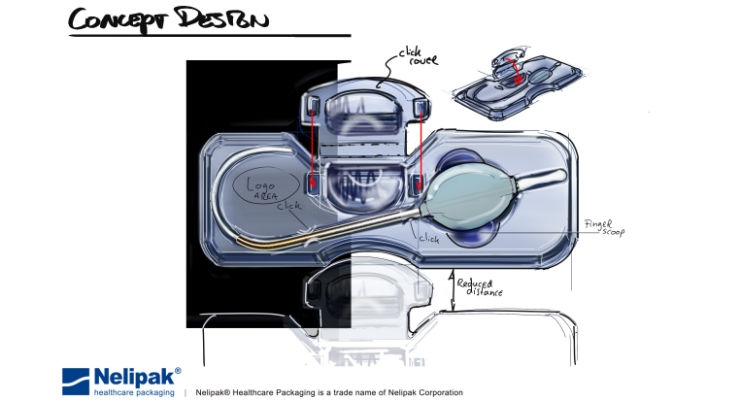

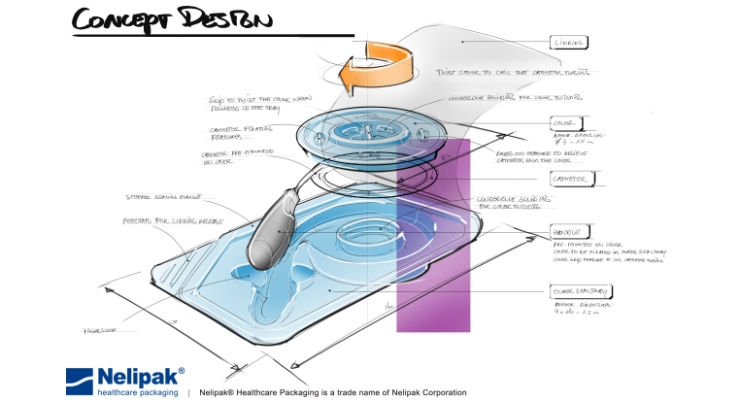

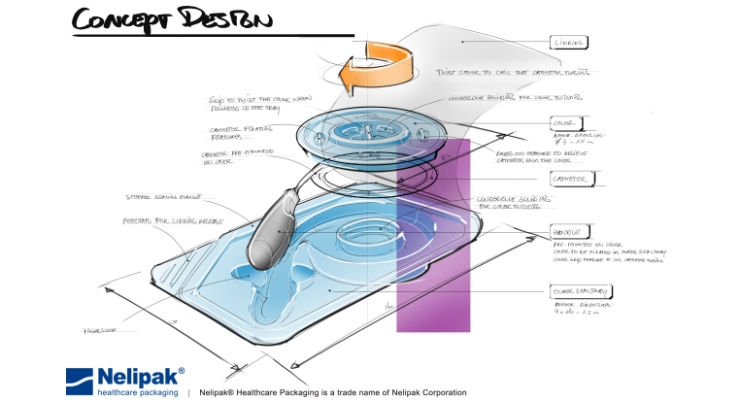

One of my stops was a company with which I was already familiar. Nelipak provides custom packaging solutions for medical device manufacturers. While seemingly a traditional supplier from afar, when one gets a little closer, the company is revealed as a fairly innovative firm. When I first met with the company at another industry event, I was introduced to Pieter van Gool, lead digital sketch and design engineer at Nelipak. He was working diligently behind a digital design sketch tool that enabled him to create a custom packaging solution based on a discussion he might have with a potential client, in real time. The result was nothing short of a piece of artwork. The digital blueprint enabled a more traditional electronic design file to be created from the sketch. I’ve included a couple images from Nelipak, because simply describing the work van Gool produces doesn’t do it justice.

Pieter van Gool's sketches look fantastic and really offer customers a realistic view of what the end packaging and product could look like.

During my meeting at Medica, I also reunited with Nelipak’s president and CEO Mike Kelly. He explained how the company was truly seeking to transform into a full solution-based packaging supplier, instead of one that simply thermoformed to customer specs. In fact, Kelly painted the picture of Nelipak serving as the packaging “division” for medical device OEMs. The investment and resources required to bring the necessary expertise in-house are tremendous; utilizing a firm like Nelipak to accomplish and fulfill packaging needs makes sense, especially for smaller medtech OEMs. Combining this company vision with the unique sketch approach to packaging development makes Nelipak stand out in the medical device supplier market.

The ITL Group

Moving into the diagnostics regions of Medica, I was fortunate enough to meet with a company that specifically developed a product for the event. The “imaginary” diagnostic solution showcased the capabilities of the companies. Not only did the device feature near-field communication, wireless charging, and Bluetooth data transmission, it was also controlled through an app and was sleeker in appearance than many consumer devices entering the home today.

Got a chance to try out the diagnostic sample device at ITL's booth for myself.

Carl Lincoln, head of marketing and business development at Integrated Technologies Limited (ITL for short)—the company behind the device that looked more appropriate for a gaming show than a medical technologies event—introduced me to one of the company’s senior engineers, Steve Hope. Hope is ITL's new product development manager. He explained that while the device on display was simply an example of the companies’ capabilities for the diagnostics space, its functionality was all based on real-world needs and projects they had worked on previously. It was also a project tasked to their more entry-level engineers as a way to get their feet wet on a diagnostics technology project. The look of the device was certainly an innovative approach to addressing the trend of more point-of-care diagnostics technologies moving into the home, and therefore, requiring a less clinical appearance. With the device, The company both positioned itself as understanding the needs of today’s diagnostics OEMs and found a clever way to showcase its capabilities with a “real world” solution.

Atomo Diagnostics

Continuing to wander around the diagnostics halls at Medica, I came across another innovative solution that addressed the problem of the many moving parts involved with lateral flow diagnostics. As the below video shows, a single device can address all the required steps of a blood test. Atomo Diagnostics has created the device that’s presented in the video—shown as an HIV test—which can be used for any lateral flow blood test.

I spoke with Hans Fredman, Atomo’s chief commercial officer, and John Kelly, the company’s founder and CEO. They showed me some of the more recent iterations of the device incorporating a “trigger” that deployed the required solution for the test (the dropper bottle is still used in the video). With this single device, the finger prick, blood collection, solution deployment, and results are all accomplished in this one device. Further, the device had safeguards in place that prevented the steps from being completed out of order. Fredman and Kelly also showed me variations that enabled the device to be synched with a smartphone to track results over time or send data to a healthcare provider. After seeing how many booths had the more traditional lateral flow solutions, it was easy to see how this technology was a step above the other offerings in the hall.

Medica is always exciting and a must attend event for those in the medical device manufacturing space (or those covering it, like myself). While incremental innovation will always be on display, it makes instances like those mentioned here all the more interesting. It is easy to appreciate the dedication and creativity that goes into any piece of medical technology, but it’s critically important to recognize when a device demonstrates the next level of innovation over the more common offerings in the market. It will be interesting to see from where that innovation hails at Medica in 2017.

While the impressive figures boasted by the show were a sight to see, slightly less impressive were the advancements in medical technology innovation (or, more appropriately, lack thereof). Medical devices are fantastic pieces of technology, but when one attends an event like Medica, the concept of incremental innovation really begins to materialize. Advancements from one year to the next are subtle—colors are sharper, devices are more powerful, certain tools are smarter, etc. But the true breakthrough technologies are more challenging to find. Medica 2016 did offer a few examples, however, of technologies and companies making an impact with impressive innovation.

Nelipak

One of my stops was a company with which I was already familiar. Nelipak provides custom packaging solutions for medical device manufacturers. While seemingly a traditional supplier from afar, when one gets a little closer, the company is revealed as a fairly innovative firm. When I first met with the company at another industry event, I was introduced to Pieter van Gool, lead digital sketch and design engineer at Nelipak. He was working diligently behind a digital design sketch tool that enabled him to create a custom packaging solution based on a discussion he might have with a potential client, in real time. The result was nothing short of a piece of artwork. The digital blueprint enabled a more traditional electronic design file to be created from the sketch. I’ve included a couple images from Nelipak, because simply describing the work van Gool produces doesn’t do it justice.

Pieter van Gool's sketches look fantastic and really offer customers a realistic view of what the end packaging and product could look like.

During my meeting at Medica, I also reunited with Nelipak’s president and CEO Mike Kelly. He explained how the company was truly seeking to transform into a full solution-based packaging supplier, instead of one that simply thermoformed to customer specs. In fact, Kelly painted the picture of Nelipak serving as the packaging “division” for medical device OEMs. The investment and resources required to bring the necessary expertise in-house are tremendous; utilizing a firm like Nelipak to accomplish and fulfill packaging needs makes sense, especially for smaller medtech OEMs. Combining this company vision with the unique sketch approach to packaging development makes Nelipak stand out in the medical device supplier market.

The ITL Group

Moving into the diagnostics regions of Medica, I was fortunate enough to meet with a company that specifically developed a product for the event. The “imaginary” diagnostic solution showcased the capabilities of the companies. Not only did the device feature near-field communication, wireless charging, and Bluetooth data transmission, it was also controlled through an app and was sleeker in appearance than many consumer devices entering the home today.

Got a chance to try out the diagnostic sample device at ITL's booth for myself.

Carl Lincoln, head of marketing and business development at Integrated Technologies Limited (ITL for short)—the company behind the device that looked more appropriate for a gaming show than a medical technologies event—introduced me to one of the company’s senior engineers, Steve Hope. Hope is ITL's new product development manager. He explained that while the device on display was simply an example of the companies’ capabilities for the diagnostics space, its functionality was all based on real-world needs and projects they had worked on previously. It was also a project tasked to their more entry-level engineers as a way to get their feet wet on a diagnostics technology project. The look of the device was certainly an innovative approach to addressing the trend of more point-of-care diagnostics technologies moving into the home, and therefore, requiring a less clinical appearance. With the device, The company both positioned itself as understanding the needs of today’s diagnostics OEMs and found a clever way to showcase its capabilities with a “real world” solution.

Atomo Diagnostics

Continuing to wander around the diagnostics halls at Medica, I came across another innovative solution that addressed the problem of the many moving parts involved with lateral flow diagnostics. As the below video shows, a single device can address all the required steps of a blood test. Atomo Diagnostics has created the device that’s presented in the video—shown as an HIV test—which can be used for any lateral flow blood test.

I spoke with Hans Fredman, Atomo’s chief commercial officer, and John Kelly, the company’s founder and CEO. They showed me some of the more recent iterations of the device incorporating a “trigger” that deployed the required solution for the test (the dropper bottle is still used in the video). With this single device, the finger prick, blood collection, solution deployment, and results are all accomplished in this one device. Further, the device had safeguards in place that prevented the steps from being completed out of order. Fredman and Kelly also showed me variations that enabled the device to be synched with a smartphone to track results over time or send data to a healthcare provider. After seeing how many booths had the more traditional lateral flow solutions, it was easy to see how this technology was a step above the other offerings in the hall.

Medica is always exciting and a must attend event for those in the medical device manufacturing space (or those covering it, like myself). While incremental innovation will always be on display, it makes instances like those mentioned here all the more interesting. It is easy to appreciate the dedication and creativity that goes into any piece of medical technology, but it’s critically important to recognize when a device demonstrates the next level of innovation over the more common offerings in the market. It will be interesting to see from where that innovation hails at Medica in 2017.